Motorcycle fairing wraps have emerged as an innovative solution for motorcycle customization and protection, making them increasingly popular among business owners in the motorcycle industry. By providing both aesthetic upgrades and functional protection, these wraps can appeal to a diverse customer base looking to enhance their riding experience. This article will delve into the aesthetic and functional benefits of these wraps, explore the materials and technologies employed in their production, and analyze the cost-effectiveness and market demand surrounding motorcycle fairing wraps. Business owners will gain insights into how leveraging these products can drive profitability and improve customer satisfaction in a competitive marketplace.

Style That Protects: How Fairing Wraps Combine Visual Impact with Practical Performance

Style That Protects: How Fairing Wraps Combine Visual Impact with Practical Performance

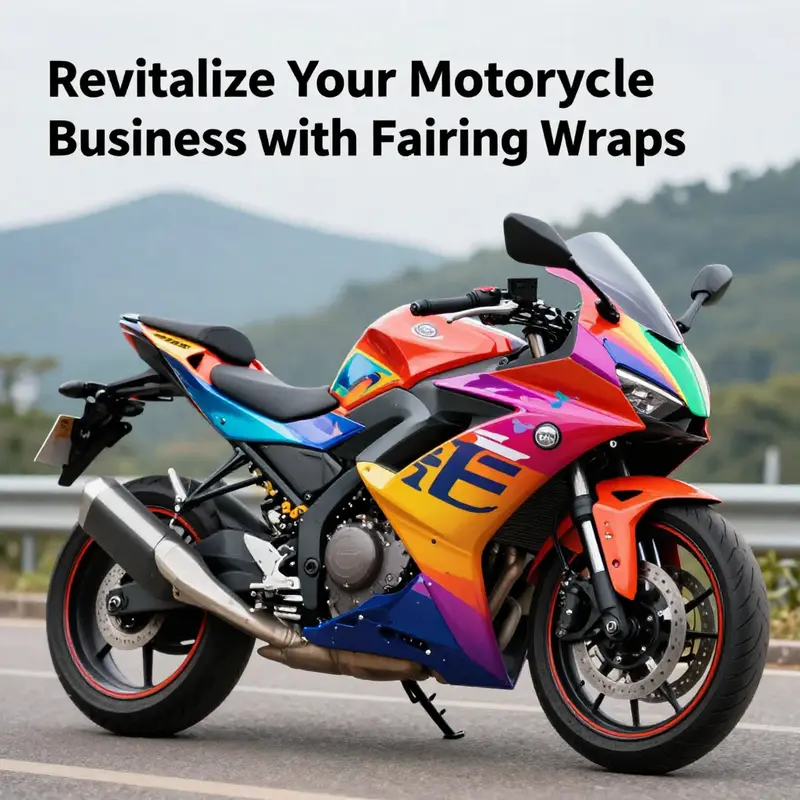

Motorcycle fairing wraps offer an elegant solution to a simple rider impulse: change the look of a bike while keeping its original condition intact. They sit at an intersection of design freedom and pragmatic protection. A well-chosen wrap can refresh a motorcycle’s personality, make it stand out at meets, and perform as a serviceable shield against the small but relentless hazards of the road. This chapter explores how fairing wraps deliver both aesthetic delight and functional advantage, and why many riders now treat them as strategic upgrades rather than merely cosmetic add-ons.

At the most visible level, wraps are about visual identity. They let riders craft a surface narrative without committing to permanent alterations. Modern films come in a wide range of colors, textures, and finishes. Gloss and satin bring out crisp graphics and high-contrast schemes. Matte and textured films deliver subtlety and depth. Metallic, pearlescent, and brushed effects mimic costly paint processes but cost far less and are fully reversible. The design possibilities extend beyond solid color: detailed prints, layered graphics, and custom artwork translate onto fairings with fidelity that was once impossible outside high-end shops. Riders can coordinate accents, match helmets, or create layered themes that respond to events, seasons, or moods.

The visual versatility of wraps also means creators can experiment. A design that looks right for urban riding might not fit a track day aesthetic. With wraps, it’s feasible to swap schemes between uses. This flexibility encourages creativity. It turns the bike into a canvas for rotating expressions while preserving the underlying panels. For those who value variety, wraps transform the motorcycle into a modular style platform.

Durability plays a central role in why wraps have grown popular. High-quality films resist UV fading and retain color vibrancy for years. They are engineered with protective coatings that ward off minor abrasions and environmental contaminants. The finish protects printed graphics and underlying paint from prolonged sun exposure, rain, and airborne grit. In short, the visual benefits are long-lived because the material itself resists the very forces that usually degrade surface appearance.

This brings us to the functional heart of wraps: protection. A wrap functions as a sacrificial layer between the open world and the fairing’s original finish. Road debris, small stones, and incidental contact leave marks on the film first. Many small scratches will affect only that outer layer. When the film is replaced, the fairing beneath often looks like new. That sacrificial quality is especially useful for riders who rack up miles in mixed conditions. Long trips that cross weather zones, gravel access roads, and urban streets place steady wear on painted panels. A wrap absorbs much of that wear.

Because wraps are thin and flexible, they protect without altering a bike’s fit or aerodynamics. They conform to curves, recesses, and edges. This close adherence preserves the fairing’s intended airflow characteristics. Riders who care about handling and wind management find that wraps maintain the original design’s integrity. There is no need to compromise performance for appearance.

Maintenance benefits also emerge from this protective relationship. A wrapped surface is easier to clean and tends to hide fine swirl marks that would show on paint. Most films accept gentle washing solutions and routine care with standard microfiber cloths. They do not require polishing or complex paint correction procedures. Over time, that simplicity translates into cost savings. There are fewer trips to the detailer, and less need for restorative paint services. For owners planning to sell, the maintained condition of underlying panels supports healthier resale prospects.

Resale value is an important practical consideration. When panels underneath a wrap remain intact, the original finish preserves its market appeal. Potential buyers often appreciate a motorcycle that shows minimal surface wear and retains its factory paint. A removable wrap that protected the original finish becomes a selling point. It demonstrates that the motorcycle was cared for and that its outward appearance can be returned to stock quickly. This dynamic is why many savvy owners choose wraps to protect high-mileage machines destined for eventual sale.

Insurance implications should not be overlooked. Wrapped surfaces are generally seen as reversible modifications. Since a wrap can be removed without damaging the original paint, insurers and lenders may view the upgrade as less risky than permanent customization. This can simplify valuation and claims processes where visual modifications might otherwise trigger questions. Riders should, however, confirm policy details with providers before assuming universal coverage advantages.

Beyond protection and resale, wraps support fast visual iteration for manufacturers, dealers, and builders. They enable rapid presentation of colorways without repainting panels. For short-run prototypes, marketing bikes, and display units, wraps are a cost-effective way to test public response or showcase limited-livery schemes. They also help dealers feature multiple looks on the same chassis across different campaigns. The reversibility of wraps means a bike can move from one campaign to another with minimal downtime and expense.

When considering fairing wraps, material choice matters. Films vary by thickness, adhesive formulation, and top-coating technology. Thicker films offer enhanced protection against gouges and heavier abrasions. Specialty top coats improve UV resistance and chemical repellency. Some films include air-release channels to streamline large-panel applications and reduce bubble formation. Understanding these properties helps riders match film selection to intended use. Long-haul riders will favor films with high UV stability and chemical resistance. Track riders may prioritize adhesion and heat tolerance. Urban commuters often choose films with scratch-repellent coatings and easy-clean surfaces.

Installation technique is equally crucial. While some experienced DIYers achieve professional results, many riders choose trained installers for complex panels. Proper installation ensures edge sealing, uniform adhesion, and longevity. It also prevents premature lifting at stress points. An installation that respects panel geometry reduces the chance of debris getting trapped beneath the film, which could otherwise cause visual defects over time. A considered installation balances tight fit with the film’s natural tension limits.

Beyond the practical, wraps enable safety-minded customization. Reflective and high-visibility films increase conspicuity at night. Strategic placement of reflective strips or high-contrast areas can improve how quickly other road users judge a motorcycle’s position. Without changing the bike’s mechanical characteristics, these visual upgrades enhance safety through better detection. Even subtle contrasts, when placed thoughtfully, can improve lateral visibility in twilight conditions.

Care routines for wrapped fairings are straightforward. Use mild detergents, rinse thoroughly, and dry with soft towels. Avoid harsh solvents and abrasive pads, as these can degrade top coats. For long-term upkeep, occasional application of products formulated for film care will restore luster and improve hydrophobic properties. When a film’s edges start to lift or when surface damage accumulates, controlled removal and replacement restore both appearance and protection. The process places a limit on cumulative repair costs compared with repeated paint correction and touch-ups.

Aesthetic continuity is another advantage of wraps. They can replicate factory colors or create complementary contrast. For owners who customize other components—like seats, exhausts, or handlebars—wraps provide a cohesive way to coordinate the visual theme. They allow matching or contrasting textures and finishes across multiple panels. This flexibility supports complete design language, from subtle tone-on-tone treatments to bold, statement-making schemes.

Cost considerations shape the wrap-versus-paint decision. Painting panels can be expensive, especially when matching complex metallics or layered effects. It requires prep work, time for curing, and the risk of overspray or imperfect color matching. Wraps often come at a fraction of the cost and deliver equally striking visual results. They also minimize time off the road: many wrap installations are completed in hours rather than days, which suits riders who want minimal downtime.

Wraps are especially useful for unique or older machines. For bikes whose original paint may be difficult to reproduce or source, wraps provide a reliable way to refresh aesthetics. They can replicate textures and patterns that would otherwise demand specialized painting techniques. For classic or limited-run models, a wrap lets the owner maintain originality beneath a modern surface.

Design fidelity and print quality matter for complex graphics. High-resolution printing on premium films reproduces intricate logos and photographic elements with remarkable clarity. Precise color calibration ensures that printed hues align with expectations. This fidelity makes wraps attractive for riders who want bespoke artwork without the cost of hand-painted finishes.

Another practical advantage is damage localization. If a crash or significant contact mars a small area, replacing a damaged panel or a discrete wrapped section can be far cheaper than repainting entire panels. This modularity streamlines repairs. It reduces the time and money involved in restoring a bike to showroom condition.

Wraps also encourage experimentation without lasting commitment. Riders can test color schemes, sponsor graphics, or event-themed looks for short runs. This reduces the barrier to creative changes and promotes a culture of evolving aesthetics. For builders and teams, wraps allow different liveries for different events, an efficient approach for seasonal or promotional campaigns.

Environmental factors also play a role. High-quality wraps can reduce the need for solvents and paint-related chemicals used in conventional repainting. They cut down on sanding and the associated particulate waste. While wraps are not a perfect environmental solution, they can reduce the frequency of resource-intensive painting jobs over a bike’s lifespan.

There are limits to what wraps can do. They will not fix structural damage or correct panel deformation. They cannot substitute for repairs needed to restore original fitment. Nor do they create a significant increase in impact resistance against heavy collisions. Riders should view wraps as a complement to sound mechanical maintenance and accurate damage repair, not as a replacement.

Still, the balance between aesthetics and protection is where wraps excel. They offer an economical path to dramatic change, protect the original finish, and simplify long-term upkeep. For riders who want to experiment or preserve resale value, wraps deliver clear advantages. For teams and dealers, they speed iterations and lower display costs. And for riders focused on safety and utility, reflective and high-visibility options add measurable benefits without affecting performance.

Finally, when choosing to wrap, consider the whole system: the film grade, the installer’s experience, and the intended lifespan for the design. A thoughtfully selected film applied with care maximizes both visual impact and protective value. For those exploring new fairing options, browsing recent releases can spark ideas and point toward compatible kits and films; a good place to see fresh offerings is the collection of 2023 new fairings.

For further reading on how wraps influence the market value of motorcycles over time, see this industry analysis: https://www.bikeexif.com/2026/01/cool-motorcycle-wraps-resale-value/.

What Fairing Wraps Are Made Of: Materials, Printing and Protective Technologies

Materials, printing and protective technologies

Motorcycle fairing wraps combine material science, precision printing and surface engineering to turn a fragile body panel into a durable canvas. The choice of substrate governs flexibility, longevity, and protective performance. The printing method determines color fidelity and the range of achievable effects. The finish and lamination determine scratch and UV resistance. Together these elements create wrap systems that meet different rider priorities—cost, appearance, maintenance, or endurance. This chapter walks through the technologies and materials that underpin successful fairing wraps and explains how they work together in real-world applications.

At the foundation is the film itself. Modern fairing wraps use a handful of film families chosen for strength, stretch and surface finish. PVC-based films remain common because they balance cost and performance. They are flexible enough to cover contours and resist weathering for a season or more. Their chemistry offers reliable adhesion and good printability. PVC films can lose flexibility under extreme UV exposure and may harden after many years. That brittleness shows as cracking around tight edges on older installs, which is why long-term projects often avoid pure PVC when longevity is the priority.

Vinyl films are closely related to PVC but typically formulated for richer color and improved longevity. Contemporary vinyl wrap films arrive with polymer blends that reduce yellowing and extend pliability. They print exceptionally well, so complex graphics and photographic imagery remain sharp and rich. Their adhesive systems are tuned to peel cleanly, which makes them popular for temporary or rotating liveries. Many riders choose vinyl when they expect to change designs seasonally or want confidence that a removal will not harm underlying paint.

Thermoplastic polyurethane, or TPU, represents a higher-performance option. TPU wraps are tougher and more flexible than standard PVC or vinyl. They resist abrasion and can absorb impacts from stone chips more effectively. A key advantage is the self-healing property of many TPU formulations; minor scratches will reflow with heat and become nearly invisible. TPU also tolerates heat and UV exposure better, maintaining elasticity and appearance across harsher climates. The trade-off is cost. TPU films are more expensive to manufacture and print, so they tend to be used where protection and a long service life justify the investment.

Polyester and latex-based wraps occupy more specialized roles. Polyester films bring dimensional stability and strong tensile properties. They are useful for flat panels and for layered constructions where rigidity helps prevent lifting at edges. Latex-based films and coatings are highly conformable. They stretch well and can follow complex three-dimensional curves with fewer seams. Custom shops sometimes use latex-backed laminates when they must drape a design across intricate cowlings and recesses. These materials are less common for mass-market wraps, but they appear in projects where shape conformity matters as much as surface protection.

Beyond the film family, finish and texture expand the aesthetic toolkit. Wraps are available in gloss, satin, matte, textured, brushed-metal and simulated carbon-fiber finishes. Textured films use a patterned top layer to disguise micro-scratches and to create a tactile quality. Simulations of metal, chrome and pearlescent effects rely on specialized print layers and reflective pigments, often requiring very precise lamination to retain depth and sheen. Choosing a texture affects maintenance and visibility; matte films tend to show fingerprints and scuffs more readily, while gloss finishes hide swirl marks and shed liquids.

Printing technology is the bridge between raw film and finished design. Digital printers for wraps fall into several categories: solvent, eco-solvent, latex and UV-curable. Each has different inks and drying methods, which influence color gamut, durability and environmental handling. Solvent and eco-solvent systems penetrate vinyl and bind well, offering strong outdoor durability. Latex printers use water-based pigments with polymer carriers and deliver excellent color stability with faster curing. UV-curable printing uses inks that harden instantly under ultraviolet light, producing highly scratch-resistant prints with vibrant pigments. High-detail or photographic wraps typically use printers capable of rich, continuous tones and tight dot placement, ensuring a smooth finish without banding.

Printing alone is not enough. A protective laminate seals the ink and provides the primary resistance to abrasion, chemicals and direct UV radiation. Laminates come in gloss, matte and textured varieties, and their chemistry matters. Hard laminates add scratch resistance but may reduce conformability over complex edges. Softer, tougher laminates bend and stretch, allowing installations to conform without lifting, but they may scuff easier. Some topcoats include anti-graffiti properties or hydrophobic treatments that help water bead and slide off the surface. For riders who want both long life and a brilliant finish, a high-quality clear laminate over a printed vinyl or TPU film is the best compromise.

Adhesive systems are a subtle but critical part of performance. Modern wraps use pressure-sensitive adhesives formulated to bond securely to painted or plastic fairings while allowing repositioning during installation. Two adhesive strategies are common: permanent and removability-tuned. Permanent adhesives aim for long-term stability and strong anchorage at edges. Removability-tuned adhesives include liners or adhesive profiles that release cleanly with heat and time. Many adhesives incorporate air-release channels or micro-texturing to reduce trapped bubbles during application. Clean removal depends on adhesive selection and on the condition of the underlying surface. Paint that is older, cracked, or previously repaired may not provide the ideal substrate.

Installation technologies and techniques matter as much as materials. A proper surface preparation routine improves adhesion and longevity. Clean, degreased panels with a dry, dust-free finish allow adhesive to bond uniformly. Heat is a principal tool; installers use controlled heat to soften films for edge wrapping and to activate some adhesive chemistries. Heat guns and low-temperature ovens let TPU and vinyl conform to compound curves without overstressing the film. Stretch rescue techniques and torque-limited hand tools help prevent micro-tears during insetting. Professional installation also addresses seams and edge sealing. Agents and edge tapes can protect vulnerable junctions from water ingress and lift.

The combination of film, ink and laminate also dictates how a wrap responds to the environment. UV-stable pigments and UV-resistant laminates reduce fading. TPU and modern vinyls resist ozone and temperature cycling better than older PVC. Chemical resistance matters in urban and coastal environments where road salts and cleaners are common. High-performance laminates resist solvents and detergents, making them easier to clean without degrading the design. For riders in hot climates, heat tolerance prevents softening or adhesive squeeze-out. In cold climates, flexibility at low temperatures prevents cracking during winter rides.

Performance considerations extend beyond durability to functional impacts. A properly applied wrap is nearly weightless and does not change aerodynamics in a measurable way. However, a poorly installed film that flutters or lifts at edges can create drag and compromise safety. Surface texture also affects airflow at a micro-level. Smooth gloss laminates maintain laminar flow across the fairing, while rough textures may create additional turbulence. For track-focused bikes, installers often opt for satin or gloss finishes and tight seam control to preserve aerodynamic integrity at high speeds.

Maintenance and repair are part of the technology story. Different materials require different care. TPU and high-quality vinyl are more forgiving; minor abrasions will often blend with heat or gentle buffing. Matte and textured films typically need specialized cleaners to avoid sheen changes. Many wraps respond poorly to high-pressure washers near edges, so hand washing or using lower-pressure rinses is recommended. When damage occurs, patch repairs can be more straightforward than repainting. Localized panels can be removed and replaced, and high-resolution printing allows exact color matching of custom graphics. Removal technologies also matter; heat and adhesive solvents aid lift, but improper removal risks damaging the base paint.

Sustainability and end-of-life considerations are emerging elements of wrap technology. Some manufacturers offer films with lower volatile organic compound content in adhesives and inks, reducing off-gassing during application. Recycling remains a challenge because multi-layer films combine inks, adhesives and protective laminates. Advances in single-polymer constructions and in solvent-free laminates are easing recycling, but the market for recycled wrap material is still developing. For fleet or dealer applications where wraps are temporary, the ability to remove and reuse films on other panels can reduce waste. Reuse requires gentle removal and careful relamination, and it typically favors higher-cost films that maintain adhesion after lift.

Choosing the right material and technology comes down to priorities. If budget and short-term style changes are central, a high-quality vinyl printed with eco-solvent inks and covered with a gloss laminate will deliver vivid color at a reasonable price. If protection against chips and long-term UV exposure is the priority, TPU with a clear hard laminate makes more sense. For wraps that must follow complex shapes without seams, latex-backed laminates or highly conformable vinyls are preferable. When a rider wants special effects—metallic, pearlescent or color-shift finishes—select film blends and printing processes designed for those pigments. In many cases, a hybrid approach offers the best balance: a conformable vinyl base for shape-fitting, high-resolution printing for detail, and a tough clear laminate for protection.

Installation standards and professional practices elevate outcomes. Experienced installers evaluate panel geometry, choose the appropriate film and lamination, and sequence the work to minimize seams. They use heat and tension carefully to avoid overstretching. They also consider how panels meet hardware and vents, and they plan wrap edges to minimize exposure to impact or chemical contact. For riders who prefer a DIY approach, smaller changes such as tank decals or single-panel wraps are achievable with patience, correct tools and quality film. For full-fairing projects, professional installation typically pays off in time saved and a blemish-free finish.

Finally, the application of fairing wraps has become part of broader OEM and aftermarket workflows. Manufacturers and dealers use wraps to trial colorways and graphics without committing to permanent paint lines. Track teams use wraps for temporary liveries or for testing aerodynamic changes without repainting. In each case, the critical interplay between the chosen film, printing process and laminate determines whether a wrap is a temporary visual test or a long-term protective solution. For riders exploring options for specific models, there are specialized product lines made to match the contours of many popular bikes. For example, custom fairings for high-performance sport models have dedicated wrap treatments to ensure fit and finish across complex bodywork; see fairings for YZF for a sense of model-specific options.

The technology behind motorcycle fairing wraps has matured. Film chemistry improved, printing systems broadened the creative palette, and laminates added the resilience riders need. The right combination delivers both show-winning looks and everyday protection. Choosing wisely requires understanding how each material behaves, how prints hold up under the sun, and how films adhere and age. With that understanding, a fairing wrap becomes a deliberate technical choice rather than merely a cosmetic one.

External resource: https://www.cycleworld.com/motorcycles/tech-and-innovation/motorcycle-fairing-wrap-materials-technologies/

Value, Demand, and ROI: How Fairing Wraps Reshape Motorcycle Customization

Cost-effectiveness and market demand are reshaping how riders customize motorcycles. Fairing wraps have moved beyond optional styling to become a strategic choice for owners, dealers, and designers. They deliver a combination of visual flexibility, protection, and financial sense that paints and permanent modifications rarely match. This chapter explores that balance of cost and value, explains what drives demand, and outlines realistic scenarios where wraps outperform alternatives.

To appreciate the economics, begin with a simple comparison. A full, high-quality paint job can demand weeks of labor, multiple coats, and careful masking. It often requires disassembly, professional drying environments, and a finish that locks the bike into a single look. By contrast, fairing wraps use printed or colored films applied directly to removable panels. A partial or small wrap commonly starts around $300, representing a fraction of the cost of a full respray. Even larger, full-body wrap projects typically stay well below high-end paint prices when labor and time are considered. The initial price advantage is clear, but the true savings appear over time.

A wrap’s reversibility changes the financial calculus. Riders can test a bold graphic for a season, then return to stock or try another design without diminishing resale prospects. Paint, unless expertly matched and professionally removed, can carry a stigma in used markets. Wraps preserve original finishes underneath, creating a protection layer for the underlying fairings. That protection translates into fewer scratch repairs, less sun-induced fading, and, often, a higher perceived value when the bike is sold. Dealers and traders recognize this benefit: a wrapped test bike stays presentable longer, needs less touch-up, and can be rebranded to match campaigns or promotions.

Time is money in customization. A painted job may require days to weeks of downtime, during which a motorcycle is out of commission. Wraps usually install in hours to a few days, depending on complexity. For riders who use bikes regularly, or shops with high throughput, the shorter turnaround means lower opportunity cost. For manufacturers and event teams, wraps enable the rapid deployment of alternate liveries for shows and demos. The flexibility to swap graphics overnight makes wraps a favorite for marketing use cases where timing and adaptability are crucial.

Beyond price and time, the technical properties of modern wrap films contribute to cost-effectiveness. Advances in vinyl and polyurethane technology have improved conformability to complex curves, long-term adhesive performance, and resistance to UV and chemicals. These materials also come in specialty finishes—matte, satin, gloss, metallic, and textured—that previously required elaborate paint techniques. Achieving a similar aesthetic with paint often demands more costly materials and labor-intensive finishes. Thus, a wrap can deliver a premium look at a mid-range cost.

Market metrics underscore rising demand. The global fairing market is forecasted to grow at a robust CAGR of 12.3%, indicating increasing adoption across segments. Several forces feed this growth. Custom aesthetics remain a primary driver: owners see their motorcycles as expressions of identity, and wraps offer an economical path to distinctiveness. Second, performance-minded riders appreciate the minimal weight and aerodynamic neutrality of a film compared with elaborate aftermarket pieces. Third, commercial and industrial users seek temporary branding and promotional solutions; wraps provide an inexpensive, reversible option for show fleets and prototype testing.

The profile of the typical wrap buyer is broad but concentrated in a few key niches. Sport bike riders prioritize aggressive, track-inspired looks and clean, aerodynamic finishes. These owners often change liveries to match seasons, sponsors, or track days. Highway cruiser enthusiasts prioritize comfort and personality; they gravitate toward subtle color changes and protective finishes that preserve the bike’s original patina. Touring and adventure segments, while less focused on visual flair, value wraps for their protective qualities against gravel and the elements. Across all groups, younger riders and those active in online communities are more likely to experiment frequently with visual themes, boosting demand for temporary and economical options.

From the business perspective, shops and specialists see high margins in wraps. Materials are relatively stable in cost, and the value added by skillful installation commands premium pricing. However, reputation matters. Poor installation—visible seams, premature peeling, or trapped bubbles—erodes perceived value rapidly. Consequently, providers invest in training and quality control. This investment reduces rework costs and increases customer referrals. For motorcycle accessory retailers, partnering with reliable wrap installers enhances the overall offering and creates recurring revenue through rewraps and seasonal graphics.

For individual riders weighing options, return on investment is rarely only about upfront cost. Consider three practical scenarios. First, a rider who upgrades aesthetics seasonally can amortize a wrap’s cost across multiple looks. If a $700 partial wrap is swapped twice in three years, the effective annual cost is modest compared with repaints. Second, a commuter who wants paint protection on a high-mileage bike gains savings from avoided scratch repairs and paint correction. Third, a dealer who rotates promotional designs on floor models can reuse wraps across units; that reuse amplifies the cost-efficiency. In each scenario, wrap economics hinge on flexibility and reduced lifecycle costs rather than simple sticker price.

The pricing structure varies by scope and complexity. Small or partial wraps typical for single panels start near the $300 mark. Full-fairing wraps for modern sport bikes require more material and labor and can escalate into the mid to high hundreds or low thousands. Custom printed graphics, multiple-color jobs, and textured finishes add to costs. Yet even at higher price points, wraps compare favorably against top-tier paint finishes when factoring in time, replaceability, and protection benefits. Buyers should demand detailed quotes outlining material grades, warranty terms, and prep work. A reputable installer will account for panel removal, cleaning, and any minor repairs before application, because proper prep secures long-term adhesion and appearance.

Warranties and perceived longevity influence purchase decisions. Many wrap films offer multi-year durability against fading and weathering, but warranties depend on film grade and installation quality. Riders must understand that environmental exposure, frequent washing, and road debris affect lifespan. Proactive maintenance—gentle washing, avoiding abrasive cleaners, and periodic inspection—extends service life. Some shops offer maintenance packages that include cleaning and small-panel touch-ups, further protecting the rider’s investment. For fleet or dealership use, these service contracts make financial sense because they ensure consistent presentation and lower rework costs.

Another important economic angle is customization without commitment. Limited-edition designs, period-correct liveries for restorations, and sponsor branding for events can be trialed safely. If a design fails to resonate, it is removed without damage to original paint. This reversibility encourages creative risk-taking. Moreover, wraps facilitate testing of new visual concepts before committing large budgets to production painting on high-volume models. Design teams and marketing groups often use wraps for market validation and concept showcases. When applied strategically, wraps become not just a finish but a tool in product development and sales strategies.

Buyers should also consider depreciation and resale effects. A well-executed wrap that preserves the underlying paint can enhance a motorcycle’s appeal. Prospective buyers often prefer visible, undamaged original surfaces beneath a removable layer. Wraps that conceal damage or poorly executed paint, however, raise red flags. For sellers, transparency about the wrap’s purpose and the condition of underlying surfaces maintains trust. Cleanly applied, easy-to-remove wraps can actually expand a bike’s buyer pool by offering an immediate fresh look without hiding the bike’s original condition.

On the supply side, material improvements and printing capabilities broaden market opportunities. Digital printing enables intricate, high-resolution graphics and matched color schemes at scale. Meanwhile, specialty films mimic finishes that were once costly, like brushed metal or carbon fiber. These options make wraps appealing beyond hobbyists; corporate fleets, rental operations, and event bikes use wraps to convey branding while avoiding permanent paint. For prototypes and concept vehicles, wraps permit fast visual iterations while keeping production tooling and paint facilities out of the critical path.

Costs are not only measured in dollars but in risk management. For owners who travel long distances or ride in diverse climates, wraps offer a sacrificial layer against stone chips and salt damage. Repairing a small wrap section is faster and cheaper than paint touch-up. For racetrack teams, wraps simplify sponsor changes and livery updates between events. They also make it easier to protect costlier base finishes during tests. In short, wraps act as an insurance policy that costs far less than many traditional protective measures.

Adoption patterns show that wraps follow a diffusion curve: early adopters and competitive riders lead, followed by mainstream acceptance as benefits become widely recognized. This pattern is visible in racing paddocks, social media showcases, and urban customization scenes. As awareness grows, so do expectations around fit and finish. Installers who scale their skills and maintain consistent quality capture more business. Conversely, market saturation with low-quality providers risks undermining consumer confidence. Thus, education—both for buyers and installers—is crucial for sustainable market growth.

Cost-effectiveness extends into ancillary services. Design aid, mockups, and templating tools offer value by reducing trial-and-error. Shops that include digital proofs or sample panels in pricing demonstrate confidence and lower perceived risk. Online marketplaces that provide templates for popular models help lower design costs for riders, and they enable streamlined quoting for installers. Dealers can leverage this ecosystem by offering wrap options at point-of-sale, bundled with service plans or extended warranties to enhance margin without heavy inventory investment.

Finally, regulation and insurance considerations play a role. Some jurisdictions regulate reflective or distracting finishes. Buyers should verify that their chosen film complies with local vehicle standards. Insurance providers increasingly recognize wraps for cosmetic coverage; however, policy terms vary. Transparent documentation of material grade, installer credentials, and the condition of underlying paint simplifies claims for damage or theft. For commercial users, ensuring that wrapping work aligns with corporate branding standards and legal obligations is essential.

For riders and businesses looking to explore options, one helpful resource is to review typical fairing styles and panel shapes across popular models. Seeing how different designs translate across brands helps set expectations for complexity and cost—examples abound among Ducati fairings and other sportbike families that regularly appear in customization projects. This hands-on comparison clarifies why some models cost more to wrap than others.

For a fuller look at pricing standards and installation variables, consult a comprehensive cost guide. It outlines typical price ranges, factors that influence cost, and preparation tips that protect your investment: https://www.carinterior.com/motorcycle-wrap-cost-guide/.

Final thoughts

Motorcycle fairing wraps represent a pivotal opportunity for motorcycle businesses to engage customers with innovative, customizable options that enhance both the appearance and longevity of their vehicles. By understanding their aesthetic and functional advantages, the materials used, and the cost-effectiveness of these products, business owners can strategically position themselves in a competitive market. Embracing motorcycle fairing wraps not only meets the demands of today’s riders but also opens new avenues for profitability and customer satisfaction. As the market evolves, leveraging these wraps can lead to a thriving business in the ever-growing motorcycle community.