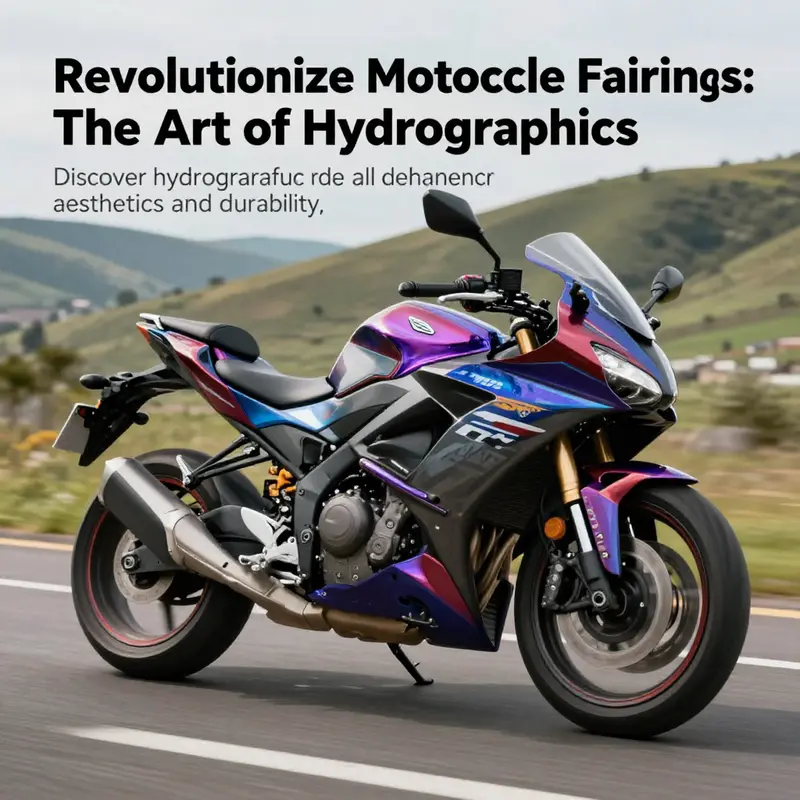

Hydrographics, or water transfer printing, is redefining how motorcycle fairings are personalized and protected. This innovative technique applies intricate designs to motorcycle components, offering an unbeatable combination of aesthetic appeal and durability. As business owners in the motorcycle industry, understanding the hydrographics process, its durability, customization options, economic implications, and environmental considerations is essential for staying competitive. Each chapter will explore these facets, providing insights into how hydrographics can elevate your business and satisfy customer demands for unique and resilient motorcycle finishes.

Depth on Droplets: Hydrographic Finishes for Motorcycle Fairings

The surface of a motorcycle is a canvas that negotiates curvature, edge, and motion. Hydrographics, or water transfer printing, allows complex patterns to wrap around fairings with a sense of depth and realism. The result can feel factory-made while carrying the rider’s signature. This chapter surveys the practical heart of the craft—the process, the materials, and the discipline that keeps hydrographics honest on curved planes and tight radii.

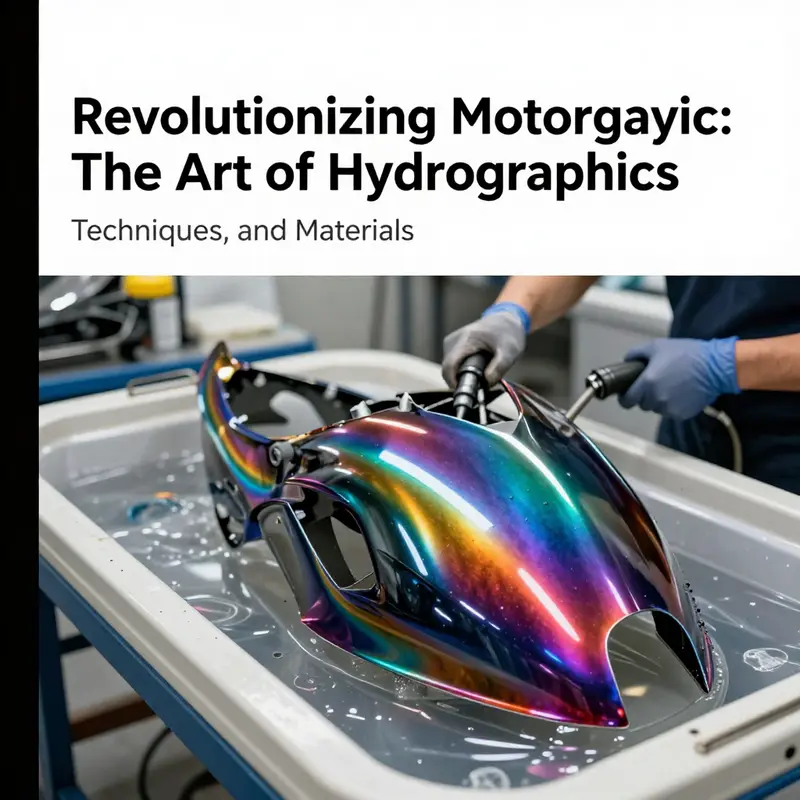

At its core, hydrographics works by laying a film bearing a design on water, where a activator dissolves a soluble base and enables the pigment layer to transfer to the part as it is dipped. Success depends on surface preparation, film behavior, and post-application sealing, all coordinating with physics and aesthetics. Preparation begins long before the film touches water. The fairing must be clean, free of wax or oils, and a primer is applied to provide a uniform, receptive surface. This isn’t mere groundwork; it sets the stage for the film to wrap around edges, contours, and seams so the pattern follows the geometry rather than fighting it. Any stray grease or dust becomes a fault line that can show after the clear coat.

When the surface is ready, the film rests on a shallow bath of water. The operator orients the design to align with the bike’s lines. The activator step then releases the ink from the film, creating a thin, flowable layer that must settle and wrap around complex curves. Submersion is deliberate: too quick and the pattern traps air or tears; too slow and you risk edge gaps. The art is in presenting the fairing so that the ink drapes smoothly and wraps around radii and transitional shapes.

Rinsing after removal is essential to remove residual cross-linked particles that could interfere with adhesion. The next act—sealing—protects the transfer from UV, moisture, and abrasion. A clear topcoat locks in color depth and gloss and preserves the illusion of depth under varying light. The right sealant resists chalking and yellowing while remaining compatible with the film and base material.

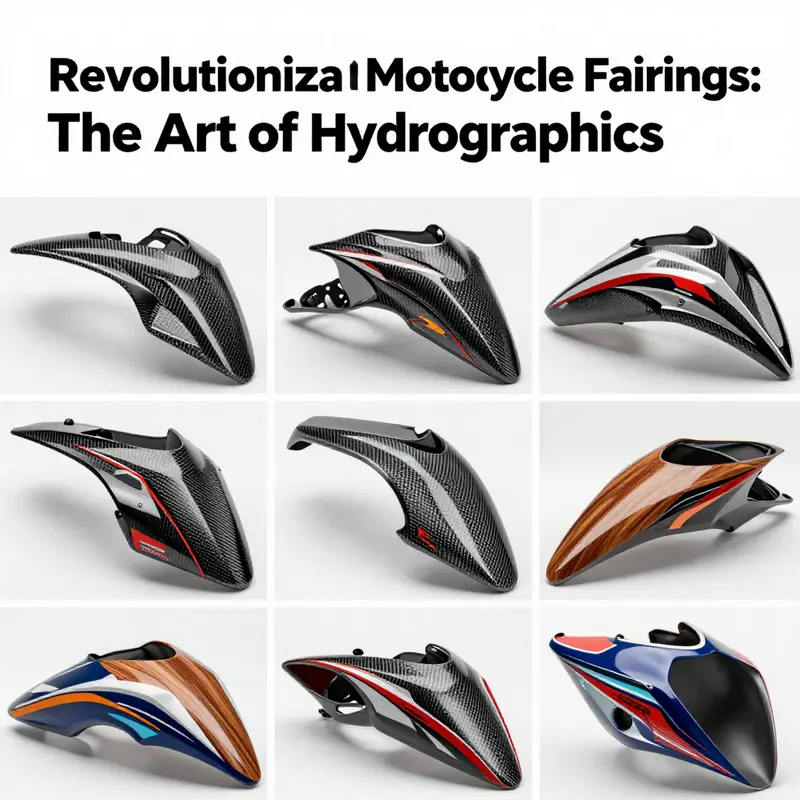

Materials for hydrographics are not arbitrary. The kit typically includes a film with a printable pattern, an activator, and a durable clear coat. The film width matters; wider rolls can cover large panels in fewer pieces, while narrower formats suit smaller accents. The activator must deliver consistent adhesion across curves and edges, while the sealant must tolerate UV exposure and abrasion without losing clarity. When done well, the finish behaves like the chosen material—carbon fiber, metallic, wood grain—without the weight or stiffness of actual composites.

Maintenance and durability considerations: because the finish is a continuous skin over the shape, full fairings benefit from a uniform look that can hide minor chips and scuffs. Repairs, when needed, are localized and less invasive than replacing entire panels. The long-term success depends on material compatibility with the base plastic, as well as the environmental exposure the bike will endure—sun, rain, and road grit.

The craft demands restraint. Rushing the dip, misaligning the film, or failing to clean dust and oils creates seams, bubbles, or edge lifts. The best results come from patient preparation, careful dipping, and a disciplined inspection at each stage. A well-executed hydrographic finish integrates with the bike’s form and light, becoming part of the machine’s identity rather than a separate layer stuck on top.

For practitioners seeking deeper mastery, the dialogue between film design, activation chemistry, and coating performance offers a rich field. Ongoing study of film composition, adhesion behavior on different plastics, and the interaction of the clear coat with the base color will yield more predictable results. The practice increasingly blends traditional handcraft with digital design workflows to ensure patterns align with geometry when it matters most in motion. The result is a discipline that respects both artistry and engineering, delivering surfaces that feel authentic to the bike while offering expressive opportunities for personalization.

External resources can provide standards-focused technical detail on water transfer papers and hydrographic films, including properties, performance, and application guidelines. A deeper dive helps ensure long-term integrity under UV exposure, moisture, and abrasion.

null

null

Liquid Identity: Crafting Personalized Visual Identities on Motorcycle Fairings with Hydrographics

Hydrographics, at its core, is a dialogue between water and design, a method that translates intricate ideas into the curved, unforgiving geometry of a motorcycle fairing. It sits at an intersection where art meets engineering, where a single film can carry the texture of wood, the weave of carbon, or the sweeping lines of a custom mural and render them onto a three-dimensional shell that must endure heat, vibration, UV exposure, and weather. The result is not a simple layer of color but a layered illusion—depth and realism that flirt with the eye and the feel of a factory finish in one seamless transfer. The technique begins with a printed film, a thin sheet designed to release its image when submerged in water. The film is chosen not only for color and pattern but for how it behaves on contoured surfaces. It must loosen at the right moment, wrap around edges, and settle into depressions without tearing or lifting. That behavior is engineered into the film and the accompanying activators, and it dictates how well a given design can survive the realities of the ride: rain, gravel, wind, and the sun’s relentless glare. What makes hydrographics compelling for fairings is precisely this balance between fidelity and resilience. It can mimic a carbon fiber weave with stunning accuracy, render a convincing wood grain on a panel that would otherwise require hours of hand painting, or reproduce complex camouflage and custom artwork with a fidelity that would be difficult to achieve by traditional means. The process is not about disguising a surface so much as revealing its potential, transforming a plain shell into a statement without sacrificing the structural integrity or aerodynamic requirements of the bike. And because the fairing is a single, dynamic surface that wraps around cylinders, curves, and sharp radii, the choice of film and how it is applied becomes a narrative of geometry as much as color. The preparation phase is deceptively simple in description but critical in practice. The surface must be spotless, free of oils, waxes, and fingerprint residues. Any contaminant can cause micro-blisters or edge lift after dipping, which would spoil the illusion of the pattern conforming to the shape. A stable base coat, often in a neutral or matching color, is applied to control the final hue depth and to provide a uniform canvas for the print. The selected hydrographic film is then laid onto a water bath with a release layer that allows the image to detach precisely when activated. The fairing is dipped at a controlled angle and speed, which ensures the pattern aligns with seams, ribs, vents, and bulges. The dip is rarely a single moment but a coordinated choreography—the part rotates, the operator calibrates immersion depth, and the film clings like a second skin, following every plane and contour. After withdrawal, the surface is immediately rinsed to remove detack agents and any residual film residue. The pattern’s edges may reveal themselves as clean lines or gentle blends, depending on how well the layer is prepped and how carefully the film was chosen for the particular geometry of the fairing. The subsequent stage introduces a clear protective coat, a crucial shield against UV radiation, moisture, and abrasion. The film’s pigments are susceptible to fading or dulling under sun exposure unless sealed by a robust topcoat. A clear layer not only preserves color and detail but also adds scratch resistance and durability to the finished panel. In practice, the film’s performance is as much about chemistry as it is about design. A film engineered for UV resistance and water durability will retain its vibrancy longer, especially when the bike sits outdoors or spends extended periods in damp or salty environments. This is a practical consideration for riders who park near the coast, ride through rain, or expose their machines to road debris at high speeds. The choice of film, the quality of the activator, and the precision of the dip all influence how the final finish holds up over months and seasons. The appeal of hydrographics lies in the breadth of design possibilities. Patterns can range from the unmistakable look of carbon fiber to the organic, tactile feel of real wood, to bold, graphic art that makes a rider’s statement unmistakable. Camo patterns offer tactical aesthetics, marble or granite textures convey a sense of weight and luxury, and even high-gloss metallics can be achieved through specialized films and topcoats. The technique is well suited to full fairings, where the goal is a cohesive narrative across every panel. When a rider selects a multi-panel design, continuity becomes a design constraint as much as a creative opportunity. The grain or weave must flow smoothly across the joints and edges, which requires careful planning. A well-planned layout anticipates where panels will meet and how the grain will align after assembly. This is not merely about matching colors; it is about aligning the entire surface to present a single, uninterrupted visual logic from one angle to the next. It is here that hydrographics highlights its advantage over more traditional painting methods: the film’s pattern, once aligned and secured, can wrap around complex geometries with a degree of precision that would demand intricate masking and airbrushing if attempted by hand. The practical outcomes extend beyond aesthetics. Customization through hydrographics is a form of branding that can reflect a rider’s identity, team affiliation, or personal flavor. A rider can integrate logos, color schemes, or graphic motifs that echo the rest of the gear and accessories, creating a unified look from helmet to heel guard. The possibility to apply specific patterns across an entire fairing family enables a rider or a team to maintain visual consistency while still embracing individual expression. For those focused on the Honda platform, the design language can be extended through the broader Honda fairings category, where pattern continuity across different models and years is particularly valued. See the Honda fairings collection for reference and inspiration, which demonstrates how a single visual concept can be adapted to multiple chassis configurations without losing its identity. In a broader sense, hydrographics is also an accessible path into higher-end finishes without the endurance costs of custom hand-painting. The investment is in film quality, process control, and post-application protection, rather than in the hours of meticulous brushwork that historically defined motorcycle artistry. The durability story is reinforced by the clear coat, and the finished surface can be crafted to resist weathering and light abrasion while maintaining a premium look. That combination of durability and depth is what makes hydrographics a practical option for enthusiasts who demand both style and performance. Maintenance and care for hydrographically finished fairings are straightforward but meaningful. Gentle cleaning with mild detergents preserves the clarity of the pattern and prevents micro-scratches from developing on the coated surface. Aggressive solvents or abrasive pads should be avoided, as they can compromise the clear layer and lift edges, especially on curved sections. When minor damage occurs, the affected panel may be locally repaired, and, if necessary, re-dipped. The ability to rework a fairing without stripping the entire motorcycle reduces downtime and keeps the bike looking cohesive. The ecosystem around hydrographics is informed by a practical understanding of materials science as much as artistic taste. The same film technologies that decorate automotive parts and furniture have found a home in motorcycle customization because the demands—resilience, colorfastness, edge conformity, and long-term gloss—match the realities of riding. The industry has evolved to include films with enhanced flexibility for three-dimensional forms, adhesives designed to minimize air entrapment, and coatings that deliver a factory-like sheen without sacrificing tactile texture. This progression enables designers and riders to experiment with more complex compositions, including layered or composite looks where a carbon-like weave might sit atop a wood grain base or a translucent color overlay to add depth. The broader market for hydrographics continues to expand as more riders seek personalization that respects the bike’s lines while offering a distinctive signature. Innovation in film design and application techniques also invites new collaborations between designers, fabricators, and riders, creating opportunities to tailor not just the visible pattern but the overall tactile and visual relationship between fairings and the rider’s stance, aerodynamics, and stance on the road. For those exploring brands and catalogs of parts, the approach extends beyond mere decoration; it becomes a language of identity that travels with the bike from street to track. In the end, the choice of hydrographics as a customization path rests on a balance of aesthetic ambition, practical durability, and the willingness to engage with a finishing process that treats the fairing as a canvas and a component at once. The result is a factory-like finish that still feels personal, a look that carries both the rider’s taste and the bike’s character into every ride. For readers seeking a deeper technical grounding, a comprehensive guide to the standards, properties, and applications of water transfer papers offers valuable context on film composition, adhesion dynamics, and performance benchmarks that underpin choices in this field. External resource: Understanding Water Transfer Paper For Motorcycle: Standards, Properties, and Applications. [https://www.hydrographics.com/understanding-water-transfer-paper-for-motorcycle-standards-properties-and-applications]

Value on the Surface: Weighing Costs, Craft, and Custom Hydrographics for Motorcycle Fairings

Every motorcycle is a small, moving billboard for its rider’s taste. When designers and shop owners choose hydrographics to finish fairings, they are not just selecting a look; they are selecting a cost structure that blends material expense, labor, and long-run value. Hydrographics, or water transfer printing, turns complex patterns into an applied surface on plastic or composite fairings. The film carries the design, and the dipping process transfers it onto the curved geometry with a level of alignment and depth that is hard to reproduce with simpler prints. The economics of this choice hinge on balancing several moving parts: the price of the film and coating materials, the precision labor required to avoid defects, the added protection needed to preserve color and gloss over years of exposure, and the way the finished surface interacts with air flow and ride quality. When viewed through this lens, hydrographics becomes less about a single appearance and more about a lifecycle decision that can shape a brand’s affordability, customization speed, and perceived value on the street.

From a cost perspective, hydrographic film itself sits at a relatively accessible price point. The film is engineered to transfer color, texture, and depth onto a broad range of substrates, especially plastics and composites used in modern fairings. The material cost is not negligible, but it is typically far lower than the tooling and spray requirements of traditional hand painting or the layered complexity of metallic finishes. Where the economics diverge sharply is in the downstream steps. A successful hydrographic finish requires meticulous surface preparation, careful masking of edges and mounting points, a controlled dipping process to avoid drips or misalignment, and a clear protective coat that seals in UV resistance and weathering. Each step adds labor hours and potential waste, particularly if the operator encounters bubbles, streaks, or edge lift on sharp curves. The result is a finish that can deliver high visual impact for a fraction of the cost of bespoke painting or multi-layer metallic effects when produced at scale or in boutique batches.

The contrast with traditional painting shines most clearly in the context of small-scale manufacturing and aftermarket customization shops. In full production, a factory that paints fairings in-house must invest in spray booths, masking jigs, color matching, and curing ovens. Even when the team can achieve a flawless look, the upfront capitalization and the risk of rework for a single model line can be prohibitive for short runs or limited-edition releases. Hydrographics presents a more economical path for low-volume production because it eliminates the need for new molds or extensive repainting for each variant. It enables rapid iteration of designs—from wood grain textures that evoke heritage to camouflage patterns that signal rugged performance—without the cost of retooling. This makes hydrographics particularly attractive for customization shops and boutique builders who aim to differentiate a model year or a limited edition without tying up capital in a large paint program.

Yet the economics are not purely favorable. The process is unforgiving of mistakes when approached without discipline. A single misaligned section or an unblended edge can ruin an entire panel, forcing re-dipping or scrapping of parts. Skilled labor matters as much as the materials themselves. The operator must not only control immersion speed and film alignment but also anticipate the surface’s interaction with the clear coat and the base color underneath. This is where the value proposition shifts from a simple price tag to a reliability metric. The more consistent the team can render the dipping process, the more predictable the lifecycle cost becomes. In practice, this means investing in training, quality control protocols, and a quiet, clean workspace that minimizes dust and humidity fluctuations. A shop that standardizes pre-cleaning, film handling, and post-application curing can reduce waste and shorten cycle times, turning what could be a fragile, one-off finish into a repeatable product with scalable margins.

Another layer of economic consideration involves durability and long-term maintenance. Hydrographic finishes rely on a cured clear coat to protect the design from UV exposure, moisture, and abrasion. If the coating is neglected or poorly applied, color fade and micro-scratches can accelerate, reducing the perceived value of the finish and prompting earlier replacement or rework. On the other hand, a robust clear coat with proper surface preparation can dramatically extend the aesthetic life of a fairing. When designers and shop owners price this into a package, they must decide whether to offer a standard protection option or an upgraded, more weather-resistant sealant. The result is a two-tier value proposition: an affordable, high-visual-impact finish for daily riders and a more durable variant for riders who subject their machines to harsh climates or track days. In practice, this choice often mirrors customer expectations and brand positioning. A brand that markets customization as a core attribute may bundle a higher-end protective layer as part of the package, while a value-oriented line may emphasize lower initial cost with the understanding that maintenance intervals will be longer than usual and periodic touch-ups may be required.

When the design brief asks for a fairing to conquer both form and function, it becomes necessary to consider integration with contemporary aerodynamic expectations. The CFD-driven understanding of airflow over a fairing has evolved to emphasize smooth, continuous surfaces and uniform finish quality. Any micro-imperfections—minor waviness, subtle edge lifting, or inconsistent gloss—can disrupt laminar flow and, in some cases, alter drag characteristics enough to affect fuel economy and rider comfort over long distances. This isn’t a warning that hydrographics inherently harms aerodynamics; rather, it underscores that the finish must be applied with the same rigor as the base shape. A well-executed hydrographic layer remains nearly invisible to the eye but plays a crucial supporting role in the overall performance package. For manufacturers balancing aesthetics with performance metrics, this means the finishing station must be treated as a design constraint as well as a marketing asset. The illusion of a flawless, factory-grade appearance can be undermined by careless handling or inconsistent coating thickness, which would subtly erase the perceived sophistication of the finish and erode the buyer’s willingness to invest in premium customization.

From a strategic perspective, the proliferation of customizable aesthetics has made hydrographics a compelling option for differentiating product lines and aftersales support. Market analyses across the industry indicate rising consumer demand for unique, eye-catching finishes that can be adapted to reflect personal identity or brand narratives without incurring the penalties of bespoke painting. Hydrographics is well suited to this demand because it offers a broad palette of textures—wood grain, carbon fiber, camouflage, and bespoke graphic schemes—without the expense and lead times associated with traditional finishes. The economic value, then, rests not only on the look but on the speed to market and the ability to offer personalization at scale. For small-batch manufacturers, this translates to shorter cycle times, lower minimum order quantities, and a wider array of high-margin options for loyal customers who crave individuality without paying the premium price of custom paintwork.

Operationally, the decision to deploy hydrographics on fairings also hinges on the compatibility of materials and the supply chain. The film itself is designed to transfer coatings onto curved and contoured surfaces, but the substrate compatibility matters. Plastic and composite fairings must be properly prepped to maximize adhesion, and the post-dip curing process must be compatible with the base resin’s chemistry. In practical shop terms, this means aligning substrate prep, film choice, activating agents, and clear coat chemistry to minimize rework. It also means recognizing that some models, due to their distinctive contours or integrated LED fixtures, demand specialized masking and fixture hardware. The cost calculus thus includes not only the base film price but the incremental tools and fixtures required to handle complex shapes safely and repeatably. In the long run, these investments translate into more consistent outcomes, fewer returns, and better customer satisfaction, which in turn support repeat business and referrals—key drivers of profitability in a market where margins are often razor-thin on entry-level projects.

For readers exploring the broader ecosystem of aftermarket fairings, the category pages for specific brands illustrate how hydrographics sits within a portfolio of customization options. For example, product categories dedicated to certain manufacturers provide an at-a-glance sense of how designers mix hydrographic finishes with color-matched plastics and performance accessories. See how these curated surfaces are organized in regional and brand-focused catalogs, such as the BMW fairings collection, which demonstrates how a shop can present a coherent customization pathway that starts with an intent and converges on a finished piece. This kind of structure helps clients visualize the economic envelope of a project—from idea to gate-ready bodywork—and reinforces the value of a stream-lined process that preserves both aesthetics and performance. BMW fairings

In sum, the economics of hydrographics on motorcycle fairings are a balance sheet of art and engineering. The material costs of film and coatings are a starting point, but the true driver of profitability is the meticulous craft—preparation, dipping, inspection, and sealing—that transforms a sheet of film into a durable, eye-catching, and aerodynamically conscious surface. When shops invest in skilled operators, reliable quality control, and a clear value proposition that communicates both aesthetics and protection, hydrographics can unlock a compelling blend of customization speed and cost efficiency. The approach is especially potent for smaller teams and boutique brands that want to offer personal expression at scale without the overhead of conventional paint shops. As consumer taste continues to pivot toward personalization, hydrographics remains not merely a finish but a strategic capability—one that can translate vivid design into durable, road-ready value that riders feel every time they glance down at the fairing and every mile they ride.

External reference: https://www.hydrographics.com/blog/hydro-dipping-film-composition-performance-and-how-it-is-used-across-industries/

Green Dips on Curved Armor: Navigating the Environmental Footprint of Hydrographic Motorcycle Fairings

The visual punch of a motorcycle can be as telling as its engine note, and hydrographics has opened a door to almost limitless surface artistry. Yet behind the illusion of depth lies an environmental footprint that travels across the product life cycle—from film production to disposal. Emissions can occur during the creation of the film, the preparation of the surface, and the dipping and curing steps, as well as in the handling of waste water, solvents, and broken trim pieces. The three dimensional shape of fairings, with curves and edges, adds processing steps that can increase energy use and material consumption. Understanding these realities is essential for riders and shops who want both style and stewardship.

Fortunately, the industry is moving toward greener material choices and cleaner processes. Films are increasingly built from recycled plastics or bio-based composites, while water-based inks and low-VOC adhesives reduce emissions during application and curing. Cleaner rinsing practices, better filtration, and responsible waste management help limit chemical discharge. Advances in film chemistry also seek to preserve flexibility and adhesion without relying on fossil-fuel based components. The result is a finished look that remains vibrant while requiring fewer hazardous inputs in production and maintenance.

Durability matters as much as design in environmental terms. A tough, well-sealed topcoat extends the service life of a panel, reducing chips, moisture ingress, and the need for early replacement. When a finish resists degradation, it lowers material turnover and the energy associated with remanufacture. At the same time designers must balance durability with impact resistance, UV stability, and compatibility with rider conditions. A resilient finish can be re-applied or refreshed with minimal waste if designed for serviceability and easy maintenance.

Lifecycle thinking also invites practical rider choices. Seek out studios and brands that publish environmental performance data, that minimize waste, and that promote recycling at end of life. Favor processes that maximize coverage with fewer re-dips or refinishes, and that offer recycling pathways for the film and backing materials. Where possible, prefer films and adhesives that can be safely recycled or repurposed, and support cleaners and rinses that are non-toxic and easy to treat.

Taken together, these considerations show that hydrographic artistry and environmental responsibility can go hand in hand. By choosing sustainable materials, cleaner processes, and providers with transparent practices, riders can enjoy expressive finishes without compromising ecological values. The result is a more sustainable future for hydrographics that still embraces bold shapes, striking textures, and personal style on the road.

Final thoughts

As the motorcycle industry evolves, hydrographics stands out as a crucial innovation for owners looking to enhance their offerings. By leveraging the unique designs, durability, customization options, and economic benefits associated with hydrographics, business owners can better serve their customers and increase their market competitiveness. With growing awareness of environmental impacts, understanding sustainable practices in hydrographics further enriches the business strategy, catering to environmentally conscious consumers. The incorporation of hydrographics into motorcycle fairings is not just a trend; it reflects a deeper commitment to quality and personalization in motorcycle design.