Motorcycle fairing brackets play a crucial role in the overall performance, safety, and aesthetic appeal of motorcycles. These components not only ensure that the fairing – the motorcycle’s bodywork – is securely attached, but also greatly influence a rider’s experience, especially at high speeds. As riders navigate complex terrains and execute daring maneuvers, the integrity of these brackets becomes paramount. In this exploration, we will discuss the importance of fairing brackets in aerodynamics and safety, the materials used in their construction that contribute to their durability, and the differences between OEM and aftermarket options. By understanding these elements, motorcycle business owners can better appreciate how selecting the right fairing brackets can impact their products and services.

The Hidden Skeleton of Speed: How Motorcycle Fairing Brackets Bridge Aerodynamics, Safety, and Riding Experience

Beneath the gleam of paint and the sweep of curved panels lies a quiet, unassuming network of metal and polymer that makes the whole machine behave the way riders expect. Motorcycle fairing brackets are more than just fasteners; they are the structural spine that holds together the artistry of aerodynamic design and the practicality of everyday riding. When we talk about speed, stability, and efficiency, the brackets that anchor the fairing to the frame may seem invisible. Yet their role is everything from shaping air flow to shaping the rider’s sense of safety and control. A robust, precisely aligned bracket system preserves the intended geometry of the fairing, maintains the integrity of the electrical and lighting harnesses embedded in the bodywork, and ensures that the whole assembly performs as a coherent, aerodynamic unit rather than a cluster of loosely connected panels. The deeper we look, the more we see how these brackets translate the theory of air resistance and downforce into tangible ride quality and rider confidence. In this chapter, we traverse the physical and practical terrain of fairing brackets, exploring how material choices, fitment, installation, and maintenance converge to influence aerodynamics and safety, and how riders balance the trade-offs between factory originals and aftermarket options without compromising the machine’s fundamental alignment and safety profile.

From a high-level perspective, fairing brackets function as the interface between the bike’s frame and the exterior bodywork. They must endure the relentless vibrational environment of a motorcycle accelerated through wind, turbulence, and varying road textures. The loads placed on brackets during straight-line acceleration, cornering, braking, and even minor impacts demand a combination of stiffness, fatigue resistance, and damping. This is where material science meets mechanical design. Steel offers exceptional strength and fatigue resistance, but it adds weight. Aluminum alloys strike a favorable balance between strength and weight, helping to preserve the bike’s overall mass distribution and its handling characteristics. Reinforced plastics or advanced composites can further reduce weight and contribute to precise molding of integrated features such as wind deflectors and air intakes. The choice among these materials is not merely about raw strength; it is about matching the bracket system to the bike’s intended use, the expected load spectrum, and the environmental conditions the machine is designed to endure.

The alignment of the fairing itself is the daily discipline that determines the bracket’s effectiveness. If brackets are installed with even a small misalignment, the entire fairing can shift out of the designed plane, altering the intended airflow around the bike. In the wind tunnel sense, a misaligned panel can cause local separations that degrade laminar flow, increase drag, and invite turbulence that unsettles stability at high speed or in gusty conditions. Misalignment is not merely a cosmetic concern; it has practical consequences for fuel economy, engine cooling air pathways, and the performance of features embedded in the fairing—such as wind deflectors, intake ducts, and lighting units. When brackets maintain their intended geometry, the fairing contributes to a clean, smooth pressure distribution along the bike’s silhouette, helping to keep lift low and downforce where it belongs. This, in turn, improves grip at the front wheel and enhances confidence through corners and in crosswinds.

The aerodynamic benefits that engineers attribute to fairings are, by design, highly sensitive to mounting integrity. The fairing’s aerofoil-like shape interacts with the airstream in ways that are both subtle and consequential. The majority of the downforce generated by a modern motorcycle’s front fairing arises not from a single dramatic feature but from the cumulative interaction of multiple surfaces that work together to optimize pressure gradients around the wheel, fork, and rider. Poor bracket fitment or worn connections can disrupt this synergy. For example, a slight sag in a lower fairing panel can create a local wake that pulsates behind the front wheel, while a loosened upper bracket can alter the angle of attack of deflected air, increasing drag and reducing the bike’s straight-line stability. In windy conditions, crosswinds become a test of the bracket system as much as of the rider’s skill. If the fairing is loose, it can flutter or flex under gust loads, adding buffeting to the rider and disturbing the helmet’s wind management system. These are not abstract considerations; they translate into measurable outcomes such as higher fuel consumption, greater rider fatigue, and a temporary or ongoing decrease in stability when the rider needs predictable handling most.

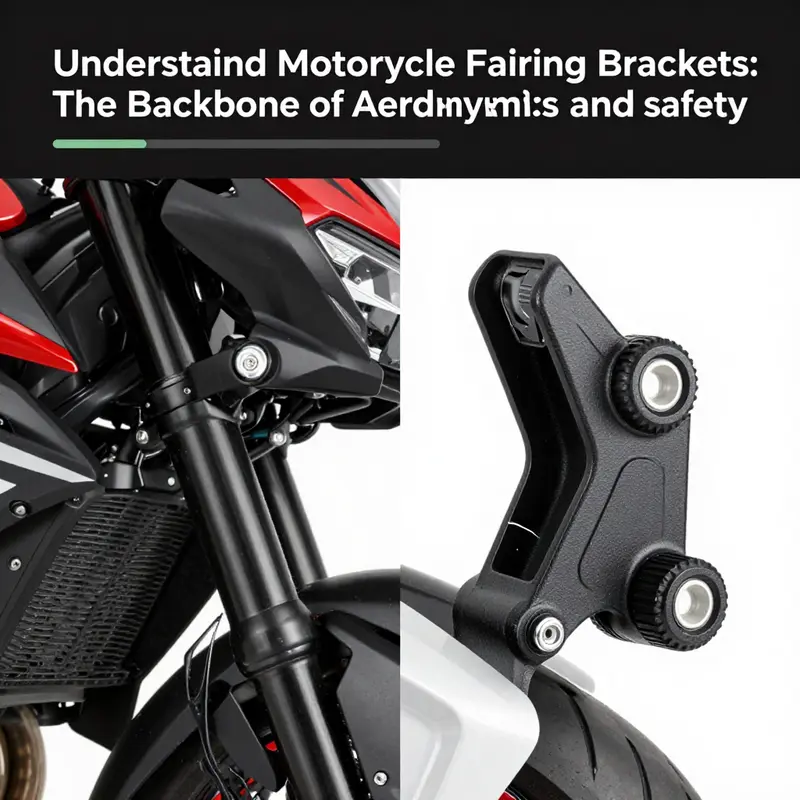

The safety dimension of fairing brackets extends beyond ensuring the panels stay attached in ordinary riding. Fairings often house critical components—wind-deflecting elements that shield the rider from direct wind pressure, integrated lighting for visibility, air intakes for engine cooling, and even crash-absorbing features designed to distribute impact forces. Brackets must be robust enough to support these elements under stress, including sudden decelerations, unavoidable minor impacts, or a fall where panels absorb part of the energy. In such scenarios, a bracket system that maintains precise alignment helps preserve the intended protective role of the fairing. If a bracket fails mid-ride, the consequences can range from increased wind noise and poor rider protection to a compromised cooling path or misrouted electrical connections. The difference between a well-engineered bracket system and a makeshift arrangement can be the line between a minor incident and a dangerous situation.

The reliability of a bracket system hinges on meticulous installation and ongoing maintenance. Proper torque specification is a simple yet essential discipline. Over-tightening can introduce stress concentrations that crack brackets or distort mounting points; under-tightening invites motion, micro-movements, and eventual wear. The vibration environment of a motorcycle means that brackets must tolerate micromotion without transferring it into fatigue or audible noise. Regular inspection becomes a routine that riders should integrate into post-ride checks and service intervals. Signs of wear to watch for include corrosion at mounting bosses, cracks radiating from bolt holes, deformation at the flange lines, or any shift in the panel alignment pattern that previously existed. If a bracket is compromised, replacing it promptly preserves the stability of the entire fairing system and its aerodynamic function, which in turn sustains rider comfort and safety.

The decision between factory-original brackets and aftermarket options is, for many riders, a question of fidelity versus flexibility. Factory brackets are designed to match the frame geometry and the original fairing system to a known standard. They offer exact fitment, preserved compatibility with factory electrical systems, and a predictable maintenance profile. However, they can carry a higher price and, depending on the model, more weight. Aftermarket brackets open possibilities for weight reduction, stiffness tuning, and performance-oriented adjustments. They can enable unique fairing configurations that suit a rider’s style or a project build. Yet they require greater care in selection and installation. The frame geometry of motorcycles can vary from model to model, and even small variances in subframes, mounting points, or electrical routing can affect alignment and load distribution. The safest approach is to pursue brackets that have been validated for the model in question and to adhere strictly to torque values, alignment procedures, and the spec sheets provided by the bracket manufacturer and the vehicle’s service manual.

A practical aspect of this decision is fitment compatibility. Even tiny deviations in mounting hole spacing or the contour of a mounting pad can throw the entire fairing out of alignment. To mitigate that risk, riders and technicians often rely on a detailed checklist that spans the entire fairing system: verify each mounting point’s surface condition, confirm hole spacing with the frame geometry, check electrical harness routing for chafing risks, and inspect the integrity of any integrated components like wind deflectors or LED assemblies. The process is not merely about bolting panels to the frame; it is about preserving the fairing’s designed aerodynamics and ensuring all integrated devices function as intended, under all riding conditions.

When considering the rider’s broader goals—whether to maximize top speed, improve downforce at the front, or simply preserve a pristine aesthetic—brackets become a tuning parameter rather than a mere hardware choice. A lighter aftermarket bracket, when properly matched, can reduce inertia and slightly improve front-end response. A stiffer bracket system may better resist panel fatigue and flutter at high speeds, which in turn reduces creaking noises and micro-movements that can irritate a rider after long sessions. Yet the benefits hinge on an impeccable fit. A bracket that is lighter but misaligned can cause more drag, more noise, and poorer handling than a heavier, well-fitted OEM alternative. The balance point lies in a precise, model-specific evaluation that weighs weight savings against the risk of misalignment and durability under real-world riding conditions.

In practical terms, this evaluation often leads riders to consult official service manuals when planning bracket installations or replacements. For example, model-specific documentation from manufacturers provides exact instructions for bracket inspection and replacement, including torque specifications, sequence of tightening, and recommended inspection intervals. These manuals are not decorative extras; they are the procedural backbone that ensures the fairing and brackets function as originally intended. They detail not only how to tighten bolts but how to verify the fairing’s stability during dynamic testing, how to test for panel flutter under simulated wind loads, and how to check for interference with other components such as mirrors, fuel tanks, and electronic enclosures. For riders engaged in performance-oriented builds, awareness of these guidelines helps prevent issues that could otherwise undermine aerodynamics or safety.

A practical mindset for riders who replace or upgrade brackets is to approach the task as a system upgrade rather than a single component swap. The fairing, the brackets, and the mounting hardware form an interconnected web that governs the bike’s exterior geometry and how the air flows around it. A well-chosen bracket set respects this interconnection, aligning with the fairing’s intended curves, the frame’s geometry, and the electrical harness layout. The installation must preserve not only the physical mounting points but also the pathways for sensors or actuators that live within the fairing. When these elements are misrouted or strained, the risks extend beyond cosmetic misalignment to include potential sensor inaccuracies or electrical failures that could affect lights, fairing-integrated cooling, or ride-by-wire systems.

For readers who want to explore a tailored approach to bracket selection, a hands-on mindset—rooted in measurement, model-specific compatibility, and careful testing—works best. Begin by confirming the exact year, make, and model of the motorcycle, and then cross-check the frame geometry and mounting pad locations with the bracket’s specification sheet. If possible, compare the new brackets against the original ones to ensure symmetry in mounting pad spacing and thickness. Use a torque wrench and a clean, dry mounting surface to avoid over-torquing or shifting during the process. If any pad surfaces show signs of wear, corrosion, or deformation, address them before proceeding. It is not unusual to encounter slightly different bracket systems across submodels or regional variants; when in doubt, reach for the model-specific guidance in the official service documentation or consult a trusted technician who has direct experience with that model’s fairing architecture.

Rounding out the discussion, the broader ecosystem of fairing systems—and, by extension, the brackets that hold them—benefits from a thoughtful curation of parts that respects both heritage and innovation. Some riders prefer to maintain a showroom-like level of originality, seeking factory brackets to preserve resale value and to guarantee seamless integration with original fairings and electrical harnesses. Others lean into personalization, selecting brackets that reduce weight, augment stiffness, or permit inventive aerodynamic tuning. In either case, the guiding principle remains consistency: alignment must be preserved, loads must be adequately resisted, and the entire assembly must work in harmony with the bike’s geometry and the rider’s expectations.

The broader message for enthusiasts and professionals alike is that brackets are not a mere afterthought. They are a critical interface that translates the designer’s aerodynamic intent into a practical, rideable product. The best brackets support long-term reliability by resisting corrosion, fatigue, and vibrational wear while maintaining precise alignment across the life of the bike. They enable the fairing to perform its role in wind management, rider protection, and equipment integration. And they offer a platform for riders to tailor their machines—subtly or dramatically—without compromising the essential safety and aerodynamic performance that fairings are built to deliver.

To illustrate how these principles translate into real-world decisions, consider this scenario from the rider’s workshop. A rider who takes part in track days and spirited street riding seeks a lighter, stiffer bracket system to improve front-end feel and cornering confidence. The rider weighs the potential gains in inertia reduction against the risk of increased panel vibration and the need for meticulous alignment. They compare OEM brackets with a carefully selected aftermarket option, verifying that the latter is designed for the same frame geometry and mounting points. They consult the manufacturer’s torque specifications and perform a measured installation, taking care to re-check alignment after the first few rides and again after any subsequent maintenance that might impact panel positions. They also inspect the fairing’s integrated components—wind deflectors, LED lighting, air intakes—to ensure continued performance and reliability. In this approach, the bracket system becomes a deliberate part of the bike’s performance equation rather than a passive support. The result is a more predictable instrument that responds with the rider’s intent, without surprising flutter, noise, or misalignment that could undermine safety or efficiency.

In closing, the bracket network that binds the fairing to the motorcycle frame deserves ongoing respect as a performance and safety-critical subsystem. Its integrity supports the fairing’s aerodynamic mission, the rider’s comfort and confidence, and the machine’s reliability across a spectrum of riding environments. The choice between OEM and aftermarket brackets should be guided by a careful assessment of fitment, load paths, weight, and long-term durability, backed by model-specific documentation and tested methodologies. By approaching installation and maintenance with the same diligence you would apply to critical engine or brake components, you ensure that the fairing—not just its shape, but its entire ecosystem of fasteners, brackets, and embedded features—continues to contribute to the machine’s performance, safety, and riding enjoyment.

Internal link for model-specific context and further exploration: the Suzuki fairings category provides a practical reference point for understanding how brand-specific fairing ecosystems align with bracket systems. You can explore the collection here: Suzuki fairings category.

For a broader, authoritative reference on installation and maintenance practices, consult the official technical documentation from manufacturers that offer comprehensive guides tailored to specific models. This resource provides detailed procedures for fairing bracket inspection and replacement, including torque specifications and assembly sequences. External resource: BMW Motorrad service manuals for model-specific procedures.

The Material Backbone Behind Motorcycle Fairing Brackets: Strength, Weight, and Endurance

The material choices behind motorcycle fairing brackets ride beneath the surface of every high-speed ride, yet they determine, more than any single bolt or weld, how well a bike preserves its aerodynamics, protects its rider, and sustains its long-term value.

These brackets are not glamorous parts, but they play a pivotal role in converting the quiet power of a motorcycle into a stable, controlled machine. They must endure a relentless combination of vibration, temperature swings, moisture, salt, and occasional impacts, all while keeping the fairing precisely aligned with the frame and electrical interfaces. The materials selected for these brackets are, in essence, a statement about intent: a commitment to keep the rider protected, to preserve the bike’s silhouette against wind forces, and to ensure that every external layer—airflow, cooling, and electronics—remains intact under fatigue and time.

The chapter that follows examines the material spectrum, from heavy, rugged metals to lightweight, impact-absorbing plastics, and explains how the choice of material influences performance, maintenance, and the lifecycle of the bike itself. And as a practical note for riders and builders alike, the discussion is anchored in the realities of real-world operation: the way a bracket behaves under dynamic loads, the way it ages in sun and rain, and the way it integrates with the broader system of the motorcycle’s bodywork and mechanical architecture. To navigate this material landscape clearly, it helps to start with the broad categories and then move into how each category translates into riding characteristics, maintenance demands, and compatibility considerations.

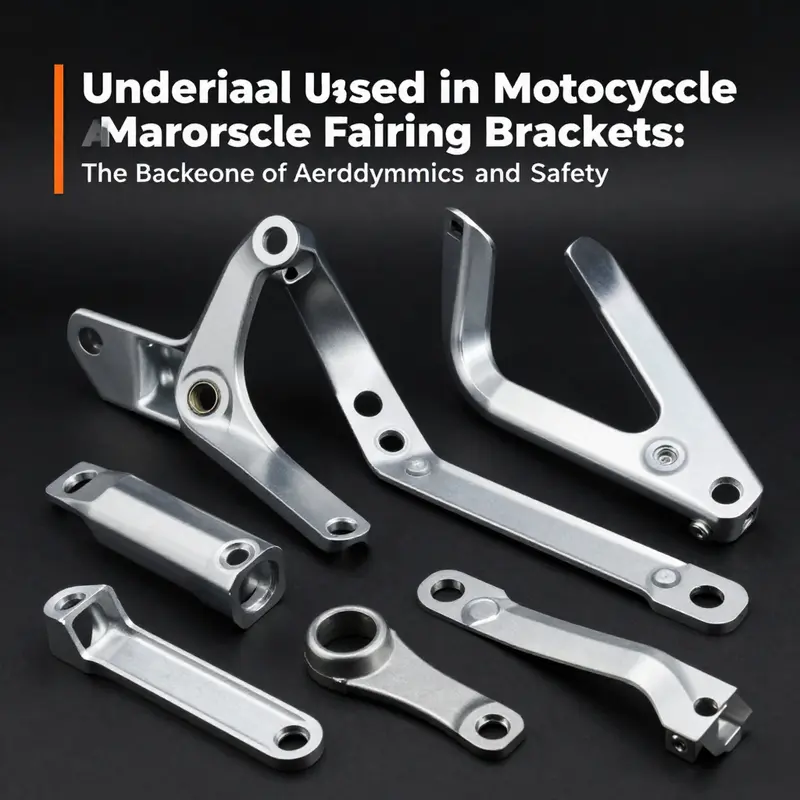

Metallic foundations—steel, aluminum, and stainless steel—offer a spectrum of strength, stiffness, and resilience that directly affects how a fairing remains in place at speed. Steel, especially carbon steel, is celebrated for its formidable strength and durability at a relatively low cost. It provides a robust backbone that can resist bending and fatigue even when the fairing is subjected to the forces of high-speed gusts, rough pavement, or a minor collision with road debris. However, this strength comes with weight. Brackets formed from steel are often heavier than their alloy and composite counterparts, and they require careful attention to coatings and corrosion protection to prevent rust in the presence of moisture, road salt, and humidity. In environments where moisture exposure is high or where salt spray is common, even a stout steel bracket can begin to suffer if protective finishes are compromised or if coatings wear thin. In those settings, the engineering team may prioritize protective plating or painting, or even switch to corrosion-resistant variants, to preserve longevity without sacrificing the geometry that keeps the fairing aligned.

Aluminum alloys present a different balance. Aluminum’s lightness is a prized attribute for performance-focused builds and for riders seeking to shed weight without sacrificing necessary stiffness. A bracket crafted from aluminum typically achieves a favorable strength-to-weight ratio, aiding the overall reduction of inertial load that arises from the fairing’s movement. Aluminum is also inherently resistant to corrosion, a property that makes it well-suited to the kinds of environmental challenges a motorcycle faces—wet roads, humidity, and exposure to the elements—without the same risk profile that uncoated steel carries. Yet aluminum is not a perfect substitute in every scenario. It can be more sensitive to galvanic corrosion if it comes into contact with different metals in the assembly, and certain aluminum alloys may be more susceptible to fatigue under repetitive bending or micro-movements induced by engine vibrations and aerodynamic loads. In performance applications, where every gram matters, aluminum brackets are often paired with optimized geometric designs and sometimes with reinforced sections to maintain stiffness where the fairing bolts to the frame. The manufacturing approach matters here: extrusion, forging, or CNC machining can tailor the bracket’s cross-sections to resist torsion and bending without adding excess weight, all while preserving the precise geometry required for proper fairing fitment and electrical harness routing.

Stainless steel sits at the more expensive end of the material spectrum, yet it brings an unmatched level of corrosion resistance and durability. In brackets exposed to harsh weather, road salt, and persistent UV exposure, stainless steel helps ensure that the structural connection remains sound and that the mounting points do not degrade over time. The higher cost reflects not only the material itself but also the manufacturing challenges involved in forming and finishing stainless components to exacting tolerances. For riders who demand longevity and who operate in climates where corrosive elements are a persistent concern, stainless steel brackets offer a reassuring margin of fault tolerance. They do not completely eliminate maintenance—protective coatings and periodic inspection remain wise practices—but they reduce the likelihood that a bracket will promote creaking, loosened fitment, or misalignment after many seasons.

Polymer and composite routes offer a different paradigm—one rooted in weight reduction, impact resistance, and heat management. Plastics and composite materials, including modified nylon and various reinforced polymers, are increasingly used where the interaction of weight, damping, and temperature is critical. Modified nylon formulations can exhibit excellent toughness, dimensional stability, and thermal resistance, making them a strong candidate for areas near the engine or other heat sources where temperature excursions would challenge metal brackets. The self-lubricating properties of certain polymers can help reduce wear on mounting interfaces, which translates into quieter operation and longer-lasting fastener integrity. Moreover, plastics and composites can be engineered to absorb vibrations more effectively than rigid metals, which contributes to a more stable fairing experience by reducing the onset of buzzing or rattle at high speeds or on rough surfaces. The downside is that polymers can suffer from creep under sustained load, particularly if exposed to elevated temperatures, and their stiffness is generally lower than that of metal. In practice, engineers select polymer brackets for roles that benefit from damping and attack them with gasketing strategies or metal inserts where necessary to sustain load paths and maintain precise alignment. When combined with reinforced fibers, plastics can approach the stiffness and heat resistance needed for demanding riding conditions, while still delivering a notable weight advantage.

The blend of materials is rarely a matter of choosing one path; it is the art of combining methods to achieve the right mechanical signature for a given model and use case. For example, a bracket designed to support a heavier, fully faired configuration might lean toward a metal core with a polymer cover or a polymer ribbing that adds damping without dramatically increasing weight. In other configurations, a bracket might be primarily aluminum with a carbon-fiber composite insert at critical load points to reinforce torsional stiffness without bloating weight. The objective is to align the bracket’s mechanical behavior with the fairing’s functional demands: precise fitment, stable aerodynamics, and compatibility with the electrical harnesses and mounting hardware that pass through or around the bracket width. This multi-material approach reflects a broader engineering principle: the system-level performance of the motorcycle’s bodywork is only as good as the weakest link in its connection to the frame, and the bracket is the bridge between aesthetic sculping and structural reality.

The design process that governs these material choices is informed by manufacturing realities and by the environmental and operating conditions the bike will encounter. Metal brackets often rely on established forming technologies—stamping, casting, forging, and precise machining—to achieve exact mounting points, holes, and threads that align with the frame geometry and with the fairing’s interface points. When plastics or composites are in use, injection molding or advanced resin transfer molding can create complex, integrated features that reduce assembly time and provide tailored damping at strategic locations. In both cases, the goal is to minimize tolerances that could contribute to misalignment or gaps in the fairing’s outline, which can degrade aerodynamics and create wind noise or flutter at high speeds. The material’s response to loads—yield strength, elongation, fatigue limit, and creep resistance—drives choices about wall thickness, rib locations, and the presence of reinforcements. In a well-engineered bracket, those ribs and reinforcements are not decorative; they’re precisely positioned to maintain geometry under the repeated vibrational cycles that every ride sustains.

Beyond raw material properties, the bracket’s life is shaped by how it interacts with the broader ecosystem of the motorcycle’s design. The frame geometry, the fairing’s own weight and stiffness, and the arrangement of fasteners, clips, and electrical connectors all feed back into material selection. A bracket must tolerate the torque applied during installation and the loosening risks that can arise from vibration, especially in high-frequency regimes typical of race-track environments or rough road surfaces. In the best cases, brackets are finished with protective coatings, whether a corrosion-resistant plating, a powder-coat layer, or a weather-resistant paint system, to shield against moisture and road grime. A well-protected bracket not only survives but also maintains a stable fit and consistent torque over years of service. It’s common to see design strategies that anticipate maintenance intervals—bolts checked at yearly service or every major ride—so that any nickel-sized looseness is detected before it translates into misalignment, which would ripple through the fairing’s line, the rider’s perception of wind pressure, and the overall character of the bike’s silhouette.

Material choice therefore is not merely an engineering footnote but a core determinant of performance, feel, and even resale value. Factory-original brackets, built to exact factory tolerances, offer the purest assurance of fitment with the fairing and the electrical system, and they help preserve the bike’s original geometry. But they are not always the lightest or the cheapest option. Aftermarket brackets, by contrast, can emphasize weight reduction or enhanced damping, sometimes at a higher risk of misalignment if the chosen material and design do not harmonize with the bike’s frame and fairing contours. The careful reader will recognize that this trade-off—between precision and customization, between rugged durability and weight savings—depends on how the rider uses the bike. A track-focused machine may justify the expense and complexity of high-performance, multi-material brackets, while a street rider seeking longevity and predictable maintenance may prefer the proven robustness of metal brackets with proven corrosion resistance and straightforward repairability. In either path, the materials chosen shape not only the bracket’s own performance but also the dynamic relationship among fairing, rider, and machine, preserving the aerodynamic envelope and the functional integrity of the front end under a spectrum of riding conditions.

To connect the technical with the practical, consider the way a bracket’s material profile affects upkeep. Metal brackets demand attention to fastener integrity, surface coating condition, and potential corrosion at contact points where different metals meet. Over time, thermal cycling can influence permissible torque ranges, and minor surface changes can alter the seat of the fairing, inviting rattles or a misaligned panel line. Polymer-based brackets, with their damping and wear-resistant traits, may reduce noise but can require vigilance for creep or UV-induced changes in dimensional stability, particularly in hot engine compartments or direct sun exposure. The most successful implementations blend the strengths of these materials, matching the bracket’s function to the bike’s intended use, environment, and maintenance plan. For riders who seek a balanced approach, a bracket that maintains alignment with a light but stiff aluminum core and a polymer-insulated interface can deliver a quiet, predictable ride with manageable maintenance. For those chasing the utmost in endurance and weather resilience, a stainless-steel backbone with a protective coat might offer a longer service interval and more predictable performance in salt-laden environments.

In the end, the chapter on materials for motorcycle fairing brackets is a reminder that the small, unseen parts of a motorcycle often carry the weight of performance and longevity. The choice of steel, aluminum, stainless steel, or modified plastics is not an abstract exercise in material science but a practical argument about how a rider and a machine will work together over time. It is a decision that shapes how cleanly the bike cuts through air at 200 kilometers per hour, how quietly the rider experiences wind and vibration, and how resilient the bike remains after years of exposure to heat, rain, sun, and road grit. For anyone building, restoring, or simply understanding a modern sport bike, appreciating this material backbone helps illuminate the delicate choreography that occurs every time you twist the throttle and the fairing snaps into its ideal position against the frame, directing airflow with precision and reliability. The literature and standards that guide these choices reinforce a shared commitment to performance and safety. Industry standards bodies provide specifications for materials used in automotive and motorcycle components, offering benchmarks for strength, durability, and environmental resistance. These guidelines help designers select materials that perform consistently across a range of operating temperatures and loading scenarios, ensuring that a bracket will hold in place under the forces of cornering, turbulence, and road irregularities. For readers who would like to explore the technical depths of material performance in this domain, a valuable external reference is the SAE J2520 standard, which outlines material properties and testing techniques relevant to automotive and transportation components.

For those who want to see how the material story translates into real-world product choices and design practice, the catalog of fairing components offers a spectrum of configurations that illustrate the marriage of form and function. The pathway from raw material to a finished bracket involves careful material selection, precise fabrication, and rigorous testing to confirm that fitment, endurance, and performance meet the demands of riding at high speed and in varied weather. The bracket’s construction thus serves as a microcosm of the broader engineering philosophy that underpins modern motorcycles: optimize weight and stiffness where it matters, protect against the elements where durability is critical, and ensure that every interface—whether it is a bolt, a clip, or a seam—works together with the rider’s intent. In this sense, the chapter on materials is not a solitary technical note but a thread that ties the visible lines of the fairing to the unseen but decisive forces that govern how a motorcycle feels, rides, and ages.

As the discussion draws to a close, it is worth circling back to the practical implications for riders and builders who are weighing bracket options on their next project. The material foundation of a fairing bracket influences more than just weight; it affects how the panel stays aligned through vibrations, how the harnesses route without chafing, and how easy it is to service the fasteners after a winter ride. It also informs the choice between OEM solutions, which deliver guaranteed compatibility with the rest of the bike’s architecture, and aftermarket alternatives, which can offer weight savings, improved damping, or enhanced corrosion resistance but may require more meticulous inspection and careful torque management during installation. Wherever the project sits on that spectrum, the guiding principle remains consistent: select materials that harmonize with the bike’s geometry and operating environment, and respect the assembly constraints that maintenance and repair will impose down the road. The result is a fairing that not only looks right but behaves predictably under load, supports the rider’s control inputs, and endures through the miles with grace and reliability. For readers seeking a cue to broader material innovations in motorcycle manufacturing, the 2023new category page offers a concise snapshot of how material strategies are evolving in tandem with design ambitions, while staying firmly tethered to the practical realities of fitment and durability. 2023new

Externally, the literature of materials science and industry practice continues to push the envelope in ways that will increasingly influence bracket design. The ongoing development of high-performance polymers with improved heat and UV resistance, the advent of advanced aluminum alloys with superior stiffness-to-weight ratios, and the refinement of corrosion-resistant coatings will likely yield brackets that are simultaneously lighter, stronger, and more durable. Advances in additive manufacturing also open possibilities for optimized bracket geometries with internal channels for lightning-fast harness routing or integrated damping features that would be impractical with traditional manufacturing. These trends suggest a future where fairing brackets become even more closely tailored to the dynamic demands of each model, with performance targets defined not by generic category labels but by the exacting needs of track days, street commuting, or long-haul touring. The chapter’s focus on materials, after all, is a doorway to understanding the broader evolution of motorcycle bodywork—where every gram saved and every millimeter of stiffness gained translates into a more predictable ride, a cleaner aerodynamic profile, and a longer life for the bike’s carefully engineered front end.

For readers who want to anchor this discussion in accessible, standards-based guidance, the external reference to the SAE J2520 standard provides a foundation for evaluating material performance in a robust and transferable way. This standard, and others like it, helps engineers translate laboratory measurements into real-world reliability. By integrating such standards into the material selection process, designers and technicians can anticipate how brackets will behave under the rigors of daily riding, track sessions, and cross-country tours. In the end, the material choices behind fairing brackets reveal a quiet but decisive truth about riding: performance is built on the union of form and function, and function begins with material choice. When the bracket’s material design is done well, the fairing kisses the wind with confidence, the rider feels the ride rather than the support, and the bike remains a faithful companion for miles and miles of riding that matter. The next chapter will continue to unfold how mounting hardware, fasteners, and mounting geometry complete the picture, tying together materials, fitment, and the rider’s experience in a single, coherent journey.**

null

null

Final thoughts

Motorcycle fairing brackets are not merely functional components; they are vital to creating a safe and efficient riding experience. Understanding their significance in aerodynamics and safety is crucial for anyone in the motorcycle industry. Knowledge about the materials used in these brackets further delineates the choices available and their implications on performance. Finally, discerning the differences between OEM and aftermarket options enables business owners to cater to the diverse needs of riders. By prioritizing the right fairing brackets, businesses can enhance their offerings, ensuring customer satisfaction and safety on the roads.