Motorcycle fairing molds are pivotal in shaping the performance and aesthetics of modern motorcycles. As business owners delve into the intricacies of procurement and production, understanding the holistic framework surrounding fairing molds becomes essential. This article will unveil the critical materials and technical details that underpin the design and function of fairing molds, explore key manufacturing hubs in China—specifically Guangdong and Zhejiang provinces—and offer strategic insights for sourcing in 2026. Furthermore, we will examine how technology transforms mold production and design, ultimately impacting the market for motorcycle fairings. With this comprehensive perspective, businesses can navigate the complex landscape of fairing molds to enhance their offerings and competitive edge.

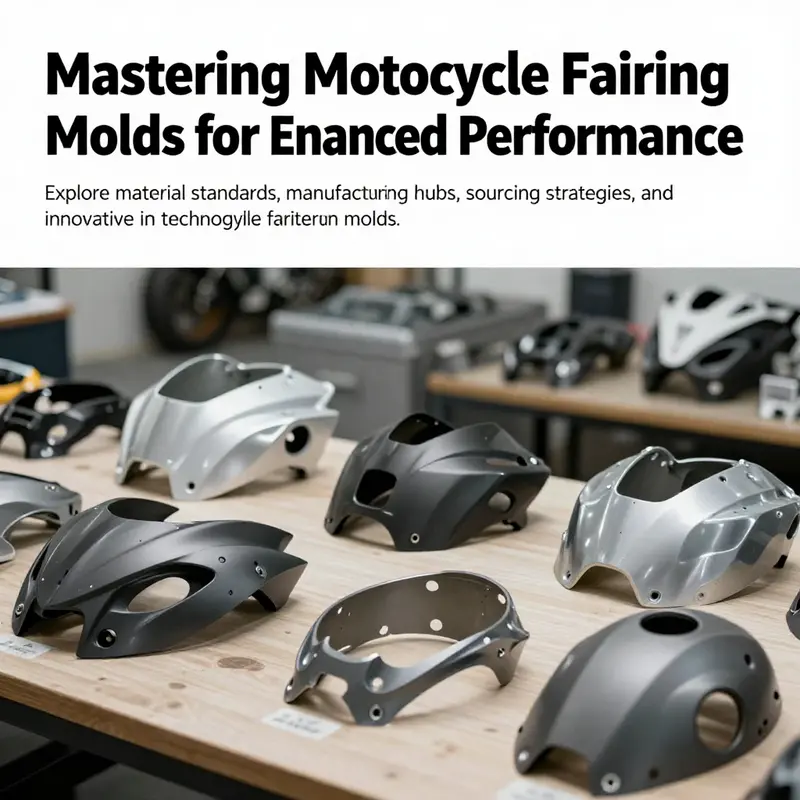

Shaping Speed: Material Standards, Precision, and the Hidden Architecture of Motorcycle Fairing Molds

The motorcycle fairing mold is more than a template for a plastic skin or a composite shell. It is the silent architect of aerodynamics, a stubbornly precise tool whose form determines how clean the air becomes around a rider at high speed, how well the chassis stays shielded from the elements, and how a brand’s visual language translates into an instantly recognizable silhouette. In the factory floor microcosm, the mold absorbs cycles of heat and pressure, tells the resin when to cure, and wields influence over cycle times, surface quality, and the fidelity of every vent line and curvature. When a mold is well conceived, the final fairing emerges with dimensional stability, a flawless surface, and the durability to withstand exposure to weather, UV radiation, and the mechanical repercussions of a rider’s day-to-day riding. When it is not, the same mold yields parts that warp, sink, or display glossy imperfections that undermine performance and perception alike. This is the hinge between design intent and production reality, where material science, precision engineering, and process control converge to turn a digital shape into a repeatable, high-quality hardware component.

Material choice anchors this entire chain. In the realm of molds for motorcycle fairings, steel—especially tool steels with robust heat resistance and wear characteristics—remains the workhorse for high-volume production. A steel mold can endure repeated heating and cooling cycles, resist deformation, and preserve critical tolerances across thousands, sometimes millions, of cycles. Its rigidity helps maintain the integrity of delicate draft angles and fine radii that govern both the aesthetics and the functional fit of the final part. Aluminum, by contrast, offers a different calculus. It is lighter and generally faster to machine, which makes it attractive for shorter runs, rapid prototyping, and test batches where turnaround time is paramount. Yet aluminum’s lower hardness and greater susceptibility to wear mean it can require more frequent maintenance in a production environment or be reserved for pilot lines and low-volume manufacturing where cycle time savings offset the need for longer mold life. Composite materials—fiberglass-reinforced epoxy or other resin systems—occasionally appear in mold construction, typically for niche or rapid-prototyping scenarios. They can deliver quick iteration without the heavy capital investment of metal tooling, but their longevity under high-cycle demands is limited relative to metal molds. Materials must meet stringent dimensional stability and thermal expansion criteria. The mold environment itself imposes strict requirements, since differential expansion between mold material and the resin system can creep into the finished part as micro-scale distortions that ripple into misalignment with the rest of the vehicle’s assembly.

The final fairing, in turn, is not a mere function of the mold’s rigid geometry. The chosen molding resin, the exterior paint or coating system, and the curing dynamics all interact with the mold to determine surface quality and long-term durability. The surface finish of a mold is a critical parameter: a precision surface with a roughness target well below a micron—Ra less than 0.4 micrometers in many high-end applications—yields a gloss and reflectivity that do not require extensive post-mold polishing on every part. This level of finish reduces cycle interruptions, minimizes post-processing labor, and supports consistent aesthetic outcomes across large production lots. A well-finished mold contributes to a final part whose surface can shed water quickly, resist micro-scratches from wing nuts and ties, and maintain color and gloss integrity under UV exposure. The mold physicist and materials engineer work in concert to translate a digital surface into a physical reality that looks and performs as intended through thousands of cycles.

Designing a fairing mold is not only about the surface. The internal geometry matters as much as the exterior contour. Cavity design, for instance, is a careful exercise in balancing fill dynamics with venting and cooling. Draft angles, typically in the 2 to 5-degree range, ensure that the molded shell can be released without dragging or distorting delicate corners. If drafts are too shallow, ejection becomes a struggle, risking part damage and unsatisfactory wall thickness; if drafts are excessive, the finished part’s contour may misalign with mounting interfaces. Integrated venting prevents air entrapment at the part’s thick sections, which can otherwise cause surface defects or incomplete filling. Cooling channels must be engineered to promote uniform cure across the entirety of the cavity, reducing warp and sink marks that betray the mold’s health or the resin’s flow behavior. In modern practice, these considerations are not left to experience alone; engineers rely on CNC machining and increasingly on three-dimensional simulation tools to predict how resin flows, where stress concentrates, and how thermal gradients will shape the finished product. A modular approach—designing the mold in sections such as front and rear halves or upper and lower assemblies—facilitates complex geometries and simplifies maintenance or repair without cascading downtime. Tolerances are tight; many OEM-grade requirements demand ±0.1 millimeter or better, a threshold that makes metrology a daily discipline on the shop floor.

Beyond the mold itself, the manufacturing ecosystem surrounding fairing production emphasizes repeatability and traceability. ISO 9001 certified suppliers often supplement their tooling with automated painting lines and UV-resistant coating technologies to ensure the final fairing not only looks premium but also endures environmental exposure over time. The post-mold processing chain—surface treatment, coating, assembly, and inspection—must mirror the mold’s precision. Any variance introduced after demolding risks erasing the gains achieved during design and injection or layup. In the case of composite fairings, the mold’s fidelity to the intended geometry translates directly into the composite layup’s outcome. Fiber orientation, resin flow, and cure kinetics all interact with the mold’s shape. When done well, the result is a light, stiff shell with a surface that accepts decals and paints cleanly, with minimal pigment migration or micro-cracking at the edges. In practice, manufacturers maintain a tight control loop between mold condition and downstream processes, using data collected from each cycle to calibrate injection or layup parameters, resin viscosity, and cure temperature profiles. The interplay between mold physics and process chemistry is a quiet, continuous optimization, one that often reveals itself in small gains: a tenth of a second shaved from a cycle, a margin of improved surface gloss, or a few tenths of a millimeter in wall thickness consistency that translates into a stable fit across thousands of assemblies.

A fairing mold’s life cycle also depends on how well the design accommodates future iterations. Modular construction—using interchangeable inserts or plug-and-play sections—allows rapid reconfiguration to fit evolving design languages or new chassis interfaces without rebuilding a mold from scratch. This flexibility is increasingly important as manufacturers pursue differentiated styling cues across model variants or limited-edition runs. In such contexts, the mold becomes a platform rather than a single-use tool, enabling customized curvature, venting patterns, and cooling architectures that preserve overall process efficiency while enabling customization. The digital thread connected to the mold—CAD data, simulation results, and metrology records—enables predictive maintenance and proactive replacement schedules. When a mold shows signs of wear, engineers can measure the cavity surface integrity, compare current geometry against baseline, and determine whether a refurbishment or a full replacement is warranted. This is not merely cost control; it is a guarantee of consistency that underwrites both performance and brand integrity.

The global manufacturing landscape for motorcycle fairing molds is heavily influenced by regional strengths and logistics. In several major manufacturing clusters, a tightly integrated supply chain can markedly shorten lead times and reduce total cost of ownership. Guangdong Province in China, for example, has developed a dense, vertically integrated ecosystem with thousands of facilities specializing in polymer injection molding, precision machining, and automated surface finishing. The advantage is not only scale but speed: lead times can be significantly shorter when a single geographic region coordinates material procurement, tooling, painting, and logistics within the same network. Bonded warehouses positioned near major ports support efficient, Delivered Duty Paid shipping to major markets, smoothing cross-border timing and reducing administrative overhead for buyers. In contrast, Zhejiang Province tends to emphasize innovation and customization, especially for smaller batch production and high-precision work where design nuances or limited-edition features demand tighter tolerances and bespoke channeling of cooling or venting systems. For buyers, the procurement task becomes a strategic partnership, balancing price with capability, responsiveness, and design iteration speed. Key evaluation criteria include certifications and quality management systems, production capacity, experience with custom tooling or design-for-manufacture adjustments, material compatibility testing, and export readiness. In practice, forming long-term collaborations with suppliers in these regions yields benefits that extend beyond price per unit: faster iterations on new designs, more flexible scheduling, and the ability to scale production as demand shifts from prototype through to volume manufacturing.

The cross-functional nature of mold design also means that the discussion cannot overlook how final fairing materials behave in service. Though this chapter centers on the mold, the mold’s role in shaping composite and thermoplastic shells is inseparable from the properties of the materials the shells themselves will ultimately employ. For composites, the resin system and reinforcement strategy interact with the mold to define surface fidelity and edge quality. For thermoplastics, mold texture, heat transfer, and ejection forces influence the part’s dimensional outcomes, which must align with the assembly interfaces that connect the fairing to the frame, the fuel tank, and the windscreen. The compatibility of resin chemistry with the intended environment—fuel exposure, temperature cycling, and UV loading—also guides the choice of mold material and surface finish. In some contexts, engineers design molds to accommodate post-mold painting or coating workflows; in others, the entire aesthetic is achieved by the resin and the surface treatment applied after demolding. The common thread is that the mold’s geometry and its surface integrity must translate into predictable, repeatable outcomes across a spectrum of materials and finishing processes.

Within this ecosystem, the path from concept to finished fairing is a disciplined journey of validation. Digital twins, finite element analysis, and flow simulations help predict how a mold will behave under cure and how potential defects might emerge. Engineers validate with physical prototypes before committing to a full toolset, ensuring that the chosen materials, the cooling topology, and the venting scheme will yield the target surface and structural performance. The result is a manufacturing philosophy that prizes precision, durability, and the ability to deliver consistent, high-quality cosmetic and aerodynamic outcomes. The final product is not merely a shell; it is a body that has been sculpted through a process that fuses material science, machine capability, and the discipline of meticulous process control. When these elements are aligned, a fairing mold becomes a reliable workhorse—a tool that enables its designers and fabricators to meet the demands of OEM programs, aftermarket customization, racing performance, and restoration with equal grace.

For readers navigating procurement or shop-floor decisions, a practical takeaway is that the mold’s suitability is measured not just by the shape it casts but by the life-cycle economics it enables. A steel mold with robust cooling channels may carry a higher upfront cost but can deliver longer service life and lower per-unit costs in high-volume runs. An aluminum mold offers rapid prototyping benefits, a crucial advantage during the early stages of a project. Modular design elevates flexibility, allowing design teams to test new aerodynamic concepts without decommissioning the entire tool. And a supplier network that can harmonize design, machining, finishing, and logistics will reduce time-to-market while maintaining the quality that riders and brands expect. In this sense, the motorcycle fairing mold is a confluence of art and engineering, a product whose impact is felt in the wind tunnel, in the paint booth, and in the showroom where the rider first encounters the line, glow, and silhouette that define a bike’s presence on the road.

To support the broader narrative of how these molds are produced and sourced, a related resource offers deeper insights into the materials and processes behind fairing production, including how molds shape fiberglass and other composites. For a broader view of the market’s material choices and manufacturing strategies, the following external reference provides a practical primer: https://www.airtechmotorcycles.com/buyers-guide/fairing-materials/ . In the same vein, readers seeking a glimpse into the online ecosystem of fairing catalogs and model-specific design languages may explore the 2023-new category as a lens into how new geometries propagate from digital concepts to molded reality. For a concrete, non-brand reference to a broad cataloging resource, you can explore the 2023 new fairings category here: https://ultimatemotorx.net/product-category/2023new/.

External resource: AirTech Motorcycle Fairings Buyers Guide on fairing materials (external reference) https://www.airtechmotorcycles.com/buyers-guide/fairing-materials/

Forging Precision on Two Rivers: How Guangdong and Zhejiang Drive Motorcycle Fairing Mold Manufacture

The motorcycle fairing is more than a protective shell; it is a blend of aerodynamics, durability, and identity. The mold that shapes this shell sits at the intersection of heat, polymer science, and precision engineering. In the global supply chain for aftermarket and OEM fairings, two Chinese provinces—Guangdong and Zhejiang—stand out as the most intense foci of skill, infrastructure, and rapid execution. The chapter that follows threads together the physics of molding, the realities of scale, and the strategic advantages that these two hubs provide to manufacturers, assemblers, and buyers who need reliability, repeatability, and speed without sacrificing design fidelity. It is a narrative of how local ecosystems, long specialized in plastics and coatings, translate into a worldwide capacity to turn a CAD concept into a finished, paint-ready shell that can withstand sun, rain, fuel additives, and the cybernetic scrutiny of a modern showroom floor. The mold, after all, determines the final silhouette, the line of the surface, the subtle curvature that catches light and creates the illusion of motion even when the bike is standing still. And because molds govern tolerance and repeatability, they also govern the lifespan of the fairing in service, the ease of subsequent repairs, and the consistency of color and gloss across thousands of parts in a single production run. Within this context, Guangdong and Zhejiang operate as complementary engines of capability, each contributing distinct strengths that, when combined, create a manufacturing rhythm hard to beat for high-volume, aesthetic-sensitive components. The overall system rests on a deliberately layered chain of processes: rapid prototyping to validate form and fit; precision tooling to translate a validated design into a durable cavity; controlled materials science to balance rigidity, toughness, and surface finish; and streamlined logistics to deliver a finished product with minimal lead time and maximal predictability. The result is not merely a mold or a kit of parts; it is a coherent production philosophy that turns design intent into a consistent, market-ready reality.

In Guangdong, the manufacturing tempo is defined by scale, integration, and proximity to advanced logistics. Cities like Foshan and Guangzhou harbor thousands of factories that specialize in polymer injection molding, machining, and post-minterial finishing. The ecosystem benefits from a dense supply of high-performance resins, pigments, additives, and finishing technologies, all synchronized within a single regional rhythm. The facilities here are often vertically integrated, meaning that from mold design through to final packaging, a single supplier can orchestrate multiple stages of the value chain. This vertical integration translates into leaner lead times and tighter control over quality. The ability to run large volumes on high-precision aluminum molds makes it possible to produce hundreds of thousands of identical fairing shells with tight tolerances and reproducible surface textures. Aluminum molds, favored for their thermal conductivity and lightness, allow for faster cycle times and easier heat transfer management during the curing and demolding phases. In the more demanding high-volume environments, stainless steel molds come into their own for durability, wear resistance, and long life in challenging production lines. ABS and HDPE are common plastic choices that sit alongside metal molds, used not only to form the final fairing segments but also to prototype mold forms themselves when quick iteration is essential. ABS provides a balance of impact resistance, processability, and surface quality that makes it a natural candidate for both mold and part, while HDPE offers a cost-effective option for simpler geometries or lower-cost lines where rigidity and precision requirements are less stringent.

The Guangdong story is also about speed-to-market. Port-centric logistics, including large ports and bonded warehouses near key entry points, enable what buyers often call DDP—Delivered Duty Paid—capabilities. The practical impact is tangible: lead times can be substantially shorter when a supplier can consolidate shipments and facilitate export processes close to major trade routes. This isn’t merely about saving days; it’s about reducing the risk of delays in a market where fashion cycles for motorcycle aesthetics can shift quickly and demand can surge in response to new model debuts or limited-edition releases. In an integrated Guangdong operation, a project can move from CAD to a finished mold with surface-ready finishes in a fraction of the time it would require in more fragmented environments. The province’s reputation for scale also helps stabilize costs. With thousands of machines and a dense pool of specialized talent, the cost per unit tends to become more predictable as volume rises, contributing to a favorable total cost of ownership for buyers planning long-run production or multi-year aftermarket partnerships.

Zhejiang, by contrast, shines as a center of precision, customization, and design refinement. Here the emphasis is often on niche, lower-volume, higher-accuracy work that requires a surgical level of control over tolerances and surface fidelity. Zhejiang’s mold makers and tooling shops have cultivated deep competencies in complex cavity design, multi-cavity arrangements, and intricate ejection systems that preserve delicate surface details during release. The region’s ecosystem is particularly well-suited to small-batch runs and bespoke kits for limited-edition designs, sport-oriented configurations, or retrofitted fairings that demand exact-fitting based on tight vehicle specifications. The tooling prowess in Zhejiang is complemented by strong R&D support, enabling rapid iteration—often driven by computer-aided simulations and rapid prototyping methods such as 3D printing or CNC-assisted model making. This enables designers and buyers to test form and fit before committing to a full tooling build, reducing risk as new fairing geometries enter production. The emphasis on precision also helps when the final product must meet exacting tolerances for clarity of line, continuity of curvature, and a uniform coat under UV exposure. The result is a mold shop that can deliver high-fidelity justice to design concepts, with the capability to reproduce micro-sculptured surface features and complex draft angles that ensure the finishing processes—priming, painting, and clear coating—perform predictably across the life of a panel.

The complementary nature of these two provinces translates into a supply chain that can handle both broad scale and delicate detail. For buyers, this creates a practical path from initial design to mass production, or from one-off prototypes to series runs that demand the same exacting standards across thousands of components. The architecture of this ecosystem supports a spectrum of applications, from sport and street bikes to scooters and touring motorcycles. The market demand for fairings has grown alongside the need for aerodynamic efficiency and distinctive style. A well-engineered mold in this context must deliver an accurate replication of a designer’s intent, with consistent wall thickness, uniform resin flow, and minimal sink marks or warping that would compromise the appearance or performance of the final part. It must also accommodate the realities of assembly, such as mating features with frame rails, mounting points, and integrated electronics housings. Each cavity within the mold must be designed to produce not only a perfect silhouette but also the practical dimensions that enable seamless assembly on a range of models without custom modification. In other words, the mold acts as the contract between engineering intent and manufacturing reality.

Material choices are central to that contract. Aluminum molds are valued for their heat transfer properties and lighter weight, which translates into faster cooling and shorter cycle times. In high-volume operations, the overall throughput can be significantly accelerated when a mold manages heat effectively, reducing the risk of thermal distortion that can ripple across thousands of parts. Stainless steel molds, while heavier and more costly upfront, deliver durability and wear resistance that pay dividends over long production runs. When the final fairing demands robust impact resistance, stylish surface finishes, and manageable processability, ABS plastic becomes a common protagonist for the mold and the part alike. ABS is not simply a material for the shell; it is a design driver that informs mold wear patterns, draft design, and ejection strategies. HDPE provides a lower-cost alternative for simpler geometry or pilot programs where mold longevity is less critical. The choice among these materials is never abstract; it shapes the mold’s geometry, ejection mechanisms, and cooling channel layout, as well as the resin’s stability under typical service conditions and during the color and finish stages of production.

Draft angles, which may seem like a minor detail, play a decisive role in how cleanly a part releases from the mold and how smoothly the surface finishes after painting. Subtle variations in draft can prevent or promote distorted lines, affecting both visual appeal and geometric accuracy. Ejection systems—the arrangement of cores, lifters, and plates that thrust the part out of the mold—must accommodate the fairing’s intricate curves while minimizing the risk of mark defects on the surface. Cooling channels, precisely engineered in the mold, govern cycle time and dimensional stability. The efficiency of a cooling system not only shortens production runs but also reduces the risk of warpage after demolding. In transmission lines of this kind, CNC machining takes center stage. Advanced CNC mills carve complex cavities with tight tolerances, while 3D printing and additive techniques enable rapid prototyping of mold inserts, cooling channels, or release features before committing to expensive metal production. These technologies shorten iteration cycles and enable more precise validation of fit and finish before any tool steels are ground and polished to final form.

Quality assurance in this environment is both a technical and managerial discipline. ISO 9001-certified suppliers, for example, implement standardized procedures that cover every step from raw material testing to final inspection. Automated painting lines and UV-resistant coating technologies are common in both provinces, guaranteeing the final fairing not only looks premium but also stands up to environmental exposure over time. The paint line’s fidelity depends on the mold’s ability to deliver a consistently glossy surface with minimal texture variance. The coating system must adhere well to ABS or PC-ABS blends, tolerate fuel exposure in some configurations, and resist chalking or discoloration under prolonged sunlight. The mold’s surface finish directly influences the efficacy of the coating and the overall durability of the final assembly. In a broader sense, these finishing capabilities feed into after-sales service and brand perception, which are increasingly important in a market where visual identity and performance meet at the interface between rider and machine.

From a procurement standpoint, navigating the Guangdong–Zhejiang ecosystem requires a disciplined approach. Buyers assess suppliers on certifications, production capacity, and the ability to deliver design and customization options at scale. Material compatibility testing and export experience become especially critical when managing global distribution. Long-term partnerships in this dual-hub context yield predictable pricing, shorter turnaround times, and greater design latitude for iterations. The strategic value lies in the ability to move from concept to validated mold to production with minimal friction. A mature supplier network offers not only tooling expertise but also design-for-manufacturability guidance, helping clients translate aesthetic ambitions into manufacturable geometries that meet tolerance requirements while preserving the intended silhouette under real-world use.

In practical terms, the two provinces’ strengths reduce risk and increase speed for buyers working with aftermarket kits or OEM components that require consistent performance across a range of models. When a design concept must be validated quickly, Zhejiang’s precision tooling and rapid prototyping help confirm fit and finish, while Guangdong’s capacity and logistics enable a swift move to full production with controlled costs. This dynamic is especially valuable for kits that require tight alignment with mounting points, fairing segments that must mate seamlessly with underbody panels, and paint schemes that demand uniform color and gloss across panels and edges. The result is a supply chain that can sustain fluctuating demand—whether for a hot new model or a steady stream of updated decals and finishes—without compromising the core attributes of the mold: accuracy, durability, and repeatable surface quality.

For buyers seeking reliable suppliers, the value proposition of Guangdong and Zhejiang is not merely the existence of two regional hubs but the presence of a mature, responsive ecosystem that can accommodate both large-volume programs and bespoke, design-forward projects. The ability to move from a first-off tool to a high-volume run, while maintaining strict tolerances and a premium surface finish, is what makes these regions stand out. A strategic approach often involves selecting partners based on a balance of technical capability, production capacity, and export experience, with a preference for those who can demonstrate a track record in complex cavity geometry and robust ejection systems. Long-term partnerships can unlock more favorable pricing, faster iteration loops, and greater resilience in the supply chain when global logistics face disruption.

The broader narrative of fairing mold manufacturing, then, is not simply about the machines or the materials. It is about how specialized communities organize around shared problems—heat management, precise tolerances, and finish quality—and how those communities establish a common language of process, validation, and delivery. Guangdong and Zhejiang exemplify a model in which scale and precision are fused into a coherent capability. They show that molding is an industrial discipline as much as an art: the art of shaping a shell that strikes the right balance between aero efficiency and rider appeal, the science of controlling heat and resin flow to avoid defects, and the logistics of turning a concept into a ride-ready product in a way that keeps commitments and preserves value.

Internal resource pools and supplier networks in these provinces often highlight a recurring theme: the importance of testing early and testing often. Prototypes and pilot runs enable designers to verify the fairing’s fit on a range of frame geometries, confirm the resilience of the coating under UV and fuel exposure, and ensure that the final assembly integrates cleanly with other components. When the design is approved, the transition to production carries with it a confidence that the tooling will produce consistent results, and that the supply chain can deliver the same results across multiple batches and across different model variants. In practice, this means that a single mold, built to handle a family of fairings with shared mounting interfaces, can yield a reliable series of panels that are uniform from batch to batch, color to color, and production line to production line. It is this predictability that underwrites long-term aftermarket programs and OEM collaborations alike, giving buyers a stable basis for planning, pricing, and market timing.

For readers seeking more on the broader market and supplier landscape, one accessible resource is the global sourcing ecosystem that catalogs verified mold and kit suppliers. This reference point offers a practical overview of capacities, certifications, and export experience that buyers should consider when comparing options across provinces and regions. External resources provide a wider lens on the capabilities that underpin the Chinese fairing mold supply chain, offering a context for how these molds scale, how they are tested, and how international standards are applied across different manufacturing environments. External link: https://www.alibaba.com/showroom/motorcycle-body-mold.html

To connect a concrete example back to the content above without naming brands, consider a hypothetical but typical buyer journey: a procurement manager seeking a mid- to high-volume fairing program might begin with a shortlist of Guangdong-based suppliers known for rapid tooling and integrated finishing. After an initial design review, Zhejiang-based tooling shops might be engaged for precision mold inserts and complex cavity features that demand tight tolerances. Prototypes generated through rapid prototyping methods validate form and function, allowing the team to refine draft angles and ejection logic before committing to a final tool. The project then transitions to mass production on metal molds with robust cooling channels and optimized ejection systems, guaranteeing consistent wall thickness and surface texture across thousands of parts. The final stage includes the painting line and UV coating process, ensuring the color fidelity and glaze depth required for a premium look that endures exposure to sunlight and weather. This sequence is not merely a manufacturing pathway; it is a disciplined orchestration of people, processes, and technologies that turns a design concept into a tangible product that riders will trust and admire. The dual-hub dynamic—Guangdong’s scale and Zhejiang’s precision—creates a competitive, responsive framework that supports both continuous improvement and rapid innovation in the field of motorcycle fairing molds.

In sum, the story of motorcycle fairing mold manufacturing in these two provinces is a story of specialization applied at scale. It is about how thousands of small, highly skilled operations can together deliver complex tooling, surface finishing, and finished parts that meet stringent performance and aesthetic criteria. It is about the capacity to turn a design dream into a manufacturable, durable, and beautiful shell that helps a motorcycle slice through air with minimal drag, while presenting a surface that gleams under showroom lights and holds fast under the rigors of real-world riding. The two rivers of Guangdong and Zhejiang meet here to produce not merely parts but a reproducible experience of quality, from the first draft angle to the last coat of UV-resistant clear. This is the essence of modern fairing mold manufacture: a disciplined blend of physics, materials science, engineering, and logistics that turns imagination into riding reality.

Internal link reference: For readers exploring current popular fairing designs and their availability in aftermarket categories, see Honda fairings. Honda fairings

Sourcing Motorcycle Fairing Molds in 2026: A Strategic Playbook for B2B Buyers

Strategic Playbook for Sourcing Motorcycle Fairing Molds in 2026

Sourcing a motorcycle fairing mold today requires a blend of technical knowledge, regional strategy, and disciplined supplier management. Demand is shifting toward model-specific, high-performance bodywork as customization grows and electric motorcycles advance. Buyers must go beyond price to secure tooling that delivers consistent part fit, finish, and durability. This chapter lays out a cohesive approach that ties manufacturing realities to procurement choices. It helps purchasing managers reduce risk, shorten time to market, and capture long-term cost advantages.

Start by matching your program goals to regional strengths. China remains the leading supply base for fairing molds, but capabilities vary by cluster. Guangdong delivers scale, fast lead times, and mature injection-molding systems. Choose Guangdong when you need volume, predictable cycles, and automated paint lines. Zhejiang and Jiangsu offer flexibility, skilled finishing operations, and strong CAD-driven prototyping skills. They are ideal for small runs and complex surface textures. Shanghai supports high-end engineering, especially for electrical vehicle platforms that demand waterproofing and structural testing. Aligning your product roadmap with these strengths reduces trial and error during supplier selection.

Material and process decisions should be settled early. Common mold and part materials include aluminum, stainless steel, ABS blends, and HDPE. Aluminum molds offer lighter weight and superior thermal conductivity, which speeds cycles for large runs. Stainless steel excels for long-life tooling needed in extended programs. ABS and polycarbonate-ABS blends are typical for aftermarket fairings because they balance impact resistance and finish quality. Document which materials are acceptable for both mold and final parts. Ask suppliers for material data sheets and compatibility testing reports. Fuel additives and environmental stressors can degrade some plastics. If your parts will face chemical exposure or prolonged UV, insist on UV-stabilized resins and validated coating systems.

Technical readiness is the next filter. A qualified supplier should demonstrate in-house mold-making capabilities including CNC machining, EDM, and mold-flow analysis. These capabilities cut iteration time and reduce outsourcing risks. Confirm the supplier’s experience with cavity design, draft angles, ejection systems, and embedded cooling channels. Ask how they control warpage and sink marks. Demand specific examples where their tooling solved common fairing defects. If they lack direct experience, require third-party validation or a pilot program to de-risk the contract.

Set measurable procurement KPIs. Rely on codeable performance indicators, not opinions. Track on-time delivery rate, reorder rate, and response time. Suppliers hitting above 97% on-time delivery are generally operationally mature. A reorder rate above 30% typically signals product-market fit and consistent quality. Response time matters for engineering change requests and issue mitigation. A vendor who answers within 6–8 hours is more likely to resolve urgent problems quickly. Embed these KPIs into contracts and link them with tiered incentive or penalty clauses.

Certifications and testing cannot be an afterthought. For regulated markets, request documentation that supports CE, RoHS, and other region-specific approvals. For electric models, require IP67-compliant testing for waterproofing and structural fatigue tests tied to battery longevity. Ask for third-party lab reports from recognized bodies. Where necessary, organize pre-shipment audits through reputable firms. These audits verify that what appears on paper matches what happens on the shop floor.

Factory audits should be practical and targeted. A competent audit covers tooling assets, quality control procedures, and environmental health and safety practices. Verify whether the supplier maintains real-time production tracking and batch traceability. Digital proof of conformity, like a digital twin or serialized testing records, reduces disputes at acceptance. Also evaluate their painting line processes. Automated electrostatic painting and UV-resistant coatings extend fairing life and reduce rework.

Protect intellectual property from the outset. Use non-disclosure agreements and clearly defined ownership clauses for tooling. If feasible, retain ownership of final CAD models and approve any modifications. For sensitive designs, consider splitting obligations across multiple vetted partners. This reduces exposure from a single-point compromise. Also plan for tooling repatriation or local machining if geopolitical risk rises.

Build a structured sampling strategy. Insist on a pre-production sample run. Evaluate fitment, finish, and mechanical integrity against an agreed checklist. Use fixtures to confirm assembly tolerances. Run accelerated aging tests where applicable. If paint or plating is part of the deliverables, validate adhesion and color match under controlled lighting. Set acceptance criteria and document deviations. Approve only after sign-off from engineering and quality teams.

Logistics and commercial terms matter as much as manufacturing. Choose delivery terms that match your internal import and warehousing capabilities. Some Guangdong suppliers offer bonded warehouse services and DDP shipping. That simplifies customs for North America, Europe, and Australia. Negotiate transportation lead times and inventory buffers. For high-variability programs, stagger tooling payments and align milestones with sample approvals and pilot production runs.

Price strategy should be total-cost oriented. Low per-tool quotes can hide future costs. Account for tooling lifecycle, maintenance, and expected shot count. Estimate cost-per-part at common cycle rates. Include secondary operations like painting, plating, and inspection. Also include costs of compliance testing and potential rework. When comparing suppliers, normalize costs to the same assumptions so you compare apples to apples.

Foster innovation through partnerships. Suppliers investing in R&D return value in reduced weight, improved aerodynamics, and integrated heat shielding. Seek partners who can iterate on CAD files, suggest design for manufacturability improvements, and prototype quickly. Encourage their engineers to participate in early design reviews. A collaborative supplier shortens iteration cycles and often reduces production costs.

Mitigate supply risk with a layered approach. Use a primary supplier for volume and a secondary vendor for emergency support. Establish contingency plans for raw material shortages and port disruptions. Consider geographic diversity within China, or a mixed sourcing model that leverages nearby clusters for speed and remote clusters for niche capabilities. Maintain safety stock while balancing working capital.

Measure and optimize continuous improvement. Post-launch, track field returns, warranty claims, and aesthetic issues. Feed this data back into the mold maintenance schedule. Implement periodic tool requalification to detect wear and maintain tolerances. Use batch traceability to link field incidents to specific production runs. Regular supplier reviews should focus on defect trends and corrective actions.

Finally, practical procurement checklists make execution simpler. Before awarding a contract, verify: certified in-house mold-making, CNC and EDM capability, mold-flow simulation use, sample approval procedures, third-party test reports, KPIs embedded in contract, IP protection clauses, logistics and DDP options, and clearly defined warranty terms. Maintain a supplier scorecard and use it to guide future sourcing decisions.

Sourcing motorcycle fairing molds in 2026 is not a single transaction. It is a strategic program that evolves across design, tooling, and production phases. Buyers who combine regional strategy, technical due diligence, and disciplined supplier management will win on cost, quality, and time to market. For a snapshot of recent model-level developments and aftermarket trends, review the catalog of 2023 releases and design trends in the linked internal resource: 2023 fairing releases.

For a deeper practical guide to sourcing from China in 2026, consult the updated supplier manual linked below. It outlines certification checklists, recommended KPIs, and audit templates used by procurement teams worldwide.

https://www.sourcingguide2026.com/motorcycle-fairing-supplier-guide-china-b2b/

Engineering the Aerodynamic Envelope: Technology-Driven Craft of Motorcycle Fairing Molds

The motorcycle fairing is more than a protective shell; it is the front line of aerodynamics, a carefully sculpted envelope that negotiates air, heat, and vibration at speed. The mold that shapes this shell sits at the heart of performance, aesthetics, and durability. In modern manufacturing, technology does not merely support this process; it defines it. From the first digital sketch to the final coated surface, the journey of a fairing mold is a chronicle of precision, material science, and process optimization that translates into a smoother, faster, more fuel-efficient ride. A well-crafted mold is the quiet engine behind every gleaming contour, guiding resin flow, setting surface finish, and ensuring repeatability under the thermal and mechanical demands of mass production. The chain from concept to component is long, but it is anchored by a suite of technologies that make the difference between a fairing that looks good in a brochure and one that performs reliably in the field.

The design stage begins with a deep understanding of the bike’s overall aerodynamic goals and the rider’s needs. Engineers rely on advanced computer-aided design (CAD) to translate those goals into precise digital models that capture the exact curvature, draft angles, and surface textures required for high-performance fairings. These digital blueprints are not merely aesthetic; they encode tolerances, mating features, and tool-paths that will govern every subsequent step. When the model is deemed stable, the data flow continues to computer numerical control (CNC) machining, where a master mold is sculpted with a level of accuracy that would be impractical to achieve by hand. CNC processes can reproduce the intricate contours of a modern fairing with repeatable fidelity, enabling rapid iteration cycles. In this way, virtual testing and physical prototyping are tightly coupled—what is validated in the computer can be refined in the shop, and what is learned in the shop informs another pass at the screen.

Materials science has evolved the very substance of molds. Aluminum and steel alloys dominate the toolbox, selected for their combination of stiffness, thermal conductivity, and wear resistance. Aluminum, in particular, offers excellent heat dissipation and a lighter footprint, which is beneficial for high-volume runs. Steel alloys bring enduring wear resistance that can endure long-term use in rigorous industrial environments. The choice of material is not simply about durability; it also touches the cooling sequence that will govern cycle times and dimensional stability. A well-chosen mold material behaves predictably under repeated heating and cooling, resisting warping and maintaining tight tolerances that preserve the fidelity of the final fairing’s surface. The mold’s cavity, draft, and cooling channels must work in concert with the resin system and the chosen reinforcement to guarantee that the part comes out straight, unwarped, and ready for finishing.

Manufacturing methods have also diversified, expanding the toolbox beyond traditional milling. Vacuum forming and resin transfer molding (RTM) are increasingly common for lightweight, high-strength shells. The materials used in the final fairing—fiberglass, ABS plastic, polycarbonate, carbon fiber composites—each interact with the mold in distinct ways. Vacuum forming excels at producing large, lightweight shells quickly, while RTM enables high-strength, low-weight composites with consistent resin distribution. The mold must accommodate these processes, including features like properly angled draft, smooth radii, and well-designed ejection systems that can release the finished part without surface damage. The mold’s surface finish is not incidental; it interfaces with coatings and paints that protect the part and sustain its appearance in harsh weather conditions. Automated painting lines and UV-resistant coating technologies, often integrated into the production line, ensure that the final product not only looks premium but also survives sun, rain, and road grime without fading or cracking.

Simulation tools have become indispensable in this ecosystem. Aerodynamic CFD (computational fluid dynamics) simulations, coupled with structural integrity analyses, enable virtual testing of airflow around the fairing and the reliability of the mold under cycling loads. These digital experiments can reveal potential issues—flow separation, pressure hotspots, or areas prone to material fatigue—before a single piece goes to the shop floor. The result is a dramatic reduction in material waste, a shorter time-to-market, and a design that can be iterated rapidly to meet evolving performance targets. In this virtual-physical loop, data-driven decisions replace guesswork. As the digital twin of the mold evolves, engineers can optimize channeling for cooling, refine ejection geometries to minimize part distortion, and ensure that the finished fairing achieves the intended aesthetic with consistent gloss and texture.

Global sourcing and a dense manufacturing ecosystem amplify the technological narrative. In the market for motorcycle fairing molds, regions known for scale, integration, and speed have shaped a competitive landscape. Guangdong Province stands out as a powerhouse of scale and integration, where thousands of specialized factories—equipped with advanced polymer injection molding systems, automated painting lines, and UV-resistant coating capabilities—work in a tightly connected industry cluster. The advantage here is not only volume but the ability to compress lead times through bonded warehouses near major ports and efficient export logistics. Lead times can be significantly shorter when suppliers operate with fully integrated ecosystems, enabling customers to move from design concept to production-ready tooling with fewer handoffs and less waiting. Zhejiang Province complements this with strengths in innovation and customization. It is particularly strong in small-batch, high-precision work, where unique surface textures, niche geometries, or limited-edition finishes demand a level of craftsmanship and flexibility that larger, higher-volume operations may not prioritize. Together, these clusters form a robust global sourcing framework that balances scale with the agility needed for design iterations.

For procurement professionals, the mold supply chain is as much about capability and responsiveness as it is about price. Quality certifications, robust design and customization capabilities, material compatibility testing, and export experience are critical evaluation criteria. Relationships in Guangdong can unlock faster turnarounds and more favorable terms for large-volume runs, while Zhejiang can be the go-to for bespoke projects and rapid prototyping. The procurement philosophy, then, is one of strategic partnership: align on technical standards, establish clear communication channels for design changes, and cultivate a network of suppliers who can contribute iteratively across the product life cycle. The objective is not simply a single mold but an ecosystem of molds, processes, and coatings that can deliver consistent performance across generations of fairings.

The end-to-end mold journey also intersects with the aesthetic and protective demands of the product. The mold’s quality directly shapes the final surface finish, which influences not only the bike’s visual identity but also its perceived quality and market value. Surface texture, gloss uniformity, and edge sharpness are all molded into the product from the outset. This means the ejection system and cooling channels must be designed to preserve surface integrity during part removal and cooling. The integration of UV-resistant coatings through automated lines extends the life of the finish, while environmental testing confirms durability against fuel vapors and road chemicals. It is a reminder that technology in mold production is not merely about replication of form; it also secures longevity and brand equity in a marketplace where visual impact and functional reliability walk hand in hand.

A practical takeaway for readers who manage or evaluate mold suppliers is the importance of alignment across design, materials, and process choices. The mold is the interface where digital intent becomes physical reality. Every design choice—from the alloy selection and cavity geometry to the cooling circuit architecture and the ejection strategy—must be consistent with the chosen manufacturing process and finishing plan. This alignment reduces risk, shortens cycle times, and yields fairings that meet strict tolerances while maintaining aesthetic fidelity. A holistic approach—embracing CAD-driven design, CNC precision, material science, advanced forming processes, and intelligent simulation—creates a resilient mold architecture capable of supporting both high-volume production and boutique, high-precision work.

For readers seeking a concrete sense of how these principles translate into online options, a representative catalog of aftermarket fairings can illuminate the practical side of this technology-driven ecosystem. See a Yamaha fairings catalog to understand how digital design intent, manufacturing capability, and surface finishing converge in a real-world product line. This reference point helps bridge the theory of mold technology with the tangible displays and specifications encountered by buyers and engineers alike. You can explore the catalog here: Yamaha fairings catalog.

The broader narrative of technology in motorcycle fairing mold production is not simply about equipment; it is about an integrated workflow that turns a concept into a high-performance, durable, and visually compelling product. It is about the discipline to define a target surface, predict how resin and reinforcements will behave within the mold, and anticipate how a part will respond to mechanical and environmental stress after a thousand miles of highway and racetrack punishment. The mold is the engine of this discipline, and the technologies surrounding it—design software, machining, materials, simulation, and coatings—function as a symphony, each instrument contributing to a harmonious result. When these elements align, the final fairing emerges as a precise, repeatable, and scalable component that supports not just speed and efficiency but the rider’s confidence and the brand’s promise.

External insights from the research literature underscore how rapidly this field is evolving. Detailed discussions of manufacturing precision, rapid prototyping, and integrated supply chains highlight the global momentum behind modern fairing molds. For practitioners seeking deeper exploration of sourcing strategies and supplier capabilities in this space, a widely cited guide provides practical perspectives on how to evaluate and collaborate with Chinese suppliers and other global manufacturers. This resource emphasizes certifications, capacity, design and customization expertise, material compatibility testing, and export experience as core criteria for successful partnerships. As technology continues to advance, the mold remains the bridge between digital design and the durable, aesthetically compelling fairing that riders rely on every time they twist the throttle.

In sum, the role of technology in motorcycle fairing mold production and design is foundational. It binds the aerodynamic theory of the shell to the realities of manufacturing, ensuring that precision, performance, and polish are not afterthoughts but built into the mold itself. From the initial CAD sketch through CNC fabrication, materials selection, advanced forming processes, and the ultimate coating and finishing lines, technology orchestrates a continuous loop of improvement. The result is a family of molds capable of delivering consistent quality across multiple production cycles, with the flexibility to accommodate new shapes, textures, and finishes as demand evolves. This is the practical embodiment of engineering that respects both performance science and the rider’s experience, a discipline where every digit in the design data translates into a smoother ride and a more resilient, visually striking product in the hands of motorcyclists around the world.

External resource: Alibaba Motorcycle Fairing Supplier Guide\n

Final thoughts

Understanding the multifaceted aspects of motorcycle fairing molds—from the materials employed to the key manufacturing hubs and the integration of technology—offers business owners unique opportunities to enhance their product lines and operational efficiencies. As sourcing strategies evolve, particularly with insights tailored for 2026, companies can position themselves competitively in the aftermarket motorcycle industry. By fostering relationships with suppliers in China’s dominant regions and leveraging technology in production, businesses are poised to capitalize on innovations and demand, ensuring their fairings not only meet performance standards but also resonate aesthetically with consumers.