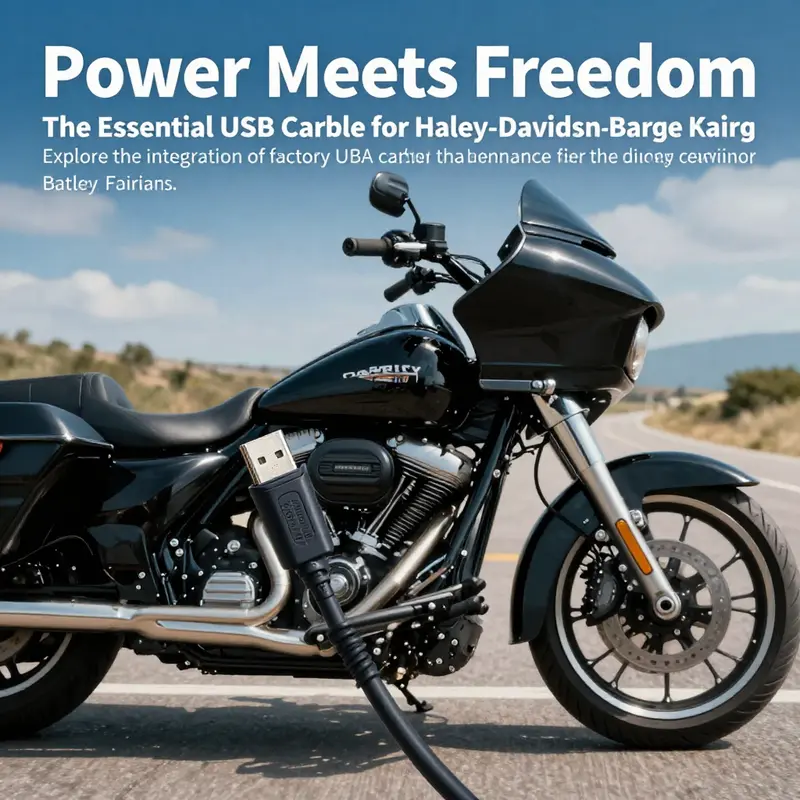

In an age where connectivity is crucial, motorcycle riders, especially those with Harley-Davidson models featuring Batwing fairings, can greatly benefit from factory USB cables. These specialized cables, designed specifically for Harley’s electrical systems, play a pivotal role in ensuring that devices like smartphones and GPS units remain charged and ready for the road. This article delves into the importance of factory USB cables, their compatibility and specifications, and provides a comprehensive guide to installation and maintenance, empowering business owners to enhance customer satisfaction and riding adventures.

Power on the Move: The Integral Role of Factory USB Interfaces in Batwing Fairings

The Batwing fairing is more than a protective shell; it is a cockpit extension that houses navigation, communication, and charging capabilities. Within this enclosure, a factory USB interface cable plays a quiet but decisive role. It threads through the fairing with an eye toward durability and safety, aligning with the motorcycle’s power system to deliver clean power and reliable data paths. When riders depend on a phone for navigation or weather updates, having a dedicated charging outlet inside the fairing keeps devices ready without clutter or risk. The design philosophy goes beyond making a port accessible; it preserves the bike’s aesthetics while ensuring the system remains robust in vibration, moisture, and temperature swings.

The routing of the cable is careful: tucked along internal frames or routed behind the windscreen, through preformed channels. This yields a clean look, reduces snag hazards, and minimizes wear. The USB interface supports the riding experience by providing a power source that is regulated and protected from surges, while the data path remains available for firmware updates or communication with the Skyline OS display and the audio system. The cable and connectors are sealed against spray and moisture, and shielding helps mitigate EMI from the bike’s electrical system and other devices. Connectors resist corrosion and wear, designed for repeated assembly and disassembly.

Usability: The USB system is integrated with the bike’s power management, supporting common charging protocols and protecting sensitive devices. Having this inside the fairing reduces risk of device failure mid journey and preserves the cockpit’s clean lines. The factory approach offers predictable behavior, better diagnostics, and a cohesive aesthetic. Aftermarket cables may offer more ports or features but can introduce compatibility concerns.

The broader context: The Batwing USB interface embodies a design discipline: route behind protective surfaces, shield power and data lines, secure against vibration, and connect through a user friendly interface that remains unobtrusive. It bridges modern connectivity with traditional riding experience, enabling real-time navigation, hands free communication, and a calm cockpit.

For those exploring options, resources on electrical integration emphasize that a well integrated USB interface is a cornerstone of a rider’s digital toolkit, a compact power path that respects the bike’s geometry.

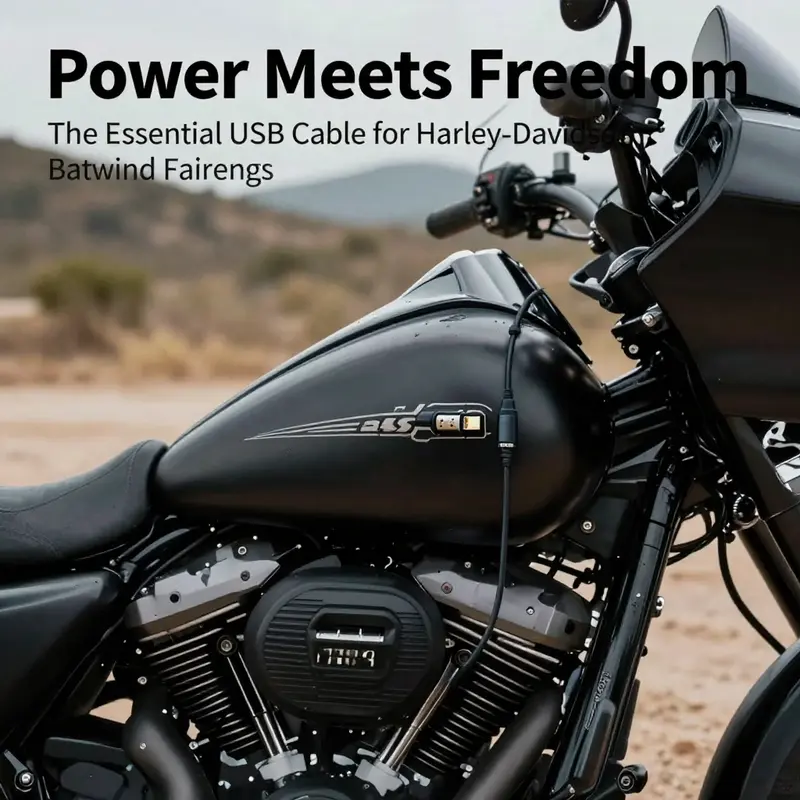

Plugging In: The Quiet Architecture of Factory USB Cables for Batwing Fairings on Modern Touring Motorcycles

In the world of touring motorcycles, the Batwing fairing is more than a stylistic feature; it is a compact, purpose-built ecosystem that brings information, connectivity, and charging capability to the rider in a place where navigation, media, and communications become practical on-the-go tools. The factory USB cable that travels through this architecture may seem like a small component, yet it stands at the core of how a modern bike sustains power, maintains data flow, and preserves the integrity of the rider’s digital life while carving long miles into the saddle. The cable is not just a wire; it is a carefully engineered conduit that balances electrical performance, environmental resilience, and mechanical durability with the demands of wind, vibration, and weather. Its role emerges most clearly on days when the road unfolds with sun, rain, and temperature extremes, and the rider depends on a smartphone for navigation, a GPS unit for offline maps, or a music source that keeps cadence and concentration aligned with the road beneath the wheel. In such moments, the USB cable becomes a quiet partner, delivering steady energy and reliable data channels that keep devices responsive without intruding on the ride’s rhythm. The essence of this design philosophy is straightforward: connectivity must be accessible yet unobtrusive, power must be steady yet safe, and the entire system must operate harmoniously with the fairing’s geometry, the control clusters, and the rider’s intent.

To understand why the factory USB cable deserves closer attention, it helps to consider the Batwing fairing’s physical footprint. The fairing shelters a complex web of electrical routes, mounting structures, and instrument clusters, all of which must accommodate a modern suite of electronics. The USB-C port, embedded within the Batwing, sits at a deliberate intersection of accessibility and protection. It is placed where the rider can reach it without leaning forward or contorting posture, yet it is shielded from the most aggressive elements and from unintended contact during tight maneuvers. The port’s location is not arbitrary; it reflects a design that anticipates both daily use and long-haul endurance. The factory cable designed for this port complements that intent by offering a geometry that fits the available space with minimal clearance issues, a sheath that resists chafing against fairing contours, and connectors that align snugly with the port during engagement and disengagement. In this sense, the cable becomes part of a holistic system rather than a standalone accessory, contributing to the overall reliability and user experience that riders expect from a machine built for expansive travel.

The electrical side of the equation is equally deliberate. The cable must deliver sufficient current not only to charge devices rapidly but also to minimize voltage drop across the length of the run. In a bike that can travel hundreds of miles between service stops, even small inefficiencies translate into noticeable performance losses, slower charging, or erratic device behavior. The factory cable is engineered with a gauge that matches the bike’s power distribution philosophy, ensuring that a phone, a navigation tablet, or a compact GPS unit receives a stable heartbeat in the form of clean, continuous power. It is also designed to minimize electrical noise that could otherwise interfere with sensors, radio receivers, or the audio system—an important consideration in a bike where the rider depends on clear audio cues for navigation prompts or alerts. Where the cable routes through the fairing, its shielding is dense enough to protect against EMI/RFI, yet flexible enough to bend with the fairing’s contours as the rider moves through different riding positions or leans into curves. The connectors themselves are designed to resist corrosion, a simple but persistent threat in environments that range from coastal humidity to sudden downpours and the spray that sometimes follows misty or muddy roads. The synergy of these choices—proper gauge, robust shielding, moisture resistance, and secure connectors—transforms a simple charging lead into a dependable link that supports a rider’s evolving digital needs.

Beyond the raw electrical characteristics, the cable’s physical durability is a product of deliberate mechanical engineering. The Batwing fairing is not a static structure; it experiences constant vibration and occasional shocks from rough pavement, speed bumps, and freight-train crossings that punctuate long trips. The factory cable is designed with strain-relief features at both ends, reducing the risk that repeated flexing at the point of entry into the port will lead to eventual fatigue or intermittent connections. The outer jacket is chosen for resistance to abrasion and UV exposure, and its ribbing and texture assist in guiding the cable along the fairing’s internal channels without binding. Inside, the conductor insulation and conductor layout are arranged to tolerate a certain degree of bending without compromising signal integrity or electrical performance. This isn’t about a single moment of plug-in reliability; it is about a lifetime of compatibility across a spectrum of temperatures, moisture levels, and riding disciplines—from quick country-road commutes to weeks-long, cross-country treks.

From a rider’s perspective, the practical benefits are most evident in how the cable enables a broad digital experience while keeping the cockpit tidy. The USB-C port is part of a connected display ecosystem on the bike, an arrangement that integrates with the on-board interface to provide consistent access to navigation apps, real-time ride data, and media playback through a fused user experience. The cable’s data path supports not only charging but also data transfer, which means that when a rider connects a device, it can exchange information with the bike’s display system. This makes it possible for a route plan or preferred points of interest to sync with the display, for calls or messages to route through the interface selectively, and for music streaming to be controlled from the handlebar cluster or the rider’s device. The practical impact is that the rider can remain focused on the road while the device remains in the flow of the ride, not in a pocket or backpack, with battery life sustained by the cable that did not require frequent manual intervention.

Of course, any integrated system must acknowledge compatibility realities. The factory USB-C cable is specifically paired with bikes that feature the Batwing fairing and the corresponding onboard platform. On bikes that lack this exact pairing, the cable may not perform as intended, either because the port geometry differs, the power and data requirements diverge, or the protective features that shield the connection from the elements do not match the hardware’s layout. In practice, that means riders working with older configurations or with non-OEM fairings should seek adapters or certified alternatives that align with the port’s specifications and environmental protections. The goal is to preserve a seamless interface across the pairing of fairing, display, and power delivery system, so that every component contributes to a predictable and safe user experience rather than forcing compromises that could degrade performance or reliability. This compatibility logic, in turn, underlines the importance of sourcing cables that are designed and tested for the precise combination of fairing geometry, port placement, and climate exposure that comes with touring in diverse geographies.

The broader ecosystem around the cable includes optional accessories that enhance connectivity and comfort. Dealers and riders alike may explore additional interfaces that expand the capabilities of the Batwing’s USB-C port, such as cables or housings designed for better audio integration or for additional device charging options. When considering these accessories, the recurring theme is safety and warranty. Factory-approved or certified aftermarket cables are recommended because they are tested to meet the same standards of compatibility and reliability as the original hardware. Using products without the appropriate testing can introduce risks—loose connections, unexpected shutdowns, or degraded performance that could affect navigation or communications in the middle of a ride. In the end, the choice is not simply about having more ports; it is about preserving the harmony between power, data, and the rider’s intent so that the system remains a trustworthy partner over thousands of miles.

In practical terms, the rider who understands this design ethic approaches installation and daily use with a measured, almost ritual mindset. The fairing’s internal routing must be managed so that the cable does not rub against sharp edges or through tight gaps that could abrade the jacket. The port itself benefits from a clean engagement—firm, not forced—and from a gentle disconnect that preserves the seal against moisture. When the cable is plugged in, a brief confirmation through the display or the associated indicators ensures that charging and data transfer are both active. The rider’s devices then begin to draw power with a calm, unhurried cadence rather than a heroic surge that risks thermal stress. Such behavior is not born from fanfare but from an understanding that reliability in the saddle is built through consistent, respectful handling of the gear that carries the rider’s most essential tools.

The topic of compatibility leads naturally to a broader discussion about fairing interfaces and the way riders relate to their bikes. A Batwing fairing is more than a housing; it creates a physical and symbolic boundary between the rider and the road. When the USB-C port and its cable are integrated with this boundary, they become part of a routine that keeps the rider’s digital life tethered to the journey rather than dispersed along pockets and bags. The factor that matters most is not the speed of data transfer in isolation but how effectively the connection supports the rider’s goals: finding the next turn, updating a map in real time, streaming a preferred playlist, or receiving weather alerts that influence a planned route. In this sense, the factory cable is a quiet enabler of intention. It is a small but significant piece of a larger system built to sustain the rider’s focus on the road, the motorcycle’s handling, and the dignity of a journey measured in miles rather than moments.

For readers who want to explore broader context on fairings and mounting interfaces beyond Harley’s lineup, a practical reference is to examine the Honda fairings category, which showcases how aftermarket and OEM interfaces are designed to integrate with a bike’s structural and electrical frameworks. This exploration provides a useful contrast that highlights the common engineering challenges across brands: space constraints, weather sealing, route management, and robust but flexible cabling. See: Honda fairings.

In wrapping these ideas together, the essential takeaway is that a factory USB cable for the Batwing fairing is not a mere conduit but a carefully engineered linkage. It represents the convergence of electrical discipline, mechanical resilience, and thoughtful rider-centric design. It embodies a philosophy that every component in the cockpit—no matter how small—contributes to a safer, more enjoyable ride. When the cable is chosen and installed with attention to the bike’s exact configuration, when it is routed with care, and when it is treated as part of the bike’s living system, it helps deliver a seamless digital experience that respects the rider’s focus and preserves the integrity of the journey. The result is a ride where technology serves as a support rather than a distraction, where charging and connectivity feel effortless, and where the Batwing fairing remains a stage for sight, sound, and signaling rather than a tangle of cables and complications.

External resource for official specifications and further details can be found here: https://www.harley-davidson.com/en_us/motorcycles/standard/street-glide/2026.html

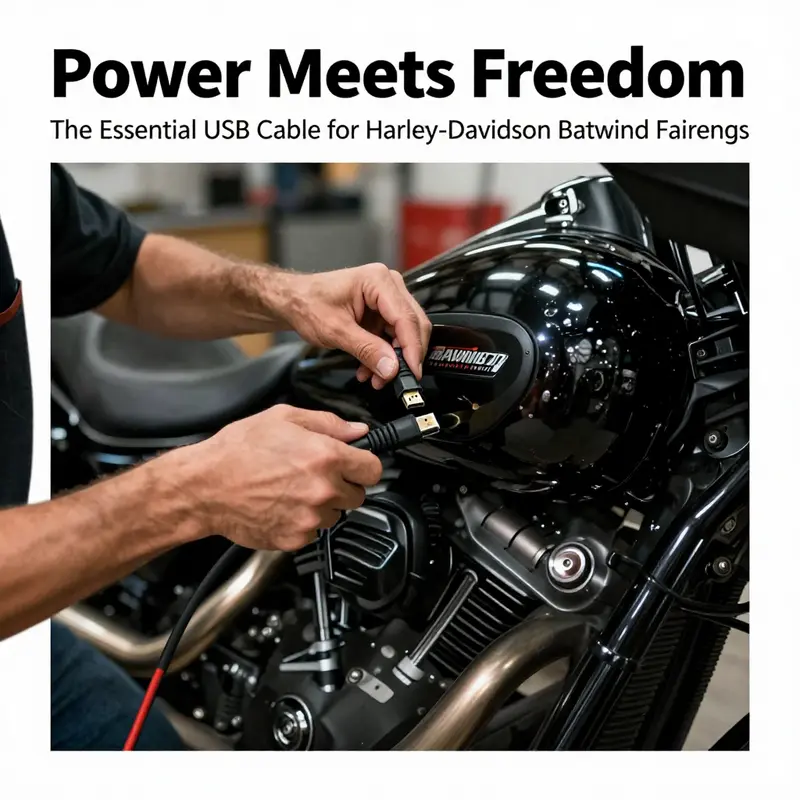

Power, Protection, and Seamless Integration: Installing and Maintaining Factory USB Cables in Harley-Davidson Batwing Fairings

The modern ride demands more than raw torque and wind at speed; it requires a quiet, dependable source of charge that travels with you from dawn to dusk. On Harley-Davidson motorcycles that wear Batwing fairings, the inclusion of a factory USB interface is not merely a convenience but a carefully integrated feature. It is designed to supply power to a phone, GPS, or other devices while preserving the cockpit’s clean lines and protecting the bike’s electrical system from vibration, moisture, and harness wear. The logic behind this integration is practical: a dedicated, purpose-built path for power helps prevent improvised solutions that can lead to shorts, blown fuses, or degraded performance in the middle of a long ride. The Batwing fairing, with its sculpted channels and protective shielding, creates a specific environment for a charging cable, and understanding that environment is the first step toward a connection that lasts as long as the bike itself.

A factory USB cable is more than a set of wires. It is an engineered interface that considers the bike’s electrical load, the rider’s accessibility, and the rigors of riding on varying terrain. The design anticipates the kind of mounting troughs, grommets, and routing pathways that OEM engineering tends to emphasize: protected passages where cables can flex without chafing, grommets that seal against moisture, and attachments that prevent the cable from shifting under the constant vibrations generated by a touring bike. When you set out to install or inspect this kind of system, you are participating in a broader tradition of OEM integration—one that values clean physics, long-term durability, and rider safety as much as aesthetics. This approach is especially important when the cable must weave through a dash compartment, pass through a grommet, and emerge into a cockpit area where control buttons and display legibility must remain uncompromised.

The installation starts with a mindset focused on reliability. The routing path and the mounting points must respect the bike’s frame geometry, the fairing’s contours, and the rider’s line of sight. Route planning is not a mere afterthought; it is the backbone of a system that can survive tens of thousands of miles of exposure to heat, rain, road salt, and occasional mud. If you imagine the cable as part of the motorcycle’s living electrical system, you begin to see why the details matter. The dash compartment is a common home for an access point. A 27-millimeter hole is often specified as the entry point for the USB cable; this dimension matches the diameter of the connector harness and provides a margin that prevents pinching. The path from the dash into the fairing’s back area must be deliberate, guided by the existing cable bundles and designed to minimize abrasion. Passing the cable through the rear grommet is a crucial step. The grommet’s job is to seal and cushion, so any modification to accommodate a twin USB cord setup must be conservative and precise. A careful trim, a minor reshaping, or a small widening of the grommet’s opening can be enough to maintain a weather-tight barrier without compromising the grommet’s tenure against vibration, water intrusion, or dirt ingress. The goal is a seamless, professional finish that also respects the bike’s serviceability. When the cable exits the grommet, it should align with other harnesses, not cross over vital control pathways, and never exaggerate the cable’s bend radius. A clean, well-planned routing reduces the risk of snagging, pinching, or exposing conductors to movement that could degrade insulation or alter electrical performance.

In the cockpit, where the USB interface meets the rider, the relationship between accessibility and protection becomes most evident. The dash area often houses the USB port, a location chosen to balance convenience with shielding. The cable must reach this point without pulling on the port or creating a tug during vibrations. A robust strain relief at the port is instrumental in extending the life of the connection. Strain reliefs absorb the micro-movements that travel through the bike’s structure when riding over uneven pavement, a common scenario for long-distance riders who demand reliability in all conditions. Once installed, the routing should be checked against the fairing’s interior geometry. The cable should sit away from any edge of the dash, the throttle assembly, or switchgear. It should not interfere with the operation of this equipment or obscure any indicators. The installation is not finished with a simple shove of the cable into a hole; it is a careful choreography that arranges the internal harness in a way that minimizes friction and heat exposure while allowing for easy service if the port or cable ever needs attention.

Maintenance is the invisible partner to good installation. It begins with regular inspection, a practice that should become part of routine bike maintenance because the electrical system, like any mechanical system, rewards forethought. The grommets—those resilient rings that cushion the path where the cable travels from cockpit to fairing—should be examined for cracks, stiffness, or moisture intrusion. Grommets degrade with age and exposure, and their condition governs how well the routing remains sealed against water and grit. A worn or loose grommet can allow vibrations to transfer into the cable, accelerating wear at the bend points where the wire heads into and out of the dash compartment. The cable connections themselves deserve periodic scrutiny. Look for signs of corrosion on terminals, discoloration at solder joints, or any looseness that could indicate a failing connector. Even in a system designed for rugged use, connectors are likely to loosen over time if the bike is ridden aggressively, parked outdoors, or subjected to frequent rapid temperature shifts. A simple, routine touch-up—tightening a clamp, reseating a connection, or cleaning a contact with an appropriate electronic contact cleaner—can forestall more serious issues. For many riders, the habit of performing these checks after a long ride or a trip through heavy rain becomes as ingrained as checking tire pressure.

The practice of maintenance also extends to the cable sheath and its surface. Cable insulation should show no nicks, cracks, or flattening. Any abrasion that exposes copper can lead to short circuits or water tracking along the conductor under damp conditions. If the sheath shows wear, it is wise to replace the affected segment rather than risk a failure at an inconvenient moment. Weather sealing remains a non-negotiable element of longevity. The dash compartment and the fairing interior should maintain their protective barriers, so periodic re-sealing around the grommet and along the edge of the dash opening becomes part of the preventive rhythm. In time, you may discover that the factory approach to cable routing anticipates such maintenance rituals. The design invites riders to engage with the system rather than bypass it, reinforcing a culture of care that keeps the electrical backbone strong through miles and seasons.

In discussing installation and maintenance, it is useful to place the USB cable within the broader ecosystem of fairing hardware and OEM engineering. The Batwing fairing, with its quiet, wind-influencing silhouette, has long been a focal point for riders who value both style and function. The way an OEM cable is integrated into this space informs how riders think about other fairing-mounted access points, including those for communication devices. The principle remains consistent: routing should respect the fairing’s geometry, protect against the environment, and allow quick access for service. In the wider universe of fairings, the approach to routing and weather sealing can be seen in other brands and models as well. For readers who want a broader perspective on how fairings accommodate electrical access points, consider exploring the general idea of fairing hardware in related categories such as Yamaha fairings. This broader context helps illuminate why a neat, durable USB path matters and how it mirrors the care given to other OEM systems. Fairings for Yamaha bikes keeps in mind how similar structures—grommets, routing channels, and protective gaskets—are deployed across different brands, reminding us that good engineering travels beyond a single model or badge.

A critical thread running through installation and maintenance is alignment with official procedures. The best outcomes come when riders reference the factory manuals that accompany the motorcycle. Those manuals describe the precise hole diameters, grommet dimensions, and torque figures that ensure the system remains within spec through years of use. The emphasis is not decorative; it is functional. The integrity of the electrical path depends on following the manufacturer’s guidance so the USB interface continues to deliver clean power without compromising the bike’s electrical architecture. This approach also supports warranty considerations, should they ever apply, by demonstrating that the installation adheres to the prescribed methods rather than relying on ad hoc improvisations.

For riders who want to verify the practical, hands-on aspects of this setup, the official service manual is the primary resource. It provides the exact steps, diagrams, and cautions that accompany the installation and ongoing maintenance. While the specifics may vary by model year and fairing configuration, the underlying logic remains the same: a protected route, a secure port, and an inspectable path that can be serviced without requiring dismantling the entire fairing. This is the essence of an OEM-integrated USB solution—quiet, reliable power that does not distract from the road or the rider’s concentration.

In sum, the chapter on installing and maintaining factory USB cables in Harley-Davidson motorcycles with Batwing fairings is really about preserving the harmony between form and function. The Batwing’s beauty is complemented by a robust electrical extension that respects the bike’s design. Proper routing through a dash opening, thoughtful grommet modification, vigilant maintenance of connections and insulation, and adherence to official maintenance procedures all work together to deliver a charging solution that endures. The rider benefits from uninterrupted power for devices, the dashboard remains uncluttered, and the motorcycle preserves its weatherproofed integrity. It is a small but meaningful example of how modern motorcycles blend electrical sophistication with enduring mechanical resilience.

External resource: For official procedures and detailed maintenance guidance, consult the Harley-Davidson service manual at https://www.harley-davidson.com/content/dam/harley-davidson/owners/manuals/2026/breakout/2026-breakout-owner-manual.pdf

Final thoughts

The integration of factory USB cables in Harley-Davidson motorcycles with Batwing fairings represents a significant advancement in rider convenience. By ensuring seamless connectivity for devices and optimizing power delivery, these cables not only enhance the riding experience but also meet the demands of modern technology. For business owners and motorcycle enthusiasts alike, understanding the specifications, installation, and maintenance of these cables is essential for providing exceptional service and ensuring customer satisfaction in the ever-evolving landscape of motorcycle accessories.