Motorcycle fairing mounts are crucial for ensuring the stability and aesthetic appeal of a motorcycle’s bodywork. These components play a vital role in enhancing a motorcycle’s performance by keeping the fairing securely attached to the frame while also providing the necessary aerodynamic efficiency. Understanding the various types of motorcycle fairing mounts, their performance characteristics, and proper installation techniques is essential for business owners in the motorcycle industry. This knowledge can enhance customer satisfaction by helping riders choose the appropriate mounts for their specific needs. In the following chapters, we will delve into the diverse types of fairing mounts available, examine their performance and functionality, and explore installation compatibility, ensuring a comprehensive understanding of this key motorcycle component.

Anchoring the Front: A Deep Dive into Motorcycle Fairing Mounts and Their Role in Performance and Style

Anchoring the Front: A Deep Dive into Motorcycle Fairing Mounts and Their Role in Performance and Style

Fairings shape a motorcycle’s silhouette and its aerodynamic behavior, but the unseen engineering that keeps that silhouette steady at speed is the family of fairing mounts. These components do more than simply hold plastic to metal; they anchor the front end to the bike’s frame, govern how air flows over the surface, and determine how mirrors, lights, and vents align with the rider’s line of sight and riding posture. The best mounts do not merely survive vibrations; they tame them, translating the engine’s torque and the road’s irregularities into smooth, predictable behavior that riders can feel in the palms, shoulders, and chest. The result is not just a cleaner look or a quieter ride, but a front end that remains faithful to the intended aerodynamic profile, even as speed climbs and the pavement becomes rough.

To understand why fairing mounts matter so much, it helps to imagine the fairing as a delicate skin stretched over a rigid frame. The skin alone would flutter, distort, and eventually fail under gusts, engine heat, and road shocks. The mounts are the skeleton that anchors that skin while preserving its shape and function. In practice, the mount system must resist three intertwined demands: mechanical stiffness to keep the fairing from shifting under load; vibration isolation so the fairing does not act like a drum on rough pavement; and precise alignment to preserve clarity of vision for the rider and to maintain the designed airflow. Each of these demands influences the choice of mount type, the materials used, and the mounting geometry.

There are three broad families of fairing mounts that riders and builders commonly encounter: universal mounts, OEM mounts, and custom-fit mounts. Universal mounts are designed to accommodate a wide range of frame geometries. They are versatile and usually more affordable, making them a practical option for aftermarket fairings or for riders who swap skins frequently. The trade-off, however, is fit precision. Because these mounts must span multiple designs, their clamp positions and bracket interfaces can be somewhat generic. This can translate into minor misalignments or a little extra vibration transfer if the mounting points do not align adjacently with the frame’s natural stiffness paths. Yet for many riders, the flexibility of universal solutions is a compelling advantage. They enable a rider to experiment with different fairing shapes, to retrofit a sportbike with a street-ready body, or to outfit an older machine with modern styling without a complete frame rethink.

OEM mounts offer a different proposition. Engineered by the motorcycle’s original manufacturer, these mounts are created to match precise mounting points, maintain designed geometry, and integrate with the bike’s electrical, fuel, and cooling pathways. An OEM mount provides a high level of certainty in fit and finish; the fasteners, bracket radii, and mounting flanges are tuned to the bike’s geometry and the fairing’s geometry to achieve optimal alignment with the windscreen, headlamp, and side panels. For riders who prize factory-grade compatibility and the assurance that replacement parts will align with the exact tolerances the machine was built around, OEM mounts are a natural choice. The downside can be limited compatibility with aftermarket components or with non-standard fairing shapes, which may require adapters or bespoke fabrication to achieve a seamless look and feel.

Custom-fit mounts sit somewhere between the two. They are tailored either to a specific motorcycle model or to a rider’s personal preferences, and they frequently incorporate advanced materials to optimize strength and weight. In high-end or specialty builds, a custom-fit system may deploy aluminum alloys with precise wall thicknesses, or even carbon fiber elements, to stretch stiffness without adding bulk. The result is a mounting interface that can accommodate aggressive airflow objectives, complex mirror brackets, or integrated lighting while maintaining a clean, cohesive front end. Custom-fit mounts require more careful planning, including detailed measurement of frame geometry, an understanding of load paths during acceleration and braking, and often a willingness to commission fabrication or a workshop to produce the finished product. They reward the rider who seeks maximum control over front-end dynamics and aesthetic, with the understanding that the process may demand more time and investment.

In this spectrum, the choice of mount type is not merely about rigidity or price. It shapes how a rider perceives the bike as a system. A stiff, well-tuned mount can translate into crisp steering response, reduced flutter at high speed, and a more precise alignment of the mirrors and lights. A mount that isolates vibration can make hours in the saddle feel less fatiguing, which matters on touring days and long track sessions alike. Equally important is the mount’s contribution to the bike’s aesthetic and the way the front ends acknowledge the rider’s intent. A clean interface between fairing and frame is not a cosmetic choice but a statement about how the bike is used and how it will endure the demands of sustained high-speed riding, exposure to road grime, and environmental stressors.

When selecting a fairing mount, a rider must consider more than fit. Material quality plays a central role in longevity, especially where salt air, road salt, UV exposure, and heat from the engine can accelerate wear. Aluminum alloys and marine-grade composites are popular for their corrosion resistance and favorable strength-to-weight ratios. Finishes—from anodized textures to matte black coatings—also influence maintenance: a finish that reduces glare while resisting micro-abrasions will help preserve the front’s silhouette over thousands of miles. The interface between mount and fairing is where two worlds meet: the geometry dictated by the fairing’s cutouts, the edge bevels, the attachment points, and the frame’s own shape and hardness. A mount designed with precise tolerances will ensure fasteners seat without binding, gaps stay uniform, and the fairing sits flush against the surrounding panels, preserving both aero efficiency and styling.

In practice, the configuration of a fairing mount affects more than how the fairing looks. It governs how a rider positions mirrors, how a headlight is aimed, and how air is channeled around the rider’s legs and the machine’s silhouette. A well-designed mount helps a mirror stay stable through gusts, reduces the chance of vibration-induced chatter, and keeps the mirror’s field of view clean and usable. It can also provide a reliable anchor point for auxiliary devices that riders want within easy reach during a journey. A modern mounting system may incorporate features such as integrated channels or plug-in fasteners that simplify routine maintenance or accessory upgrades. The discipline of design that informs these features reflects a broader principle: mount design should be as thoughtful as the fairing itself, because it is the invisible constraint that enables everything else to perform as intended.

From a rider’s perspective, the decision process often begins with compatibility. A given motorcycle model has a defined set of mounting holes, brackets, and cable routing paths. A universal mount may cover a wide range of models but will require careful alignment and sometimes modification to fit perfectly. An OEM mount, by contrast, offers a direct map to those points, ensuring the fairing aligns with the windscreen’s focal line and the headlamp’s cutouts. A custom-fit approach can unlock a more integrated look and superior aerodynamic control but demands precise measurements and a willingness to engage a fabricator or a shop that understands the interplay between load paths and aesthetic intent. These decisions are rarely about a single metric like weight or stiffness alone; they are about the synergy of fit, finish, and function across the entire front-end geometry.

Riders who want to extend the utility of their fairings often explore accessory options that tie directly into the mount system. Mirrors mounted on the fairing betray a rider’s desire for a compact front end, and the right mounting strategy can keep those mirrors from vibrating or shifting during a lean into a corner. Lighting integration can also be facilitated by a mount system designed with mounting points and channels for fixtures or wiring runs, allowing a clean, weather-resistant setup. Even small accessories, such as edge-cut trim or black finishes, can influence how the fairing reads from the rider’s line of sight and how the bike’s face presents itself at a stoplight or on a display platform. If a rider plans to use cockpit devices—such as navigation or action cams—the mount must offer stable, adjustable, and damped positioning. A robust system will provide a ball-and-socket style freedom that permits 360-degree adjustment while damping vibrations from the road. For long rides and aggressive riding postures, this flexibility becomes more than convenience; it becomes reliability, ensuring that devices remain readable and accessible when the road goes from smooth asphalt to a rougher surface.

Material choice and engineering detail also influence the long-term maintenance equation. The best mounts resist corrosion, tolerate UV exposure, and stand up to frequent cleaning with standard motorcycle-protective solutions. They keep their geometry through temperature cycles and do not soften under repetitive loads. The importance of geometry cannot be overstated. A small misalignment in the mounting geometry can propagate into a biased airflow footprint, which over thousands of miles translates into measurable performance differences. Even a fraction of a degree of misalignment can alter the fairing’s effective angle of attack, subtly changing the bike’s drag profile, feathering the boundary layer, and affecting the rider’s comfort and control. In other words, small details matter because they accumulate over time and speed.

The selection criteria for fairing mounts, when considered holistically, come down to a few core questions. Is the mount compatible with the motorcycle model and fairing design? Are the materials and finish robust enough for the riding environment, including heat, sunlight, moisture, and salt exposure? Is installation straightforward, or does it require specialized tools or professional service? Does the mount offer the desired combination of adjustability and stability, especially for devices or accessories that a rider wants to position with precision? And finally, does the setup preserve the intended aesthetic and aerodynamic intent of the fairing design? These considerations are not merely concerns of form; they illuminate how the fairing mount participates in the bike’s dynamic behavior and rider experience. When a rider answers these questions in a way that aligns with their riding style—whether that means a calm, high-speed cruise, a corner-hunting track day, or a rugged, touring adventure—the mount becomes a decisive factor in how the bike feels and performs.

In the broader marketplace, the spectrum of mounts reflects a diversity of riding goals. For those who prioritize straightforward maintenance and broad compatibility, universal mounts coupled with straightforward installation kits provide a dependable route. For riders who demand perfect integration with a specific model and a factory-like finish, OEM mounts offer reassurance and precision. For enthusiasts chasing optimization or a bespoke front end, custom-fit mounts present an opportunity to tailor stiffness, geometry, and accessory compatibility to an exacting standard. Regardless of path, the goal remains consistent: a front end that is secure, predictable, and harmonious with the rider’s intent.

The role of fairing mounts in modern motorcycle design also highlights an ongoing collaboration between form and function. Designers and engineers think about how the front end communicates with the wind, with the rider’s posture, and with the bike’s overall mechanical performance. A mount that reduces flutter at highway speeds helps the fairing stay in place as air loads shift with the rider’s body language and the bike’s acceleration. A mount that allows precise mirror and light alignment contributes to rider safety and situational awareness, two attributes that become increasingly critical as bikes push into higher performance envelopes and longer adventure itineraries. Even the subtle stylistic decisions—the way a bracket exposes the fairing’s edge, the hue and finish of fasteners, or the way a clamp line catches the light—are part of a cohesive visual message about how the machine is meant to be experienced.

For riders who want to explore model-specific options without committing to a full custom build, a useful approach is to examine fairing lines designed around a particular model family. Model-specific lines often provide a clean integration with the bike’s original geometry, while still offering the flexibility to adjust the fairing’s angle, height, and alignment. In this context, the broader ecosystem of components—mirrors, windshields, vent ducts, and edge finishes—comes into play as part of a cohesive system. The idea is to treat the fairing and its mounts as a single design problem rather than as separate parts. When this mindset is adopted, it becomes easier to foresee how a mount choice will interact with the windstream, the rider’s posture, and the bike’s weight distribution, especially during aggressive cornering or when riding in conditions that demand quick, repeatable responses from the front end.

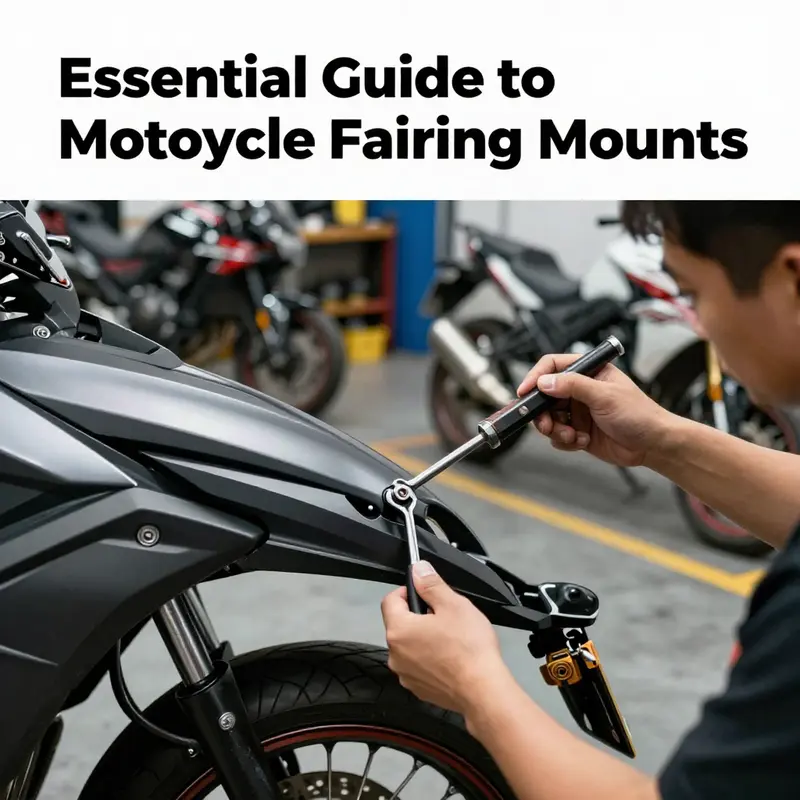

Carrying this philosophy into practice, riders often consult fit guides and technical specifications that accompany each mounting system. These guides help ensure that the selected mount aligns with the frame’s geometry, that the attachment points are accessible, and that the fairing’s cutouts accommodate the headlight, indicators, and air intakes without compromise. The guidance may also include maintenance reminders, such as checking fasteners for loosening after long rides, inspecting anti-vibration dampers for wear, and confirming that the windscreen’s mounting screws remain tight and properly torqued. Although these steps may seem routine, they are essential for preserving the bike’s performance envelope and for sustaining the rider’s confidence at speed.

In sum, fairing mounts are a quiet but essential system in a motorcycle’s architecture. They translate design intent into real-world performance by balancing stiffness, vibration control, alignment accuracy, and aesthetic cohesion. They enable the rider to see clearly, to hear the road softly through the handlebars, and to enjoy a front end that behaves as a unified body rather than a disparate collection of parts. The next time a rider looks at the front of a motorcycle, the eye should notice more than a fairing line; it should recognize a mount that has done its job well—holding, aligning, and enduring with the quiet reliability that makes high-speed riding feel both exhilarating and secure. For riders exploring model-specific options, a visit to a Honda fairings collection can illuminate how the fairing and its mounts are designed to work in concert with a particular platform, revealing how a disciplined mounting approach translates into a refined front-end experience.

For further reading on general principles and practical considerations when choosing fairing mounts, see an external guide on fairing selection and mounting best practices: https://www.carinterior.com/motorcycle-fairing-guide-how-to-choose-the-right-one/.

Internal link for model-specific exploration: Honda fairings collection.

null

null

null

null

Final thoughts

Choosing the right motorcycle fairing mount is critical for both performance and aesthetics in motorcycling. The diverse types of fairing mounts available each cater to specific riding styles and performance needs, from high-adjustability RAM GPS mounts to durable U.S. Military-Grade mounts. Understanding how these mounts function and the installation processes will empower business owners to better serve their customers, ensuring their motorcycles maintain optimal functionality and style. By integrating this knowledge into your operations, you can enhance customer loyalty and satisfaction in a competitive market.