Motorcycle fairing graphics not only enhance the visual appeal of modern bikes, but they also play a vital role in branding and aerodynamics. For business owners in the motorcycle industry, understanding the intricate relationship between design and functionality of fairings is crucial for catering to customers’ needs. This article will explore three key areas: the design and functionality of motorcycle fairing graphics, the materials and technology used in production, and current trends in customization. By delving into these chapters, business owners can gain insights that will help them make informed decisions and stay competitive in the market.

Layered Velocity: The Design and Function of Motorcycle Fairing Graphics

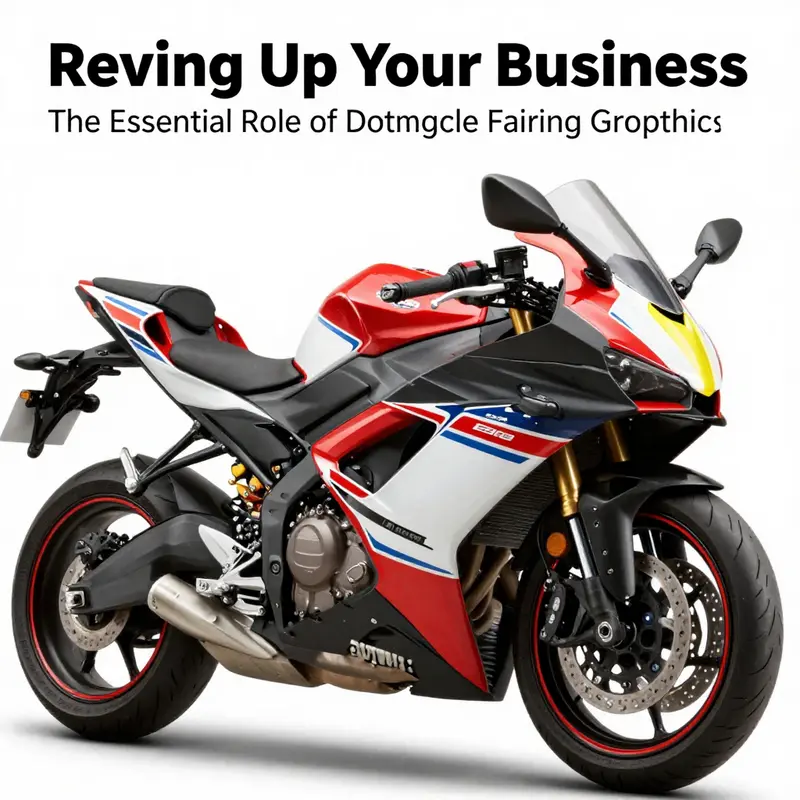

The surface of a motorcycle is more than a shell; it is a dynamic canvas where form, function, and identity converge at high speed. Graphics applied to the fairing extend this convergence, translating a rider’s personality and a brand’s presence into a language that travels as fast as the machine itself. The best graphics do more than catch the eye; they work with the bike’s lines to emphasize aerodynamics, reinforce visual flow, and reduce the cognitive load on the rider by creating quick recognition and a sense of cohesion between rider and machine. In sport, track, and adventure motorcycles alike, the fairing graphics function as an integrated system, not a decorative add-on. They are part of the surface that cuts through air, part of the protection that shields inner components, and part of the storytelling that communicates speed, skill, and purpose to an onlooker and to the rider in the saddle.

Design and aesthetic intention begin with an understanding of silhouette. The fairing is a curved, complex geometry composed of plastic or composite materials that must smoothly negotiate speed, wind pressure, and vibration. Graphics designers think in three dimensions, mapping color, line, and texture to the fairing’s contours so that the visual effect remains steady as the bike leans and as the rider angles into a corner. A well-conceived graphic scheme lines up with the bike’s architectural features—the shoulder of a fairing panel, the arc of a side intake, the taper of a front cowl—so that the eye travels along a deliberate path. The eye movement reinforces perceived stability at speed and can even influence perceived airspeed and handling. This is why large blocks of color sit alongside elongated strokes that mimic motion, while sponsor marks or team colors are placed in zones where they will remain legible under sprinting light and long exposure as the bike accelerates down the track.

Material choice anchors the graphic’s behavior in the real world. Modern motorcycle graphics rely on high-performance vinyl films designed for durability, resilience, and clarity. These films carry UV-stable pigments and weatherproof coatings that resist fading and cracking under sun, rain, and the broad temperature swings typical of riding environments. The adhesive layer is engineered to balance initial grab with long-term removability, so a rider can refresh a look without permanently altering the fairing substrate. The graphic layer is often laminated to add an extra barrier against abrasion and micro-debris, extending the life of the artwork without adding significant weight or thickness. When a graphic is engineered in this way, it becomes less about a single image and more about a resilient skin that remains consistent across thousands of miles of wind, heat, and vibration.

The layering itself matters. The base fairing provides structural protection and a smooth carrier for the graphic. The graphic film adheres to the surface, then a clear protective layer caps the design to shield it from stone impacts and road spray. The result is a surface that can endure the harsh realities of riding while preserving the artwork’s integrity. At the same time, the visuals must not interfere with the fairing’s aerodynamics. Edges and seams are kept flush, with careful trimming that prevents flutter at high speeds. In a well-tuned graphic installation, the color transitions and edge work follow the fairing’s natural edges, reducing opportunities for flow separation and minimizing drag-inducing micro-turbulence. This is not mere decoration; it is a deliberate engineering choice that supports stability and efficiency.

The scope of graphics ranges from permanent, meticulously applied designs to removable, modular kits. Permanent graphics offer high detail and a unique signature that can endure years of aggressive riding, but they carry higher costs and a longer path to change. Removable graphics, by contrast, empower a rider to adapt the bike’s look with evolving tastes and season-specific color schemes. They are often more affordable and market-friendly for amateur racers and everyday riders who want frequent style updates without a long-term commitment. The choice between permanence and reversibility reflects a rider’s philosophy as much as their budget. It also speaks to resale value, since some buyers prefer the option to swap in a design that matches their own identity or a future sponsorship program.

The design discourse also travels through production and distribution channels. In a global context, the fairing graphics ecosystem depends on a tightly coordinated supply chain that can deliver consistent quality at scale. Materials suppliers, printers, laminators, and applicators must align to keep color fidelity, edge sharpness, and adhesive performance uniform across batches. The result is not simply faster production; it is a predictable, repeatable quality that riders can trust when they order a kit or a replacement panel. Even at the level of customization, the core standards—UV resistance, weatherproofing, and durable adhesion—remain constant because those attributes determine how a graphic behaves during a sprint, a wet ride, or a long-distance trek.

Industry organization supports these capabilities through vertically integrated ecosystems in key manufacturing hubs. In regions known for motorcycle component production, such as major centers in Asia, factories combine polymer injection molding, automated painting lines, and UV-resistant coating technologies to produce fairings with uniform durability and precise finish. This integrated approach enables rapid turnaround times and cost-effective sourcing for teams and riders seeking customized graphics kits or full fairing sets. It also makes possible a spectrum of options, from off-the-shelf pre-designed schemes to highly tailored wraps that reflect a team’s color story or a sponsor’s branding. The outcome is that graphics are not merely applied to a surface; they are produced as part of the fairing’s life cycle, from initial vibration and heat testing to long-term exposure on the road.

Riders seeking personalization encounter a continuum of choices. Pre-designed kits offer an immediate path to a new look while preserving a professional finish. These kits can range from factory-style racing stripes to more expressive motifs that echo a rider’s taste or a team’s visual language. For those who want something uniquely theirs, customizable options allow adding numbers, names, or original artwork. The practical appeal of customization lies in its balance of speed, accessibility, and impact. A rider can achieve a striking, cohesive look without sacrificing performance or reliability. Online marketplaces and design studios have made it feasible to preview how a graphic will sit on a given silhouette before committing to a purchase or a full wrap. In this context, the graphic becomes a true interface between rider identity and mechanical performance.

From a workflow perspective, applying decals and wraps demands careful preparation, precise alignment, and thoughtful finishing. A recommended approach emphasizes surface cleanliness, temperature control, and careful testing of edge adhesion before full deployment. Riders and installers should ensure the fairing is free from wax, oil, and dust and that the surface is dry and slightly tacky to promote optimal adhesion. Alignment is achieved with lightweight straightedges or templates that help position the design in three dimensions. Heat application, if used, softens the vinyl slightly to conform around curves, enabling a seamless transition across panels. Finally, trimming and burnishing lock edges and squeegeeing out air bubbles to achieve a uniform, wind-resilient finish. An authoritative guide on the mechanics of decal application exists for those who want to master the details of alignment, heat usage, and edge sealing. This resource offers practical steps that can elevate the final outcome and reduce the risk of lift or misalignment over time.

The conversation around graphics also encompasses practical trade-offs. Permanent designs can raise the initial barrier to entry because of higher costs and the longer lead times required for customization or installation. They may also complicate resale negotiations if a potential buyer seeks a different aesthetic or color story. Removable graphics, with their lower cost and flexible lifecycle, empower riders to refresh the bike’s appearance with relative ease. For sport-oriented riders, who frequently replace liveries to reflect a team’s colors for a season or to signal a personal milestone, this flexibility is especially valuable. The market responds accordingly, offering modular kits that can be swapped between models or seasons, and even universal components that adapt to various fairing shapes. It is a reminder that the graphics system is not just about the art on the surface; it is also about the rider’s evolving relationship with the machine and the freedom to redefine that relationship when the mood or sponsorship changes.

Within this broader ecosystem, the concept of compatibility and adaptability matters as much as the artistry. Graphics must be designed to accommodate a range of fairing geometries without sacrificing readability or flow. They also must contend with different surface finishes, from matte to gloss to textured coatings, each of which interacts differently with the vinyl film. Pre-fit testing on sample panels or mock-ups helps artists anticipate how a design will behave when wrapped around a real bike. This pragmatic approach reduces waste and ensures that the final product aligns with the rider’s expectations for color accuracy, edge closure, and overall perceived quality. The dynamic interplay between design intent and real-world performance is where graphics truly earn their keep, proving their worth not only by catching the eye but by reinforcing a sense of control and confidence for the rider.

The narrative surrounding fairing graphics is not merely about personal style; it is about how art and engineering collaborate to create a coherent riding experience. Graphics support visibility in traffic, recognition on track, and brand storytelling under the harshest conditions. They provide a layer of identity that makes a bike instantly legible to spectators while maintaining the integrity of the fairing’s surface and the machine’s aerodynamic profile. That is why the industry treats graphics as a legitimate, essential facet of motorcycle design, not a cosmetic afterthought. When the rider leans into a corner or powers out of a bend, the graphic layer remains as a constant, a visual echo of speed, precision, and control that travels with the machine and the rider alike.

The practical implications extend to how riders access and implement these graphics. For those curious about current offerings and new releases, there is a growing emphasis on accessible options that align with the evolving aesthetic expectations of riders without compromising performance. The availability of 2023 new fairings, for example, demonstrates how graphic design and fairing technology converge to deliver fresh looks that still honor the underlying engineering principles. A practical signal of this trend can be found in the online catalog that showcases updated designs and catalog-friendly formats. See the 2023 new fairings collection for a sense of how designers are balancing vivid colorways with the need for durability and aerodynamic compatibility. 2023 new fairings collection.

For riders who prefer a hands-on approach to applying graphics, the literature offers concrete, experience-tested steps. A widely referenced step-by-step guide outlines preparation, alignment, heat application, and edge finishing in clear terms. While many specifics depend on the exact film and adhesive system chosen, the core principles—clean surfaces, careful measurement, controlled heat, and deliberate burnishing—remain universal. This guidance is particularly valuable for those who choose removable graphics, where reapplication and repositioning opportunities are part of the design lifecycle. For practitioners looking to deepen their practical skill, following a proven protocol can improve outcomes and extend the life of the graphic layer, even as riders experiment with different styles and configurations over time. External readers may consult a detailed, technique-focused resource that walks through the nuances of decal application, from surface prep to final sealing. External resource: https://www.motorcycleforums.com/threads/how-to-put-decals-on-motorcycle-fairings-step-by-step-guide.123456789/

In summary, motorcycle fairing graphics embody a synthesis of design finesse and engineering discipline. They translate speed into color, shape into motion, and identity into a tangible surface that endures wind, sun, and road abuse. They reflect a broader industry reality in which graphics are developed not as an afterthought but as a coordinated part of the bike’s performance package. The journey from concept to road involves material science, aerodynamic awareness, and a culture of customization that invites riders to participate in their machine’s evolution. The result is a living system where art and engineering move in lockstep, producing a visual language that travels as fast as the bike itself. To explore how this language continues to evolve, readers may engage with emerging fairing lines and design innovations that respond to both rider demands and the ever-shifting aesthetics of the riding community.

The Fabric of Speed: Materials, Technology, and Motorcycle Fairing Graphics

Graphics on motorcycle fairings are more than decorative; they are a dialogue between speed and science, blending artistry with engineering to express identity while enduring ride and race.

When a rider looks at color, form, and line, they see layers of material science at work: films engineered to flex with curves, inks that resist heat and sun, and surfaces that stay put under grit and rain.

Fairing graphics must look striking in photos and endure long days of sunlight and abrasion. The best graphics achieve both aesthetic impact and functional performance. They cling to curved, vibrating shells and survive heat, wind, and scuffing.

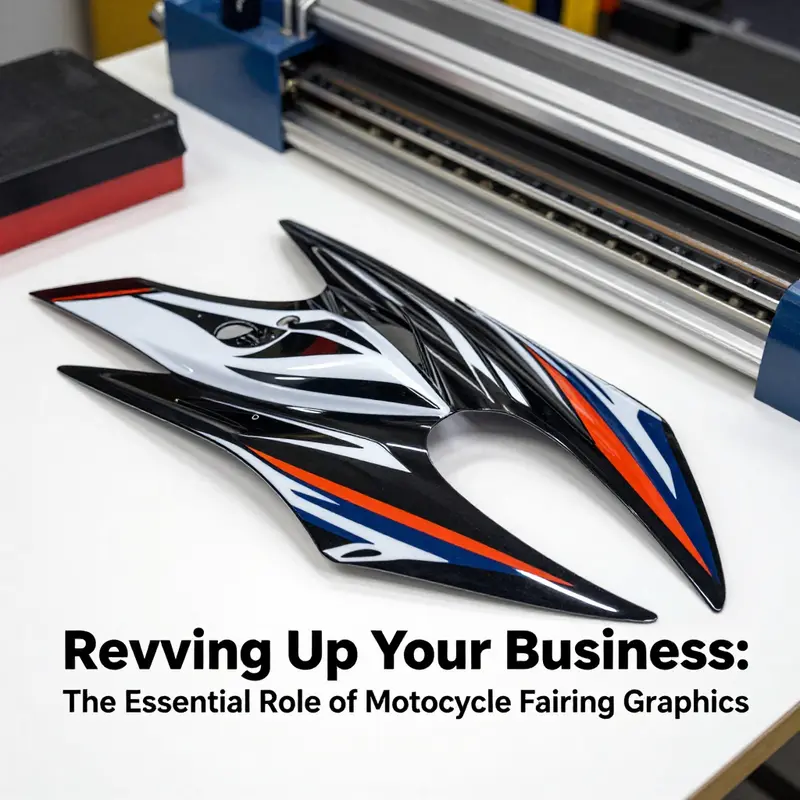

This chapter surveys the materials and processes behind modern graphics kits. The heart of the capability lies in polymer films such as vinyl (PVC-based) with flexible, durable backbones, UV resistance, and abrasion resistance. A protective laminate atop the color layer adds defense and can be gloss or matte, affecting color saturation and glare.

Digital printing enables high-resolution images, gradients, and logos to wrap around complex forms, with UV-curable inks offering fast curing and color fidelity. Lamination and transfer films provide edge integrity and sacrificial protection against peeling on edges and contours.

Manufacturing ecosystems emphasize control of substrate, adhesion, color, thickness, and finish to ensure repeatability across models. Customization options range from factory-inspired kits to bespoke artwork applied as full-coverage designs or accents, while maintaining structural integrity and rider comfort.

Proper installation relies on clean surfaces, controlled heat, and careful handling to avoid air traps and edge lift. The interplay of color science and aerodynamics shapes perceived speed, guiding hue shifts and gradient placement to maintain legibility around fasteners and seams.

In practice, graphics must align with the fairing’s geometry, edges, vents, and panel seams, ensuring the brand language remains uninterrupted. The graphic’s lifespan is tied to maintenance practices such as washing and occasional retouching, all compatible with the laminate and adhesive system.

Together, design and material science make graphics an extension of the bike’s identity—an expressive layer that travels with the machine without compromising performance.

null

null

Final thoughts

The significance of motorcycle fairing graphics transcends mere decoration; it embodies a blend of artistry, engineering, and identity. Business owners in the motorcycle market who understand the intricacies of design, material selection, and customization trends can greatly enhance their offerings and appeal to diverse consumer preferences. Emphasizing these aspects can lead to competitive advantages, customer loyalty, and ultimately, success in the thriving motorcycle industry.