As a business owner in the motorcycle industry, it’s crucial to understand the importance of motorcycle fairing protectors. These accessories serve as a first line of defense against damage from impacts and debris, increasingly vital for maintaining the motorcycle’s aesthetics and integrity. In this guide, we’ll delve into the construction and materials of these protectors, highlighting the specifics that drive quality and effectiveness. Additionally, we will explore installation processes and compatibility with different motorcycle models, ensuring that you can choose the right solution for your clients. Finally, we’ll touch upon the cost benefits and the aesthetic value of using fairing protectors, underlining their necessity for any motorcycle enthusiast’s protection strategy.

How Fairing Protectors Are Built: Materials, Design and Real-World Performance

How fairing protectors are built: materials, design and real-world performance

A fairing protector’s value starts with what it’s made of and how it’s made. Riders choose protectors to block scrapes, deflect road debris, and limit damage during low-speed drops. The materials, the structural design, and the way a protector mounts to the bike determine how well it performs. This chapter follows the lifecycle of a protector from raw material to installed component. It explains why certain choices are common, and how those choices change behavior on the road.

Most protectors balance three goals: absorb or deflect energy, add as little weight as possible, and keep the bike looking integrated. The market achieves these goals by using a small range of proven materials, and by combining them in specific ways. Aluminum and carbon fiber are the two headline materials. High-impact thermoplastics, urethanes, and layered composites fill the rest of the field. Each option behaves differently during impact, over time, and under heat.

Aluminum is widely used because it offers predictable strength and ductility. When engineered into slider cores or reinforcement plates, aluminum resists deformation and spreads impact forces across a wider area of the fairing. That prevents localized punctures or crack initiation in the plastic bodywork. Designers commonly machine or cast aluminum parts and then anodize them for corrosion resistance and color. An anodized finish also adds a protective layer that resists abrasion. Aluminum cores are often paired with sacrificial outer surfaces, so the aluminum takes the structural load while the outer shell bears scrapes. This layered approach allows the protector to be replaced at a fraction of the cost of the fairing.

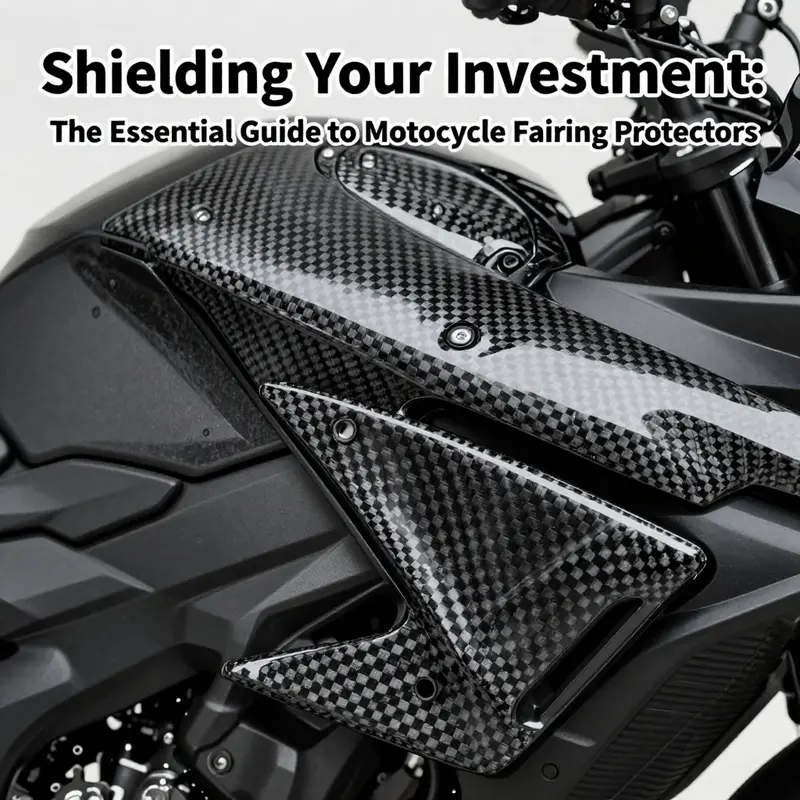

Carbon fiber occupies the other end of the spectrum. It offers a superb strength-to-weight ratio and excellent stiffness. Carbon protector shells are typically made from woven fibers set in a resin matrix. When molded correctly, the resulting part resists abrasion and can redirect impact energy away from sensitive areas. Carbon performs best when the goal is to minimize added mass while keeping high resistance to deformation. That is why many performance-focused protectors use carbon or carbon-reinforced composites.

Carbon also brings an aesthetic benefit. The textured weave and glossy finish match premium components on many bikes. But carbon is not invulnerable. It tends to be more brittle than aluminum, which means it can crack under very sharp impacts. Designers mitigate this by controlling fiber orientation, increasing resin toughness, or combining carbon with a more ductile backing material.

High-impact engineered plastics are the most ubiquitous protectors for everyday use. Materials such as thermoplastic polyurethane (TPU), polycarbonate, and reinforced nylon absorb and dissipate impact energy without significant permanent deformation. These plastics flex on impact, reducing the force transmitted to the fairing. Because plastics are lighter and cheaper to shape, they are often used for molded covers that follow the contours of a bike’s bodywork.

Thermoplastics also tolerate minor surface damage well. Scratches can often be buffed out or hidden beneath a thin film. Some systems use self-adhesive polymer films applied directly to painted surfaces. These films protect against stone chips and small abrasions, and they act as a sacrificial skin. When paired with more rigid base protectors, they form a layered defense that addresses a wide variety of threats.

Beyond the core material, many protectors incorporate thermal or adhesive layers. Heat shielding becomes critical near exhaust headers and engine casings. Thin aluminum-backed, aluminized insulators are a common addition. They reflect radiant heat and protect thermally sensitive plastics and paints. When a protector sits between an exhaust and a fairing panel, that thermal layer doubles as a mechanical buffer. The aluminum layer spreads heat, while the adhesive keeps the protector in place without transferring stress to the fairing.

Mounting strategy is another crucial design dimension. A protector must attach securely while allowing predictable energy transfer during impact. Bolted mounts that anchor to the frame or engine provide strong, repeatable attachment points. When designed correctly, bolts route load paths into robust structures, reducing point stresses in the fairing. Sliding or sacrificial elements can be built into the mount to manage the worst-case energy. For example, a replaceable bobbin that shears or slides will dissipate energy and protect the fairing bolting points.

Adhesive-mounted protectors use high-performance tapes or molding adhesives. These are ideal for contoured panels and for protecting paint from chafing. Adhesive systems distribute loads across a wider area than a single bolt, so they reduce the risk of concentrated failure. However, adhesive joints demand careful surface preparation and will age under UV and heat exposure. When adhesives fail, the protector often peels away cleanly, leaving the fairing intact. That failure mode is preferable to catastrophic cracking.

Designers also consider how protectors interact with aerodynamics and ergonomics. A protector that protrudes sharply can catch on pavement and cause an abrupt transfer of forces. Smooth, tapered profiles reduce snag risk. Likewise, weight distributions matter for handling. A bulky protector near the fork or swingarm can change steering feel. High-performance designs therefore prioritize low mass and smooth integration.

Finishes and coatings add a practical layer to any protector. Anodizing, powder coat, and UV-stable paints enhance corrosion resistance. Clear coats over carbon protectors prevent the glossy weave from yellowing under sunlight. Overlays and textured films improve scratch resistance. Some finishes are formulated to abrade away under repeated contact, intentionally sacrificial so they can be refreshed without replacing the entire protector.

Longevity depends on material selection, environmental exposure, and maintenance. Aluminum cores resist long-term deformation but can corrode if coatings fail. Carbon resists corrosion but may delaminate if moisture reaches the resin interface. Thermoplastics withstand moisture well but will slowly degrade under intense UV exposure. Routine cleaning and inspection extend service life. Small issues like loose fasteners or chipped adhesives are easy to fix before they cause larger problems.

Cost versus benefit is a constant trade-off. Aluminum and carbon components command higher prices due to material and manufacturing costs. Plastic options are more affordable, and they offer broad protection for most street riders. The right choice hinges on riding style. Commuters who face frequent stone chips and gutter debris often select adhesive films and engineered plastics. Track and performance riders favor low-mass carbon or robust aluminum cores anchored to the frame.

Custom fitment is a practical advantage for model-specific protectors. Riders get better coverage when protectors are tailored to a bike’s curves and bolt locations. Many manufacturers design kits that match a given fairing geometry, simplifying installation and improving aesthetics. For those who appreciate brand-specific solutions, categories of fairings and protectors exist for major marques. Riders interested in Yamaha model options can explore available covers and fairing kits at Yamaha fairings.

Manufacturing methods influence cost and performance as well. Carbon parts typically come from hand-layup or vacuum-bagged molds. These methods control fiber alignment and resin content, ensuring consistent strength. Thermoplastic pieces are usually injection molded. Injection molding allows tight tolerances and repeatable shapes at low per-unit cost. Aluminum parts are either CNC-machined, die-cast, or extruded and then machined. Each process has trade-offs in strength, surface finish, and unit cost.

Hybrid approaches combine materials to play to each material’s strengths. A common pattern uses an aluminum internal skeleton with an outer thermoplastic shell. The aluminum skeleton takes the peak loads, while the outer shell absorbs abrasion and hides the structural core. Another hybrid uses a carbon outer skin with an energy-absorbing foam core. The foam crushes under severe impact, dissipating energy while the carbon shell remains mostly intact.

Testing and validation matters. Good protectors undergo impact tests, UV exposure tests, and thermal cycling. Impact tests measure how much energy reaches the fairing under specified drops or slides. Thermal testing validates adhesive integrity and material stability near heat sources. UV testing predicts how coatings and polymers will age in sunlight. Lab testing doesn’t guarantee real-world performance, but it narrows the gap between expected and actual behavior.

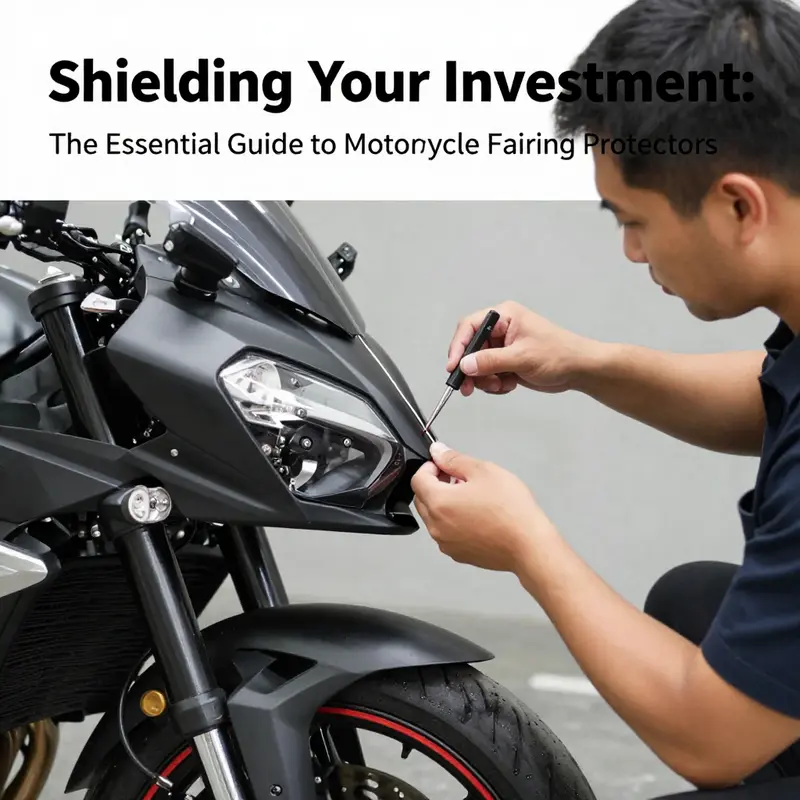

Installation considerations affect function. A protector mounted too loosely can pivot under load and cause unexpected contact points. Over-tightening fasteners can stress mounting bosses and create cracks. Installers should follow torque specifications and use thread-lock where required. For adhesive protectors, surface cleaning with a solvent removes oils and waxes, ensuring an even bond. If the installation crosses paint seams or joins panels, alignment is critical. Small misalignments can amplify forces during an impact.

Maintenance and repair are straightforward for most protector designs. Replaceable bobbins, wear plates, or adhesive pads keep repair simple. Owners should inspect fasteners periodically and clean protectors with appropriate products. Abraded adhesives can be refreshed with replacement tape. Small cracks in carbon parts can sometimes be stabilized with epoxy, but visible structural damage warrants component replacement.

Choosing the right protector ultimately combines context and priorities. Weigh the importance of weight, cost, longevity, and appearance. Decide whether the protector should be sacrificial or structural. Consider where on the motorcycle protection matters most. Side fairings and belly pans face different hazards than front fenders. Assess local riding conditions—gravel roads and urban commutes create different threat profiles.

A well-made protector extends the life of bodywork and preserves resale value. It lowers the risk of expensive repairs and keeps a bike visually appealing. Understanding how materials behave, how mounts transfer load, and what finishes protect against the elements helps riders make informed decisions. The best protector fits the bike, matches the rider’s priorities, and integrates with the motorcycle’s existing hardware.

Practical selection tips: choose rigid cores where structural loads are likely, and flexible films where stone chips are the main concern. Favor replaceable wear parts for high-contact zones. When performance matters, prioritize low mass and high stiffness. For everyday riding, a layered approach mixes an adhesive film with molded plastic protectors anchored at strategic points.

The marriage of material science and clever engineering produces protectors that work. Whether the goal is to hide cosmetic marks or to stop a crash from wrecking a fairing, the right construction makes the difference. Riders who understand the trade-offs can choose protectors that fit their bikes and their style. That knowledge turns a simple accessory into a thoughtful investment in the motorcycle’s longevity and appearance.

Guarded Curves: Installation, Compatibility, and the Subtle Value of Motorcycle Fairing Protectors

The motorcycle fairing is more than a silhouette in the wind; it is a shield that protects the bike’s most visible and costly skin while shaping the rider’s experience. When riders talk about protecting the fairing, they are really talking about keeping the bike’s lines intact, preserving resale value, and reducing the constant drama of minor misadventures that accumulate on urban streets and rustic back roads alike. A well-chosen fairing protector does not simply layer on a layer of plastic or carbon fiber. It becomes a quiet partner for the ride, absorbing the sting of debris and the occasional brush with a curb, a guardrail, or a stray stone kicked up by a tired tire in slow traffic. The result is not only a cleaner aesthetic but a more durable foundation for the bike’s bodywork, one that preserves the integrity of the panels beneath and reduces the cascade of repairs that can follow an otherwise small accident or scrape. In this way, protectors are both practical and prudent, a small investment with the potential to save much larger sums spent on repainting, panel replacement, or air-pocket repairs that can ripple through a bike’s value over years of ownership.

Material choice matters as much as the decision to install a protector at all. The common options—carbon fiber and high-impact plastics—each bring a distinct set of strengths to the table. Carbon fiber offers an exceptional balance of stiffness and lightness. Its weave and resin system create a panel that resists deforming under minor impacts and retains a sharp, factory-like appearance that can harmonize with the bike’s aesthetics. The trade-off, of course, is cost; carbon fiber protectors tend to demand a higher price, not just at purchase but also potentially at installation if perfect alignment is pursued. On the other hand, high-impact plastics provide robust protection, broad resilience against chips and scuffs, and a broader range of price points. They are easier to mold or trim to fit, making them attractive for riders who value a reliable shield without getting lost in the complexities of weight and performance. For riders who spend a lot of time on rough roads, country lanes, or urban corridors where the chance of a stray chunk of gravel is nontrivial, these plastics can deliver a pragmatic, value-conscious protection strategy.

A protector’s purpose reaches beyond mere blunt-force defense. It helps maintain the fairing’s original contours, which is key for both aerodynamics and aesthetics. A well-fitted protector preserves the intended airflow around the fairing, reducing turbulence that could otherwise feed into the engine bay or rider’s wind stream. Even when the protector is only a partial shield—say, a winglet or a narrow strip along the lower edge—it can contribute to a smoother silhouette and a more efficient ride, especially at higher speeds or during long, steady-state cruising. The effectiveness of any protector, though, rests on precise compatibility with the bike. That truth sits at the core of the decision-making process: fitment matters as much as the material. If a protector does not align with the fairing’s mounting points, curves, and attachment points, it can introduce new risks: vibrations, rattles, or an imperfect seal that allows moisture and road grime to find its way behind the panel. The compatibility conversation is not a seasonal afterthought; it is a prerequisite, a careful check that ensures the protector behaves as designed rather than as a cosmetic add-on that compromises safety and function.

To determine whether a given protector will work for a specific motorcycle, riders are advised to consult the manufacturer’s compatibility list. That directive might seem obvious, yet it is routinely ignored in the rush to shield a bike quickly. Even minor differences in frame geometry, fairing contours, or mounting brackets between model years can relegate a seemingly identical protector to an ill fit. This is especially true for two common scenarios: when a bike has undergone a previous aftermarket modification and when the model year introduces a revised fairing shape. In both cases, a one-size-fits-all approach becomes a liability rather than a solution. It is not just a matter of volume or capacity; it is about ensuring that the protector closes cleanly against the fairing surface, without gaps that could trap moisture or cause premature wear, and that the mounting points line up with the bike’s original brackets, screws, or bonding surfaces. The caution around compatibility—“reference lists are guidance, verify fit before purchase”—is not hyperbole. It is a practical safeguard against the disappointment of misfit parts that look right on the box yet refuse to align with the bike in the garage.

When the right protector is identified, installation becomes the next deciding moment. The installation landscape is varied, reflecting the diversity of designs that populate the market: some protectors secure at factory-style mounting points, others rely on adhesive pads, and many use a hybrid approach featuring a combination of small bolts and high-bond tapes. The installation script, if one could call it that, emphasizes a careful, methodical approach. Begin with a clean application area. Dirt and oil can undermine adhesive bonds and create micro-scratches that mar the fairing’s surface. The cleaner the surface, the more secure the bond or fastener will be, and the longer the protector will remain in service without shifting or loosening. The next step is to follow the manufacturer’s instructions with precision. The margin for error is small: over-tighten a fastener and you risk cracking the fairing; under-tighten and you invite rattles and misalignment. In some designs, modest modifications may be required. Those adjustments should be approached with caution and a respect for the original fairing finish. It is easy to underestimate how even a small trimming line, a careful scuff mark, or a slight reorientation of a mounting tab can alter the protector’s alignment, the edge clearance around nearby components, and the way the wind flows along the surface. The best practice is to treat installation as a measured, deliberate process, pausing to check alignment after each step and ensuring that the final seating feels firm, even, and flush against the fairing.

The conversation about installation does not exist in a vacuum; it is part of a broader continuum that considers the rider’s needs and riding style. For daily commuters negotiating pothole-riddled streets, a protector’s primary virtue may be its durability and cost effectiveness, with a practical emphasis on resisting chips and scuffs that accumulate from routine urban debris. For sport-touring riders exploring winding routes at speed, the emphasis might tilt toward maintaining aerodynamic efficiency and minimizing bodywork damage in high-speed, high-load conditions. In such contexts, the geometry of the protector—the way it shares the fairing’s burden without compromising balance or handling—becomes almost as important as the choice of material. A protector that is too aggressive in its extension or too stiff in its mounting may alter the feeling of feedback through the handlebars or subtly affect the steering feel in certain maneuvering scenarios. Conversely, a well-integrated protector that nudges the surface and blends with the fairing can enhance the rider’s confidence, providing a sense that the bike remains faithful to its original design even when a little extra protection is required.

The discussion would be incomplete without acknowledging the broader ecosystem of fairing protection, including the idea of expanding protection through larger fairing systems. In some cases, riders seek more comprehensive solutions—half or full fairings—that deliver a broader shield while offering different degrees of access to engine components and maintenance points. These larger systems introduce new layers of complexity in terms of installation, alignment, and balance, and they demand careful consideration of airflow, weight distribution, and the potential need for professional alignment. For many riders, a staged approach makes the most sense: start with targeted protectors for high-risk areas, assess fit and ride feel, and then decide whether more extensive protective upgrades are warranted. This measured path respects both the technical constraints of the motorcycle and the rider’s longer-term goals for performance and aesthetics.

In the same breath, it is useful to recognize the practical economics of protectors. The initial purchase may pale in comparison to the potential repair costs of fairing damage, especially when the damage threatens more than cosmetic finish. The logic is straightforward: a small, well-placed shield today can prevent a larger panel replacement tomorrow, which is not merely a matter of expense but of time and downtime. For riders who own multiple bikes or who switch models frequently, there is another benefit: the availability of protectors in modular, component-based formats allows the rider to protect specific areas with targeted pieces rather than investing in a full cover. The financial and personal convenience are real and often decisive when weighing the decision to install protectors.

For riders who want a practical, model-specific starting point, there is value in exploring model-focused catalogs that curate fitment and geometry data. On the platform hosting a range of fairings across brands, the Honda fairings page serves as a useful example. It illustrates how a model-specific catalog can organize compatible panels and mounting options in a way that respects the bike’s design philosophy while enabling protective upgrades. The link below offers a direct path to those model-specific options and can help a rider gauge whether a given protector is likely to meet their needs before committing to a purchase. Honda fairings

The overarching theme here is compatibility as a practical discipline. Before any protector leaves the garage, the rider should confirm that the chosen solution aligns with the bike’s frame geometry, fairing contours, and mounting points. If a safe, stable fit is achieved, the protection benefits can be realized without compromising the bike’s aesthetics or performance. The right protector becomes a micro-portfolio of choices that balance materials, compatibility, installation approach, and intended riding context. Carbon fiber may achieve the ultimate in lightness and stiffness for some, while durable plastics may offer the flexibility and resilience that suits another rider’s daily grind. The best decision, paradoxically, is not just about choosing one material or one design but about understanding how those choices interact with how a rider uses the bike, where the bike goes, and how it is maintained over time.

A final note on the reliability of information: the riding community benefits most when riders approach protection as an informed, iterative process. Use compatibility guides as a starting point, treat installation as a careful craft, and remain attentive to the way a protector behaves in real-world riding. If a protective piece is not perfectly matched to your bike, do not force it into place. Seek alternatives that fit or consider professional installation services that can achieve a precise alignment without compromising the fairing’s finish or structural integrity. This measured approach preserves the bike’s original design while enabling riders to enjoy the safety and aesthetic value that a good protector provides. For deeper, up-to-date guidance on choosing the right fairing, see a practical industry overview that highlights selection criteria tailored to different riding styles and motorcycle models, and keep in mind that compatibility information is only as good as the latest model-year revisions.

External reference for further reading: https://www.motorcycle.com/motorcycle-fairing-guide/

In closing, the journey of choosing and installing a fairing protector is less about chasing a single perfect piece and more about building a coherent protection strategy. It is about knowing your bike, understanding the contours that define its on-road personality, and selecting protectors that respect that personality while offering a durable shield against the elements. The most satisfying outcomes come when fit, form, and function align—so that every ride feels like a continuation of the bike’s intended design, only with an extra layer of resilience against the world outside the pavement. For riders who want to explore further model-specific options, a visit to the Honda fairings catalog or similar model-focused collections can illuminate the most compatible paths, helping to ensure a seamless, confident alignment between protector and fairing and turning what could be a routine upgrade into a lasting enhancement of the motorcycle’s character and durability.

null

null

Final thoughts

In conclusion, motorcycle fairing protectors are not just optional accessories; they are essential for safeguarding the investment that motorcycle owners make in their vehicles. Understanding how they are constructed, installed, and the financial advantages they offer will enable you as a business owner to provide informed recommendations and ultimately better service to your customers. By recognizing their contribution to both safety and aesthetics, you can enhance the overall value you offer in the motorcycle market.