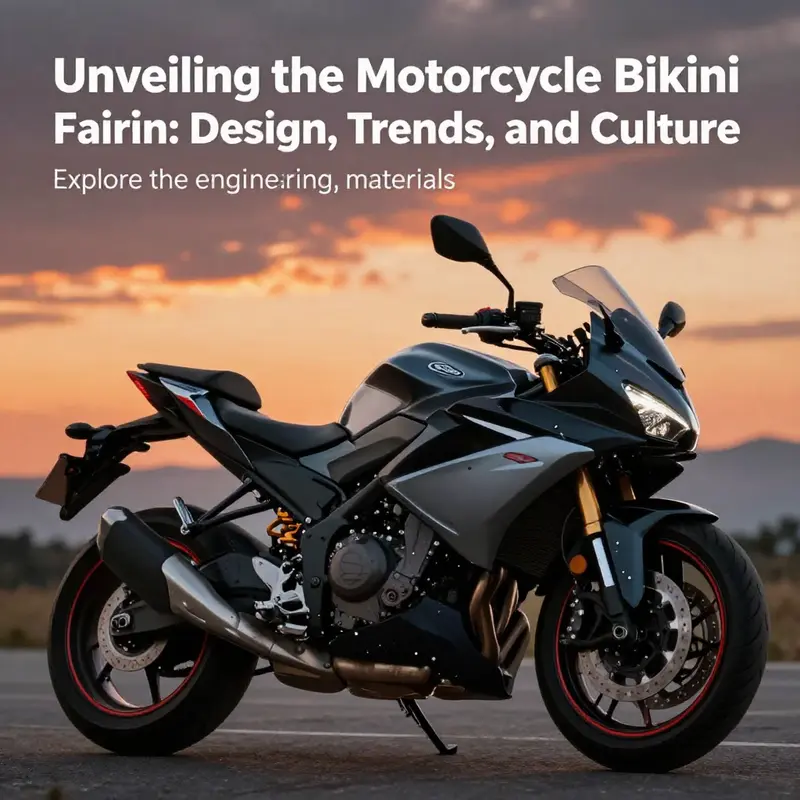

Motorcycle bikini fairings have become a staple in enhancing both the aesthetic and functional aspects of biking. These lightweight, semi-enclosed body components specifically cover the front end of motorcycles, offering improved aerodynamics and rider comfort at higher speeds. Designed to meet the demands of both performance enthusiasts and style aficionados, bikini fairings bridge the gap between retro designs and modern engineering. This article delves into the intricate details of bikini fairings, segmented into five chapters that provide a thorough understanding of their design, manufacturing advances, economic implications, maintenance, and cultural impact in the motorcycle community, thus enriching the narrative for business owners and enthusiasts alike.

Edge of Stability: Engineering the Aesthetics and Aerodynamics of Bikini Fairings

The bikini fairing sits at a nuanced intersection of performance, protection, and perception. It is not merely a stylistic flourish for sport or retro-inspired bikes; it is a carefully engineered interface that shapes how air meets the machine and how the rider experiences that encounter. In its most purposeful form, a bikini fairing covers only the upper front of the bike—shielding the headlight and instruments, guiding the wind around the rider, and leaving space for the engine’s breathing and the bike’s silhouette to breathe as well. This minimalist geometry aims to reduce drag and stabilize the flow without smothering the rider’s sense of openness, visibility, and control. The engineering challenge, then, is to fold these sometimes competing demands into a shape that performs, protects, and pleases the eye.

From an aerodynamic standpoint, the core objective is to guide the air in a smooth, predictable path as the motorcycle slices through the atmosphere at speed. Compared with full-coverage fairings, bikini designs leverage the advantage of reduced frontal area while exploiting streamlined contours that encourage a clean separation of flow around the bike’s nose, front suspension, and the rider’s torso. The result is a lower drag coefficient and a calmer flow field in front of the rider’s helmet. Yet the design cannot neglect the realities of heat management and component protection. The front area often houses lamps or instruments and may include partial engine coverage; the challenge is to protect these components from the brunt of wind and rain while ensuring they remain accessible for maintenance and replacement. This delicate balance is at the heart of modern bikini fairing engineering.

Engineers bring substantial rigor to the task through iterative analyses that blend fluid dynamics with structural integrity. Computational fluid dynamics, or CFD, has become the workhorse of modern design. Using platforms that support parametric modeling and high-fidelity simulations, designers test a spectrum of shapes, radii, and intake placements to coax smoother air paths around the bike. Fine-tuning the trailing edge and the shoulder lines reduces early flow separation and minimizes turbulent eddies that can rob stability at high speeds. In practice, this means adjusting the fairing’s resistance to reattachment of the boundary layer and shaping the edge to transition the flow gently from the fairing to the surrounding air. Such precision is not decorative flourish; it translates directly into reduced buffeting, lower wind noise, and more consistent cooling of the radiator and surrounding components.

Material choice further determines the performance envelope of bikini fairings. The highway for lightness and resilience often runs through high-polymer ABS plastics for mass-produced parts, where injection molding lends itself to tight tolerances and repeatable geometry. For more specialized applications or premium models, carbon fiber-reinforced polymers bring strength with minimal weight, supporting stiffer structures that can dampen vibration and improve the overall sensing of airflow. The manufacturing path—from rapid prototyping with 3D-printed models to final production via injection molding or composite fabrication—needs to preserve the exacting geometry uncovered in CFD studies. The surface finish matters too; primer, paint, and clear coats must withstand UV exposure, wind-driven rain, and cycle wear, all while preserving the aesthetic line that defines the bike’s face.

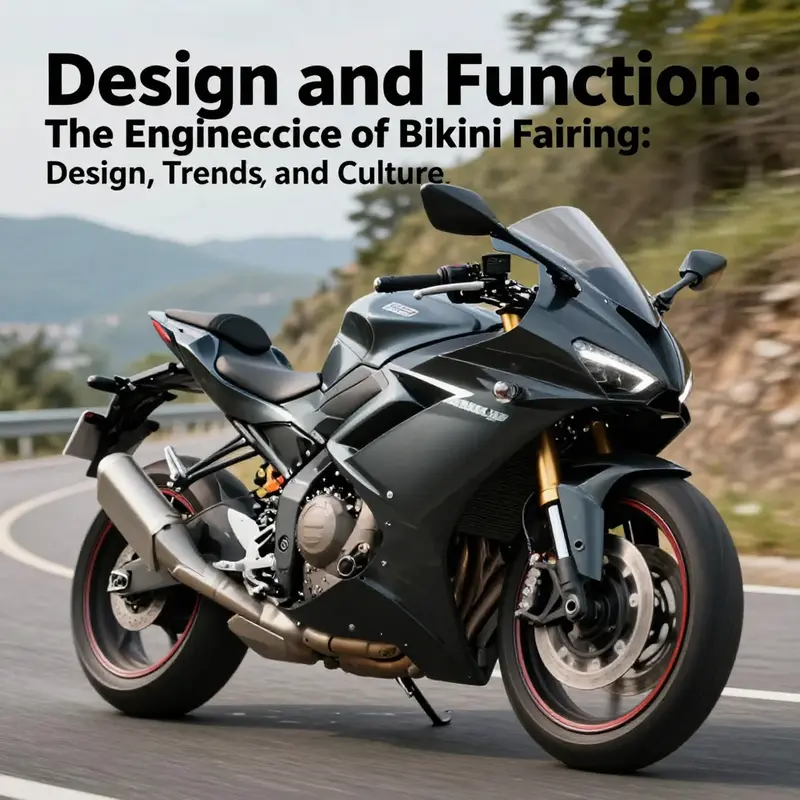

The dialogue between form and function extends to human factors. A bikini fairing must not obscure the rider’s view or obstruct the instrument cluster. In addition, the housing for headlights, indicator lamps, and cooling ducts must be accessible, serviceable, and robust against vibration and impact. Designers increasingly consider micro-ergonomics: how the fairing’s inner contours affect the rider’s posture, how air travels over the helmet, and how the wind pressure at certain speeds interacts with the rider’s arms and chest. Some designs incorporate subtle chamfers and ribbing that direct air in a manner that reduces lift at the rider’s chest while maintaining a quiet cockpit. In higher-end configurations, there is room for features such as vents or mild buoyant curves that gently guide air toward the radiator or away from sensitive electronics, maintaining a balance between cooling efficiency and drag reduction.

A growing thread in the engineering narrative is the potential for adaptive or active aero elements. While traditional bikini fairings rely on passive geometry, advances in materials science and control logic open the door to adjustable deflectors, tunable vortex generators, and other smart air-management devices. Conceptually, these systems respond to speed or throttle input, altering the local flow patterns to optimize stability and rider comfort in real time. Although such systems add complexity and cost, they demonstrate how modern fairings can be more than fixed shells; they become dynamic interfaces between machine and environment.

From the standpoint of integration, the bikini fairing is a multi-disciplinary product. It must cohabitate with the motorcycle’s frame and suspension, align with the lighting and instrumentation, and harmonize with the exhaust and cooling pathways. The mounting interfaces must be robust enough to withstand vibration and occasional impact, yet simple enough to facilitate installation and replacement. The chosen geometry also has to accommodate a range of radii and rider sizes; a truly versatile design may offer or require adjustments to preserve the intended airflow behavior across riders and riding positions. In this light, the fairing is not a static skin but a carefully tuned component whose impact ripples through the entire machine’s dynamics.

Market realities drive decisions about production volume and cost. A bikini fairing that uses a straightforward ABS shell with a polished surface is accessible to a broad audience, with price points that begin at a modest level and scale upward with materials and complexity. For riders who prize the look and the lightness of a semi-covered front, the opportunity lies in selecting a design that aligns with their bike’s character and their riding goals—whether those goals emphasize outright speed, everyday comfort, or a vintage aesthetic that nods to the era when naked and retro-styled bikes dominated the scene. The broad availability of these components across different brands and styles has helped democratize aerodynamics, turning what was once a specialized upgrade into a common customization path for many riders seeking better balance between airflow and rideability.

For riders who want to align a new look with a specific brand’s language, it is useful to explore catalogues that curate compatible fairings for a variety of models. A practical path for riders and shops alike is to search for a specific category that reflects the bike’s lineup and the fairing’s intended aesthetic. This approach can help ensure a coherent silhouette and mounting compatibility, while preserving the expected performance characteristics that drew a rider to the bikini fairing in the first place. Among the available resources, Suzuki fairings product category offers a representative sense of how these parts are organized in the market and how brands approach fitment and style without derailing the bike’s fundamental geometry. The analogy extends to other brands as well, where the goal remains consistent: a lightweight, aerodynamically informed front end that respects the rider’s line of sight and the machine’s cooling needs.

As with any performance modification, the successful adoption of bikini fairings hinges on thoughtful integration rather than cosmetic appeal alone. A well-executed design will feel as if it belongs to the original frame, with edges and angles that seem natural rather than imposed. It should improve the bike’s cornering sense by smoothing the streamlines around the front wheel and the rider’s torso, yet it must not introduce unwanted vibrations, wind noise, or heat buildup. The result is a front end that reads as a coherent unit—where the shape, material, and mounting deliver a practical gain in stability, a visually coherent identity, and a tangible sense of enhanced riding confidence at speed. In the broader arc of motorcycle aerodynamics, bikini fairings embody a philosophy: optimize the transition of air around the rider while leaving space for personal expression, mechanical integ rity, and the distinctive personality of the machine.

External resource for further reading is provided below to illuminate how broader aerodynamic principles inform these practical choices. For a more technical overview of how simulation-driven optimization informs motorcycle aerodynamics, see Altair’s overview of motorcycle aerodynamics: https://www.altair.com/industries/motorcycles/

From Carbon Weaves to CFD: The Materials and Manufacturing Revolution Behind Bikini Fairings

The motorcycle bikini fairing sits at an improbable intersection of lightweight engineering and practical rider experience. It is a semi-exposed shell that covers the crucial forebody, shielding lights and instruments while maintaining the freedom of a nimble machine. Over the decades, the evolution of these fairings has tracked a broader arc in engineering: the move from simple, hand-shaped shells to highly engineered, aerodynamically sophisticated components that blend material science with digital design. The modern bikini fairing is not merely an aesthetic statement; it is a carefully tuned system whose form, fabric, and fabrication methods work in concert to manage airflow, reduce buffeting, and improve rider comfort at speeds where wind pressure and noise become fatigue factors. In this sense, the chapter you are reading sits at the heart of an ongoing dialogue between what a shell is made from, how it is made, and how it behaves when the bike leans into a corner and the wind jokes with the rider’s perception of stability.

The first decisive wave in the material story of bikini fairings was the shift from heavier, traditional composites to lighter, stiffer options. Early shells often relied on fiberglass and resin systems that offered workable strength and formability but carried tangible weight penalties and limited stiffness. As performance demands intensified, the push toward carbon fiber reinforced polymers became irresistible. Carbon fiber, with its extraordinary strength-to-weight ratio and high stiffness, could dramatically reduce the mass of the front end while preserving structural integrity under aerodynamic loading. The benefit is not merely a lighter surface; it is a more rigid, dimensionally stable shell that resists deformation at high speeds and under the vibrations generated by a fast-moving machine. This matters because any squish or twist in the shell under load can alter airflow characteristics, degrade the intended aerodynamic profile, and reintroduce buffeting into the rider’s line of sight and comfort. For those aiming at a sportier or more retro-leaning aesthetic, carbon fiber also offers a distinctive, premium finish that aligns with the ethos of performance-oriented motorcycles.

Yet material choice is never only about weight. The behavior of a bikini fairing in wind—how it redirects flow, where it stalls, and how it couples with the rider’s position—depends on the interaction of resin content, fiber orientation, and surface quality. In high-end applications, the resin-to-fiber ratio must be tightly controlled to avoid excessive brittleness or creep under load. This is where manufacturing methods begin to matter as much as the material itself. The advance from simple lay-up processes to more controlled fabrication methods has allowed engineers to realize complex geometries that were once impractical. Vacuum bagging and autoclave curing, for instance, enable a resin distribution that is evenly consolidated and free of voids. The resulting structure exhibits uniform stiffness across the shell and a surface finish that can be relied upon for accurate flow behavior. The ability to produce a curved, multi-axial layup without sacrificing surface smoothness makes it possible to integrate features such as vent channels, edge radii, and transitional forms that minimize flow separation at aggressive lean angles. In practical terms, this means a bikini fairing can be shaped to guide air into a purposeful path—creating subtle low-pressure zones that assist with downforce on the front wheel without producing excessive drag elsewhere.

Of course, the story does not end with carbon fiber alone. While high-performance materials lead the vanguard, the broader market and rider demographics still demand resilience, cost-effectiveness, and compatibility with a diverse range of bikes. Here, high-grade polymers such as ABS-based composites often serve as the backbone of mid-range fairings. They provide a forgiving balance of impact resistance, moldability, and surface finish, making aftermarket options accessible to a wider audience. The important point is that advanced design does not happen in a vacuum. Instead, it sits on a continuum that includes decisions about material selection, manufacturing tolerances, and post-processing practices, all of which influence the final aerodynamic behavior. These choices are increasingly guided by digital tools that model the interaction between the shell and the air, a shift from purely empirical testing to a data-driven design approach.

The role of computational methods in shaping bikini fairings cannot be overstated. Computational Fluid Dynamics, or CFD, has become a central tool for engineers seeking to predict how a surface will interact with turbulent air and varying angles of attack. CFD allows designers to test countless iterations of surface contours, edges, and relief features in a virtual environment before a single physical prototype is built. The virtue of this approach lies in its speed and its capacity to reveal subtle flow phenomena that are difficult to observe in wind tunnels. A typical objective is to minimize unsteady pressure fluctuations that contribute to buffeting, especially when the rider negotiates turns at high speeds. Engineers can choreograph the fairing’s vertical silhouette, the integration of grooves or channels, and the seamless blending with the headlamp and instrument cluster to create a cohesive airflow pattern. When done well, the design supports a form of passive aero control, aligning the front-end flow with the bike’s lean trajectory and maintaining a stable, predictable response at the bars.

The digital design ethos is complemented by advanced manufacturing techniques that ensure the intended geometry is actually realized in physical form. Vacuum bagging compresses the laminate during cure, helping to expel air pockets and to bring the layers into intimate contact. Autoclave curing further enhances quality by applying uniform heat and pressure, reducing residual stresses and improving surface integrity. Together, these processes deliver parts whose thickness, stiffness, and surface texture meet exacting specifications. The surface finish, in particular, matters because a glossy, smooth exterior reduces skin-friction drag and yields a more repeatable aerodynamic profile. Such manufacturing fidelity is crucial when the goal is to achieve repeatable behavior across a range of riding conditions and lean angles. It is a reminder that performance in this domain is as much about the precision of fabrication as it is about the elegance of the design.

Beyond the technicalities, there is a philosophy at play. The bikini fairing represents a design niche that embraces the idea of a modular, adaptable front end. It allows riders to tailor the look, the weight, and the air movement characteristics of their motorcycle without sacrificing practicality. In this regard, the fairing functions as a tuned system rather than a mere cosmetic shell. Its success hinges on a delicate balance: the shell must be light enough to contribute to performance, stiff enough to resist deformation under wind and vibration, and shaped enough to direct the air in a way that supports handling and rider comfort. The intersection of advanced materials and sophisticated manufacturing makes this balance possible, enabling a new generation of fairings that perform as well as they appear. And because aftermarket options exist across a wide spectrum of bikes, the conversation about bikini fairings has moved from a niche with limited parts to a broader ecosystem of compatible designs and configurable aesthetics. For readers curious about model-specific options, one can explore aftermarket entries tailored to popular platforms such as sport and sport-touring configurations; see Yamaha fairings for YZF models as an example of how a modular approach can expand compatibility and customization options.

In terms of the broader market and the rider’s experience, the trajectory of material and process advances suggests a future where even more radical geometries can be produced with confidence. With CFD guiding the early design and precise manufacturing methods delivering the finished product, the gap between concept and reality narrows. Riders can expect fairings that optimize airflow at a wider range of speeds, provide improved protection against weather and debris, and maintain a visually compelling, era-defining look. All of this happens without abandoning the practical goals of reliability and serviceability. The result is a coastal plain of possibility where form and function converge in a single, coherent front end. As more manufacturers and aftermarket suppliers adopt this integrated approach, the bikini fairing evolves from a simple aerodynamic add-on into a carefully engineered component that sustains performance, comfort, and style across a spectrum of riding contexts.

External resource: Aircraft dynamics in MotoGP—the future of design

Internal link: For enthusiasts exploring model-specific aftermarket options that align with the discussed material and fabrication advances, see Yamaha fairings for YZF.

市场趋势解码:整流罩在摩托市场的经济影响与消费偏好

在摩托车的前脸语言中,整流罩扮演着既是科学又是审美的核心角色。尽管媒体和玩家之间常有对“比基尼整流罩”这一名词的误解,行业实际关注的,是整流罩本身在空气动力学、造型与功能整合方面的综合表现,以及它如何驱动消费与产业链的互动。2025年中国市场规模达到约128亿元人民币,全球市场规模则超过340亿元。这样的数字并非孤立的统计,它们折射出一个连锁反应:从材料、模具、表面处理到整车制造与改装市场的协同升级。全球展望也相当乐观,预测到2032年全球整流罩市场将接近680亿元人民币,其年复合增长率接近十个百分点。驱动因素并非单一,而是多层面的共同作用:经济增速、城市化、骑行文化的全球扩散,以及对高性能摩托车的持续需求。对于产业链上的企业而言,这意味着更强的向上拉动效应。整流罩的生产不仅涉及塑料注塑、模具设计、表面涂装与精密加工,还带动了上游材料、涂层工艺、以及自动化装配的创新投放。与之相关的定制化和轻量化趋势,也推动了整车厂与改装市场的融合,促使品牌对前脸设计的叙事性与可持续性并重。尽管全球市场在增长,但区域分布呈现差异化特征:中国、东南亚与欧洲市场对高性能、个性化整流罩的需求最为旺盛。这些地区的消费群体在购买时,既看重空气动力学带来的实际效益,如降低风阻系数15%到20%、显著提升高速稳定性与加速响应,也关注风噪下降的舒适度提升,尤其在长途骑行和赛事型驾驶场景中,这些性能改进转化为切实的驾驶体验。与此同时,设计偏好正在从单纯的功能性转向“美学+品牌叙事”的综合考量。越来越多的买家希望整流罩承载辨识度,碳纤维纹理、简约流线、以及可定制涂装成为主流。对于价格敏感的群体,中端市场仍是核心,单价通常在500至1500元之间,强调性价比与安装便捷性;而高端定制化整流罩,尤其在碳纤维材料与原厂级别的风格化设计领域,价格往往超过3000元,目标客户是追求极致审美与独特收藏意义的车迷。政策与环境因素也在把行业推向更高的技术门槛。严格的尾气排放与能效标准催生了对更高等级空气动力设计的需求,促使整流罩在形状、材料选择与集成度方面不断优化。再生材料和可回收塑料的应用也逐步成为品牌的绿色卖点,与全球向可持续供应链转型的趋势相呼应。就材料选择而言,ABS、PC/ABS等高分子材料、以及玻璃纤维、碳纤维等复合材料的组合使用,成为实现重量减轻与刚性的常态路径。制造商在追求更高强度与更优表面质量的同时,也在探索可回收与再利用的生产方式,以降低生命周期对环境的影响。对消费者而言,这不仅是性能的提升,也是对“更环保车世代”的认同与参与。为了把握品牌与市场的对接,行业正推动数字化与跨渠道体验的融合。例如,AR试装、在线定制平台与即时渲染,帮助用户在下单前就能感知成品的气质与视觉效果。这种数字化营销不仅提升了购买信心,也加速了从线下改装店到线上商城的转化率。对行业而言,未来的竞争焦点在于如何把“轻量化、智能化与模块化”融合在一体化的前脸解决方案中,既保留个性化的表达,又确保耐用性与维护便利性。若以设计与工程的视角审视,整流罩的走向更强调材料创新、结构优化和集成化设计的三角平衡:在尽量减重的同时,保持足够的冲击与耐久性;在前灯、摄像头、雷达等组件的嵌入上实现更高的系统集成度;在装配与维护方面确保用户可快速更换、便于DIY改装。对于研究者和从业者而言,这些趋势也意味着需要更紧密的跨学科协作:材料科学、流体力学、表面涂装、热管理、以及数字化用户体验设计的共同协作将成为常态。值得一提的是,在市场信息不断更新的环境下,消费者偏好呈现出“グローバル共性+区域差异”的特征。全球层面,用户普遍追求更高的空气动力效率、静音体验与前脸的高端质感;区域层面,价格敏感度、改装文化的成熟度、以及对本地车型的适配度,决定了不同市场的细分策略。为读者提供一个直观的例证,若希望看到品牌叙事与车型匹配的实际呈现,可以参考某些车型系列的整流罩设计趋势,这些设计在不同市场的接受度与再设计需求也在持续变化。对于关注具体车型与品牌的读者,进入 Honda 钢性前脸类别的页面可以看到与车型定位相吻合的整流罩设计风格与市场导向的组合,这样的信息对理解区域市场与品牌沟通具有借鉴意义。你可以通过此链接浏览不同车型的整流罩设计方向:Honda fairings。展望未来,整流罩市场将继续在高性能、轻量化、智能化和个性化之间寻找新的平衡点。产业方应在保持技术领先的同时,加强绿色制造与可持续供应链管理,以应对全球环保法规和消费者对环保意识的提升。总之,尽管“比基尼整流罩”这一表述在行业内并非标准术语,但整流罩作为核心部件在经济与消费层面的影响力只增不减。它不仅塑造了车辆前脸的气质,也推动了材料科技、制造工艺、数字化营销与可持续发展之间的协同进化,成为理解当代摩托市场的重要镜像。外部参考资源:格隆汇对2025年中国摩托车整流罩行业市场格局的分析,为读者提供了对市场规模、竞争格局及应用细分的全面洞察。你也可以通过相关外部研究进一步拓展对全球趋势的认知。外部参考链接:格隆汇报告

From Aesthetics to Aerodynamics: A Practical Guide to Installing and Maintaining Bikini Fairings

Bikini fairings sit at the intersection of form and function on modern motorcycles. They are lightweight, semi-coverage components that cloak the headstock area—enclosing the headlight, portions of the instrument cluster, and a segment of the upper engine bay—without wrapping the entire bodywork. This design keeps air flowing smoothly around the bike while preserving a rider’s sense of freedom and control. For riders who chase a blend of sport spirit and retro flair, these fairings offer a compelling middle ground: a visual punch that doesn’t sacrifice the practical air management essential at speed. The practical benefits extend beyond looks. By diverting high-speed wind, bikini fairings help reduce buffeting and wind pressure on the rider’s helmet, which can translate into a more relaxed neck posture and less fatigue over long stretches. They also shield vulnerable components such as the front lighting and instruments from rain and road debris, contributing to a more consistent riding experience in variable weather. The material choice—typically a high-grade plastic or polymer blend developed for impact resistance—tends to favor durability and lightness, ensuring that the gains in aerodynamics are not offset by excessive weight or stiffness. In practice, a well-designed bikini fairing becomes a subtle partner in the bike’s overall character, amplifying both the rider’s mood and the machine’s performance envelope without demanding heavy structural compromises.

Installing and maintaining these components is not merely about aesthetic alignment; it requires respect for compatibility, fit, and the gentle balance between rigidity and vibration. Across many models, the attachment points are designed to marry directly with existing mounting hardware or with bracket systems that clamp to the frame or subframe. Because models vary in geometry and year-to-year changes may shift the position of mounting holes, the first step is always to confirm that a chosen fairing is compatible with the specific bike. This check avoids misalignment that could irritate the rider, rub against moving parts, or create unintended gaps that catch wind differently than intended. Once compatibility is established, a careful inventory of parts becomes the next priority. A typical kit includes the fairing panels, mounting brackets, fasteners, spacers, and, occasionally, dampers or padding to control vibration transfer at contact points. Inspecting every piece upon receipt ensures there are no cracks, deformations, or missing components before the installation even begins. A clean, well-lit workspace and a clear plan for the sequence of mounting reduce the risk of damage during assembly and help preserve the finish on both the bike and the new panels. The practical path through installation hinges on a disciplined approach to alignment and torque, rather than sheer force. The instructions in most authoritative references emphasize a methodical process: verify hole alignment, perform a dry fit, then tighten in a cross pattern. This approach minimizes the risk of warping the plastic, creating cosmetic gaps, or inducing localized stress that could lead to cracking after a few hours on the road. A careful finger-torque check—tight, but not crushing—ensures that clamps hold firmly without deforming the plastic or distorting the panels. In this process, the role of small, subtle details matters almost as much as the bigger decisions. The insertion of rubber spacers or soft dampers at contact points can dampen the wind-induced chatter that becomes audible at highway speeds. A thin smear of silicone-based grease at the back edges of the panels or at the contact surfaces can also reduce friction during mounting, which helps to preserve the surface finish and makes future removal easier without gouging the plastic.

The narrative of installation should also accommodate the rider’s need for control and visibility. While bikini fairings honor the eye with a low-profile silhouette, they must not impinge on steering geometry, cable routing, or the range of motion of controls. After the brackets are snugly attached and the panels snapped into place, a careful verification sequence follows. A gentle shake by hand checks for any looseness or audible rattle at mounting points. A light rotation of the handlebars and a quick test of the front brake and clutch action—without riding off—can reveal any interference that only becomes apparent when forces are transmitted through the steering system. If there is any contact during these checks, a reassessment of fit is warranted. The goal is a resilient installation that can withstand the vibrations and pressure of real-world riding while remaining stable and quiet at speed. To support this, some riders add small cushioning pads or washers at strategic contact points where a tiny amount of movement could otherwise generate noise. The overall message is simple: a properly installed bikini fairing should feel like a natural extension of the bike, not an afterthought bolted on at the end of a long assembly list.

Beyond the initial install, maintenance plays a vital role in preserving performance and appearance. Regular inspections become part of the routine just as one would inspect tires or brakes. A periodic check—every few hundred miles or after rough roads—helps catch loose fittings before they become an issue. It is prudent to revisit torque values at these intervals, guided by the manufacturer’s recommendations. Cleaning should follow a straightforward regimen: use a mild, neutral cleaner and a soft cloth to wipe the surface; avoid harsh solvents, abrasives, or anything that could dull the finish. Prolonged exposure to direct sunlight invites aging of the plastic—so where possible, park in shade or use a cover when the bike is stationary for extended periods. If you ride in wet conditions, dry the panels after a ride to prevent water spots and to reduce the risk of corrosion at any metal-fastened joints. While the fairing is designed to withstand normal wind-driven stresses, it does not bear structural loads. If you notice cracks, significant deformation, or consistent loosening, the prudent course is to replace the affected piece rather than attempting a makeshift repair. This caution is echoed by safety-minded manuals that stress the importance of proper installation torque and secure fit for external cosmetic components, especially on high-speed, high-vibration platforms.

For riders who want to explore variations within the same family of products, there is value in reviewing the broader catalog of fairings in a neutral, model-agnostic way. This contextual exploration can help a rider understand which shapes and coverage levels best suit their bike’s geometry, stance, and riding goals. See the internal fairings catalog for a neutral overview of options and fit considerations. This resource provides a practical sense of how the fairing family adapts to different bikes, without implying endorsement of any single style. Such exploration can refine a rider’s expectations about how a bikini fairing integrates with existing bodywork, how much coverage is offered, and how the air stream interacts with the windscreen and rider position. In the end, the installation and maintenance story is a careful dialogue between the rider, the bike, and the fairing itself. It is less about assembling a rigid gadget and more about composing a coherent aerodynamic package that respects the bike’s personality while delivering predictable performance under varied conditions. If in doubt, rely on the official guidance that accompanies any aftermarket external part, and treat the installation as a chance to fine-tune the balance between aesthetics and aerodynamics rather than merely attaching a cosmetic shell.

For further reading on best practices and torque specifications, consult the official owner’s manual or manufacturer-recommended documentation. This precise guidance ensures you are applying the correct clamping force and aligning mounting points exactly as intended. As a practical reminder, the following external resource offers a detailed reference for installation considerations and torque expectations relevant to roadside maintenance and safe operation: https://www.yamaha-motor.com.cn/support/manuals/2025-yamaha-scooter-clarino-i125-manual. Keeping these references in view helps ensure that the bikini fairing remains a trusted ally on the road rather than a source of concern after a windy gust or a rough pavement patch.

速度的轮廓与文化的记忆:比基尼整流罩在摩托车界的地位与演变

比基尼整流罩在摩托车文化中不仅是功能性的车身部件,更是一种独特的美学语言。它把速度、技术、个性紧密绑定在一起,让骑手在风中寻找自我。早在二十世纪中叶的风格变革中,设计者尝试让空气以可控的方式穿过前部,减少涡流和风噪。传说中,1948年的一个设计者尝试通过线条和曲面来引导气流,这一理念逐步演变成今天所熟知的半覆盖式外壳。虽然名字听起来简单,但其带来的影响却深远:它改变了摩托车与人之间的关系,让高速成为一种可观照的风格选择,而不仅仅是一种工程优化。

在随后的几十年中,70年代的咖啡赛车文化将这一部件推向了象征性的高度。那时的设计强调露出的驾控姿态与简洁的线条,前部半覆的外壳仿佛为骑手盖上一层动感的火焰。并且,这种造型让日常行驶也充满仪式感,成为一种生活方式的表达。进入80年代和90年代,市场上出现的多款经典车型以其锐利的轮廓、低沉的坐姿和标志性的涂装将比基尼整流罩推向了颠峰。它们不是只为赛道而生,更以其视觉冲击力塑造了整车的个性与气质,成为粉丝与收藏家心中的灵魂符号。

今日的比基尼整流罩已经越过简单的工程需要,成为一种跨越年代的记忆载体。它承载着“速度即艺术”的理念,展示了空气动力学、机械美学与个人风格之间的对话。对于许多车迷而言,选择半覆盖式的前部并非退回到过去,而是一种以保留的方式重新诠释速度的语言。它允许骑手在风的呼吸里感知前进的节拍,同时保留对全局空气流场的控感。在这个过程中,材质和制造工艺也让它在现代市场中仍具吸引力——高分子材料配合注塑成型,既保证了轻量与强度,又能通过表面喷涂实现耐磨与美观。价格区间的弹性让更多人有机会尝试这类设计,既能保留传统美学,又能结合当代的骑行需求。

与此并行的,是比基尼整流罩在社区中的文化传播。它不仅是车身部件,更成为一种叙事工具,被写进写真、被拍成影像,成为改装历史中的一个章节。当骑手把半覆式前部装在一辆线条干净、定位明确的车型上时,仿佛在讲述一个关于速度、技术与自我的故事。人们在改装与展示中寻找共鸣,讨论如何通过细微的几何变化保留经典气质,同时容纳日益严苛的空气动力学需求。对许多新一代骑手来说,这是一种对历史的致敬,也是对个人风格的试验场。比基尼整流罩不再只是一个配件,而是成为一个可被讲述的叙事符号,连接上一代与现在的驾驶经验。

如果你愿意进一步了解这类前部设计在不同车型上的兼容性与选择,可以浏览相关的零件集合,探索不同造型与材质的组合,甚至只是在收藏清单里偶尔补充一个半覆盖的前部。 Honda fairings 的页面就提供了一个入口,帮助你理解不同品牌在保持风格一致的同时,如何通过微小的改动实现气动优化与视觉统一。 Honda fairings

然而,正是这种跨时代的美学与工程的结合,让比基尼整流罩在摩托车界拥有独特的地位。全整流罩已经成为主流,但这类半覆盖式前部继续在复古爱好者、收藏家和热衷于特定风格的骑手群体中保持强烈的情感联系。它们提醒人们,速度不是单纯的数字,而是一种能感知、能被记住的体验。这样的观念也让设计师与制造商在现代化框架下保留更多古典线条的可能性,使新旧之间的对话持续进行。

从历史叙事的角度看,比基尼整流罩更像是一座桥梁,跨越工程的冷峻与美学的热烈。它让我们看到,技术的进步并不一定意味着风格的消逝,相反,恰恰是在对 past 与 present 的尊重中,才孕育出对速度的新理解。进入21世纪,很多改装文化的讨论会将这类设计放在更宽的语境中——它不仅是部件的选择,也是对“个人表达”与“共同身份”的探寻。摩托车不再仅是交通工具,而成为一种会说话的载体,一种让人们通过轮廓、色彩与线条来讲述自己的故事的媒介。

总之,比基尼整流罩的文化影响不仅体现在它的工程功能上,更深藏于历史记忆与美学史的脉络里。它承载了从咖啡赛车到现代复古风格的演变,是速度、风力与个性三者之间的温柔平衡。它提醒我们,设计的意义往往在细节中显现——在半遮挡的灯组、在简约而有力的前部轮廓,以及在用材与表面处理上的用心。正是在这样的细节里,骑手与观者共同感知到:摩托车并非只有移动的工具,更是承载文化记忆的艺术品。

外部参考来源: https://www.britishmotorcyclehistory.org.uk/bikini-fairing-history

以上文字尝试在史诗般的叙事与具体的文化分析之间取得平衡,既说明了为何比基尼整流罩在历史上具有重要地位,也解释了它在当代改装与收藏场景中的持续魅力。

Final thoughts

Motorcycle bikini fairings symbolize more than just aesthetic enhancements; they represent an intersection of technology, style, and cultural expression within the biking community. Business owners and enthusiasts alike can benefit from understanding the rich tapestry that surrounds these parts. From their innovative design and diverse materials to their impact on the market and rider experience, bikini fairings play a crucial role in shaping how we view and engage with motorcycles today. Effectively leveraging this knowledge can foster opportunities for growth and innovation within the industry, making it essential to stay informed about these evolving components.