DZUS fasteners play a crucial role in motorcycle fairings, offering a blend of functionality and aesthetic appeal that is essential for both performance and custom builds. As business owners in the motorcycle industry, understanding these fasteners’ attributes can significantly enhance your product offerings and customer satisfaction. This article delves into the comprehensive overview of DZUS fasteners, discusses material and design considerations, guides installation and maintenance, and examines market sources for these components, empowering you with informed decisions for your motorcycle fairing projects.

The Quiet Lock: Quick-Release Fasteners and the Aerodynamics of Motorcycle Fairings

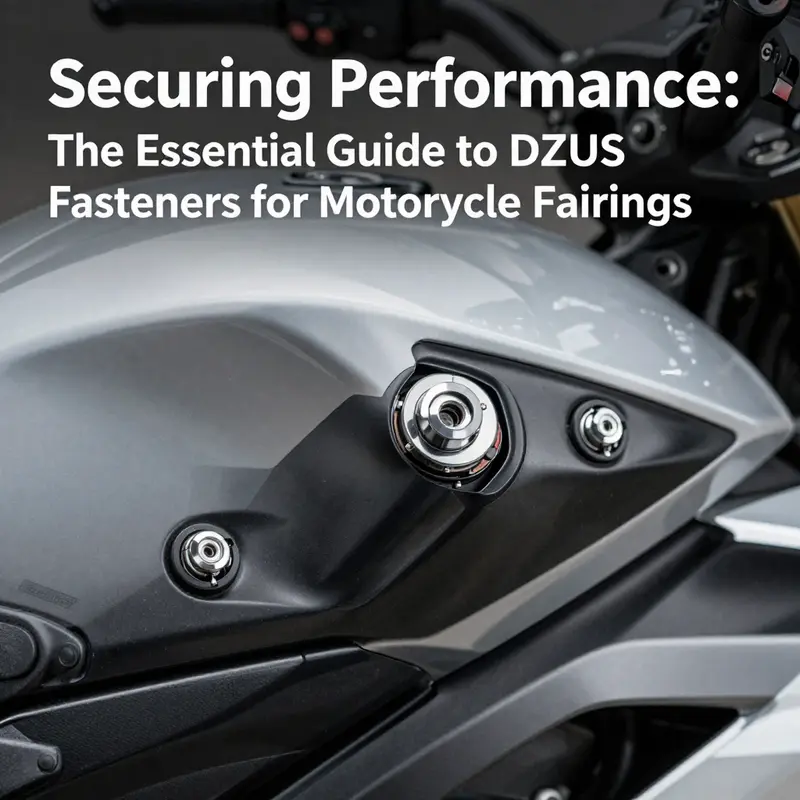

The fairing is often spoken of in terms of air flow, cooling, and the silhouette it gives a machine as it slices through wind. Yet the fastening system at the heart of that sculpted shell works just as hard, even if its work remains largely invisible to the casual observer. A well-chosen quick-release fastener—one that uses a stud and rivet clip pairing—does more than hold panels together. It preserves the smooth lines that keep drag low, it supports reliable access during maintenance, and it guards against the kinds of fatigue that can arise from the constant vibration of high-speed riding. In practice, these fasteners perform at the intersection where engineering meets practicality: they must resist heat, moisture, and grit, while allowing a rider or mechanic to remove and reattach a fairing with a minimum of fuss. The result is a system that quietly rewards careful sourcing and precise fit with a level of reliability that riders come to rely on on race tracks, in cold garages, and along sunlit highway climbs alike.\n\nAt the core of this fastening system is a straightforward idea made durable through thoughtful design. The mechanism combines a small shaft, typically around 5 millimeters in diameter, with a locking end that measures about 6 millimeters across. This compact geometry is chosen to minimize intrusion into the panel joints while delivering a secure engagement that can withstand significant vibration and wind pressure. To the eye, the joints appear flush and almost self-evident; to the installer, they are the point where design intent becomes a practical reality. The fairing panels themselves can be constructed with flush-mount heads that lie almost level with the surface, or with raised-head options that afford finger access when it’s time to release or reseat a panel. In either case, the aesthetic objective remains the same: clean lines, consistent gaps, and panels that look as if they were formed as a single shell rather than assembled from discrete parts.\n\nThe choice of materials further reinforces this blend of form and function. Stainless steel and aluminum are the steel bones of most high-performance applications. Stainless steel brings robustness, corrosion resistance, and longevity in grit-filled, wet environments. Aluminum, with its lighter weight and respectable strength-to-weight ratio, helps keep unsprung mass in check—an advantage on performance bikes where every gram matters for handling and acceleration. The combination of material properties matters not only for longevity but for the way the fasteners behave under load. A fairing that must sustain at-track temperatures while enduring rapid, repeated insertions and removals needs hardware that won’t corrode, gall, or seize. The result is a system that stays true to its geometry even after hundreds of heat cycles and the occasional rough surface strike when riding in less-than-perfect conditions.\n\nA key advantage of a true quick-release system is the balance it strikes between secure fitment and easy access. In the sprint toward the track day threshold or the meticulous routine of a weekend rider, the ability to remove a fairing without tools in many situations translates into tangible time savings. This does not imply a blanket removal of procedure or safety; rather, it reflects an approach that respects both the aerodynamics of a tight, laminar fairing and the practical reality that maintenance and inspection are regular necessities. Panels must be hinged, clipped, or snapped into place with consistent precision, and the fasteners must hold without allowing micro-movements that can introduce flutter noise or a degraded seal around the edge of a panel. The vibration environment at speed is not a polite one; the fastening system must resist loosening, while still permitting straightforward reassembly when inspection or upgrades are due.\n\nWhen a rider considers these components, compatibility becomes more than a matter of style. It is about ensuring the thread size, head type, and installation method align with the bike’s chassis geometry and the fairing design. The standard kit for a typical circuit-ready setup often includes eight studs paired with matching rivet clips. This configuration provides a robust Backbone for securing large sections of fairings that bear the brunt of wind load and air pressure at elevated speeds. It also offers a practical distribution of clamping force, minimizing panel flex and the associated risk of fastener loosening. The distribution pattern matters because a single loose fastener can alter the aerodynamic surface enough to create a small but noticeable drag penalty or a tiny buzz at certain RPMs. For riders who pursue precision, these details translate into real-world performance gains—better airflow, steadier cockpit temperatures, and more predictable handling characteristics through corners and down straights.\n\nAesthetics and aerodynamics sit side by side in this narrative. Where a raised-head design may allow easy access for maintenance without disengaging the panel, a flush-mount arrangement helps preserve the smooth external profile that engineers strive for when shaping the airfoil-like surfaces of a modern fairing. In either case, the head design is chosen with care to maintain a seamless surface that minimizes any protrusion that could trap boundary layer eddies or create noise under high-speed air. The choice is rarely about flash alone; it is about ensuring that the fastener’s silhouette disappears into the overall contour, so the rider experiences nothing but the intended line and the expected performance.\n\nFrom a practical standpoint, sourcing and selecting components becomes a matter of model compatibility and intended use. It is important to confirm the correct thread engagement for the stud and the clip, particularly given the potential for different fairing designs across brands and generations. In some cases, a manufacturer will offer a dedicated kit that aligns with popular fairing layouts, while in others the rider may need to piece together a set that matches the exact panel geometry. Beyond the sheer fit, the quality of the rivet clips matters. They must clasp firmly without deforming under repeated contact with the stud head, and they should resist creeping at elevated temperatures so that a panel remains aligned over many miles and many heat cycles. The reliability of the system, in other words, rests on the harmony between the stud and the rivet clip—the two halves of a single, well-made mechanism.\n\nAs riders explore their options, the availability of products through specialized suppliers, online marketplaces, and direct manufacturer channels becomes a practical consideration. The documentation behind these fasteners emphasizes a straightforward criterion: compatibility with the bike model and fairing design, followed by attention to how the parts will be installed and serviced over time. For riders who are assembling or refurbishing a set of fairings, it is prudent to verify the specific head type, the method of engagement, and the per-panel distribution of fasteners, especially when large sections of fairing are involved. A well-planned layout helps to ensure that the panels can be removed quickly for routine maintenance or track-day preparation without compromising fit and aerodynamics on reassembly. In addition, a careful mind-set toward corrosion resistance—choosing stainless steel or aluminum where appropriate—helps preserve both the function and the appearance of the panels decades into the life of the bike.\n\nFor those who are curating a body of parts tailored to a particular brand or model line, a practical touchstone is to review how the fairing ecosystem has evolved in catalogs dedicated to that platform. The catalog expands beyond the fasteners themselves and into how the entire panel system is designed to work with the bike’s frame, mounting points, and airflow considerations. A rider who is shopping with a specific brand in mind may find it helpful to explore a curated collection of fairings and components in a single place. In such cases, the combination of a well-matched fairing set and a compatible quick-release fastening system can yield a coherent, performance-oriented presentation that keeps blemish-free panels in place while maintaining effortless serviceability at the track or on the road. For riders looking to align with a particular model family, a dedicated category such as Honda fairings can serve as a useful touchpoint; see the catalog of Honda fairings for a sense of how panels are designed to integrate with a complete bike platform. Honda fairings.\n\nThe story of these fasteners is, therefore, one of careful balance. They must be strong enough to secure panels under the stresses of wind and vibration, yet adaptable enough to allow rapid removal for maintenance or quick changes during track-day preparation. They must resist corrosion and galling, maintaining their clamping force over time, even as the temperature swings and the road textures become rough. They must be compatible with a range of fairing geometries—from tightly locked, low-drag configurations to more open, rider-accessible designs. And they must do all of this while preserving the smooth, uninterrupted lines that define the motorcycle’s silhouette. In this way, the fastener system becomes a silent partner in performance, one that complements the engineering of the fairing itself rather than competing with it for attention.\n\nUltimately, the choice of a quick-release fastening solution for motorcycle fairings is about ensuring reliability without sacrificing accessibility or aesthetics. The right system amplifies the benefits of a well-designed fairing by ensuring that every edge, every joint, and every seam remains secure through a rider’s daily commutes and through the demanding cycles of track days and endurance events. It also makes routine maintenance less of a chore and more of a seamless, repeatable process—one that respects the rider’s time and the machine’s need to stay aerodynamically consistent, even after months of wear. This is the essence of a well-executed fastening strategy: a quiet lock that keeps pace with the loud, high-performance world it serves, a system that disappears into the fabric of the bike while doing the heavy lifting that enables speed, reliability, and resilience on every mile.\n\nExternal reference: For a more detailed overview of genuine quick-release fasteners for motorcycle fairings, see this external resource: https://www.motorcyclefairingparts.com/dzus-fasteners-kit

Solid, Seamless, and Serviceable: Material and Design Considerations for Quick-Release Fasteners in Motorcycle Fairings

Every fairing on a modern motorcycle is a carefully engineered skin that balances aerodynamics, aesthetics, and access. The way it is fastened to the chassis matters just as much as the shape of the panels themselves. When riders talk about performance, they often focus on engines, suspensions, and exhausts, but the hardware that keeps the fairing secure under all weather and road conditions plays a quieter yet essential role. In this chapter, we explore how material choice and design philosophy for quick-release fasteners influence durability, maintenance, and the overall look of the bike. The aim is not to prescribe a single solution, but to offer a cohesive framework that helps builders and riders select fasteners that harmonize with the panel materials, the vibration profile of the motorcycle, and the intended service life of the project. The result is a fairing system that remains robust through countless removals and reattachments while preserving a clean, integrated appearance that honors the bike’s original lines and the rider’s performance goals.

Material choice is the first hinge of this framework. Motorcycle fairings are often crafted from fiberglass, ABS plastics, or increasingly from lightweight composites such as carbon fiber-reinforced polymers. Each material presents its own challenges for fastening. Fiberglass and ABS, for example, possess different hardness and compressibility characteristics. The fastener material must not induce undue stress on the panel during installation or under the cyclic loads of riding vibrations. If the panel is too hard for the fastener’s grip mechanism, the thread engagement can suffer, leading to stripped threads or a creeping misalignment that worsens as vibrations continue. Conversely, a panel that is too soft for a given fastener can smear or deform around the grip, creating play that undermines rigidity and seal performance. A careful designer thus references a practical guideline: verify that the panel’s hardness and thickness sit within the fastener manufacturer’s recommended range for proper engagement. Even without naming a particular guideline by brand, the principle remains the same—compatibility between panel substrate and fastener geometry is nonnegotiable for long-term reliability.

The material pairing also drives the choice between flush-mount and raised-head configurations. For a sport-focused aesthetic and for optimizing aerodynamics, flush-mount fasteners are appealing because they minimize drag and create a seamless surface line. Yet, a flush system increases the precision required during assembly and service. The mating holes must be drilled with exact tolerances, and the panels must be aligned with care to avoid misalignment that could stress the fastener or the panel, especially under heavy vibration. Raised-head alternatives, by contrast, offer obvious benefits for accessibility and tolerance to minor misalignment. They provide a tactile cue for engineers and riders alike that a panel has been fully engaged, and they can simplify installation in constrained spaces where access to both sides of the panel is limited. For a fairing of mixed materials, designers often adopt a mixed strategy: critical sections use a raised head or a dedicated alignment feature, while standard panels use flush mounts to preserve the visual flow. In both cases, the ability to remove and reattach the panels quickly without tools is a practical advantage, particularly for maintenance, repairs, or cosmetic modifications.

The lock mechanism itself deserves close attention. Quarter-turn couplers are widely favored in these applications for their balance of security and speed. The mechanism locks with a decisive rotation, requiring only a small amount of angular motion to engage or release. This is especially valuable in environments where maintenance intervals are short or where quick access to the engine or routing behind the fairings is desirable. However, the installation process for quarter-turn systems can demand access from both sides of the panel. That means the fairing’s structural design should anticipate where fasteners will pass through, and it may require fixtures or jigs during initial assembly to prevent misalignment that would place stress on the fastener or deform the panel under load. In cases where access to the back side is impractical, designers might opt for slotted fasteners or alternative engagement schemes that preserve the quick-release character while accommodating the real-world constraints of a factory or workshop setting. Slotted variants, installed with a simple screwdriver, can still deliver rapid removal, though they may not match the ease and speed of a true quarter-turn system. The choice, then, hinges on the intended service profile of the bike and the technician’s access throughout the fairing’s life cycle.

Beyond the lock itself, the geometry of the fastener and its grip length is a central design lever. Grip length must be matched to the combined thickness of the mated panels. If the grip length is too short, clamping force is insufficient and the panel may loosen over time, especially in the face of road shocks and engine-induced vibrations. If it is too long, the fastener can protrude or create an awkward interface with the panel’s surface, interrupting airflow, or even causing cosmetic damage under load. The best practice is to calculate grip length from the actual panel stack used in the finished assembly, including any spacers, gaskets, or backing plates. This ensures repeatable clamping force across service intervals and seasons. Misalignment of grip length can also precipitate stress concentrations around the threaded stud and the panel’s mounting hole, accelerating wear and potentially initiating hairline cracks in composite skins. Alignment fixtures during setup can prevent these issues by maintaining a consistent plane and registry between the fastener and the hole, which is especially critical when multiple panels join to form a continuous skin.”

In practice, the design philosophy favors modularity and predictability. A modular system allows builders to mix and match panel thicknesses, while still preserving a uniform fastener footprint. This avoids reworking mounting holes across a complete fairing when a single panel is replaced or upgraded. Modularity also makes it feasible to swap from a flush-mount solution on one panel to a raised-head variant on another region of the same fairing, should an upgrade or a shift in aerodynamic goals dictate the change. The upshot is a fairing that can evolve in appearance and performance without cascading changes to the fastener plan. Whatever the exact combination chosen, it should feel cohesive to the eye and to the hand—the fasteners should disappear visually when mounted flush, but still be readily recognizable by touch and feel when service access is required.

Material and finish choices reinforce this coherence. Stainless steel and aluminum are common, valued for their corrosion resistance and strength-to-weight characteristics. Stainless steel offers excellent durability, particularly in humid or salty environments, but it is heavier and can be harder to machine with very fine tolerances. Aluminum reduces weight and often simplifies finishing, yet its softer nature can make threads more prone to galling or deformation if dams or spacers aren’t used properly. In composite fairings, metal fasteners are frequently combined with protective sleeves or bushings to prevent galling and to dampen vibrations that could lead to wear around the mounting holes. Surface finishes, from bright-polished to black oxide or anodized coatings, impact not only aesthetics but also friction behavior and resistance to corrosion. The best practice is to select a finish that harmonizes with the rest of the bike’s hardware and to consider a protective treatment for the mounting holes themselves, especially in areas exposed to water spray and road salt.

Sourcing and compatibility steps complete the design picture. Compatibility begins with model-specific fitment—each bike model has a unique panel geometry, hole pattern, and panel stack height. The safe approach is to confirm the fastener system’s compatibility with the bike’s model and the particular fairing design in use. This involves checking the thread size and pitch, the overall stud length, and the head geometry to ensure the fastener seats correctly without interfering with surrounding components or the panel’s edge. Specialized motorcycle parts suppliers are a reliable route, as are general retailers that stock standardized fastener systems. When sourcing, it is prudent to request a complete specification sheet and, if possible, a sample or test-fit kit to validate fitment on the actual panels. A model-focused fitment check helps avoid surprises during the final assembly or reassembly after a maintenance interval.

The integration with the rest of the bike’s ecosystem also deserves attention. A robust fairing-fastener system is part of a broader maintenance philosophy that emphasizes ease of service and repeatable results. Riders and builders appreciate a setup that allows rapid once-over inspections, quick access to internal routing for wiring and hoses, and reliable retention through a rider’s normal riding life. In practice, this means choosing fasteners that resist loosening under vibration, that do not impart high levels of stress into the panel holes, and that maintain a uniform appearance even after repeated removals. The aesthetic integrity of the fairing should be considered as part of the design brief; the fasteners should contribute to a clean, integrated look rather than look like a later add-on. The visual impact matters because fairings serve as much as a signature design element as a functional shell. When the fasteners sit flush, the eye travels along the smooth surface of the panel, reinforcing the impression of speed and precision. When properly chosen, the hardware becomes almost invisible, a quiet partner to the sculpted forms that define a bike’s character.

As riders and builders think through their options, one practical step stands out: document the chosen combination of fasteners, panel materials, and grip lengths, and create a maintenance plan that details the service intervals, torque considerations (where relevant), and replacement timelines. A clear record helps ensure consistency across track days, weekend rides, or long tours, and it provides a blueprint for future upgrades or restorations. It also supports safer, more predictable service work when multiple people interact with the bike during maintenance. For those who want to explore real-world exemplars of model-specific fairings and the way fasteners are deployed in practice, see the Honda fairings catalog for a sense of the scale and variety of panel arrangements across different models. (Link: Honda fairings)

In sum, material and design considerations for quick-release fasteners in motorcycle fairings hinge on a balanced approach. The panel material compatibility, the chosen engagement mechanism, and the grip length all converge to determine how a fairing behaves under the duress of road and race alike. A flush, integrated appearance benefits from raised or flush configurations thoughtfully applied, while the ease of service hinges on how well the mounting plan accommodates access and alignment. The selection process benefits from a methodical evaluation of panel hardness, thickness, and the interaction with the fastener’s geometry. With these considerations, a fairing system can deliver both the look and the performance its rider expects, remaining dependable through countless removals and reattachments while preserving the clean lines that define the bike’s identity. For those who want to dig deeper into serial considerations and installation techniques, a detailed, standards-based guide is available through industry reference materials. For a thorough specification guide, see a reputable source that outlines fastener installation and material guidelines: https://www.southco.com/products/dzus-fasteners.

Secure Lines, Shaped Skies: Installation and Long-Term Care of DZUS Fasteners in Motorcycle Fairings

A motorcycle’s fairing is a precise blend of form and function. It slices through air, shelters the rider, and houses components that demand ready access for service, upgrades, or inspection. The choice of fasteners is more than a matter of holding pieces together; it shapes the bike’s reliability, maintenance cadence, and even its clean aesthetic. Among the options riders and builders choose, quick-release, high-strength hardware offers a compelling mix of security and accessibility. When the goal is to keep fairings tight during a race or spirited road ride while still allowing rapid access for maintenance, the system commonly favored is a set of DZUS fasteners. This chapter walks through the practical, real-world approach to installing and maintaining these fasteners on motorcycle fairings, weaving together the craft of alignment, the discipline of torque, and the discipline of ongoing care that keeps the panels pristine and predictable ride after ride. The discussion stays anchored in the realities of modern fairing design—materials such as plastics and composites, the need for corrosion resistance, and the sometimes tricky interplay between aesthetics and function—while offering a cohesive, hands-on perspective that can accompany riders through both customization projects and routine service.

Properly installed, a DZUS-style fastener system disappears from view, leaving only the fairing’s smooth silhouette and the rider’s confidence. The mechanism’s value lies not in their flash but in how unobtrusive and dependable they become under stress. The female receptacle, which anchors into the fairing, accepts a male counterpart that cycles with a simple turn or push, depending on the model and style. The result is a clean, fast, and repeatable method to secure panels that are often the first line of defense against wind and debris while also serving as convenient gateways to the bike’s internals when service is needed. The appeal is reinforced by the fact that the components are typically crafted from corrosion-resistant materials like stainless steel or aluminum, chosen for their strength-to-weight ratio and durability in the face of road salt, rain, and humidity. The practical advantage is clear: riders can remove and reattach fairings with a level of ease that minimizes downtime and keeps the bike in competitive shape without sacrificing security.

Installation begins with a quiet, methodical attention to alignment. The male and female components must meet in true alignment to avoid cross-threading or mis-seating that can compromise seal integrity or create unwanted flex under a gust of wind. The female receptacle is usually mounted into the fairing with a method appropriate to the panel’s material and geometry. In some cases, the fairing’s construction calls for small screws or rivets to secure the receptacle, while in others, a high-strength adhesive provides a clean, fastener-less surface until the hardware is installed. Either approach requires a careful balance: adhesion or mechanical fastening must be secure enough to resist vibration and impact yet not so rigid that it becomes a source of micro-movement or stress concentration in a composite. The installer’s toolkit should include a torque wrench, and its use should align with the manufacturer’s instructions for the particular fastener series and the fairing material. Over-tightening is a common, avoidable mistake. It can crack plastic, deform the panel edge, or squeeze the locking mechanism so tightly that normal engagement cannot be accomplished. The governing principle is simple: tighten only to the spec, test fit, then release and re-tighten as needed to achieve a snug, even interface without imposing uneven stress on the panel.

As a practical matter, the installation sequence is more about progressive alignment than brute force. Start by approximating the locations where the fasteners will sit, ensuring that each hole or receptacle aligns with its mate. When the receptacle is mounted, the fairing’s surface should sit flat, without rocking or gap, across the plane of the panel. If the fairing is composite, the selection of adhesive—where used—must accommodate the panel’s thermal expansion and its exposure to flexing loads. The right adhesive should cure without releasing solvents that might interact with the fastener’s lock or the material’s resin matrix. Once the receptacles are in place, a dry run of the entire panel assembly confirms that every fastener line aligns with its counterpart. Then comes the moment of truth: the actual engagement. The act of engaging a DZUS-type fastener is a deliberate, confident motion that translates precision into a secure hold. It is one of those small rituals of motorcycling that quietly asserts reliability: when you need the panel off, it yields with a controlled, predictable motion; when you need it on, it seats with just a brief turn and a satisfying click. This is the texture that makes maintenance or upgrades less of a chore and more of a routine opportunity to check in with the bike.

The question of material compatibility often guides the choice of fastener length, head style, and mounting strategy. In modern fairings, the trend toward lightweight plastics and carbon fiber composites means the fastener set must accommodate softer backing materials and edge geometries that are less forgiving than metal panels. Flush-mount options yield the sleekest lines, minimizing the chance of snagging while riding at speed. Raised-head variants, in turn, can provide more grip in cold or wet conditions, aiding the user who wears gloves and relies on tactile feedback when engaging or disengaging the fasteners. The head’s geometry also influences air flow in the near-field of the fairing, albeit in a subtle way. The key takeaway is that the fastener kit should be selected in concert with the fairing’s design language and the rider’s maintenance habits. For those who frequently open the panels for maintenance, lighter, quick-release designs that require minimal tools can shorten service intervals significantly. For those who value a near-seamless exterior, flush-mount variants integrated into the panel edge can deliver a cleaner aesthetic, even if the initial alignment phase is a touch more meticulous.

Once installed, the fairing system must endure the ride’s realities: vibration, temperature changes, exposure to moisture, and UV exposure. Fasteners experience cyclic loading as the engine’s heat and the wind’s gusts wrestle with the panels. Over time, these conditions can broaden the acceptable tolerances or erode the lock’s bite, particularly if debris, salt, or grit find their way into the locking recesses. That is why maintenance is not a separate task but an ongoing practice. Regular inspection becomes part of the riding routine, especially after long trips, adverse weather, or high-speed sessions. Each fastener should be visually checked for tightness, and the locking action should feel firm when engaged. Any looseness, audible rattle, or movement is a red flag. If the lock begins to feel sluggish, if engaging requires more effort than before, or if there is consistent play after a standard engagement, the fastener assembly deserves closer scrutiny. The cure for such symptoms is straightforward: remove the panel, verify the alignment, check the receptacles for cracks or elongation, clean the contact points, and reassemble with fresh fasteners if necessary.

Cleaning plays a small but meaningful role in preserving reliability. Debris, salt, and road grime can settle into the contact surfaces where the fastener locks. A simple, regular cleaning routine can prevent interference with the locking action. Use a mild detergent solution to wash the fasteners and surrounding panel surfaces, then rinse thoroughly. Drying should be complete before re-engaging or testing the fasteners. Avoid harsh chemicals that might degrade plastics or corrode the metal parts over time. A soft brush can help dislodge any stubborn grime from the lock recesses, while a microfiber cloth dries and polishes the surfaces. When a fastener becomes difficult to engage or disengage, it is often a sign of grime, minor corrosion on the contact edge, or edge wear from repeated use. In such cases, cleaning alone may restore function, but if wear persists, replacement is the prudent option. Replacement parts are readily available through authorized distributors and independent retailers specializing in motorcycle hardware. The importance of timely replacement cannot be overstated; a compromised fastener can fail suddenly, risking panel loss at speed or during a cornering maneuver.

From a practical standpoint, planning for installation and maintenance also means having a small, well-curated toolkit. A micro-torque wrench, thread cleaner, and a gentle lubricant suitable for lock mechanisms can be part of the baseline toolkit. The lubricant, if used, should be applied sparingly to the moving parts and away from the locking edge to avoid attracting dirt. Lubrication should not be used on the locking surfaces themselves unless the manufacturer approves it. The idea is to preserve the lock’s integrity and its bite without creating a slippery interface that can invite misalignment or accidental disengagement. A disciplined maintenance routine also benefits from labeling and inventory management. Keeping a spare batch of female receptacles and compatible male pins on hand ensures that a minor component failure does not derail a longer ride. The capacity to quickly replace a worn part often determines whether a rider can complete a trip or has to wait for service. The mindset is simple: treat fasteners as wear items with predictable lifecycles, and you’ll avoid the anxiety of an unplanned panel loss.

In designing or choosing a setup for a particular bike, the aesthetic and the physics of airflow matter as much as the mechanical integrity. The interplay between flush-mount versus raised-head styles is not only about how the fairing looks when the bike is stationary; it also influences how the panel conforms under dynamic air loads. If a rider is pursuing a minimal, integrated look for track days, flush mounts may be preferable, provided the installation tolerances are tight and the surface is pristine. For street applications where gloves are often part of the equation and weather is a constant variable, raised-head variants can offer a tactile cue that ensures confident engagement even when conditions are slippery. The choice, again, should be made with the panel’s edge geometry, backing material, and the rider’s maintenance rhythm in mind. The broader takeaway is that fastener selection should be intentional and contextual, not accidental. The goal is to maintain the panel’s aerodynamic performance while ensuring the method of access remains straightforward and predictable for service and customization.

Riders who are integrating new fairings or upgrading an existing setup can benefit from considering how fasteners interact with the rest of the bike’s hardware ecosystem. A cohesive approach means selecting a fastener family that tolerates the same vibrational environment, corrosion exposure, and service cadence as the rest of the drivetrain and chassis components. It also means acknowledging that parts wear differently depending on exposure and frequency of panel removal. A well-chosen, properly installed fastener system reduces the frequency of rework and helps preserve the fairing’s surface finish by minimizing vibration-induced chafing or misalignment. If you are exploring replacement or upgrade options, you can locate compatible fairing panels in the broader marketplace, with a specific nod toward manufacturer-verified categories that align with your bike model. For instance, riders seeking Honda fairings can explore dedicated listings that group compatible panels, enabling a smoother path to a cohesive, performance-oriented look. Honda fairings This resource emphasizes the importance of compatibility and fitment in the broader context of fairing customization, which dovetails with the practical considerations of fastener choice and installation.

Finally, it is worth returning to the core discipline that underpins both installation and maintenance: meticulous attention to detail. The step from “this looks aligned” to “this is anchored securely” rests on a sequence of checks, tests, and sometimes a careful rework. A rider who habitually checks fastener integrity after every lengthy ride, after every wash, and after every weather event is adopting a maintenance standard that translates into reliability at speed and resilience in daily use. The beauty of DZUS-style fasteners lies in their ability to combine quick operation with a long service life when treated with respect. But the mechanism will only repay this respect if the surrounding practices—alignment accuracy, correct engagement, appropriate materials, and disciplined cleaning—are part of a coherent workflow rather than an afterthought.

In sum, the installation and maintenance of DZUS fasteners on motorcycle fairings are not about a single clever trick but about a philosophy of care. It is a process that begins with choosing compatible, high-quality components and continues through precise alignment, careful fastening, and regular, thoughtful maintenance. The aim is to protect the fairing’s aerodynamics and appearance while ensuring that riders can access internal components without ritualized wrangling or risk to the panel. The result is a bike whose panels stay true to their lines under dynamic riding conditions, while service and customization remain accessible rather than daunting. The lesson is practical: plan, align, engage, and maintain with consistency, and the benefits show up in fewer interruptions, cleaner design lines, and a riding experience that feels as predictable as it is exhilarating. For those pursuing a performance-informed, aesthetically cohesive build, the integration of reliable, quick-release fasteners into the fairing system is not an afterthought but a foundational choice that informs every subsequent decision. The journey from the first dry fit to the final tightened panel is a sequence that mirrors the precision of the machine itself, a small but essential part of elevating the ride from standard to sport-ready. For official guidance and the most current recommendations, consult the manufacturer’s resources, including the product manual, and refer to their official site for the latest installation techniques and maintenance tips. External resource: https://www.dzus.com

Market Availability and Sourcing of Quick-Release Fasteners for Motorcycle Fairings

The bodywork of a modern motorcycle is more than a cosmetic shell. It is an engineering interface between the rider, the bike’s core systems, and the environment. In this ecosystem, quick-release fasteners play a pivotal role. They enable rapid access to internal components for maintenance, upgrades, or repairs, while maintaining a clean, aerodynamically efficient exterior when the fairings are in place. The market for these fasteners reflects that dual requirement: they must be easy to operate, robust under vibration and weather exposure, and readily available in sufficient quantities to meet both mass production and bespoke builds. What riders and builders demand, in short, is a reliable, repeatable system that disappears into the bike’s design and reappears with a satisfying click when the time comes to service the machine. Market availability mirrors that demand. Across automotive and aerospace-adjacent sectors, manufacturers have refined these devices to tolerate shock, heat, and the occasional sprint down a track. For motorcycle fairings, this translates into a range of variants designed to match different fairing profiles, mounting thicknesses, and aesthetic preferences, all while preserving ease of use for the rider under any conditions. In practice, this means you will encounter several form factors within a single product family. Some fasteners are flush-mount, designed to sit flush with the fairing surface for a sleek, uninterrupted line. Others are raised-head variants, which provide tactile feedback and a little extra clearance for slightly irregular mounting surfaces or thicker composite layers. Material choice matters as well. The most common configurations use stainless steel or aluminum. Stainless steel resists corrosion from rain, road salt, and humidity, while aluminum offers a lighter mass without sacrificing strength in many fairing applications. In environments where weight is a top priority, alloy formulations or treated aluminum can reduce overall bike mass without sacrificing the holding power needed to keep panels secure at highway speeds or on the race strip. Finishes extend the aesthetic argument beyond texture and color. Black is a favorite for a discreet, stealthy look that blends with dark paint jobs or carbon fiber panels. A bright orange or other high-visibility finish is popular in custom builds and sprint setups where quick visual confirmation of panel status matters during pit stops or shifting light conditions. The finishes also serve a practical purpose: color-coded hardware can help a crew quickly identify which fasteners belong to which subassembly, reducing the time spent during maintenance or panel removal. Availability and sourcing are driven by the same physics that govern performance parts: mass production, distribution networks, and the ability to deliver consistent quality at scale. For someone restoring a vintage bike or building a high-performance machine from the frame up, the key is to locate a supplier that offers a broad spectrum of sizes and styles, with clear specifications for thread pitch, head type, and mounting thickness. In practice, this means looking beyond one-off auctions or hobbyist shops and engaging with suppliers who can provide engineering-grade documentation and bulk pricing options. The value in bulk purchases is not simply the unit price. When you buy fasteners in larger lots, you gain consistency across your build. A consistent thread engagement, the same head profile, and uniform plating reduce the risk of misfit or uneven retention as you swap panels across multiple bikes or revisions. Another element of availability is the flexibility of sourcing channels. Reputable distributors and established hardware houses are accustomed to serving the racing community, OEMs, and custom fabricators. These channels can provide rapid lead times, standardized packaging, and a return or exchange policy that minimizes downtime if a batch proves off-spec or unsuitable for a particular fairing design. The acceptance of bulk orders is not limited to traditional markets. Online retailers and direct-from-manufacturer options broaden the spectrum, offering regional stock and just-in-time fulfillment that fits a workshop’s cadence. It is common to see entry-level kits that cover a range of common fairing thicknesses, paired with a few alternative head types to cover different profiles. This breadth of choice reduces the risk that a builder will be forced into an awkward retrofit or a panel mismatch late in the project. When evaluating sourcing options, a practical mindset helps. Start by confirming compatibility with your bike model and fairing design. Check the thread size, head type, and installation method, as well as the material and finish. If you are assembling or reassembling a race bike with frequent fairing removal, prioritize a system that provides quick operation without tools in routine use, yet remains secure under wind, vibration, and taming track debris. For a rider or builder who values appearance as much as function, pay attention to color options and finish consistency across the batch. A uniform finish reduces the chance of mismatched hardware showing through the panel joints, which, in a glossy paint job or a matte carbon skin, can detract from the overall presentation. In many markets, the base price per unit starts low enough to be competitive for multiple bikes in a project, with bulk discounts that reward larger orders. Reports from suppliers indicate prices beginning around the low forties per hundred units, dropping further with larger quantities and longer-term supplier relationships. The economics are compelling for sprint car teams, track-prepped street builds, or any project where fairings are part of the performance envelope and not merely decorative. Beyond price, availability is also a matter of distribution reach. Reputable suppliers often stock a broad portfolio of sizes and profiles to cover popular fairing configurations. This breadth ensures that a builder can source everything from a single catalog, minimizing the risk of counterfeits or incompatible components. It also supports faster fulfillment, a critical factor when timelines are tight for a project or a rider is prepping a season debut. The practical upshot is clear: with the right sourcing strategy, a builder can secure a complete, compatible set of fasteners in a single purchase, reducing the complexity and risk that sometimes accompanies a custom fairing project. For those who want to explore a broader catalog of fairing options in relation to a given make or model, a convenient path is to review representative product ranges that align with the bike’s design language. For instance, a catalog focusing on a particular brand of fairings can reveal which fastener variants are preferred by fabricators or race teams for that bodywork, helping to calibrate decisions on head shapes and mounting thickness tolerances. This approach supports a cohesive aesthetic while maintaining functional reliability. A practical entry point for exploring compatible fairings and their associated hardware is to browse specific fairing categories in a dedicated supplier’s site. In many cases, the fairing category pages organize sets by model or generation, and you can quickly infer which fastener families are most compatible with a given panel style. For example, you can peruse the BMW fairings category to gauge typical mounting thicknesses and suggested head types for certain lineages, which provides a fast track to a coherent hardware strategy. See for example the category page here: BMW fairings. While shopping, keep a checklist that covers thread pitch, head profile, thickness compatibility, and the expected installation method. It is also wise to confirm whether a given fastener is designed for plastic or composite panels, as some variants are optimized for tougher substrates or particular panel thickness ranges. These distinctions matter because improper engagement can lead to vibration-induced loosening, creaking, or in the worst case, panel loosening at speed. The right choice balances mechanical performance with ease of use, both of which contribute to a better riding experience and a more professional build finish. You should also consider the procurement path. If you are managing a production schedule or a shop workflow, it can be beneficial to establish a relationship with a supplier who can deliver on a consistent cadence and offer replacement parts that match your existing specifications. That reliability reduces the risk of part-number drift, which can happen when different lots introduce slight tolerances or plating variations that affect fitment. In the end, market availability and sourcing are about aligning the hardware with the bike’s purpose. A sportbike’s fairings demand a system that can be removed and reinstalled quickly under race-day constraints, while a custom rider’s machines might benefit from a broader palette of finishes and sizes to achieve the exact visual statement they seek. The common thread across all these scenarios is a disciplined approach to selection: verify model compatibility, understand the physical dimensions, and secure a supply chain that can deliver consistent parts when you need them most. External resources that explain the broader mechanics of quick-release hardware can offer additional context to the enthusiast who wants to dive deeper into design principles and tolerances that affect function and longevity. For general information about quick-release fasteners and related mechanisms, you can consult the external resource at the end of this chapter. External resource: https://en.wikipedia.org/wiki/Quick-release_fastener

Final thoughts

Understanding DZUS fasteners is vital for business owners in the motorcycle industry. Their ability to offer quick-release mechanisms and durable designs not only enhances fairing performance but also improves customer satisfaction through ease of maintenance. Prioritizing quality materials and staying informed about sourcing channels will ensure your offerings meet the needs of modern riders. By integrating this knowledge into your product line, you’ll establish a strong reputation and increase the value of your motorcycle fairing assemblies.