Motorcycle carbon fiber fairings are reshaping the motorcycle industry, offering significant performance enhancements while also delivering aesthetic appeal. This article delves into various types of carbon fiber fairings available, illuminating their applications in the market. It further elaborates on technological advancements in their manufacturing processes, which provide compelling economic advantages for businesses leveraging these innovations. Lastly, the impact of these fairings on rider experience and safety will be examined, providing a comprehensive understanding of their benefits and value proposition in the competitive motorcycle landscape.

Shaped by Wind and Weight: Exploring the Types of Carbon Fiber Motorcycle Fairings and Where They Shine

Carbon fiber fairings sit at the crossroads of aerodynamics, engineering, and identity on a motorcycle. They are not merely cosmetic shells but performance systems that influence everything from drag and stability to heat management and ride feel. The material itself—an advanced composite with carbon filaments embedded in a resin matrix—offers a remarkable strength-to-weight ratio. This balance lets designers thin the shell without sacrificing stiffness, so the fairing can be slim and sculpted while still defending fragile components and guiding airflow. The payoff is tangible: faster acceleration, sharper braking, more precise cornering, and better fuel efficiency at speed. Yet the value goes beyond numbers. The visual language of carbon fiber—the weave, the gloss, the way light plays across its depth—speaks to a rider’s connection with performance, speed, and precision. In this chapter, we unpack the main categories of carbon fiber fairings and illuminate where each type is most effective, why riders choose one path over another, and how modern manufacturing and fitment practices expand those choices without compromising reliability or safety.

The practical landscape begins with the recognition that carbon fiber fairings come in configurations engineered for different riding objectives. At one end of the spectrum, complete fairing sets encase the entire body of a motorcycle. These are designed for maximum aerodynamic efficiency and full wind protection. They are most common on track-focused machines and high-performance sport models where the rider seeks every possible advantage in drag reduction, downforce, and smooth airflow over the rider’s torso at high speeds. The full enclosure also yields a unified aesthetic—an uncompromising, race-inspired look that signals intent and capability. At the opposite end lie partial or modular fairings. This approach replaces only specific sections of the bike, such as the front cowl, side panels, or tail section. The modular strategy is especially compelling for riders who value customization and incremental performance gains without the upfront cost and complexity of a complete set. By swapping particular panels, the bike can achieve improved aerodynamics in targeted zones, while preserving existing engineering on areas that maintain accessibility for maintenance and service. Between these two poles sits a spectrum of custom-designed fairings that blend personalization with performance. A fairing crafted for a particular rider can feature integrated vents, unique shapes, and personalized graphics, all tuned to the bike’s geometry and the rider’s temperament. In a similar spirit, race-ready fairings push the envelope on downforce and cooling. They are optimized for endurance and circuit racing, where airflow management and thermal performance become critical under sustained high-speed operation. Each configuration has its raison d’être, and understanding the distinctions helps riders decide when and why to upgrade.

What makes the complete set genuinely transformative is more than just coverage. It is the way the entire surface works as a single aerodynamic system. Full fairings streamline the front profile, smooth the flow along the sides, and defend the engine and radiators from debris and turbine-like air separation that can occur at racing speeds. When engineered with precision, these sets minimize drag while guiding air to where it can stabilize the bike’s motion, maintain consistent downforce, and reduce buffet at the rider’s helmet height. The weight savings compared with traditional ABS or fiberglass counterparts amplify the effect. Every extra kilogram saved translates into quicker throttle response, lighter steering effort, and more agile handling through sweepers and hairpin corners alike. The sonic and tactile cues of carbon—its rigidity, its slight flex under load, the assurance that the structure remains stable as temperature and speed shift—contribute to a rider’s confidence as much as any numeric gain.

Partial and modular fairings honor a different philosophy: they lower the barrier to entering carbon fiber performance without demanding a wholesale rebuild. For many riders, swapping a front cowl or upgrading the side panels delivers meaningful gains in airflow management and engine cooling while retaining the bike’s original balance and ergonomics. It is a precise art to preserve the chassis’ mass distribution and the rider’s seating geometry when only a portion of the outer shell is changed. The result can be a sharper throttle peak, crisper midrange response, and a more composed surge through mid-corner transitions, all without the expense or downtime of a full kit. Custom-designed fairings take that approach further, merging technical performance with a rider’s stylistic vision. Integrated vents that feed cooling paths, sculpted ducts that optimize crossflow, and graphics that reflect a unique narrative all contribute to a package that feels bespoke from the moment the screws are tightened. In many respects, these designs reflect a philosophy of intentional engineering rather than a one-size-fits-all solution.

Race-ready fairings inhabit a domain where the engineering conversation becomes almost clinical. Here, every line is scrutinized for aerodynamic efficiency and thermal performance. The shapes are tuned for downforce at high speeds, with a focus on maintaining stable wind pressure across the suit of the rider as corner speeds and tire temperatures push the envelope. The goal is to reduce drag and improve air extraction from between the machine and the atmosphere, so the engine can breathe easier and the bike can hold its line through sustained laps. In endurance contexts, even small gains in cooling can delay heat soak and preserve power output over longer stints. The cumulative effect of these choices is a bike that feels almost telekinetically responsive to a rider’s inputs—turn-in feels immediate, stability at the exit of a corner is confident, and the overall chassis character remains predictable as speed climbs.

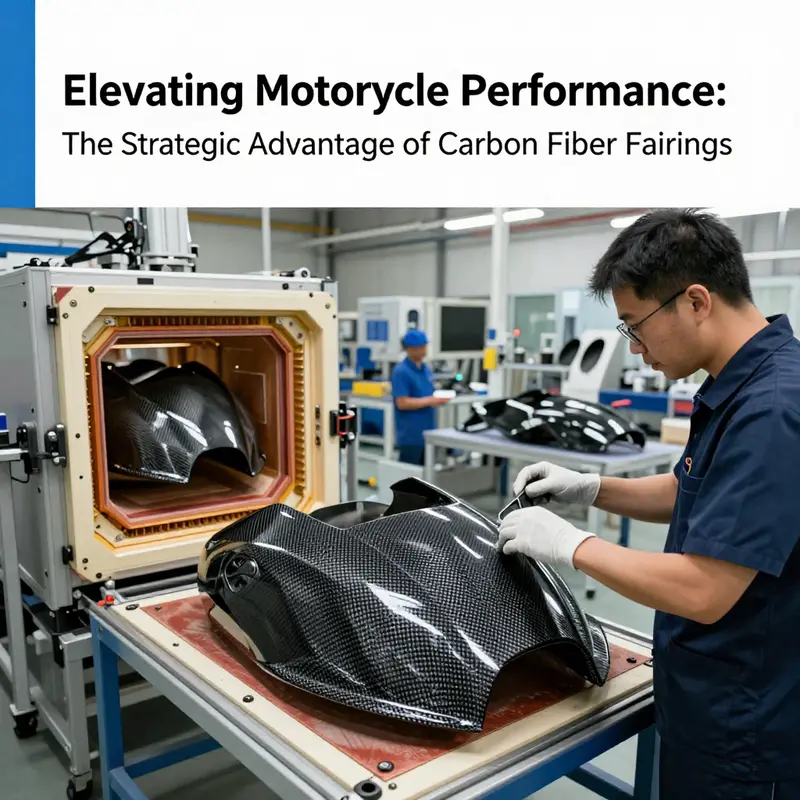

The conversation about types and applications would be incomplete without acknowledging how production realities shape these choices. Modern carbon fiber fairings are rarely monolithic curiosities; they are the product of careful manufacturing processes designed to ensure repeatable fit and consistent performance. Techniques such as autoclave curing produce stiff, dimensionally stable laminates with high resin content control. In some cases, dry carbon fiber preforms are used to reduce resin weight further, with resin infusion or vacuum-assisted methods ensuring precise plies and consistent mechanical properties. Certification and quality assurance have become standard expectations in serious supply chains. Quality marks and process standards—alongside eco-conscious packaging and traceability—help buyers trust that the panels will align with the bike’s mounting points, instrument clusters, and bodywork contours without inducing rubbing, misalignment, or paint issues under heat cycling and vibration. For riders and teams pursuing peak performance, these factors matter as much as the aesthetic and the raw weight savings.

A practical note accompanies every upgrade: fitment matters. Even the most advanced layup cannot compensate for a misaligned panel or a misfit tail section. Model-specific design is not an afterthought; it is a core feature. Engineers study the bike’s frame geometry, fairing mounting points, standoff locations, and the routing of wires and hoses to ensure the kit integrates cleanly. In the real world, that means a fairing set is not simply bolted on; it is aligned to preserve clearances, avoid heat trapping near exhausts, and leave unimpeded access to service points. The modular approach often helps here, offering a balance between wind-tunnel-informed shapes and practical maintenance needs. The end result is a kit that feels like it was built for the machine from the outset, not cobbled together after purchase.

Weight reduction remains a common thread across all categories, but the exact gains depend on the design philosophy and construction method. A premium dry carbon approach might shave weight by several kilograms per set compared with conventional composite or plastic, while high-end partnerships claim substantial performance perks when combined with a meticulous fit and finish. It is not unusual to see riders quote improvements in power-to-weight ratio, traction through corners, and throttle response in the context of a well-fitted kit. For one high-end application, a dry carbon set reduced overall mass by as much as about 2.5 kilograms per full kit, translating to a measurable improvement in power-to-weight and overall response, particularly on the street when paired with a tuned intake and exhaust strategy. Such figures underscore the holistic nature of performance upgrades: aerodynamics, weight, cooling, and chassis dynamics all interplay to shape ride quality.

As riders move from concept to purchase, cost considerations inevitably arise. Complete sets deliver the most comprehensive aerodynamic package but also command the highest price and a longer installation timeline. Partial or modular sets offer a more scalable path; they let the rider target specific aerodynamics goals while preserving core sections of the bike’s original shell. For some, a custom-designed arrangement is the ideal middle ground—size, shape, vent positioning, and graphics curated to personal taste while preserving the fundamental performance benefits. The decision often hinges on how much the rider values seamless integration with electronics, ease of maintenance, and the ability to fine-tune balance between weight savings and practicality for street use versus track dwell time. The best outcomes arise when riders work with reputable suppliers who can verify fitment, confirm compatibility with the bike’s electrical and cooling systems, and provide clear guidance on installation and maintenance.

For those who want to explore more about the principles behind choosing the right carbon fiber fairing system, a comprehensive guide offers valuable context on fit, weight, durability, and overall lifecycle considerations. The guide delves into how to compare options and balance performance gains with everyday riding realities. While the specifics of the models and races are outside the scope of this discussion, the core ideas remain the same: understand what you are optimizing for, verify fitment with your machine, and seek materials and constructions that maintain strength under load while minimizing weight. A practical takeaway is to treat the fairing upgrade as part of a broader performance package that includes suspension, tires, braking, and airflow management around the radiator and intake paths.

Riders should also consider the broader ecosystem around these components. Manufacturer-neutral attestations, certified packaging, and quality-control benchmarks help ensure that a fairing kit will arrive in serviceable condition and install without dramatic modification. A model-specific kit, even when it is a premium option, pays off when it preserves the bike’s geometry, allows for straightforward removal in the field, and holds up under the rigors of track days or daily riding alike. A well-choreographed upgrade will feel like a natural extension of the bike’s engineering, enhancing both the machine’s performance envelope and the rider’s confidence.

In closing, the decision to adopt carbon fiber fairings—whether full, partial, custom-designed, or race-ready—rests on a simple realization: weight matters, and how air flows around the bike can be as consequential as the power under the engine. The right type of fairing aligns with the rider’s goals, the bike’s philosophy, and the conditions in which the machine is most often used. When executed with attention to fitment, materials, and a thoughtful balance of aerodynamics and accessibility, carbon fiber fairings transform not just the look of a motorcycle, but its behavior on the road and the track. They become a deliberate statement that combines speed, precision, and personal expression into a single, coherent package.

Internal link reference: To see how this translates in model-specific contexts and to explore catalog-level choices that emphasize fit and finish, consider the yamaha-fairings catalog as a practical starting point for understanding modular upgrade paths and fitment considerations. yamaha-fairings

External resource for deeper guidance: https://www.vulturbike.com/carbon-fiber-fairings-guide/

null

null

The Economic Equation of Performance: Weighing Carbon Fiber Fairings in Motorcycling

The economics of motorcycle carbon fiber fairings sit at a crossroads where engineering ambition meets real-world budgeting. They are premium components designed to shave weight, optimize aerodynamics, and sharpen handling. Yet their allure is tempered by a cost that sits well above traditional ABS plastic or fiberglass alternatives. This tension between immediate price and long-term value shapes how riders, shops, and manufacturers approach fairing upgrades. To understand the full picture, it helps to look at three interlocking dimensions: the upfront investment, the lifecycle value, and the shifting market dynamics that govern pricing, availability, and performance expectations.

The upfront cost of carbon fiber fairings is the most conspicuous hurdle. Carbon fiber, especially in high-quality autoclave-cured builds, commands a material and process premium. The materials themselves are strong and light, but the real expense lies in the manufacturing techniques. Autoclave curing, resin systems, precise layups, and quality control add layers of cost that go beyond simple material pricing. For riders used to replacing cracked plastic panels after a tip-over or a mid-ride encounter with a road hazard, the sticker shock is steep. The financial barrier is not simply about buying a new set; it encompasses installation complexity, fitment accuracy, and the potential need for professional alignment and trim work. In practical terms, many aftermarket carbon fiber fairings come as comprehensive bodywork systems that require careful mounting and sometimes additional hardware. The result is a purchase that can feel daunting, especially for daily commuters or riders with tight maintenance budgets.

Yet the price tag begins to make more sense when viewed through the lens of long-term value. Carbon fiber fairings bring durability that outlasts their plastic predecessors in ways that alter lifecycle costs. They resist cracks and impact damage more effectively, reducing the frequency of panel replacements after minor mishaps or highway debris. In a best-case scenario, their toughness translates into fewer trips to a body shop, lower insurance claims related to cosmetic or aerodynamic damage, and less downtime when the bike is your primary transportation. Over the lifecycle, these durability advantages can translate into meaningful savings, even if the initial investment remains higher. In addition, maintenance requirements for carbon fiber panels tend to be lower than for painted plastics or composite shells that rely on fragile coatings. A simple, high-quality clear coat or UV-resistant finish can guard against environmental degradation, while the inner resin-impregnated layers stay structurally stable through multiple seasons of riding. In the long run, the reduced frequency of replacement parts and the lower likelihood of complete panel failure contribute to a lower total cost of ownership.

Aerodynamics is the third pillar in this economic equation, and it carries both tangible savings and nuanced tradeoffs. The lighter, more rigid architecture of carbon fiber fairings supports a cleaner, more efficient airflow around the bike. This improved aerodynamics can yield better high-speed stability, smoother acceleration, and more predictable cornering, all of which contribute to safer and more confident riding at speed. The fuel economy advantages, while highly dependent on riding style and routes, can be meaningful for riders who spend long hours on highway corridors or who travel substantial distances. In touring and sport-touring setups, where fuel economy compounds over thousands of miles annually, even a modest percentage improvement in efficiency can accumulate into noticeable lifetime savings. It is important to calibrate expectations here: carbon fiber’s performance gains are real but context-dependent. A rider cruising at highway speeds on windy days may see measurable, if not dramatic, improvements, while aggressive track riding emphasizes weight reduction and stiffness over mere fuel savings.

The durable, aero-optimized profile also influences resale value and depreciation in ways that savvy buyers monitor closely. A well-maintained carbon fiber fairing kit tends to retain its appearance and structural integrity longer than lower-cost alternatives. This translates into a higher residual value for the bike when it comes time to sell or upgrade. The higher upfront cost can then be recouped to a degree through a stronger resale price, depending on how well the system was installed, how it was maintained, and the overall condition of the motorcycle. In markets that prize performance and customization, carbon fiber fairings can be a differentiator, signaling the rider’s commitment to optimization and high-mileage reliability. This brand-agnostic narrative—that look, feel, and track-ready performance can command premium in the used-bike market—helps justify the investment to a subset of riders who view their machine as both a daily rider and a venture into performance engineering.

Market dynamics over the past few years have shifted the economics of fairings in meaningful ways. Industry observers point to a growing emphasis on lifecycle value rather than merely upfront price. A 2025 industry assessment highlighted a broader willingness among riders and OEMs to invest in premium materials because of their long-term performance and durability. At the manufacturing level, advances in composite processing—such as optimized dry carbon fiber layouts and refined resin transfer methods—are reducing waste and lowering unit costs. While not erasing the price premium entirely, these innovations narrow the gap between carbon fiber and traditional materials for a wider range of riders. Certification schemes and quality controls, including environmental and safety standards, add to the cost structure but also provide a layer of assurance that supports resale value and performance consistency across models and generations. In other words, the economic narrative is moving from “can you afford it?” to “does the investment align with my riding needs, mileage, and maintenance philosophy over the bike’s life?”

Riders who log heavy miles or participate in frequent track days often weigh this equation in pragmatic terms. For daily commuters, the premium may appear excessive when the bike’s year-to-year usage remains relatively modest. For riders who cover thousands of miles per year, the calculus shifts: weight savings and aerodynamic efficiency become factors that compound with mileage. A heavier rider or one who rides into strong headwinds on a constant basis can gain a perceptible performance edge from carbon fiber, which translates into a more confident ride and less rider fatigue over long sessions. The practical takeaway is that the value proposition is not one-size-fits-all. It hinges on mileage, riding style, climate, road conditions, and the rider’s willingness to invest in optimization that extends beyond aesthetics. Those who view their bike as an extension of a high-performance identity—whether for weekend track practice, long-distance touring, or spirited canyon runs—often place the premium fairings within a broader strategy of maintenance discipline, future upgrades, and resale planning.

In shaping decisions, many riders consult a broader ecosystem that extends beyond the poetry of lighter weight. The availability of model-specific kits matters. When a kit is designed to fit a particular model generation with high precision, installation time and maintenance access improve. That precision reduces the risk of misfit issues that can complicate servicing or require professional intervention, thereby containing long-run maintenance costs. Yet the precision itself, achieved through meticulous engineering and testing, contributes to the overall price. The ecosystem also includes aftermarket suppliers who certify their products and provide packaging that emphasizes safety, environmental responsibility, and long-term durability. Certifications and quality assurances act as a counterbalance to price, giving buyers a measure of confidence that the savings on maintenance or fuel won’t be offset by hidden repair costs or warranty headaches down the line.

From a consumer perspective, several decision-making vectors emerge. Budget-conscious riders need to balance upfront price against mileage, maintenance expectations, and the value they place on ride feel and aesthetics. For those who ride largely in urban environments with occasional longer trips, the economics lean differently than for sport-riding enthusiasts or tourers who push their machines into more demanding regimes. In this context, the economic narrative becomes less about a single number and more about a lifecycle forecast—how soon the rider expects to recoup a portion of the investment through performance gains, durability, and resale value. It is not unusual for riders to treat carbon fiber fairings as an investment in the bike’s DNA: a way to preserve structure, optimize aero balance, and sustain the bike’s visual identity under high-speed stresses and frequent exposure to road grit. The premium is then reframed as a deliberate choice to extend riding pleasure, reduce downtime, and sustain performance across years of ownership.

To illustrate how these decisions unfold in practice, consider how model-specific fitment can influence both cost and value. When a kit is tailored to a particular motorcycle generation, the likelihood of a clean, efficient installation increases. This reduces labor costs if installation is performed by a shop, and it minimizes the chance of delays caused by misfit parts or the need for additional trimming. A precise kit also enhances aerodynamics and structural integrity from the outset, which compounds the benefits discussed earlier. In this context, buyers often seek out catalogs or suppliers that emphasize model-specific fit and traceable performance data. An example of the procurement logic is to explore a dedicated catalog that lists available kits for different platforms and generations, enabling a rider to compare weight reductions, rigidity improvements, and installation ease across options. The underlying principle is straightforward: when the fit is right, the performance payoff becomes more predictable and the lifecycle value more favorable. For riders exploring these upgrades, a practical path is to consult a model-focused fairings catalog that verifies fitment and performance claims before making a purchase, rather than assembling a collection of mismatched panels that may require extra modifications or compromise aerodynamics.

Another layer in this economic dialogue is the environmental and manufacturing context. The global push toward more sustainable engineering practices places a premium on waste reduction and responsible sourcing. Although carbon fiber itself is not inherently cheap to manufacture, improved process efficiency and more selective fiber placement reduce waste and energy use per panel. This has a downstream effect on total cost and on the sustainability profile of the product. From a lifecycle standpoint, buyers are increasingly sensitive to environmental stewardship in supply chains, especially when the packaging, shipping, and disposal of composite parts are considered. While these factors do not alter the sticker price, they influence the perceived value and the willingness of buyers to invest, knowing the purchase aligns with broader values around durability, recyclability, and responsible production.

Looking ahead, the economic picture for carbon fiber fairings appears to be evolving rather than static. Manufacturing advances are tightening the gap between premium composites and traditional materials. As processing becomes more efficient and as more suppliers offer certified, model-specific kits, accessibility will improve. OEMs and aftermarket players alike are recognizing the demand for long-term value, not just fast performance. In this light, carbon fiber fairings are less a transient luxury and more an established instrument in the rider’s toolkit for achieving consistent performance, predictable maintenance, and higher sustained resale values. They are not universally essential, but for a growing segment of riders—those who measure performance in miles, stability, and the certainty of a well-preserved machine—the economic case becomes increasingly robust.

For readers who want to explore concrete pathways within this market, a practical approach is to examine model-specific upgrade options and the associated lifecycle costs, then compare those against riding mileage, maintenance habits, and maintenance access. In doing so, the narrative of carbon fiber fairings shifts from a simple price tag to a broader decision about durability, efficiency, and the ownership experience. When evaluated this way, carbon fiber fairings emerge not merely as a cosmetic enhancement but as a calculated investment in performance longevity and total ownership satisfaction. As markets continue to mature, the balance between upfront cost and long-run value will increasingly favor options that demonstrably improve stability, reduce maintenance frictions, and preserve the bike’s performance envelope over many seasons of riding.

For readers seeking a concise starting point on how to evaluate fitment and value across model-specific options, the Ducati fairings catalog provides a clear example of how manufacturers and retailers organize kits for precise fit and performance. ducati-fairings This kind of structured resource helps riders align their expectations with measurable outcomes, reinforcing the idea that the economic case for carbon fiber components rests on more than aesthetics.

External resources that synthesize market dynamics and material standards can offer broader context for this decision. For a comprehensive view of how the fairing market is evolving and what that means for cost, availability, and consumer expectations, see the external analysis at the following resource: https://www.motorcycleindustry.org/market-insights/fairing-market-dynamics-2025

Beyond the Glare: How Carbon Fiber Fairings Redefine Handling, Comfort, and Rider Safety

Riding a motorcycle equipped with carbon fiber fairings feels like engaging with a refined extension of the machine itself. The idea is simple in execution but transformative in practice: lighter weight, precise shaping, and a disciplined coupling between airflow and chassis dynamics. When the fairing shell is composed of carbon fiber—known for an exceptional strength-to-weight ratio—the bike inherits not only a leaner silhouette but also a welcomed improvement in how it responds to rider input, how it slices through air, and how it shields rider and engine from the elements. The impact on riding experience emerges from a chain of interdependent effects. The most immediate is handling. In the front of most sport and performance motorcycles, the fairing represents a substantial portion of the machine’s mass that interacts with steering, suspension, and geometric stability. Reducing that mass by even a handful of kilograms creates a more nimble front end. The rider senses quicker turn-in, brighter steering feedback, and less effort required to initiate and complete a lean through corners. This isn’t merely about speed; it’s about a tuned sensitivity that translates into confidence on uneven surfaces, imperfect road crown, or changing racing lines. The effect is particularly noticeable during rapid transitions in direction, where every gram saved in the fairing few reach the rider as faster response and more precise control. The ride becomes more instinctive, less pendulum-like, and more like a well-tought extension of the rider’s intent. This is closely related to the broader understanding of lightweight materials in high-performance bikes, where weight reduction translates into a more favorable power-to-weight ratio and a more immediate translation of rider input into chassis movement. The math behind the feel is not always explicit, but the sensation is undeniable: a lighter front end requires less force to steer and stabilizes quicker as the bike accelerates or changes direction. Aerodynamics then multiplies this effect. A carbon fiber fairing can be engineered with tighter tolerances and more exacting curvature than heavier alternatives. The result is smoother airflow that reduces drag, minimizes flutter at highway speeds, and suppresses turbulent gusts that would otherwise buffet the rider or destabilize the bike during long stretches or demanding cornering sequences. For the rider, the most tangible benefit is a calmer, quieter ride. Wind noise, a common fatigue factor on long rides, is dampened when the fairing’s shape channels air efficiently around the rider and helmet. The reduction in wind pressure not only lowers fatigue but also lessens neck and shoulder strain, enabling longer sessions with less muscular tension. This contributes to sustained focus, sharper decision-making, and a heightened sense of situational awareness on twisty roads or open highways. The rider’s comfort is not purely a matter of acoustic relief; it ties directly into how posture is maintained and how the body interacts with the bike over miles. When wind pressure drops and airflow remains well-managed, the rider experiences less shudder or buffeting at speed. This translates to a more relaxed upper body, steadier head position, and improved helmet stability. The net effect is a more comfortable ride that can stretch into longer days without the typical fatigue that can dull judgment or reaction time. Safety sits atop these experiential gains, anchored in stability, energy management, and protective design. A lighter bike is inherently more controllable, particularly at high speeds, where drag forces increase and subtle steering inputs become critical for maintaining course. The reduced drag allows the engine’s torque to be harnessed more efficiently, so the rider retains smoother acceleration and braking transitions. In braking, reduced weight means the front wheel can bite more decisively without demanding excessive lever effort, provided the brake system and tire grip are compatible with the new dynamics. The overall stability at lean, the way the fairing’s geometry governs the interaction between air and wheel track, and the more consistent airflow all work together to minimize unexpected deflections that can spike a rider’s risk under sudden gusts or surface irregularities. Beyond fresh handling, there is a dimension of protection that is often understated. The fairing, while primarily a shield against wind, debris, and moisture, is also part of an energy- management strategy in a crash scenario. Carbon fiber as a material offers high stiffness and good energy-absorption characteristics when properly engineered into a fairing system. Its rigidity helps maintain a predictable crush path that can dissipate some energy away from the rider. At the very least, a well-designed fairing keeps the rider’s line of sight clear by deflecting rain and gravel and by managing the wind-borne resistance during a gust. In practical terms, this protection means fewer stray particles striking the rider’s visor or helmet shield, which contributes to safer, more confident highway or track riding. The rider’s awareness of the environment remains high because the cockpit is less compromised by wind noise and visual disruption. The cumulative effect of these dynamics is a safer riding experience that emphasizes calm, controlled movements over reactive adjustments. It is not about turning a bike into a barrier but about ensuring that the rider can see, react, and maneuver with precision at the edge of performance. The quality of the fairing kit matters as much as the material itself. Precision fitment and engineering details—such as tab locations, mounting philosophies, and the interplay with subframes and radiators—determine how consistently the weight saving translates into real-world handling gains. When the kit is designed for a specific model era or generation, it respects the bike’s original geometry and intended riding characteristics. This alignment makes the weight reduction feel natural rather than contrived. It also preserves serviceability. The modularity of modern carbon fiber kits allows for selective replacement of sections that might sustain damage in a fall or require maintenance access. In that sense, the owner benefits not only from performance but from the practical economy of repairs and maintenance. The integration of high-precision manufacturing steps, such as autoclave curing and dry carbon fiber techniques, ensures the final product delivers the promised properties. It is not just about surface appearance; it is about sustained stiffness, dimensional stability, and resilience against highway debris and minor impacts. Certifying processes and quality controls—ISO or similar standards—provide assurance that the kit performs as promised and that its environmental footprint aligns with responsible manufacturing practices. The broader context reveals why riders seek a model-specific, carbon fiber fairing system. The industry acknowledges that weight savings matter, but it also emphasizes the cumulative effect of proper design. A well-executed kit reduces waste through precision machining, minimizes retrofit time, and preserves the bike’s balance across different riding modes. The rider’s daily experience—whether a spirited ride on a back road, a track day, or a long-distance tour—benefits from smoother dynamics, quieter wind exposure, and enhanced safety margins that come from more stable airflow and better control at the limits. It is important to acknowledge that carbon fiber fairings are a premium upgrade. Their benefits are best realized when the installation respects the bike’s architecture and when the rider’s expectations align with what the material can deliver. The investment is not just monetary. It is a conscious choice to prioritize weight discipline, aerodynamic precision, and protector-focused design that serves both performance and longevity. For riders exploring model-specific upgrades, options exist that balance weight reduction with ease of installation. The modular, fast-fit philosophy enables enthusiasts to refresh a fairing set without extensive downtime or professional labor. The takeaway is clear: the riding experience and safety profile offered by carbon fiber fairings emerges not from a single feature, but from the way lightweight, stiffness, and airflow synergy reshape the relationship between rider, bike, and road. The result is a bike that feels more agile, more stable at speed, less fatigued after hours in the saddle, and better equipped to cope with the unpredictable realities of real-world riding. To learn more about model-specific kits and how they are designed to fit particular generations or styles, you can explore a general category page that consolidates fairing options across various models. For a focused, model-aligned catalog experience, you might start with broader-category pages that present a range of fitments and mounting solutions, which can help riders gauge what to expect from a carefully engineered carbon fiber kit. In practice, the journey from concept to ride is one of careful balancing: weight, stiffness, aerodynamics, and maintenance access all must align to deliver the practical benefits described above. The rider’s safety, confidence, and comfort are the ultimate tests of any upgrade, and when these elements come together, carbon fiber fairings do more than change the bike’s look; they alter how a rider experiences the road itself. For an overview of category options and to see how such kits are organized for easy access, a general, brand-agnostic page can provide a useful reference point, and the linked category can guide you toward compatible, carefully engineered configurations. Yamaha fairings

Final thoughts

The integration of motorcycle carbon fiber fairings represents a significant evolution in both performance and safety within the motorcycle sector. By understanding the types and applications of these fairings, the technology behind their manufacturing, and the economic benefits they offer, business owners can make informed decisions that elevate their product offerings. As the motorcycle market continues to innovate, carbon fiber fairings stand out for their ability to enhance the rider experience while contributing to a brand’s competitive edge. Embracing these advancements will not only appeal to performance-focused enthusiasts but also secure a lasting position in this fast-evolving industry.