Motorcycle fairings play a crucial role in enhancing both the aesthetics and performance of bikes. As a business owner in the motorcycle industry, understanding the pricing structure of motorcycle fairings is essential. This article delves into the various cost factors influencing fairings—from aftermarket options that offer budget-friendly solutions to OEM parts known for their quality and precision. Lastly, we explore the premium pricing range of high-end materials like carbon fiber, enabling you to make informed decisions for your clientele. Each section will equip you with the insights required to navigate the fairings market effectively.

Between Skin and Speed: Navigating the True Cost of Aftermarket Motorcycle Fairings

Fairings are more than just a rider’s wardrobe for the bike; they are the visible and unseen interface between aerodynamics, protection, and personal style. The price you pay for a set of aftermarket fairings reflects a complex mix of choices, from the material that forms the shell to the level of fitment accuracy and the reputation of the maker. This chapter unpacks how those costs break down, why they vary so dramatically, and how a rider can decide what kind of protection and performance best fits a budget. In doing so, it moves beyond a simple price without context and toward a framework that helps readers decide whether to chase the cheapest option, invest in higher-performance materials, or pursueOEM-grade compatibility with a cautionary eye on price and fitment risk.

At the heart of fairing costs is a triad of decision points: aftermarket versus OEM, material selection, and the extent of coverage. Aftermarket fairings are the most common entry point for riders seeking noticeable savings. They come in a spectrum of configurations, from basic quarter or three-quarter sets that cover only the upper front portion to full fairings that envelop the bike from nose to tail. The price range for these basic to mid-range aftermarket options is broad but often friendly to riders on a tighter budget. In practical terms, a basic set can hover around $100 to $200, delivering a tangible upgrade in aesthetics and initial protection without straining the wallet. Those price bands reflect injections of cost-saving design choices: thinner wall sections, simpler mold geometry, and standard materials that are easy to mass-produce. Yet even within this affordable tier, the engineering behind the part matters. The best of these options balance cost with resilience, offering a fairing that resists cracking under typical street mishaps and that can be repaired or touched up without turning into a long, expensive project.

As one moves up the ladder, premium aftermarket fairings begin to lean on composite or reinforced materials, where durability, weight savings, and aerodynamics start to justify the higher price. Fiberglass and especially carbon fiber variants are the common pivots here. For riders who expect more than cosmetic upgrade, premium aftermarket fairings range from roughly $300 to $800 or more for complete sets, depending on whether the design is tailored for a street or a track-focused use. The improvement in stiffness, impact resistance, and weight reduction can be meaningful. Carbon fiber, in particular, promises a superior strength-to-weight profile and a crisp, race-ready aesthetic that many riders find worth the premium. The catch, of course, is that carbon fiber parts demand more exacting manufacturing and often involve more expensive finishing work to achieve pristine surfaces and correct color and gloss, especially if the parts are intended for show or competition use.

Another layer of nuance enters when considering the type of fairing and how much of the bike it covers. Three-quarter fairings, which cover the upper portion and front of the bike but stop short of the tail, typically cost less than full fairings because they require fewer components and less complex molding. The reduced scope can translate to substantially lower prices without sacrificing the aerodynamic gains and rider protection that partial shells offer. Meanwhile, full fairings—especially those designed for high-end aesthetics and track performance—align with higher price points. These complete shells are often sold as a coordinated group with precise fitment for a specific model year, which reduces uncertain gaps between pieces and minimizes the risk of misalignment during installation. In contrast, incorrect fitment is a common expedition cost when riders mix and match pieces that weren’t intended to work together, potentially leading to gaps, wind noise, or even safety concerns if mounting points don’t align properly.

The price deluge grows even more when OEM is introduced into the conversation. Original Equipment Manufacturer fairings—parts that come directly from the bike’s maker or its authorized suppliers—usually demand higher prices. This premium is driven by the guaranteed fit, the exacting tolerances required by the bike’s mounting points, and the brand’s after-sales promise. For a complete OEM fairing set fitted to a popular sport bike model, the price can easily land in the $800 to $1,500 range or more, depending on the model year, the availability of parts, and whether the set includes all subcomponents such as inner panels and mounting hardware. OEM sets offer a level of confidence in fit and finish that many riders value, particularly if the bike is used for long daily commutes or high-mileage riding where minor misalignments can compound over time. The larger price tag, however, comes not only from the material or manufacturing process but also from the tiered distribution and branding costs that come with factory-backed parts.

Beyond the spectrum of materials and coverage is the material science that informs durability and performance. For riders focused on longevity and performance, carbon fiber remains the apex in the mainstream market. Carbon fiber fairings can push the price to the upper end of the spectrum—ranging from about $1,000 to $3,000 for a complete set, and occasionally higher for specialty or track-dedicated configurations. The reasons are straightforward. Carbon fiber blends are expensive to manufacture, with labor-intensive layup processes, meticulous curing schedules, and surface finishing that demands exacting standards to avoid micro-cracks or delamination. The weight savings are real, and the structural stiffness can translate into less flex under high-speed wind loads, which in turn can contribute to more stable handling at the extreme edges of performance riding. For most street riders, carbon fiber may be overkill, and fiberglass, thermoplastic blends, or precision-molded ABS options may offer the best balance of cost and performance.

The lifecycle economics of aftermarket fairings also deserve careful attention. A well-made aftermarket shell, even if it carries a higher upfront price, can deliver long-term value through improved impact resistance and repairability, especially when sourced from reputable suppliers. As Derek Lin, a Motorcycle Composite Materials Engineer, notes, “Today’s best aftermarket fairings aren’t just cheaper—they’re often more resilient than stock, especially when sourced from reputable suppliers.” That observation frames the cost discussion not as a one-off expense but as an investment in broader protection and potentially lower replacement costs after minor accidents or scrapes. In practice, the cost advantage of an aftermarket set can grow over several seasons if the panels resist cracking, resist paint chipping, and hold their finish without needing frequent replacement. This is particularly relevant to riders who ride in urban environments with higher odds of incidental contact or who ride at street speeds where the energy of impact is less intense than on a race track but more frequent than on a long highway ride.

Another practical factor shaping price is fitment accuracy and compatibility. The rider who seeks a fully integrated, factory-like look should expect to invest more time and money into ensuring compatibility. This includes verifying year-specific revisions, model changes, and even sub-model variants, since a single model can have multiple fairing configurations across different years. It’s not unusual for riders to encounter a scenario where a given fairing set fits well on some production years but requires minor modifications for others. In such cases, the cost calculator expands beyond the listed price of the shell to include tools for alignment, additional mounting hardware, and sometimes paint and finishing work to mask any unpainted edges or exposed fasteners. The reality is that even within the same model family, the margin for error can be substantial if a buyer ignores the fitment notes or fails to confirm the exact part number before purchasing. The implication is simple: compatibility verification is not merely a courtesy; it is a cost-control step that can prevent substantial post-purchase disappointment and expense.

From a buyer’s perspective, a prudent approach to budgeting for aftermarket fairings begins with a clear assessment of goals. If the objective is a visual upgrade with reasonable protection for daily commuting, a basic or mid-tier aftermarket set may suffice. Those options provide a noticeable aesthetic transformation, protection against road debris, and a chance to customize color schemes and decals that reflect personal taste. If the rider’s emphasis centers on speed and handling, and the bike is frequently used on back-country roads or at the track, a three-quarter or full set made from tougher composites or carbon fiber may deliver more meaningful gains in stiffness and wind management. The decision can also hinge on paint and finish costs. A fairing shell is just part of the equation; painting, clear coating, and detailing can add substantial cost if the buyer wants a showroom-like finish that lasts years without fade. Some shops bundle the fairing with paint and seams to ensure color consistency, while others separate these services as ongoing maintenance. In any case, the total outlay must reflect both the tactical protection the shell provides and the aesthetic statement it makes—because appearance, after all, is part of the rider’s experience and can influence perceived value as well as resale potential.

When it comes to model compatibility and specific fitment, riders have a reliable shortcut: look for the model’s category and the exact year range. In many cases, a rider who thinks they need a full OEM set might actually achieve the fit and look they want with a well-matched aftermarket three-quarter set, provided its mounting points align with the bike’s frame and subframe geometry. This is where the discussion often returns to the practical balance between cost and risk. A potential pitfall is assuming that a lower price equals a guaranteed fitment. The market is full of options that seem inexpensive at first glance but require extra effort to align, or worse, require modifications that can weaken the mounting system or compromise protection. The prudent move is to verify compatibility with the seller or manufacturer, confirm return policies if the parts do not fit as advertised, and budget a contingency for any adapters or rework that might be necessary.

From a rider’s storytelling perspective, the economics of fairings reveal that cost is not merely a sticker price. It is a composite of fit, finish, weight, protection, and the long view on maintenance and repair. The most affordable options open doors to immediate upgrades, offering a platform to stage future improvements as budget allows. The higher-priced options, while delivering tangible gains in strength and lightweight performance, demand careful consideration of the usage context and the rider’s willingness to invest not only in the shell but also in the ancillary services that ensure a lasting, polished result. As a practical rule of thumb, begin with a clear plan for what you want your fairings to accomplish: protect, perform, or profile. Then map those goals onto a silicone-defined budget that includes paint, mounting hardware, and potential refinishing. The thinking should be forward-looking: a fairing purchase is not an isolated event but part of a broader upgrade path that touches handling, aesthetics, and even the bike’s perceived value.

For riders focused on model-specific fit and the most precise options, there is value in exploring category-specific pages that catalog fairings by brand and model family. For instance, if you’re curious about how fitment is handled across different configurations, you can browse the BMW fairings category, which offers a structured look at compatibility and design philosophy across various BMW models. This approach helps avoid the common trap of purchasing parts that appear to match but don’t actually fit due to revision changes or minor engineering tweaks. By anchoring decisions to official or well-curated catalogs, riders gain confidence that the parts will align with the bike’s geometry and mounting points, minimizing surprises and budget overruns.

In terms of real-world decision-making, a rider should also consider the end-to-end cost of ownership. The sticker price of the shell is only part of the equation. If the bike is used as daily transportation, the reliability of the mounted fairing and its weather resistance become more significant. A fairing that chips easily or loses color quickly will escalate maintenance costs as repairs mount. Conversely, a high-quality aftermarket shell that withstands day-to-day road use and occasional curb contact can reduce long-term repair costs by limiting the need for frequent panel replacements. The reliability of paint adhesion, the density of the substrate, and the quality of the inner panels all contribute to how well the final product ages. This is why some riders are willing to pay more upfront for a shape that not only looks good but also holds up over years of use.

Finally, the broader market context matters. The availability of aftermarket fairings varies with supply chains, regional demand, and the health of the motorcycle aftermarket ecosystem. When demand rises, prices for premium materials and complete sets can climb, and when supply tightens, lead times increase along with costs for custom orders. For a rider who enjoys the thrill of a build and the satisfaction of a tailored look, this market dynamic becomes part of the budgeting discipline: it’s not only about what you want now, but what you may want when the next model year arrives or when a new styling trend takes hold. In that sense, cost awareness becomes strategic planning, enabling riders to time purchases around favorable pricing windows or to leverage seasonal promotions offered by reputable suppliers that value long-term customer relationships. The goal is not to chase the lowest price at all costs but to strike a balance where the shell’s material properties, fitment accuracy, and finish quality align with the rider’s use case, lifestyle, and willingness to invest in the bike’s ongoing protection and character.

For readers who want to explore more about model-specific options and to gauge pricing patterns in real time, see the broad market listings for aftermarket fairings. The landscape is dynamic, with new molds and surface finishes entering the market regularly, and the best bargains often come from sellers who provide clear fitment notes and robust customer support. In the end, choosing the right aftermarket fairing is as much about understanding the trade-offs as it is about price alone. It’s about aligning the shell with how you ride, where you ride, and what you value most in terms of durability, weight, and appearance. The cost signal, when read with the right lens, reveals a nuanced story: you pay for fit, you pay for materials, and you pay for the confidence that the parts will perform as expected when the road turns twisty or when the track surface demands stiffness and precision. It is a story of skin and speed, where the right choice can elevate the riding experience without bankrupting the budget.

External resource: https://www.bikebandit.com/

Behind the Price Tag: How OEM Motorcycle Fairings Are Priced, from Material to Market

The price you see for an OEM motorcycle fairing isn’t a single number that comes from thin air. It is the product of a chain of decisions that begins long before the first mold is cut and ends far after the last panel is mounted on a bike. For riders and shop owners alike, the sticker price reflects more than raw material costs. It encodes the choices a brand and its suppliers make about durability, fit, performance, supply reliability, and the long-term costs of ownership. When a rider asks, “How much do fairings cost?” the conversation often stops at the surface. But in the world of original equipment manufacturer parts, cost is a conversation about value, risk, and lifecycle trade-offs that vary as widely as the bikes themselves. If you trace the path from concept to customer, the numbers begin with material selection and move through manufacturing discipline, supplier capabilities, and the realities of logistics and quality control. Those factors, in turn, determine whether an OEM fairing feels overbuilt for a casual rider or a race-ready piece that justifies a premium price through superior fit, safer mounting points, and predictable performance across seasons and miles.

Material choice is the primary driver of cost and value. In the OEM space, the same overarching categories you find in aftermarket supply chains show up with different intensities and expectations. The most common starting point is a robust, inexpensive thermoplastic like ABS. Injection molding in large, mature factories makes ABS parts supple choices for mass production and quick fulfillment. The tooling investment is substantial, but the per-unit cost drops as production volumes climb. For buyers, this translates into lower unit prices for bulk orders and a reliable supply where the dimensional stability is predictable across temperature swings and time. ABS fairings offer reliable impact resistance and ease of repair, which makes sense for daily riders or fleets that need a straightforward replacement path without surfacing delays.

Fiberglass sits at the next tier of the cost curve. It is stiffer and stronger than ABS, a quality many riders associate with improved track performance or rugged custom builds. The material itself can be less expensive than carbon fiber, but the manufacturing labor required to lay up panels by hand, trim edges, and apply finishing coats pushes the unit price higher than simple injection-molded parts. Fiberglass fairings also tend to be heavier, which matters not only for handling but for thermal and aerodynamic considerations in certain models. For a race-oriented or enthusiast audience that values stiffness, impact resistance, and the ability to tolerate the occasional heavy contact, fiberglass becomes a compelling middle ground. Yet because the process involves skilled labor and longer curing times, the per-unit cost remains noticeably higher than ABS when produced in smaller runs, a common condition in OEM pricing strategies that target limited editions or model-year updates.

Polycarbonate adds another layer of nuance to the pricing conversation. Known for impact resistance and clarity in some structural applications, polycarbonate is a step up from ABS in durability, and it can be more economical than carbon fiber in specific configurations. In OEM contexts, polycarbonate parts are often selected for sections where visibility or a combination of strength and light weight matters, all while maintaining manufacturability at scale. The price of polycarbonate fairings varies with resin quality, filler choices, and the degree of customization requested by a model’s design team. In some cases, polycarbonate can compete with fiberglass on stiffness, but its impact behavior and long-term fatigue characteristics may push buyers toward other materials when the design goals include harsh track environments or frequent heavy impacts.

Dry carbon fiber represents the apex of the material ladder in the OEM realm. Autoclave-assisted layups, tightly controlled resin systems, and meticulous surface finishing characterize this option. The financial premium is not just about the raw fiber; it encompasses the capital-intensive equipment, skilled technicians, and extended curing cycles required to achieve the promised strength-to-weight ratio. Carbon fiber fairings deliver conspicuously lower mass, improved rigidity, and a premium aesthetic, all of which carry value for high-end performance builds and limited production runs. In cost terms, dry carbon fiber is a niche product with a price tag that can exceed three figures per panel in some configurations. For the buyer, that premium is justified only when the performance gains align with the intended use, the return on investment in performance is measurable, and the part’s installation and service life are consistently predictable.

From there, the cost question widens into the realities of manufacturing processes and volumes. Injection molding remains the engine of affordability for ABS and often for polycarbonate components when produced at scale. The tooling for these processes is expensive to develop, and those up-front costs are amortized over large production runs. As a result, per-unit costs for high-volume OEM orders can be surprisingly competitive, even as the raw materials edge toward the upper end of the spectrum for a given batch. In practice, a factory in a major manufacturing hub can leverage CAD-based reverse engineering and rapid prototyping to refine fit and aerodynamic profile before committing to a full tooling run. When a company projects volumes that justify a certain scale, it can lock in favorable unit costs, reduce cycle times, and maintain consistent quality across thousands of fairing sets, which is a core objective for OEM supply chains.

Hand layup and autoclave curing, the typical path for fiberglass and carbon fiber components, introduces different economic dynamics. Labor-intensive processes and the need for specialized equipment push unit prices higher, especially for smaller batches or custom configurations. The lead times for these parts reflect both the complexity of the layup schedule and the scheduling of autoclaves, which are high-demand resources in many advanced manufacturing ecosystems. In practice, this means that if a model year requires a limited quantity of carbon fiber panels or a bespoke color and finish, buyers should expect longer lead times and a premium price relative to more commoditized thermoplastics. These dynamics are not arbitrary. They reflect the reality that, with carbon fiber and fiberglass, the value is partly derived from the craftsmanship and the precision finishing that accompany high-end materials, not solely from the raw cost of the fibers and resins.

Lead times echo the broader supply chain landscape. Suppliers located near major ports and within key distribution networks can promise faster delivery and more predictable replenishment. In a global market, proximity to Guangzhou Nansha or similar hubs can materially affect freight costs and transit times, changing the total cost of ownership by shaving off weeks of wait time and reducing the risk of stockouts during peak seasons. For businesses that depend on tight schedules—whether racing teams, dealer networks, or performance shops—these logistics details become as important as the sticker price. It is not uncommon to see OEM pricing discussions framed around a combination of material cost, production efficiency, and the reliability of the supplier’s delivery metrics. The best suppliers offer both material transparency and a credible track record for delivering parts on time, with minimal need for rework or return due to fitment issues.

The hidden costs of purchasing OEM fairings sit just beneath the surface of the sticker price. Quality assurance programs are the norm in reputable operations, and they carry a clear, often nontrivial, price. Material specifications, tolerances, and surface finishes are not negotiable audits; they are tested against OEM standards to ensure that the parts fit as designed and perform as expected under real-world conditions. The cost of this assurance is not easily separated from the base price. It manifests as stricter incoming inspection regimes, traceability documentation for every batch, and the ability to stand behind the product when a misfit or defect is discovered. Cleanliness of finish, proper alignment of mounting points, and the ability to accept factory hardware without modification are not just conveniences; they are safety and performance requirements that can influence both the buyer’s satisfaction and the part’s service life.

Another layer of cost comes from the need to minimize rework. A fairing that ships with tight tolerances may still require finish work in the shop to achieve the exact gloss, color match, or edge smoothness that a rider expects. The more the OEM project emphasizes a flawless reveal between panels, the higher the investment in polishing, coating, and color-matching processes. Conversely, a more forgiving design that tolerates slight deviations can reduce finishing labor and shorten the path from container to customer. In practice, the best OEM partners manage this balance by selecting materials and processes that deliver the desired performance with a controllable finishing workload, rather than relying on post-production tricks to hide imperfections.

Compatibility and fitment are not abstract concerns in the OEM space; they are integral to the pricing logic. When a part is designed to snap into place with exact alignment to the bike’s frame and other body panels, the engineering and testing budget grows to ensure each mounting point, screw hole, and wiring routing path aligns perfectly. The payoff is predictable assembly for the customer, fewer installation callbacks, and a reduced risk of performance compromises caused by misfit. Compatibility verification is a recurring cost, especially when a model undergoes year-to-year revisions or when a manufacturer introduces mid-cycle updates. While the upfront price may be higher, the long-term return manifests in fewer troubleshooting sessions, higher customer retention, and more efficient service experiences.

The total cost of ownership is the lens through which OEM pricing makes sense. A fairing that is cheaper upfront may incur higher long-term costs due to fragility, frequent replacements after a spill, or the need for routine refinishing. Conversely, a more expensive but well-fitted, well-finished carbon or fiberglass system may ride out a season with minimal maintenance or rework, ultimately delivering greater durability and peace of mind. For decision-makers, the evaluation is not only about the price tag but about the risk-adjusted value—the likelihood that the part will perform as intended under expected use, the ease of installation with factory hardware, and the predictability of future replacements if and when damage occurs. The strategic takeaway is simple: the best choice aligns material properties, manufacturing discipline, supplier reliability, and lifecycle expectations with how the bike is used and how much risk a buyer is willing to absorb.

The landscape for OEM fairings also reflects the dynamic balance between newer design cycles and the pressures of continued supply availability. In catalog contexts that reflect current design cycles, you may encounter a 2023new category that aggregates recent OEM and aftermarket options. This kind of grouping illustrates how manufacturers respond to evolving styling cues, aerodynamic refinements, and the practical need to standardize parts across a model year with minimal disruption to assembly lines. For buyers, the presence of such category groupings signals a frictionless way to source parts that match contemporary design language without compromising on reliability or fit. It is a reminder that the price of parts is not static; it shifts with product lifecycle decisions, engineering refinements, and the reliability calculus of the supplier network. In the end, the pricing conversation becomes a negotiation among design aspirations, manufacturing realities, and the customer’s willingness to invest in a long-term, high-confidence fit-and-finish experience.

To consider pricing in the context of the broader market, it helps to think in terms of two audiences: the daily rider seeking dependable, cost-conscious replacement parts, and the performance-focused buyer seeking top-tier materials and precise engineering. For the rider, ABS-based OEM fairings represent value through predictable fit, straightforward repairability, and a lower initial outlay. The daily-use scenario benefits from material stability, ease of sourcing, and the assurance that parts match the factory geometry. For the performance-oriented buyer, the premium options—fiberglass or carbon fiber—offer enhanced stiffness, reduced weight, and a smoother integration with the bike’s aerodynamics and handling characteristics. The trade-off, of course, is higher acquisition cost and the potential for longer lead times when customizations are requested or when production volumes do not justify the most advanced materials.

In a fast-moving market, the test of any OEM pricing model is its ability to deliver reliability alongside value. Buyers increasingly weigh the whole-life economics: the cost of shipping from the point of origin, the likelihood of rework, the friction of color-matching and finishing, and the supplier’s track record for on-time delivery. The best suppliers publish transparent material specifications and provide clear OEM-like fitment data, helping buyers forecast maintenance needs and plan inventory more effectively. The objective is a balanced decision: a part that meets performance expectations without becoming a financial sinkhole when a minor scrape occurs or when a classic model’s appeal is preserved through a careful restoration program.

In closing, OEM fairing pricing is rarely a single-point calculation. It is a composite score that rewards material integrity, process discipline, and supply chain resilience. It rewards the buyer who understands that some upfront savings can translate into higher risk if the part does not fit as intended or if the supply line falters. It rewards those who evaluate the long horizon—the maintenance cycles, the potential for rework, the ease of replacement, and the ability to maintain consistent aesthetics and performance across seasons. For a fairing that embodies a brand’s reputation for precision, the price is justified not by flashy exclusivity alone but by the confidence that, when the bike needs protection or a restoration, the OEM path will reliably deliver. The discussion, then, is less about the sticker price and more about the value proposition: a balance between material performance, manufacturing discipline, supplier dependability, and the practical realities of riding. That balance is the true cost of OEM fairings, and understanding it empowers a buyer to choose not just a part, but the right part for the intended ride, the supported service ecosystem, and the rider’s own risk tolerance.

External resource for further context: https://www.alibaba.com/product-detail/2007-Yamaha-R1-OEM-Fairings-Sourcing-Pricing_1600841783463.html

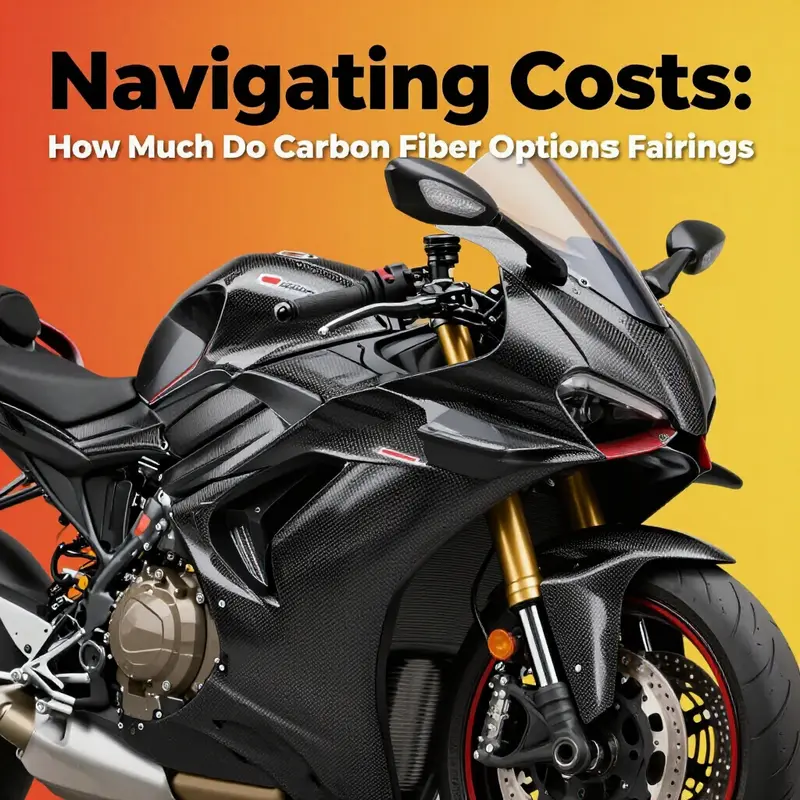

Carbon on the Crest: Unpacking the Cost of High-End Carbon Fiber Motorcycle Fairings

Carbon fiber motorcycle fairings sit at the sharp edge of performance and price, a niche where engineering demands meet a premium market. To understand what you pay for when you opt for carbon, it helps to move beyond sticker prices and look at the whole value proposition. The goal is not simply to justify or defend the high cost, but to illuminate what the investment buys: lighter weight, stiffer structures, refined aerodynamics, and a finish that can transform a bike’s profile from showroom to track-ready. In the spectrum of fairing options, carbon fiber represents the apex of materials science applied to bodywork, and the price reflects the complexity of making something that can endure high speeds, variable temperatures, and the occasional scrape without surrendering strength or shape. For riders weighing speed, handling, and heat management against budget, the decision often boils down to how much performance you want to extract and how much you’re willing to pay for it.

The cost landscape for carbon fiber fairings is not monolithic. It shifts with the motorcycle model, the design’s intricacy, the quality of the carbon fiber itself, and the manufacturing route used to produce the kit. A complete carbon fiber kit for a high-performance machine can span a broad range. For many sportbike platforms, the price ceiling is driven by two factors: the fitment precision required and the finish options that accompany the layup. A Yamaha R1, widely cited in performance discussions, can illustrate the spread. Complete carbon fiber fairings for a high-performance model like the R1 typically fall between roughly $1,500 and $3,000 or more, depending on the generation and the specifics of the kit. The variation between, say, a 2007–2014 generation and newer generations often reflects not just the exact panel shapes but the mounting hardware, the integration with electronics, and the need to preserve cooling channels and ram-air pathways. Finishes also play a role; gloss, matte, or clear weave can alter appearance and price because of differing lamination schedules and post-mold finishing work.

But the Yamaha example is not universal. In the broader sportbike category, full carbon fiber fairing kits for models such as the Kawasaki ZX-7R or Honda VFR750 generally land in a similar ballpark, typically ranging from about $1,200 to $2,800. In some cases, highly custom or handcrafted kits that push for a perfect one-to-one fit, unique weave patterns, or a bespoke finish can climb above $3,500. This is not mere vanity pricing; it reflects the labor-intensive nature of carbon fiber manufacturing. Each panel requires careful measurement, precise layups, and sometimes multiple prep and cure cycles. The result is a product that, if done well, offers better weight distribution, rebuilt aerodynamics, and a rigidity that can translate into more responsive steering and heightened stability at speed. The flip side is that the same panels demand more from the buyer in terms of care, inspection, and sometimes professional installation.

For those who want the high-end aesthetic and performance but are mindful of the total cost, it helps to separate the components of price. A carbon fairing kit is not just the sum of its panels. It includes the engineering work to ensure a precise fit against the frame and substructure, the weave quality and resin systems that govern appearance and durability, and the finishing touches that added sheen or subdued tones. The finish matters because carbon fibers are visually striking when they showcase a clear weave, but the look can be compromised by voids, resin pockets, or inconsistent lamination. Quality control, including meticulous inspection for surface smoothness and edge sealing, can add to the expense but pays off in long-term durability and a cleaner, more professional appearance.

The material itself is a different kind of cost driver. Carbon fiber is renowned for a high strength-to-weight ratio, stiffness, and excellent heat resistance, but those properties come with elevated production demands. The economies of scale present in mass-produced plastic fairings do not apply in the same way to carbon fiber. The manufacturing process—whether it relies on pre-preg carbon laid up and cured in an autoclave or on dry carbon with resin infusion—requires specialized equipment, skilled labor, and tighter quality controls. Each panel must align with the bike’s fairing mounting points, radiator intakes, and electronic housings, and any misalignment can ripple into fitment headaches, longer installation times, or the need for additional modifications. Those complications, in turn, are priced into the kit.

The price spread also mirrors a practical reality of ownership: carbon fiber fairings are not repair-proof in the same way as their plastic or fiberglass counterparts. Repairing carbon, when feasible, tends to be a specialized, often costly process. It may involve patching the laminate, replacing damaged sections, or embroiling the panel in a more extensive restoration that preserves the original shape and lattice. When you compare this with fiberglass or thermoplastic alternatives, the repair economics can influence the perceived value of carbon—especially for riders who keep a bike on the track or push it hard in spirited street riding. In some cases, the cost of replacements or professional repairs can approach or even exceed a portion of the initial purchase price, a factor riders should weigh when deciding how aggressively to spec carbon fiber.

The practical approach to budgeting for carbon fiber fairings begins with assessing fitment and purpose. If your priority is a track-focused machine with maximum lightweight performance, the investment aligns with the demands of racing safety and structural efficiency. If your aim is a street bike that looks striking and reduces weight modestly, you might seek aftermarket options with a leaner feature set and fewer integration complexities, which can translate into a more approachable price point. In either case, confirming compatibility before purchase is essential. Some carbon kits claim universal compatibility, but the reality is that fit can hinge on subtle differences in the model year, the presence of electronics housings, and the design of the radiator and intake ducts. A quick check with the parts diagrams for your exact bike, along with a cross-reference of part numbers or generation codes, can save hours of post-purchase headaches.

As with any high-end upgrade, the finishing stage is a significant value multiplier. The choice of finish—gloss, matte, or a high-end clear weave—affects not only aesthetics but the maintenance regime. Gloss finishes show scratches less readily but can highlight dust and fingerprints; matte finishes resist fingerprints but may reveal more micro-scratches over time. Clear weave gives the classic carbon look, but it requires careful post-processing to avoid clouding or yellowing over the years. Each finish has its maintenance rituals, from careful washing techniques to avoid micro-abrasion on the resin surface, to options for protective film applications that preserve the weave’s clarity. When evaluating a carbon fiber kit, it’s worthwhile to compare not just the raw price but the anticipated long-term cost of care and the warranty terms that accompany the finish and lamination.

Model-specific considerations are another layer of cost. The generation of the bike matters because fairing shapes evolved with air intake geometry, cooling ducts, and electronics integration. A kit designed for a modern generation may require different mounting brackets, different cutouts for ram-air ducts, or even integrated headlight shrouds that preserve the bike’s speed-oriented aesthetic. Conversely, older generations may benefit from simpler, lighter designs but may lack the refined fitment of newer kits. The result is that the pricing envelope can widen or narrow according to how closely the panels match the bike’s geometry and how much auxiliary hardware or modification work is needed to achieve a perfect install.

Finish quality and weave selection also influence the price. The “look” of carbon fiber comes from the weave pattern and the resin system used to lock it in place. A high-quality carbon kit often uses a consistent, tight weave with uniform resin distribution and careful edge sealing. Some kits emphasize a clear, glossy weave that reveals the texture beneath with a highly polished surface. Others are designed with a matte or satin finish to minimize glare or to suit particular color schemes. The choice can impact both the initial price and the maintenance plan. For riders who are particular about the bike’s aesthetic, a premium finish with flawless weave presentation can be worth the extra cost, as it reduces the risk of a finish that looks blotchy after the first ride through a rain shower or after a few stone impacts on a track day.

From a purchasing perspective, the value equation includes not just the panels themselves but the credibility of the maker. The carbon fiber market for motorcycles is a blend of OEM replacement parts, aftermarket specialists, and boutique builders. OEM-replacement fairings promise the most precise fit and a guaranteed interface with the bike’s fasteners and mounting points, but they command a premium that often pushes the price toward the upper end of the spectrum. Aftermarket providers, by contrast, can offer compelling pricing and broad availability, but the fit and finish can vary. One practical approach is to request reference photos, fitment notes, and, when possible, installation guidance from the seller. If a kit includes hardware or mounting brackets, confirm their compatibility with your bike’s subframe and fairing stay points. If the kit omits hardware, you’ll need to factor in those added costs into the total investment. The decision between OEM replacement and aftermarket carbon fiber depends not only on price but on how exact a replica you require and how much rework you’re prepared to endure during installation.

For riders seeking the most precise, performance-oriented option, the weight savings and stiffness afforded by carbon fiber can produce perceptible handling benefits. The reduction in mass at the front of the motorcycle can translate into quicker steering response, enhanced turn-in, and improved overall balance, especially when the bike is loaded with rider gear and track-day wheels. On the other hand, the actual gains in cornering dynamics depend on the entire system: the frame, the suspension, the wheels, and the rider’s technique. A set of carbon fiber fairings is a component in a broader performance equation. It is not a magic wand that replaces mechanical refinement elsewhere; it complements the tire choice, suspension setup, and aerodynamics package to yield the most meaningful enhancements.

Cost considerations, then, become a conversation about value rather than a single price tag. If you are evaluating carbon fiber options for a high-performance model, a practical approach is to map out the total ownership cost over the expected lifespan of your bike. Include installation time, the potential need for custom brackets, the maintenance plan for the finish, and the likelihood of repair or replacement after a crash. Then compare that total to the perceived benefit: the weight reduction, the potentially improved thermal management through more optimized shaping, and the aesthetic impact that often translates into higher resale appeal. This is not simply a matter of chasing the lightest possible kit, but of aligning the performance envelope with your riding goals, whether those goals involve track days, spirited back-road sessions, or show-stopping street presence.

In the end, the price you pay for carbon fiber fairings is a narrative about precision engineering meeting personal preference. The cost range can be broad, but the core justification rests on three pillars: performance, durability, and aesthetics. If the bike you ride demands the kind of weight reduction and stiffness carbon fiber uniquely offers, then the higher price point becomes a rational, measurable investment in how the machine behaves and how it looks when you push it. For readers who want to explore the possibilities, the Yamaha fairings category presents a well-documented starting point for model-specific choices and fitment expectations. You can browse the Yamaha fairings catalog to get a sense of how these options are organized and how they map to your bike’s year and generation. Yamaha fairings.

As a closing note, the broad takeaway is that carbon fiber fairings command a premium because they bundle together advanced materials, specialized manufacturing, precise fitment, and premium finishes. Those elements cohere into a product that can subtly but meaningfully influence speed, handling, heat management, and the visual impact of a bike. If you are weighing carbon fiber against other materials, balance the upfront cost against the long-term benefits and your intended use. For some riders, the investment will be recouped in performance margins and pride of ownership; for others, a high-quality fiberglass or plastic kit may deliver a similar aesthetic at a fraction of the price with less ongoing maintenance overhead. Either path is a statement about how a rider values weight, rigidity, heat management, and the bike’s street or track persona. The right choice comes down to your intent, your budget, and how you want the machine to perform when the throttle is wide open.

External reference: https://www.motorcycleperformance.com/yamaha-r1-carbon-fiber-fairings/ and additional industry insights can be found through trusted performance resources that discuss carbon fiber fairings in depth, including how weight reduction and finish quality interact with real-world riding scenarios. For broader context on carbon fiber performance and how it relates to price, see the external resource linked here: Yamaha R1 Carbon Fiber Fairings: Types, Key Features, and How It Supports Industrial Performance.

Final thoughts

Understanding the costs associated with motorcycle fairings is pivotal for business owners in the motorcycle industry. By recognizing the distinctions between aftermarket, OEM, and high-end carbon fiber fairings, business owners can strategically determine which products to offer to meet their customers’ needs and budget constraints. This knowledge not only enhances customer satisfaction but also helps in forging stronger business relationships. Ultimately, a well-informed approach to selecting motorcycle fairings can significantly impact overall profitability and operational success.