Motorcycle fairing fasteners play a pivotal role in safeguarding the integrity and performance of your motorcycle. These critical components not only ensure that the fairing is firmly attached to the frame but also contribute to the overall aerodynamic efficiency of the vehicle. Given the diverse range of fasteners available in the market, it becomes essential for business owners and manufacturers to understand the different types and their specific applications to make informed decisions. This article will explore the integral importance of these fasteners in maintaining structural integrity, identify various types and their practical uses, and guide you in selecting the right fasteners to enhance the performance of motorcycles.

Holding the Line: The Role of Fairing Fasteners in Structure, Safety, and Speed

The visible curves of a motorcycle—the fairings that carve the air and shape the bike’s silhouette—belie a more subtle truth: the fasteners that hold those panels together are a quiet but essential form of engineering. In high-speed riding, on rough roads, or during a sharp gust, it is the integrity of those tiny connectors that keeps the entire assembly from wobble, flutter, or detach. Far from being merely decorative fixtures, fairing fasteners endure real loads, translate wind forces to the frame, and govern how smoothly a bike behaves at speed. When they perform reliably, the rider experiences consistent aerodynamics, predictable handling, and a sense of security that lets performance dreams be pursued with confidence. When they falter, the consequence is not only a rattling panel but a potential shift in the bike’s center of pressure, a sudden increase in drag, and, in the worst cases, compromised rider safety. The balance between aerodynamics, structural integrity, and ease of maintenance rests on choices made long before a rider slides into the saddle: the selection of fairing fasteners, their materials, their geometry, and how they are installed and cared for over time.

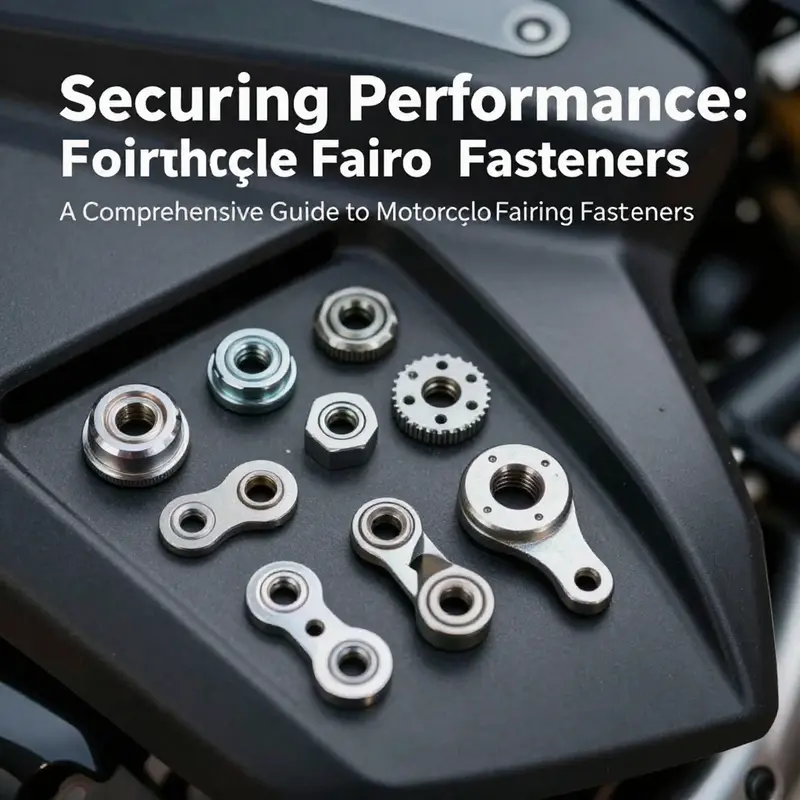

In practice, the most common fasteners securing motorcycle fairings include a family of M6 bolts and a range of retaining clips designed to lock panels to the frame with steady clamping force. These elements are chosen for predictable engagement, compatibility with the panel thickness, and the ability to carry the loads introduced by wind pressure and road shock. While M6 is a staple size, the spectrum of fasteners used across different models can span other metric sizes, and their lengths must be matched to the precise panel stack-up. In racing or off-road applications, the demand for reliability and weight savings becomes even more acute. A premium, lighter material can deliver meaningful performance benefits if it maintains strength, resists corrosion, and remains stable under repeated vibration and temperature cycling. The discussion of fasteners thus sits at the intersection of mechanical design and practical, day-to-day maintenance.

Material choice matters as much as geometry. Steel and aluminum fasteners remain common, valued for their availability and straightforward torque characteristics. Titanium, specifically Grade 5 titanium, offers a compelling combination of lightness, strength, and corrosion resistance. In the context of fairing assemblies, a titanium bolt can be roughly 40 percent lighter than stainless steel counterparts while still delivering high fatigue strength and excellent resistance to the kinds of environmental exposure fairings encounter—from rain and spray to salt spray on coastal rides. The weight savings are especially meaningful when multiplied across a full fairing kit and considered in the larger frame of the motorcycle’s overall mass, unsprung or otherwise. But material selection is not a matter of raw weight alone. The operating environment of a motorcycle is harsh: rapid temperature swings, vibration, and wind-driven debris. Titanium’s performance in these conditions makes it an attractive option for riders who want to maximize efficiency without sacrificing reliability. With the right treatment and proper thread engagement, Grade 5 titanium fasteners deliver durability that aligns with high-performance use cases, including racing and demanding off-road work, where every gram and every thread matters.

The relationship between fairing panels and the motorcycle frame is better understood if we picture the fairing as a skin that must translate air pressure into a predictable gradient of loads. The fasteners are the little anchors that ensure that skin does not peel away or float under dynamic loading. When a fairing is properly fastened, the panel plane remains aligned, minimizing gaps that could shed turbulent air. This matters because even small misalignments can alter the boundary layer around the bike, increasing drag and reducing mechanical efficiency. Conversely, too-tight a connection can transfer excessive stress to the panel-to-frame joints, increasing the risk of stripped threads, cracked bosses, or stressed mounting points after hard riding or a rough landing. The tale of fasteners is thus a balance between clamping force, panel thickness, panel flexibility, and the frame’s own stiffness characteristics. The art lies in selecting fasteners that can sustain the required clamping force without yielding or backing out under vibration, while preserving the panel’s alignment during a range of operating conditions.

A practical look at the hardware shows that the fastener ecosystem for fairings includes a spectrum of connection strategies. Traditional bolt-and-nut assemblies provide robust, repairable connections, with nuts that stay captive in the frame or in inserts threaded into the panel. Retaining clips offer a lighter, faster route to secure the panels, particularly for sections that require frequent access during maintenance or race prep. For riders who prize maintenance efficiency, quarter-turn quick-release fasteners offer a compelling option: they enable rapid, tool-free access to the fairings, a feature that becomes invaluable during track sessions, pit stops, or field repairs where minimizing downtime matters. This combination of traditional fasteners and quick-release options gives a rider a toolbox of strategies to manage the balance between secure fastening and rapid access. The design choice—whether to lean on fixed bolts, clips, or quick-release mechanisms—should be guided by the fairing’s geometry, the expected duty cycle, and the rider’s maintenance cadence.

From a design perspective, compatibility and precision are essential. The mounting points on the frame, the panel thickness, and the hardware’s threading all have to work in harmony. If the thread pitches or column strengths diverge from the panel’s needs, even a seemingly robust fastener can become a bottleneck, either through cross-threading during installation or through gradual loosening due to vibration. A consistent thread engagement is the backbone of a reliable connection. In practice, ensuring clean, well-lubricated threads during assembly helps achieve proper torque values and predictable performance over time. In the ongoing conversation about fasteners, many riders discover that the smallest changes in hardware choices can ripple through the system—altering panel alignment, changing how vibrations are transmitted to the rider, and shaping the accessory fitment across the entire bodywork.

Maintenance and inspection are not afterthoughts; they are integral to the lifecycle of fairing fasteners. Regularly checking the condition of bolts, clips, and nuts is a small but essential habit. Signs of wear, corrosion, or thread damage should prompt immediate action. In high-performance scenarios, where aerodynamics and reliability are paramount, a guided inspection routine becomes a rider’s best ally. Specific cues—such as a panel that wobbles slightly, a crack at a mounting boss, or a bolt head that looks rounded or discoloured—signal that the connection may have degraded. When such signs appear, replacing the damaged fasteners and rechecking torque to the manufacturer’s specification is prudent. Experts emphasize the importance of secure fasteners as part of routine servicing, especially on sports bikes and touring machines where aerodynamics and reliability directly influence riding comfort and performance.

For people who work directly with fairings, the choice of fasteners is often framed around three core considerations: material family, compatibility, and the service environment. Material choices—steel, aluminum, and titanium—each come with trade-offs. Steel is strong and widely available but heavier and more prone to corrosion in harsh climates. Aluminum lightens the load but can suffer from reduced fatigue resistance if the alloy or treatment is not carefully chosen. Titanium, particularly Grade 5, offers a compelling compromise of light weight and strength, along with strong corrosion resistance. The premium feel of titanium comes with a caution: the fasteners must be precisely specified for the panel’s thread engagement and the frame’s strength characteristics. Using too long a bolt, or one that is too stiff for the panel, can transmit shock into the panel bosses, accelerating wear. The end result is a fastener system that remains reliable across a broad operating envelope, provided it is correctly selected, installed, and maintained.

The practical implications of fastener choice extend to maintenance workflows. When mechanics or enthusiastic riders plan maintenance or teardown sessions, they often want to replace aging hardware with a matching, high-quality kit that preserves alignment and ease of service. A well-considered kit—comprising bolts and compatible nuts, matched to the fairing’s thickness and the frame’s geometry—can save time and reduce the risk of misfit or cross-threading during reassembly. For riders who place value on a quicker cycle between races or track days, the prospect of a quarter-turn fastener system becomes appealing. It is not just about reducing tool usage; it is about enabling reliable, repeatable panel removal and reattachment that keeps the bodywork snug and aero-efficient without the risk of over-torqued or under-secured fasteners.

In selecting a fastener strategy, the broader aim is to ensure that the connection between fairing panels and the frame remains a stable, repeatable interface. That means choosing hardware that stays engaged under vibration, resisting loosening while not encouraging overstress. This is where the combination of materials and fastener geometry matters. A titanium bolt, used with properly matched nuts and perhaps a light thread locker where appropriate, can maintain clamping force across a spectrum of operating temperatures. The choice also hinges on the fairing’s location on the bike. High-vibration zones near the engine or around the bedded wheel arch deserve particular attention, since they are the places where small loosenings can propagate into larger panel misalignments. A preventive approach—regular inspection, timely replacement of damaged fasteners, and adherence to torque specifications—keeps the fairing from becoming a loose or fluttering liability at speed.

For riders who want to explore the breadth of fairing options and their assembly considerations, a practical starting point lies in the broader catalog of fairings available through dedicated categories. This resource acts as a repository where engineers and enthusiasts alike can compare how different fairing lines are designed and fitted, including the fasteners that keep them secure. Explore the catalog here: Yamaha fairings. This internal reference helps connect the dots between panel design, mounting approaches, and the hardware suite that makes reliable assembly possible. It is through such cross-referencing that a rider can better understand the relationship between panel stiffness, the amount of clearance the panel requires, and how fasteners behave under varied riding styles. The result is a more informed maintenance plan and a more predictable riding experience, with aero efficiency preserved and the risk of unplanned downtime reduced.

The conversation about fasteners is also a reminder that design and serviceability are not separate disciplines. The choices made in the factory level—whether to use capture nuts, rivet nuts, or threaded inserts, for example—shape how a panel is secured for the life of the bike. A panel that relies on rivet nuts may require different torque specs, given the embedded strength of the insert, and the installer must ensure that the insert remains flush with the panel surface to avoid contact with other parts of the bodywork during operation. The overall system is a tapestry of choices: the panel thickness, the insert style, the bolt length, the thread pitch, the presence of any anti-seize or thread-locking agents, and the assembly process itself. Each thread engages in a chain of effects that stretch from the rider’s grip on the handlebars to the surface finish of the fairing and the bike’s aerodynamic line.

In this light, the role of fasteners becomes more than just securing a piece of plastic or composite. They are a practical translation of design intent into real-world performance. A fairing that sits square and true reduces drag and improves the bike’s stability in gusty conditions. A fastener that retains its clamping force under vibration minimizes panel movement, contributing to both rider comfort and component longevity. The structural integrity of the entire bodywork system thus rests on an invisible yet essential network of connections that can be engineered to be light, strong, and reliable across thousands of miles of riding. When the design accounts for the loads and the environment, fasteners support safer operation, more efficient aerodynamics, and a smoother experience for the rider—whether the journey is a daily commute, a weekend twist through back roads, or a high-performance sprint on a track.

The path forward for fairing fasteners, then, is practical and principled. Select materials that meet the strength and corrosion-resistance needs of the riding environment, ensure compatibility with the panel stack-up and frame geometry, and maintain disciplined maintenance routines that catch wear before it becomes a hazard. Let the design be guided by the discipline of repeatable assembly, where torque, alignment, and cleanliness of threads are not afterthoughts but core requirements. And above all, recognize that the fasteners are more than the sum of their parts: they are the quiet guardians that keep the fairing precise, the aero lines intact, and the ride safe and efficient from the first mile to the last.

External reference for further reading on fastener material performance in this domain can be found here: https://www.aliexpress.com/item/1005005237824273.html (Why M6 Fairing Bolts Are Essential for Your Motorcycle). This resource offers a deeper dive into how M6 hardware interacts with fairing panels in real-world conditions and under pressure, illustrating some of the practical considerations discussed above.

Anchors for Aerodynamics: Exploring the Types of Motorcycle Fairing Fasteners and Their Real-World Applications

The way a motorcycle slices through air begins with a single, often overlooked system—its fairing fasteners. These small, sturdy anchors do more than hold plastic and composite panels in place; they govern how cleanly the bike cuts the wind, how resistant it is to vibration, and how efficiently the entire machine can be serviced between rides or rallies. In performance-focused riding, even a few grams of weight saved, a millimeter of alignment preserved, or a millisecond shaved from a teardown time can compound into meaningful gains on the track or in the hills. This chapter looks beyond the surface shine of the panels and into the practical world of fasteners—their types, their purposes, and how riders balance competing demands of strength, weight, aesthetics, and maintenance. The story of fairing fasteners is really a story about how design thinking moves from theory into the wind, the corner, and the workshop bench, where each choice interacts with a specific motorcycle’s geometry, rider expectations, and the service routines that keep performance consistent over time.

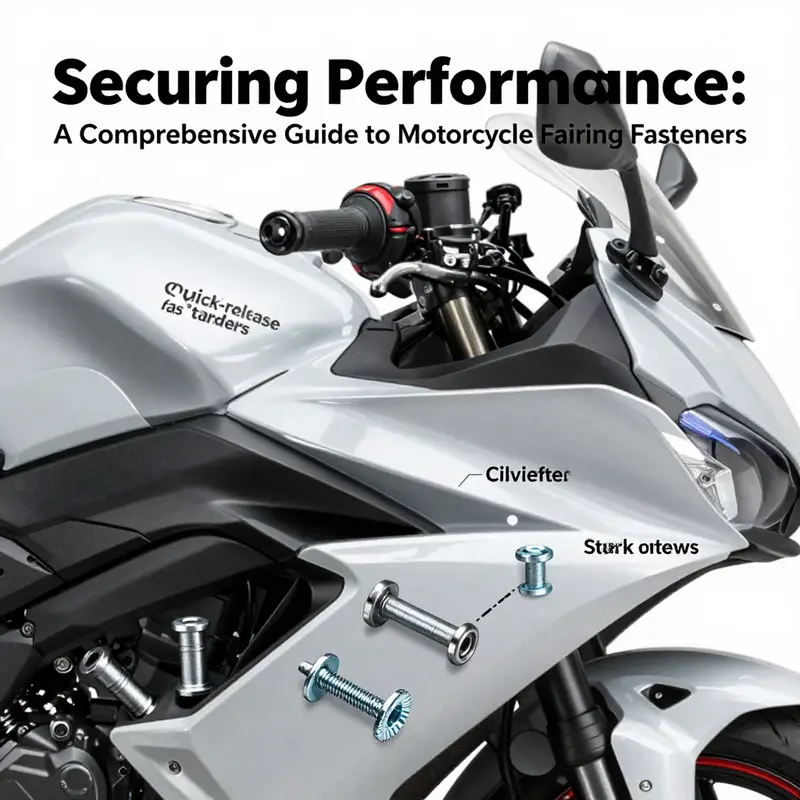

Among the many dimensions that define a fastener’s usefulness, the most immediate is the mounting method. A fairing is not a single rigid piece but an array of panels that must slot, screw, or latch to the frame in precise harmony. The first broad family you encounter is defined by how the guard or panel attaches to a fixed reference on the bike—commonly the bodywork anchor points created by the mirrors, the bar ends, or the nose and headlight shrouds. A practical, widely used method attaches a guard to the mirror base. This approach—let’s call it the Mirror Base Mount—emerges as the most versatile option across many motorcycle types. Its strength lies in simplicity: the guard is clamped or threaded into a feature that already exists on the bike, minimizing modifications and preserving factory lines. This is especially advantageous when the goal is to protect the riding posture from wind and rain while attempting to avoid any adverse impact on handling. The elegance of the mirror-base approach is that it can be deployed with a minimal toolkit and with a straightforward alignment process. It is not a radical rework; it is a prudent, reliable anchor that can endure the gusts of highway speed and the occasional bump without letting panels flutter loose.

The Mile-Wide Implication of A and Its Evolution into BC: a comparative glance at mounting strength brings us to the BC method, a more robust, purpose-built arrangement often described in terms of an optimized connection design and installation geometry. The BC method, sometimes referenced as a B+C arrangement in exploratory notes and practical guides, builds on the same fundamental objective as the mirror-base approach but with a different iron in the fire. By creating additional contact points and optimized geometries between the fairing and the bike’s frame, the BC method distributes loads more evenly. Vibration, a constant companion of high-performance riding, becomes less of a nuisance when there are more secure interfaces to absorb it. The practical upshot is evident at high speeds and when encountering rough pavement: the fairing remains firmly positioned, the gaps stay controlled, and the panel edges retain alignment. For riders who chase track days or off-road adventures, that extra stability translates into more predictable aerodynamics and less stress on the attachment points themselves. The BC method is not a one-size-fits-all solution; rather, it offers a disciplined balance between ease of installation and the heightened stability demanded by more aggressive riding styles. It foregrounds robust connectors and installation designs that can be repeated reliably, assuming the frame geometry remains within a compatible envelope.

A third method, known in technical circles as the Expansion Bolt Mount, targets a different set of priorities. In this approach, expansion bolts secure the guard to the handlebar end cap or a similarly accessible edge of the bike’s structure. The aesthetic payoff of such a method is a clean, integrated look that minimizes visible hardware and preserves the motorcycle’s visual flow. Yet, by its very geometry, the expansion-bolt solution offers less wind-buffering and rain protection compared with the more centralized or multi-point attachments of A and BC methods. The practical implication is clear: if weather sealing and wind protection are high on the priority list, or if the riding environment is exposed to significant crosswinds, this method may fall short of the performance you need. Nevertheless, for certain street configurations where the panels align tightly with the frame and the rider values a discreet external silhouette, the Expansion Bolt Mount can deliver a compelling, aesthetically pleasing compromise. The choice among these mounting styles, then, is rarely aesthetic alone. It is a matter of matching the fastener architecture to the bike’s design language, the rider’s priorities, and the environmental and load conditions most often encountered on the road or on the road-to-track passage.

To appreciate how these mounting approaches translate into real-world outcomes, it helps to consider material choices and the way they interact with the three primary methods. Common engineering practice has long relied on steel and aluminum for their predictable behavior and cost benefits. Steel offers strength and ductility, and aluminum provides lightness and corrosion resistance; in many everyday applications, these metals form a robust baseline for fairing fasteners. But performance-minded riders increasingly turn to lighter, stronger alloys when the goal is to shave grams without sacrificing reliability. Titanium, particularly Grade 5 (often referred to as Ti-6Al-4V in other contexts), stands out in this conversation. The Grade 5 titanium fasteners are notably lighter than stainless steel—roughly 40 percent lighter in typical bolt configurations—while preserving high tensile strength and excellent corrosion resistance. In a racing or off-road scenario where every ounce matters, a titanium kit can meaningfully reduce unsprung weight and rotating mass, contributing to sharper throttle response and improved suspension behavior. The hexagonal heads on such fasteners are designed for straightforward tool access, enabling quicker maintenance or routine tie-downs during pit stops. The associated nuts are matched to ensure a dependable thread engagement, which matters when repeated assembly and disassembly are routine or mandatory for the race-day tune-up. All of these considerations align with the broader principle that the fastener system should be engineered to automotive-grade standards for the particular application. This standardization supports high-stress usage while offering a buffer against environmental exposure, solvent contact, and vibration—factors that can otherwise undermine the integrity of a panel attachment over time.

Despite the appeal of exotic materials, there is a practical reality: not every rider or bike comes equipped to handle the premium cost or the specialized installation effort that high-end fasteners demand. For many, a staged approach makes sense. One might begin with a solid steel or aluminum kit to secure basic fairing panels and then evaluate the benefits of swapping to a lighter, more expensive option in select locations—say, on edges that experience the most wind load or near the inner corners of the fairing where quick repairs might frequently occur. In this context, kit composition—whether it includes a complete set of screws, studs, and clips or a subset that covers the critical attachment points—becomes a key determinant of both fit and maintenance efficiency. Compatibility is not merely about matching thread sizes (M4 through M10, for example) but about ensuring the overall length and head geometry align with the panel pockets and through-holes designed into the bike’s fairing. When the fasteners arrive as a kit engineered to automotive-grade standards, the confidence level rises for riders who expect precision and durability under adverse riding conditions.

A final layer of practical discernment concerns installation and service life. In the context of fairing fasteners, serviceability means more than just removing and reattaching panels. It implies predictable torque behavior, compatible thread engagement with the mating fastener components, and a clamped connection that resists loosening under high vibration. Quarter-turn quick-release fasteners, widely used in race-prep and maintenance contexts, embody a different philosophy: they emphasize rapid access and minimal tooling without sacrificing reliability. Suitable for panels that require frequent removal for maintenance, these fasteners enable pit-stop-like serviceability and can significantly reduce downtime between sessions. While they are not a universal cure—their performance depends on the precise fit and the loads expected in a given riding discipline—they represent a crucial option in the rider’s toolkit for fast and repeatable access to internal components.

When deciding among these approaches, riders must also consider the broader ecosystem of parts and accessories compatible with their bike’s fairing. The fairing system is, in effect, a small mechanical ecosystem: fasteners interact with gaskets that maintain weather sealing, with threaded inserts embedded in the plastics or composites, and with the frames and mounting points that define the geometry of the assembly. A holistic view of this ecosystem makes it easier to foresee issues such as stress concentration around a single bolt hole, misalignment caused by cumulative tolerances, or galling when different metals come into contact under heat and humidity. In practice, reading manufacturer specifications and certifications becomes not just a checkbox but a guard against misalignment, poor fit, and unexpected panel movement after long rides or heavy braking. The right fastener system, chosen with a view toward how it will be loaded and how often it will be disassembled, will help preserve panel integrity and ensure that aerodynamic performance remains consistent ride after ride.

This dimension of slow, deliberate design—choosing mounting method, material, and finish to match the rider’s needs—also invites a more nuanced consideration of aesthetics and airflow interactions. A fairing is as much about shaping air as it is about sheltering components. Subtle choices in the attachment geometry—the distance between mounting points, the alignment of panel seams, the spacing that governs line-of-sight to the rider’s eye—can influence how laminar the airflow remains along the bike’s flank. In tandem with these geometric considerations, the fastener’s own profile contributes to a clean, uninterrupted surface that reduces parasitic drag. For riders who track airspeed discipline or who simply chase smoother lines at speed, the selection of a fastener system that minimizes protrusions while maintaining structural integrity becomes a tangible performance lever. In such contexts, even the head shape of a bolt matters: hex heads that sit flush or recessed, corrosion-resistant coatings that preserve gloss, and finishes that resist chafing against the fairing’s paint or clear coat all play into the long-term appearance and durability of the bike.

In the broader literature of component design and safety, there are additional considerations that inform fairing fastener choices. For instance, patent literature on protective structures for motorcycle headlights highlights how enclosures and mounts must endure impact, moisture ingress, and constant exposure to vibration. While the specific applications differ, the underlying design philosophy—robust connections, predictable performance, and ease of inspection—translates well into the world of fairing fasteners. The same principles that guide the protection of critical lighting elements also guide how fairing panels are anchored and maintained. This cross-pollination of design thinking underscores a fundamental point: fasteners are not mere hardware; they are active participants in the bike’s safety envelope and aerodynamic regime. For readers seeking a deeper theoretical grounding, one may consult patent information related to protective structures for motorcycle headlights to see how robust mounting systems are conceived and validated under real-use conditions. https://www.163.com/digi/article/HHJ95R0S05589L7G.html.

As a practical takeaway, the how of choosing fairing fasteners comes down to aligning three axes: mounting method, material performance, and serviceability. The Mirror Base Mount offers speed and versatility with modest modification, the BC method supplies enhanced load distribution for rough terrain and high-speed stability, and the Expansion Bolt Mount presents a clean aesthetic with suitable but comparatively lighter wind protection. Titanium-based fasteners provide a compelling weight reduction without sacrificing strength for those who demand peak performance, though cost and installation complexity may pay a toll for some riders. Ultimately, the right combination respects the bike’s geometry, the rider’s priorities, and the environmental realities of the riding life. It is a balance between keeping the fairing securely attached, maintaining aerodynamics, and enabling efficient maintenance when wear, impact, or panel access demand it. The overall aim is to ensure that every bolt, clip, and clamp contributes to a coherent system in which the fairing’s contribution to the bike’s performance is stable, predictable, and durable across miles of riding, not just a momentary impression when the fairings are first bolted on.

For readers who want to explore related categories and broader fairing options, a contemporary catalog of fairing-related products offers a gateway to practical choices without getting lost in a fog of part numbers. You can browse a broader selection in the 2023 new category, which summarizes current design trends and common solutions while remaining agnostic about specific brands. This resource helps bridge the gap between concept and implementation, providing a useful reference point for riders who are building or updating their own fairing ecosystems. 2023 new category.

In summary, fairing fasteners are the quiet workhorses of aerodynamic efficiency and structural reliability. Their types—the Mirror Base Mount, the BC Mount, and the Expansion Bolt Mount—each carry distinct trade-offs that map to a rider’s environment and objectives. Material choices, from conventional steel and aluminum to premium titanium, shape a fastener’s life cycle in terms of weight, strength, and corrosion resistance. The modern practice of pairing robust interfaces with accessible serviceability ensures that fairings continue to perform in harmony with the bike’s overall dynamics, whether the ride is a cross-country sprint, a rugged off-road excursion, or a track-day shakedown. This integrated view of fastener selection, grounded in mounting philosophy and material science, positions the rider to make informed decisions that translate into real-world gains—more consistent aerodynamics, simpler maintenance, and a lasting connection between panel and machine. The next step is to consider how these principles play out in specific riding contexts and how a disciplined approach to fastener selection can reduce maintenance time while preserving panel integrity under demanding conditions.

Locking in Performance: The Subtle Power of Motorcycle Fairing Fasteners

The fairing is more than a cosmetic shell; it is a tuned element of a motorcycle’s stability, cooling, and aerodynamics. When riders push for speed, cornering precision, or endurance, the fasteners that secure the fairing matter as much as the engine or suspension. The right fasteners do more than keep panels in place: they maintain alignment under wind pressure, vibration, and heat. They minimize rattling and help preserve airflow that can shave seconds off lap times or improve fuel efficiency on long rides. Choosing fairing fasteners is a performance decision, not just hardware. The task is to balance safety, fit, durability, and weight, while accounting for maintenance and model-specific mounting points.

In practice, performance-minded riders approach fasteners with the same rigor as engine oil or tires. The fasteners must fit the motorcycle, the fairing material, and the operating environment. A misfit fastener can loosen at speed, promote flutter, and degrade aerodynamics. A well-chosen system locks the bodywork securely and provides a margin of safety that grows with ambition—whether carving canyon roads, chasing track records, or riding in challenging weather. The core principle is precise fit: mounting points must accept fasteners without workarounds, and the fasteners must tolerate vibration, thermal expansion, and occasional debris impact. When this principle is observed, installation is straightforward and maintenance remains predictable.

Material quality is central. Stainless steel offers durability and broad compatibility; aluminum alloys reduce mass; titanium provides exceptional strength-to-weight and corrosion resistance, but is expensive and harder to source in complete sets. The choice should reflect riding context: race builds may justify premium alloys; sport or touring setups balance cost, corrosion resistance, and serviceability. Regardless of material, the standard is long-term integrity. Corrosion, micro-pitting, or fatigue under repetitive loading can distort geometry and aerodynamics. Avoid low-grade fasteners; substandard metals or poor manufacturing can fail in subtle ways that become catastrophic at high speeds or rough terrain.

The type of fastener matters as much as the material. Threaded bolts with locking nuts, cam-locks, and quarter-turn quick-release mechanisms each offer strengths and trade-offs. Locking bolts with nuts provide proven reliability; quick-release saves time for maintenance; cam-locks offer secure clamping and ease of operation. The best choice depends on how often panels are removed, the maintenance cadence, and tolerance for movement during aggressive riding. The goal is a system that contributes to consistent, aerodynamic geometry across the entire bodywork.

Installation and maintenance are performance-critical. Follow manufacturer torque specs to avoid thread damage or panel cracking. Under-tightening invites loosening; over-tightening risks damage. Ensure adequate thread engagement, clean threads, and proper lubrication to reduce galling. Thread-locking compounds may be used for extreme vibration or temperature, but choose removable variants if quick removal is anticipated. Regular inspection should be part of every ride-ready routine: look for discoloration, thread wear, corrosion, and panel misalignment. If looseness is detected, re-torque to spec. If wear is evident, replace rather than masking the symptom with lock compounds. Proactive replacement of aging fasteners preserves safety and aerodynamics.

Sourcing is more nuanced than buying a bolt kit. Compatibility with mounting points and panel thickness matters, as do head shapes and drive types. The nut design should match the bolt for secure clamping and repeatable assembly. The aim is a cohesive kit that integrates with the fairing’s geometry and the bike’s frame. When evaluating options, consider material pairing to prevent galvanic corrosion and ensure consistent threading and resistance to seizing under heat.

A robust strategy blends OEM parts with reliable aftermarket options. OEM parts guarantee fitment; aftermarket options can offer lighter alloys or advanced locking. Reliability comes from suppliers who provide material data, finish specifications, and testing documentation. The objective is a cohesive system where every fastener complements the others and supports the riding context, reducing incompatibilities from piecemeal sourcing.

For riders focused on speed, weight matters. Titanium can offer premium strength-to-weight and corrosion resistance; aerospace-grade aluminum provides a lighter, cost-effective alternative. Avoid plastic or low-grade metal fasteners for load-bearing connections in high-stress mounts, where heat and vibration can cause failure. Material choice should align with riding conditions, maintenance cadence, and long-term reliability.

In the broader maintenance ecosystem, mounting systems and design philosophies protect the fairing and support performance. Designers consider static fit and dynamic behavior across speeds and conditions to preserve geometry and seals, enabling predictable airflow and minimal drag. The goal is fasteners with consistent seating, repeatable torque, and reliable resistance to loosening, integrated with the fairing’s design to avoid interference and ease service when inspection or replacement is needed.

As a practical note, riders with multiple models benefit from a standardized approach: check mounting point compatibility, confirm material quality, select an appropriate fastener type, and adhere to torque specs. When mounting systems are coherent across a lineup, maintenance is predictable and deployments are reliable. A model-aware fastening strategy also supports better record-keeping and a clearer plan for when components should be replaced. It’s a quiet, often overlooked form of performance discipline with tangible payoffs in smoother rides and consistent handling.

Final thoughts

In summary, motorcycle fairing fasteners are fundamental components that not only secure the fairing to the motorcycle frame but also enhance the bike’s overall performance and durability. Understanding their importance in structural integrity, recognizing the various types and applications, and making informed selections based on performance requirements will empower business owners to provide superior products to their customers. Through careful consideration and strategic choices, you can ensure that your motorcycles not only perform optimally but also resonate with the needs and expectations of today’s riders.