Motorcycle fairing screws play a vital role in ensuring both the safety and performance of motorcycles by securing their bodywork. For business owners in the motorcycle industry, understanding these fasteners is essential for product quality and customer satisfaction. This guide will delve into the significance of motorcycle fairing screws, explore the variety of materials and designs available, and provide a detailed analysis of sourcing strategies and costs. Each chapter will enhance your knowledge on how to position your business effectively in this niche market.

Fasteners at the Edge: The Hidden Power of Motorcycle Fairing Screws

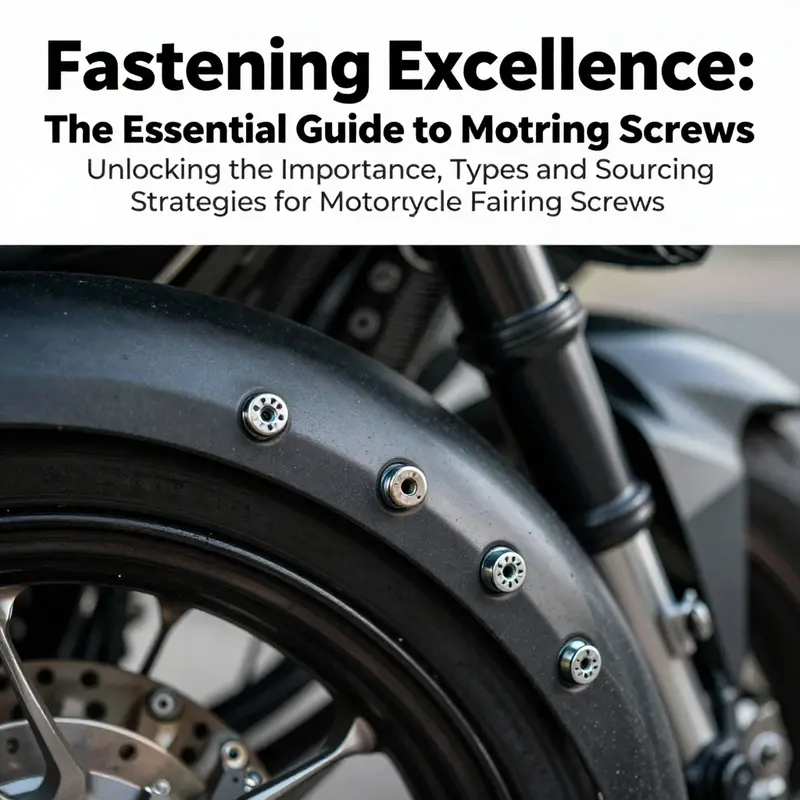

Fairing screws are the quiet workhorses of the rider’s experience, the small but steadfast hardware that keeps the skin of a motorcycle in place while the road unfurls beneath. In many conversations about bike performance, the focus settles on engines, suspension, tires, and aerodynamics in the wind tunnel of the mind. Yet the fairing, that sculpted shell wrapping the machine, relies on a network of precise fasteners to maintain its form, protect the rider, and preserve the airflow that carries the bike forward with less effort. The screws that join front fairings to side panels, that bind a rear cowl to a subframe, or that secure a belly fairing to a chassis—these are not mere afterthoughts; they are integral to the motorcycle’s integrity, both in function and in appearance. When a ride is smooth and the panels sit flush, a rider is enjoying the silent governance of small hardware that makes a much larger difference in how the machine behaves on the road.

To understand the importance of motorcycle fairing screws, one must begin with the function they serve. A fairing is more than a cosmetic shell. It channels air, reduces drag, and shields the rider from wind and debris. The screws that hold the fairing pieces together create the structural backbone of this outer shell. If the panels loosen, gaps open, or misalignment occurs, aerodynamic efficiency suffers. A fluttering edge or a loosened panel can introduce unwanted noise, increase vibration, and even reveal the underlying support structures to the elements. In worst-case scenarios, loose fasteners can lead to panel detachment mid-ride, presenting safety hazards for the rider and nearby traffic. The role of these fasteners extends beyond safety; they influence the bike’s visual cohesion. A fairing that sits misaligned—perhaps with a rail that doesn’t align with the adjacent panel line—diminishes the overall impression of precision engineering and attention to detail that many riders seek when customizing or restoring a machine.

If we look closer, the screws also contribute to rider comfort. A properly tightened panel reduces wind flutter, which in turn minimizes cosmetic wear and the ratcheting of vibration through the body of the bike. On long highway stints, that quiet, consistent ride is partly because the fairings are doing their job and the fasteners are keeping them dead-on with the frame. The feel of the bike in the saddle changes with a fairing that’s staying in place. It is as if the screws create a stable envelope around the rider, one that maintains a predictable wind interaction and reduces the fatigue that can arise from a constantly shifting shell. In practical terms, the right fasteners help preserve the intended aerodynamic profile at speed and during acceleration, which translates to smoother handling and a more confident ride.

The material choices behind these screws also matter. Across the market, the emphasis is typically on durability and resistance to the elements. Stainless steel offers excellent corrosion resistance, a crucial factor when a bike is exposed to rain, road salt, and humid climates. Aluminum screws provide a lighter option, which can be appealing for those chasing weight reduction or for bikes with lighter fairing assemblies. Some riders and builders prefer coated or treated fasteners to match the bike’s color scheme or to blend with the finish of the surrounding panels. The practical implications are straightforward: a screw that resists rust and corrosion will maintain threads and clamping force longer, reducing the need for frequent maintenance and replacement. In harsh weather or on bikes that live in damp environments, the longevity of fasteners becomes a reliability issue as much as a cosmetic one. It is, therefore, reasonable to favor high-quality hardware that can withstand the demands of daily riding and the occasional track day without showing signs of wear that would compromise the fairing’s fit.

The question of universality versus specificity also arises with fairing screws. Some riders opt for universal-fit kits that promise compatibility across a broad range of brands and models. These kits typically include a mix of M5 and M6 fasteners, nuts, and sometimes spacers designed to secure numerous fairing configurations. The appeal is clear: a single purchase can cover multiple bikes, making it easier for enthusiasts who own more than one model or who frequently customize and replace fairing pieces. However, universality has its tradeoffs. While a cross-brand kit can deliver convenience, the exact thread pitch, length, and head style must be compatible with the specific mounting points on a given bike. The wrong length can pinch or fail to reach the captive nuts, and the wrong head type can lead to stripped recesses or the need for adapters. This reinforcement highlights a recurring truth: the best outcomes come from a balance between universal fit for practicality and model-specific selection for precision. When choosing a kit, a rider should consider the number of fasteners required for their particular panels, the environment in which the bike operates, and how the finish of the screws will integrate with the surrounding hardware and plastics.

Quality in fasteners is not merely about material and finish; it is also about manufacturing tolerances and assembly ease. The fit between screw and panel boss is a detail that can determine how pleasant it is to service the bike. A well-cut machine screw with a clean thread that plays nicely with the corresponding nut or threaded insert reduces the risk of cross-threading during installation. It also speeds up routine maintenance, a practical consideration for riders who perform their own tire changes, chain maintenance, or annual fairing removal for inspection. The ease of installation becomes more pronounced when the bike needs a field repair during a long trip or at a roadside service stop. A robust kit, one that provides the right lengths and head profiles, can save time and avoid potential damage to the plastic bosses or the thread inserts embedded in the fairing itself. In this light, the choice of fastener is as much about the ease of maintenance as it is about the immediate task of keeping a panel secure.

As a rider ponders the appropriate hardware, the aesthetic dimension of fasteners often surfaces. An even, flush line of screws along a seam communicates an unbroken design language. The finish on the screw heads—whether black oxide, stainless bright, or an anodized tone that matches the fairing color—can either recede into the background or stand as a deliberate design cue. This is particularly true in bikes where aftermarket or custom fairings replace the factory panels. In those contexts, the hardware can either harmonize with the new look or become a visible, contrasting detail that reads like a signature of personalization. The latter is a deliberate choice and, in many cases, a reflection of the rider’s intent to showcase both performance engineering and individual expression.

The biodiversity of fairing screws also invites a practical, hands-on approach to maintenance. A rider who treats fastener care as part of the routine will find less risk of panel misalignment and more consistency in performance. This starts with keeping a small set of common sizes on hand and knowing where each fastener goes. It means inspecting the panel lines for gaps, listening for a faint rattle when riding over uneven surfaces, and checking the torque on critical anchors after a few hundred miles of riding. Small signs—loose head caps, rust specks on a stainless surface, or a faint squeak when a fairing panel flexes—can be early warnings that something is not quite right. Being proactive about these cues reduces the chance of a more expensive repair later and helps preserve the fairing’s life span.

When we speak about replacement or upgrade, it becomes clear how the ecosystem of fasteners supports customization and repair. For riders who are deep into restoring older bikes or modifying contemporary ones, the availability of replacement screws and related hardware matters as much as the availability of the panels themselves. A well-curated fastener kit allows you to swap a worn set without scavenging through drawers of odds and ends. It also makes it easier to transition from one set of panels to another, aligning with different aesthetic goals or aerodynamic experiments. The ability to source reliable, compatible fasteners in bulk is a practical consideration for workshop efficiency and for ensuring that a bike stays visually cohesive as its components evolve. The maintenance mindset extends to the tiny fasteners that often go unnoticed until a panel does not sit correctly. Regular checks, thoughtful storage of spare screws in labeled organizers, and a habit of wiping threads clean before reassembly all contribute to a lifecycle that keeps a bike looking and performing its best.

The broader engineering context behind fairing screws is one of an integrated system. The fairing itself is designed to work in concert with the frame, mounting brackets, and the riders’ needs. This systemic view helps explain why fasteners are chosen with multiple considerations in mind: mechanical strength, corrosion resistance, ease of replacement, and how they influence the overall thermal and aerodynamic behavior of the machine. In an era where riders often personalize bikes and push for both speed and style, the availability of robust, compatible fasteners becomes a low-risk, high-return aspect of ownership. A reliable kit lets a rider explore variations in panel configurations, experiment with different fairing materials, and evaluate how changes in alignment affect ride quality and performance without compromising safety.

From a practical standpoint, it is wise to consider how fasteners interact with the broader ecosystem of fairing hardware. The screw is part of a family that includes bolts, nuts, washers, and sometimes captive inserts. Each component has its own tolerance band and mounting requirement. A mismatch in any one piece can propagate a cascade of issues, from panel bulges to creeping gaps that collect moisture and grime. This interconnectedness underscores the value of thoughtful selection and careful maintenance. A well-kept fairing system is less prone to panel wobble, less likely to trap debris in seams, and more resistant to the wear that comes from repeated assembly and disassembly. A bike that has its panels removed for service or paint will particularly benefit from a consistent fastener strategy, so that when reassembly is performed, everything lines up as intended and the final appearance is pristine.

In the conversation about universality versus model specificity, it is useful to recall a practical decision rule. If the bike belongs to a family where the fairing design is shared across several models, or if ownership includes multiple motorcycles, a universal-fit kit can be a time-saver and a cost-effective option. Yet for models with unique mounting bosses, recessed holes, or proprietary spacing, a kit that respects the exact bolt length, head profile, and thread pitch becomes indispensable. The right choice balances the flexibility of universal options with the precision of model-specific fixtures, and it is in these margins that responsible maintenance and faithful design alignment reside. The practical choice is to balance convenience with precision, ensuring that the fasteners work with the panels they hold and the holes they engage without forcing misfits that could damage the material or undermine the seal that protects the bike’s inner components.

A note on sourcing and quality control helps frame the decision-making process. While inexpensive bulk options may seem tempting, it is prudent to evaluate the reliability of the fasteners’ dimensions, the quality of the threads, and the finish’s resistance to wear. A slightly more expensive kit that offers consistent tolerances and a corrosion-resistant coating often pays for itself through longer service intervals, reduced maintenance time, and a more cohesive final appearance. The broader point is not to compromise on the basics: the screws must engage cleanly, clamp firmly, and sustain their grip under the conditions of road use. In that sense, fairing screws become not only attachments but guardians of the bike’s structural and aesthetic integrity. They are the quiet sentinels at the edge of the bodywork, ensuring that the shell remains true under wind, heat, rain, and the constant vibrations of the ride.

For riders who want to connect more deeply with their bike’s hardware, there is value in recognizing the relationship between the screws and the panels they secure. You can honor this relationship by choosing fasteners that respect the fineness of the fairing line, that offer reliable performance in a demanding environment, and that simplify the path from removal to reassembly. In the outpouring of aftermarket and customization culture, this is where practicality and artistry converge. A rider who selects high-quality, appropriately sized fasteners can keep their machine looking as pristine as the day it rolled off the showroom floor, while also preserving the fairing’s performance characteristics. And beyond appearance, the consistent alignment of panels speaks to a discipline—careful maintenance and thoughtful replacement—that protects both the rider and the machine on every mile of the road.

In closing the practical arc of this discussion, the enduring takeaway is simple: motorcycle fairing screws might be small, but their impact is outsized. They enable the fairing to perform its essential roles with confidence: maintaining structure, supporting aerodynamics, shielding the rider, and sustaining aesthetics. They stand at the intersection of engineering and craft, where a well-chosen, well-installed fastener becomes a small but decisive factor in the riding experience. A rider who treats these fasteners not as disposable hardware but as integral components of a larger system will enjoy fewer maintenance surprises, longer panel life, and a bike that looks—and feels—right in every wind and every corner of the road.

For those who want to explore how these principles translate into model-specific outcomes and to see how the broader community discusses fairing hardware in their own bikes, there is a relevant resource that touches on brand-oriented panel alignment and the way different fairings integrate with the mounting system. Consider exploring the BMW fairings section for a model-specific perspective and to see practical examples of how fasteners contribute to the overall geometry and fit of a modern sport motorcycle. This reference can be read in conjunction with the general guidance above to appreciate how universal principles of fastener design find concrete expression in individual machines: BMW fairings.

Finally, for a deeper dive into the broader engineering and maintenance considerations that underpin fairing fasteners, the following external resource provides a detailed guide on the importance and treatment of fairing screws. It offers context, case studies, and practical recommendations that complement the discussion above: https://www.motorcyclefairings.com/guide-to-fairing-screws-and-their-importance.

Choosing the Right Fairing Screws: Materials, Head Styles, and Practical Tradeoffs

Materials and head styles that determine how your fairings behave on the road

Fairing screws are small parts with big influence. They secure exterior body panels, protect internal components, and shape aerodynamic flow. The material and head design of each fastener decide whether fairings stay tight, rattle, or corrode after a season. Picking the right combination requires balancing strength, weight, corrosion resistance, serviceability, and look. Below is a continuous, practical examination of the materials and head types you will encounter. It explains why each choice matters and how to use them in real repairs or upgrades.

Stainless steel fasteners are the default for many riders because they resist rust. Grades commonly used offer durable corrosion protection in wet climates and in salted roads. Stainless parts stay presentable without frequent painting or coating. That said, stainless can suffer from galling when two stainless pieces are tightened together. Galling is a form of cold welding that can lock threads and damage heads. To avoid it, use anti-seize compounds on threads and tighten in small increments. If removal tools are scarce, stainless heads that fit conventional tools are a smart choice, since a seized stainless fastener can quickly become an expensive headache.

Aluminum alloys appeal to riders who prioritize weight savings and appearance. Lightweight screws reduce unsprung mass and slightly improve handling feel on performance machines. Aluminum is also easier to anodize, offering colorful, low-profile finishes that match painted panels. The drawback is that aluminum is softer. Over-torquing, cross-threading, or repeated removal can round heads and strip threads in the mating part. For critical structural attachments, avoid plain aluminum fasteners unless they are engineered with hardened inserts or paired with steel nuts. Use them where form matters more than raw clamping force, such as cosmetic panels and low-stress brackets.

Titanium represents the premium end of the spectrum. It provides a superior strength-to-weight ratio and resists corrosion without coatings. Titanium fasteners are popular in racing and high-end street builds where every gram counts. Installation requires attention; titanium can also gall and has different torque characteristics compared to steel. Because the material behaves differently under load, use the correct torque values and consider using washers that prevent embedment. Given the cost, titanium is best reserved for applications where saving weight or preventing galvanic corrosion justifies the expense.

Galvanized steel screws are the budget option. They have a zinc coating that slows corrosion for a while. For basic OEM replacements or temporary repairs, galvanized hardware does the job at low cost. The coating will wear over time, especially with vibration and weather exposure, and once it fails, the underlying steel can rust quickly. Galvanized fasteners also add more mass than aluminum or titanium. Use them where cost trumps longevity, and plan to replace them with better materials when possible.

Plastic and composite fasteners fill an important role for low-load, internal attachments. They are extremely light, inexpensive, and immune to electrical conductivity. However, UV, heat, and aging can make them brittle. Avoid relying on plastic where impact resistance or clamping force matters. They are ideal for inner liners, splash guards, and trim clips that are hidden from the elements.

Beyond material, head design shapes both function and service life. Hex or Allen head screws accept hex keys and offer excellent torque control. Their recessed sockets protect the head and provide a clean, flush fit. Hex heads are common in premium assemblies and make repeated servicing easier with the correct sized key. However, users must carry the correct hex key, and worn keys can damage sockets if misused.

Torx heads have become more common because their star-shaped pattern resists cam-out and transfers torque efficiently. They are forgiving under high torque, and their design reduces the chance of stripping a head during removal. Torx bits are widely available, though less common than Phillips in some toolkits. For fairing applications that require secure clamping with minimal head damage, Torx is an excellent choice.

Phillips heads remain ubiquitous due to the tool’s ubiquity. They are simple to use but designed to slip under high torque. That cam-out characteristic protects delicate components from excessive force but makes Phillips less attractive where firm clamping is necessary. For fairings that need frequent removal, Phillips may be acceptable. For structural brackets or load-bearing points, choose a stronger head type.

Countersunk or flat-head screws create a smooth, aerodynamic surface once installed. These are essential where a flush finish matters. They require precise countersinking during panel preparation to sit properly. Misaligned countersink depth can leave the screw proud or cause the panel to sit unevenly. When aesthetics or airflow is a priority, countersunk heads deliver a factory look, but installation care is critical.

Round-head screws sit above the surface and are easier to remove. They are tolerant of installation angle errors, so they are often used where access is awkward or where the fairing design does not permit countersinking. Round heads do add a small bulge that can alter airflow minimally and alter the visual line of the fairing. Use them where service frequency is high and precision fitting is less important.

Security or tamper-resistant fasteners are favored where theft or unauthorized disassembly is a concern. These fasteners use nonstandard drives to deter casual removal. While they increase security, they complicate legitimate maintenance. If security screws are installed, keep the matching bits in a safe place. If you plan to service the bike yourself often, weigh the inconvenience of special bits against the added protection.

Thread form and length also matter. Coarse threads bite well into plastics and soft metals, while fine threads offer more precise clamping in hard materials. Use self-tapping screws for thin plastic liners and panel fasteners where no nut is present. When fastening to the frame, prefer machine screws with properly matched nuts or threaded inserts to avoid stripped threads and ensure repeatable clamping force.

Washers, nuts, and locking elements complete the fastener system. Nylon-insert locknuts resist vibration-related loosening, but nylon degrades under heat. Lock washers can help, but some designs damage soft mating surfaces. Spring washers provide consistent preload and are easy to use, yet they may require larger head sizes to seat correctly. Consider using threadlocker for permanent or semi-permanent joints, selecting a strength appropriate for future removal.

Galvanic corrosion is a practical concern when combining metals. For example, aluminum parts in contact with steel fasteners in wet environments will corrode faster. To minimize galvanic action, pair similar metals where possible, or use insulating washers and coatings. Silicone or nylon washers can both protect the panel and isolate dissimilar metals. When upgrading from original hardware, note the original’s materials before mixing types.

Installation technique impacts longevity as much as material choice. Apply torque gradually and to recommended specifications. Over-torquing can crack plastics, shear threads, or deform panel edges. Under-torquing leads to vibration, rattles, and eventual loosening. Use calibrated tools when possible, and tighten opposing fasteners in stages to draw panels evenly into place. For stainless and titanium, a light anti-seize helps prevent galling. Avoid excessive thread lubrication on plated fasteners where torque tables assume dry threads.

Maintenance makes the difference between a durable installation and frequent replacements. Inspect fasteners annually. Look for head rounding, thread corrosion, and looseness. Replace any fastener that shows damage. Keep a small supply kit matching your bike’s common sizes and head types so you can swap out stripped or missing screws quickly. For bikes ridden in harsh climates, choose stainless or better and inspect more often.

Cosmetics are also valid considerations. Anodized aluminum or colored titanium can match or accent fairing colors. For show bikes, aesthetic choices matter. For daily riders, prioritize corrosion resistance and ease of service. When choosing colored hardware, verify whether the finish will chip or fade in UV exposure and high heat. A rust-free stainless look often gives the best compromise between function and appearance for daily use.

Different motorcycles call for different priorities. Sport bikes and race machines often favor weight and torque efficiency, so aluminum or titanium with Torx or hex heads make sense. Touring bikes face weather and long mileage, so stainless steel with appropriate locking features is ideal. If you maintain your own panels frequently, favor head types that match your toolkit and avoid specialty security heads unless required.

When dealing with replacements, fitness is key. Use the correct thread pitch and diameter to avoid cross-threading. Where original captive nuts exist, use matching fasteners rather than forcing a different size. If a fairing panel has embedded metal inserts, ensure any replacement screw seats correctly and doesn’t deform the insert or strip threads.

For sportbike owners who swap or replace full bodywork often, matching the fairing’s attachment geometry is crucial. That includes screw length, head style, and spacing. Some riders prefer a metric fastener kit with a range of sizes for convenience. A well-organized kit speeds repairs and reduces the temptation to use the wrong part under time pressure.

Finally, safety is paramount. A loose fairing can obstruct wheels, snag on other components, or hide a developing structural issue. Use the most secure, corrosion-resistant fasteners you can afford for any load-bearing connections. For decorative or low-load points, balance economy with functionality. Keep the right tools on hand, protect dissimilar metal interfaces, and document torque values for future reference.

For example, when fitting aftermarket bodywork on a performance chassis, match lightweight aluminum screws to non-structural panels, and use stainless or titanium for any panels that interface with structural mounts. In daily riding conditions with variable weather, prefer stainless fasteners throughout and use locking nuts or threadlocker where vibration is likely. For sport touring or frequent highway use, stainless machine screws with properly torqued locknuts reduce maintenance while resisting corrosion.

The choice of fairing screws is rarely a single right answer. It is a series of compromises tailored to riding style, climate, and maintenance habits. Prioritize corrosion resistance for wet climates, weight savings for performance builds, and head styles that match your service tools. Use insulating elements to prevent galvanic corrosion and apply correct torque to avoid damage. With the right material and head design, fairings will remain secure, clean, and functional for years.

To see how different fairing styles use varied attachment points and fastener layouts, explore a selection of model-specific fairing offerings, such as the fairings for GSX-R available from a specialist catalog. For technical background on fastener materials, properties, and how galling and corrosion affect performance, refer to the detailed materials guide from an industrial fastener resource: https://www.misumiusa.com/en-us/technical-resources/fasteners/metal-fasteners/materials/.

Where Fasteners Meet Fairings: Sourcing, Pricing, and the True Cost of Motorcycle Fairing Screws

Balancing Quality, Cost, and Supply

Motorcycle fairing screws are small parts with outsized importance. They hold panels in place, maintain aerodynamic lines, and keep wiring and components secure. Their selection and procurement touch engineering, cost management, and rider safety. Sourcing these fasteners requires an understanding of the variables that drive price and performance, and of practical strategies that minimize risk while delivering consistent quality.

Material choice drives the conversation. Stainless steel remains common because of its corrosion resistance and predictable strength. Higher-end applications sometimes demand specialty alloys or treatments that offer better strength-to-weight ratios and superior resistance to environmental stressors. These options increase material costs substantially. Nickel and chromium content in stainless steel, for example, fluctuate with global commodity markets. Those fluctuations alter raw material costs first, and final screw prices later. A buyer who ignores material volatility will be surprised by sudden price shifts during procurement cycles.

Manufacturing precision is a second major cost driver. Fairing screws often require tight tolerances so panels fit flush and vibrations do not loosen fasteners. Achieving such precision calls for CNC machining, thread rolling, or secondary operations like tapping and chamfering. Custom head profiles, captive washers, or integrated sealing features add complexity. Each additional process step raises tooling and labor costs. Tooling amortization matters: low-volume custom runs suffer higher per-piece tooling expenses than large production batches.

Surface finish and corrosion protection further influence price. Anodizing, plating, or specialized coatings lengthen production workflows and increase material inputs. The choice between a simple passivated finish and a marine-grade coating can change unit costs by a large percentage. Environmental standards and regulations around chemical treatments also affect available finishing options and compliance costs for manufacturers.

Market dynamics determine how those material and manufacturing costs end up in a buyer’s invoice. High demand for particular motorcycle models drives scarcity or premium pricing for compatible fasteners. Conversely, markets with many suppliers tend to compress margins. Volume ordering and long-term agreements are effective ways to negotiate better unit costs when market competition is healthy. Anticipating demand cycles for motorcycle models and aftermarket trends helps buyers time purchases to leverage softer pricing periods.

Global supply chain factors complicate procurement planning. Shipping rates, port congestion, and customs duties add layers of cost beyond the factory price. Importers must account for lead times that span raw material procurement, production scheduling, finishing, and transit. Unexpected spikes in shipping costs can make inexpensive per-piece prices misleading. That is why an apples-to-apples comparison of quotations requires a landed-cost analysis. Landed cost includes the manufacturing price plus freight, insurance, duties, and local handling fees.

For many buyers, regional sourcing hubs provide cost advantages. Certain provinces and regions have concentrated expertise and efficient supply chains for automotive components. Working with manufacturers in such areas reduces lead time and offers multiple vetted suppliers to compare. Yet regional concentration raises its own risks: a local production disruption can ripple through many buyers simultaneously. Diversifying suppliers across regions can reduce this vulnerability while still capturing regional cost benefits.

Sourcing strategies must be rigorous. Start by defining the technical requirements precisely: thread diameter, pitch, head type, length, material grade, and finish. Provide those specifications to suppliers and request compliance documentation. Minimum acceptable standards should include material certificates, mechanical property data, and testing procedures. For critical components, request samples and perform destructive and non-destructive testing where appropriate. Simple checks like torque-to-yield, salt spray tests, and visual finish inspections reveal much about production consistency.

Supplier vetting is more than a checkbox exercise. Look for manufacturers with consistent quality records and traceable processes. Audit certificates show capability, but direct communication matters most. Ask how they manage tooling maintenance, quality control, and non-conformance. A transparent supplier will share inspection reports and welcome specific test requests. For buyers who prefer reduced oversight, a third-party inspection during production and at shipment provides additional assurance.

Volume matters when negotiating price. Many suppliers scale cost down for larger orders because fixed costs are spread across more units. However, oversized inventory can tie up capital and hide quality issues. A balanced approach uses tiered ordering: place an initial medium-volume order to validate supplier performance, then scale up with repeat orders under negotiated terms. Consider blanket purchase agreements that lock in prices for scheduled releases. These agreements combine predictability for buyers with stable demand for suppliers.

For buyers with limited storage capacity or variable demand, just-in-time ordering can appear attractive. But motorcycle fairing screws are vulnerable in tight supply scenarios. Even minor delays in receiving screws can halt vehicle assembly or delay a repair job. To mitigate that risk, maintain a minimum safety stock calibrated to lead time volatility and criticality of the part. Safety stock calculations should factor in supplier lead time variability, transit risk, and the consequence of stockouts.

Cost analysis is not only about unit price. Total cost of ownership captures purchase price, transport, inspection, replacement rate, warranty claims, and the labor cost of installation and rework. A cheaper screw that corrodes or strips quickly raises lifetime costs. High-quality fasteners may cost more upfront but reduce warranty claims and maintenance time. Quantify labor costs associated with fastener failure. Even low-cost screws can become expensive when they necessitate service downtime or parts replacement.

When evaluating quotations, convert all prices to a consistent basis. Use per-piece landed cost at meaningful volumes. Ask suppliers to detail pricing tiers, tooling charges, sample costs, and warranty terms. Some suppliers provide kits of assorted sizes to match diverse models. Kits can simplify logistics but may include unnecessary inventory for specific needs. Custom kits sized to a fleet or a production run often achieve better value by aligning exactly with usage patterns.

Negotiation levers include lead time flexibility, payment terms, and bundled order opportunities. Suppliers often value predictable cash flow and purchase schedules as much as price. Offering longer-term contracts or faster payments in exchange for better unit pricing can be beneficial. Additionally, consider partnering on incremental design changes that lower production complexity. A slight standardization of head styles or thread types across a range of models reduces tooling changes and lowers production costs.

Compliance and traceability are non-negotiable for many buyers. For aftermarket parts that touch safety-critical functions, traceable batches and material documentation are essential. Establish lot tracking tied to inspection records. If recalls occur, traceability limits exposure and supports targeted corrective actions. Where legal frameworks specify product standards, ensure suppliers can provide compliance certificates.

The risk of counterfeit or low-quality fasteners persists in global markets. Authenticate suppliers through references and trade credentials. Avoid purchasing from vendors that cannot substantiate their manufacturing processes. If prices are dramatically lower than market rates, treat that as a red flag. Low prices sometimes reflect shortcuts in material composition, heat treatment, or surface finishing. These shortcuts often reveal themselves in field failures.

Packaging and marking matter too. Fairing screws often come in mixed kits or small bags. Properly labeled packaging reduces assembly errors and protects threads from damage. Consider specifying corrosion-inhibiting packaging for long transit times or humid environments. Clear labeling that indicates part numbers, material grades, batch numbers, and production dates simplifies inventory control and warranty management.

Logistics strategies can unlock savings. Consolidated shipping reduces per-shipment overhead. Combining orders across model lines or coordinating shipments with other parts lowers freight costs. However, consolidation must respect lead time priorities. Using freight forwarders with expertise in automotive components can also speed customs clearance and reduce delays.

Local warehousing or drop-shipping arrangements offer different trade-offs. Warehousing provides immediate access to parts but increases holding costs. Drop-shipping reduces inventory holding but lengthens lead time to the final customer. For high-turnover fasteners, a hybrid approach often works best: keep a core inventory centrally and use drop-shipping for less frequent or bulky items.

Cost management practices should include periodic supplier re-evaluation. Market conditions change; a supplier that was competitive two years ago may no longer offer the best value. Regularly solicit competitive bids and benchmark prices. Use total cost metrics rather than focusing solely on per-piece price. When re-evaluating, consider switching costs, validation overhead, and the benefits of supplier stability.

Small modifications can yield large savings over time. For instance, standardizing a single thread size across multiple panels or models simplifies tooling and lowers per-piece costs. Consolidating head types where functional requirements allow reduces complexity in assembly. Such design decisions should balance aesthetic and functional needs with long-term procurement benefits.

For fleets and repair shops, knowledge of model-specific fastener requirements is vital. Many motorcycle models share fastener specifications, which allows bulk buying across model lines. For buyers who source parts for a range of motorcycles, grouping purchases according to shared specifications simplifies inventory and reduces per-piece costs. For readers looking at model-specific fairings, review compatible fastener sets for the models you service, such as the collection for Kawasaki Ninja fairings.

Finally, use reliable industry data to inform decisions. Public datasets and market analyses provide insight into raw material trends, regional capacity, and shipping forecasts. These resources help anticipate cost movements and prepare procurement strategies accordingly. For detailed sourcing landscape and price variation data, consult comprehensive industry resources such as CN Open Data: https://www.cnopendata.com/.

Final thoughts

Motorcycle fairing screws are more than just simple fasteners; they are indispensable components that contribute to a motorcycle’s overall integrity and performance. Understanding their importance, exploring the various types available, and implementing effective sourcing strategies can greatly enhance your business’s offerings. By investing in high-quality fasteners, you not only ensure safety and performance but also build customer loyalty and trust in your brand. Staying informed and adaptable in this niche sector will position your business for success in the competitive motorcycle market.