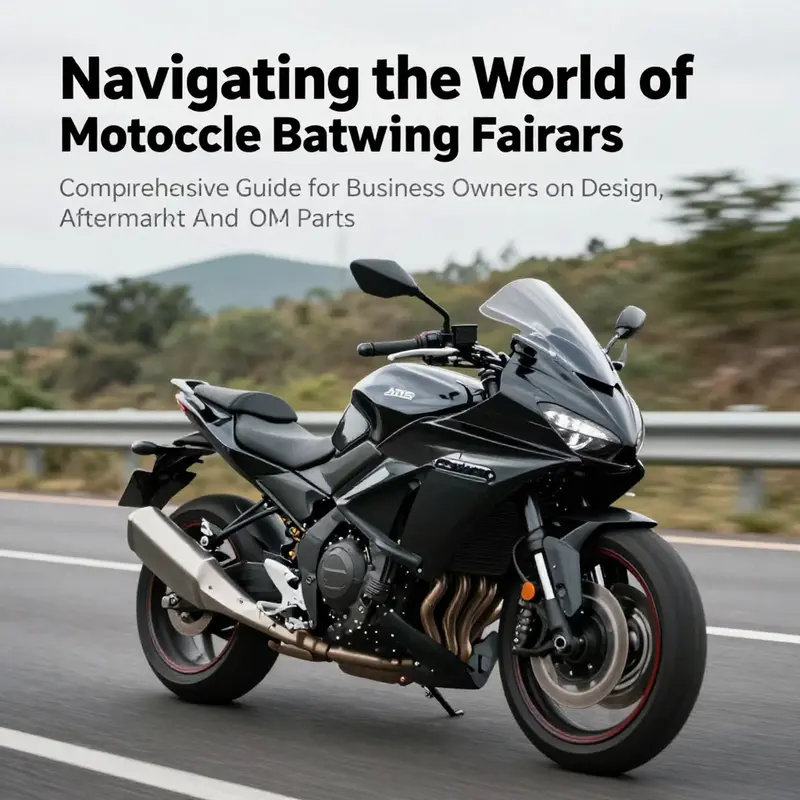

Understanding motorcycle batwing fairings is essential for business owners in the motorcycle industry. These distinctive windshield assemblies, characterized by their bat-like profile, play significant roles in performance and aesthetics for touring and cruiser motorcycles. This article illuminates the fairing’s design and functionality, explores aftermarket customization options, and highlights the importance of original equipment manufacturer (OEM) parts and accessories. Each chapter will delve into these aspects, offering insights to enhance business strategies and meet customer needs.

The Shielded Horizon: Design, Aerodynamics, and Everyday Riding with Batwing Fairings

The batwing fairing is more than a front piece of plastic and glass. It is a statement about how a machine meets the road, how wind becomes a companion rather than a force to contend with, and how a single shape can unify function with identity. When a rider glances down the road, the fairing frames the sightline and carves a line through the air that feels almost deliberate in its sweep. The design is unmistakable: a broad, outward-curving shield that wraps around the headlight and forks, creating a silhouette reminiscent of wings that have learned to glide rather than slice. This is not merely an aesthetic flourish; the shape is shaped by a careful negotiation with air itself. The profile is engineered to reduce pressure differentials and turbulent eddies at speed, guiding air to flow in a way that smooths the rider’s experience behind it. In practice, that means less helmet buffeting, quieter helmet and ear-cabin noise, and a more predictable, stable ride even when the road throws gusts and crosswinds the rider’s way. The fairing’s width plays a dual role: it protects and it directs. It shelters the upper body and seating area, creating a sheltered corridor that makes long days in the saddle feel more tolerable and, paradoxically, more effortless. In a deeper sense, it also personalizes the machine. The broad sweep of the fairing gives the bike a generous, almost cinematic presence on the highway, a visual argument that the motorcycle was built not only to cover ground but to do so with a particular poise. The shape, then, does double duty—streamlining the machine while signaling a rider’s intent to pursue distance with purpose. The way the fairing translates wind into a calmer atmosphere is a subtle form of choreography between rider, machine, and environment. The air that would otherwise hammer against the rider is redirected, slowed, and tuned to flow along the sides of the bike rather than into the cockpit. The resulting experience can feel like a quiet progression rather than a loud contest with the weather, and that sense of ease changes how a journey unfolds, mile after mile, hour after hour. The batwing silhouette also serves a practical aim beyond comfort. By wrapping around the front in a broad arc, it helps stabilize handling at higher speeds and during lane changes where abrupt gusts can challenge balance. The stabilization comes not from brute rigidity alone but from how the fairing interacts with the bike’s steering geometry, the mounting points, and the path of least resistance for the airflow. In other words, the fairing becomes a passive aerodynamic partner, maintaining directional clarity and reducing the fatigue that accumulates when the air refuses to yield to the rider’s rhythm. The sight of the fairing—its wings, its sweep, its generous apex over the wheel—carries with it a clear message: this is a touring machine designed for distance, weathering, and the quiet confidence that comes from a well-planned wind management strategy. The tactile reality of this design emerges in routine use. When the rider leans into a straight highway stretch or threads through rolling country lanes, the fairing’s air-guiding effect translates into more predictable veering forces and a steadier feel at the bars. The effect is particularly noticeable in calm but persistent crosswinds, where the shape’s influence helps maintain a straight path, reducing micro-corrections that would otherwise interrupt focus and pace. The aesthetic of the batwing—bold, expansive, and almost sculptural—harmonizes with the bike’s other lines. It frames the instrument cluster, follows the slope of the fairing’s surface, and integrates with the bike’s overall silhouette in a way that makes the front end feel cohesive rather than tacked on. The design logic also considers maintenance realities. The fairing is typically manufactured from durable, impact- and weather-resistant materials that resist cracking and fading under sun exposure. The choice of a sturdy, shatter-resistant substrate keeps the shape true over years of use, protecting the rider from road debris while offering a reliable canvas for any color or finish that a rider may prefer. The mounting system, often a direct attachment to the bike’s structural framework, is chosen to preserve rigidity without introducing excessive flex that would undercut the aero advantages. A well-executed mounting arrangement spreads load and maintains alignment between the windshield, the headlight aperture, and the fork crown. That coherence matters when the rider negotiates uneven pavement, where a loose or misaligned fairing can translate small bumps into unsettling vibrations. The result is a front end that feels integrated rather than improvised, a sense that the bike and its shield were designed as a single, responsive organism rather than two separate components joined together. Material choices are more than a matter of durability; they influence the feel of the ride. ABS plastics and other resilient composites provide a balance of impact resistance, lightness, and flexibility that helps the fairing absorb road chatter while preserving crisp lines. The finish options—whether glossy, matte, or textured—allow a rider to tailor the bike’s face to personal taste, reinforcing the idea that the fairing is part of a broader conversation about style and function that unfolds with every mile traveled. In this sense, the batwing fairing is a kit that invites riders to tune their experience. It asks them to think about height, angle, and integration with a chosen windshield. The basic choices available—windshield heights that range from compact to commanding—give riders concrete levers to shape the wind encounter. A shorter windshield can emphasize speed and an open-air feel, while taller options translate to more enclosed comfort, especially in cool mornings or when weather shifts. The taller configurations are particularly effective at deflecting wind over the torso and shoulders, reducing lift and fatigue in long rides. The interplay between windscreen height, rider posture, and seating position is a carefully calibrated triangle. The top edge’s relation to the rider’s eye line is not arbitrary. When positioned just below the line of sight, the wind path remains smooth, and the air streamline continues to hug the rider’s helmet rather than hitting the crown of the head with abrupt turbulence. This alignment supports an unobstructed forward view while stabilizing the air that would otherwise swirl around the cap and ears. Maintenance and care are part of sustaining this aerodynamic advantage. Regular inspection for cracks, chips, and weathered edge seals matters because even minor damage can alter the airflow pattern or introduce unwanted buffeting. Cleaning routines that preserve the smoothness of the surface also help maintain the shape’s intended interaction with the air. The fairing’s front surface can harbor dirt and road grime, and a consistent cleaning schedule reduces any micro-abrasions that might erode the finish or the smoothness that aids airflow. The fairing is, ultimately, a collaboration between engineering and taste. It is a practical tool for reducing wind load while modeling a rider’s relationship with the road and the elements. It is also a canvas that invites personalization through finishes, accessories, and minor, thoughtful upgrades. The aftermarket landscape, when approached with diligence, offers ways to tailor wind management to specific climates, road textures, and riding styles. For example, a rider who spends long hours on highways can elect additional deflectors or vent trims that refine airflow without sacrificing the sense of enclosure and security the fairing provides. Conversely, a rider who values a more open feel at moderate speeds might opt for a more compact windscreen and a streamlined profile that preserves the bike’s agility while preserving comfort. The core objective remains the same: a front end that yields to the road with dignity, that supports a rider’s stamina over miles, and that mirrors a philosophy of design where function and form are not rivals but collaborators. In the broader marketplace, the batwing is one of several approaches to wind management on touring and cruiser platforms. The architecture of the fairing—the wrapping, the sheltering, the shaping—often informs choices across brands and generations. For enthusiasts who enjoy exploring the ecosystem of motorcycle fairings, the available options across a range of makers and families provide a language of common principles: wind deflection, stability, and the balance between visibility and protection. This shared vocabulary helps riders assess fitment questions and installation realities with greater clarity. For readers who want to view related categories and see how fairings adapt to different machine geometries, a convenient reference path invites exploration beyond the batwing silhouette. A broad catalog exploration is accessible through the fairings category that covers BMW models, illustrating how similar wind-control strategies translate across the spectrum of touring and sport-touring machines. BMW fairings offers a window into how manufacturers and aftermarket suppliers converge on the idea that wind, when managed thoughtfully, can become a productive partner rather than an adversary. It is a reminder that a single design choice—how the front of the bike meets the wind—ripples through handling, comfort, and the rider’s ongoing relationship with the road. Compatibility remains a practical concern in the live world of motorcycling. Batwing fairings are produced in multiple configurations to align with diverse frames, fork arrangements, triple-tree geometries, and electrical routing requirements. Installers and riders must verify fitment through model-year checks and mounting instructions, because even small deviations in fork offset or instrument cluster placement can shift the wind flow in ways that affect buffeting and ride quality. This is not a problem of aesthetics alone, but of physics translated into everyday riding. When fitment checks are performed and components are installed with attention to torque guidelines and seal integrity, the result is a front end that behaves as an integrated system. The rider notices that the air arrives as a managed stream, not as a chaotic gust, and the motorcycle feels ready to take on long days with the same poise it displayed on the showroom floor. In the end, the batwing fairing embodies a philosophy of travel. It fuses a sense of protection and a sense of scale—the wingspan of air itself, and the rider’s will to move through it. It invites a conversation about how design translates into daily riding: less fatigue, more focus, and a clearer dialogue with the road ahead. The transition from a simple windshield to a full, enveloping front end marks a shift in how a rider perceives distance and weather. It is a choice that signals intent—toward endurance, toward comfort, toward a ride that remains a pleasure rather than a test of resilience. And while the wind may always be present, the batwing fairing redefines what it means to ride with confidence, to travel farther, and to do so with a sense of architecture that honors both the machine and the rider. External reference: for a practical, official spec reference on windshields and batwing configurations, you can consult a catalog entry detailing the 12-inch windshield option at the publisher’s site: https://www.harley-davidson.com/ca/en/accessories/motorcycle-parts-and-accessories/windshields/batwing-fairing-12-in-windshield.html

null

null

Winged Authenticity: How OEM Batwing Fairings Preserve Fit, Form, and the Ride

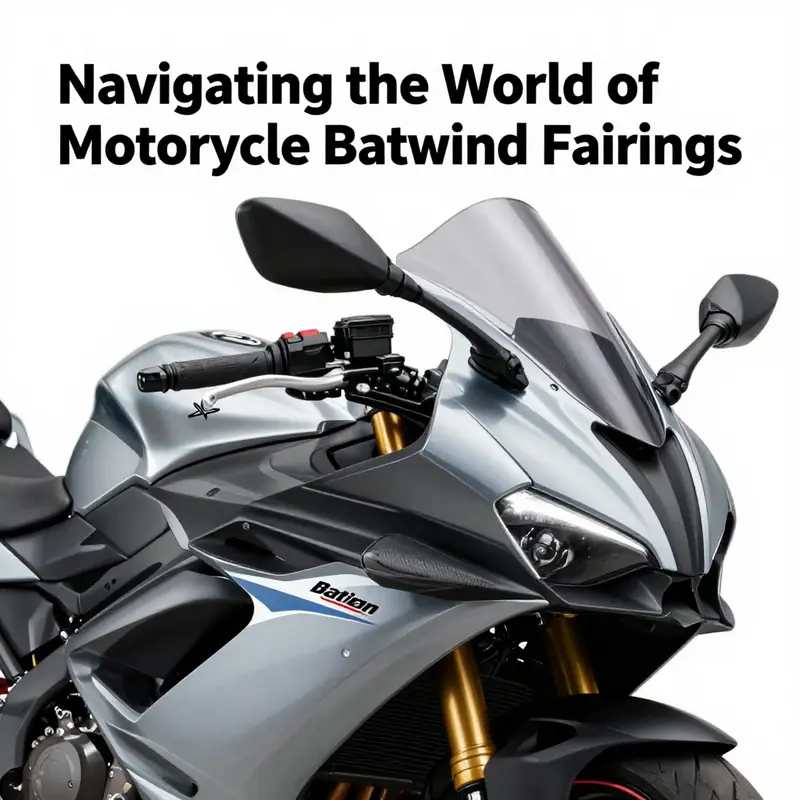

The batwing fairing on a touring or cruiser motorcycle is more than a shield from wind. It is a deliberate design statement that blends aerodynamics, rider comfort, and visual continuity with the bike’s overall silhouette. In the world of OEM parts, the batwing is not a single piece but a system of components that must work in concert. When a rider chooses an original equipment manufacturer (OEM) fairing and its accompanying accessories, they are choosing a package that guarantees compatibility, predictable performance, and a degree of resilience that aftermarket alternatives rarely match. The chapter that follows treats the batwing as both a functional enclosure and a long-term wardrobe for the motorcycle’s front end—one that must endure road conditions, weather, and the evolving preferences of riders who value steadiness on the highway as much as a distinctive look.

At its core, the batwing fairing is designed to harmonize with the bike’s chassis, its electrical harnesses, and its instrument cluster. A true OEM approach does not merely attach a shell to the frame. It aligns mounting points with the bike’s geometry, routes wiring with care to avoid chafing or interference, and preserves the windscreen’s relationship to mirrors, headlight orientation, and the fairing’s own internal air pathways. This alignment matters because even minor deviations in fit can alter aerodynamics, increase noise, or affect the rider’s line of sight. The result is a front end that feels integrated rather than added on, with every line, edge, and joint contributing to a cohesive riding experience.

A significant reason riders gravitate toward OEM batwing components is the confidence that comes with proven fitment. OEM pieces are tested for a specific year and model, with the frame geometry, steering rake, and fork offset all factored into the design. That means windshields at a chosen height do not just mount securely; they interact with the fairing’s contour to generate a predictable airflow pattern. The deflectors, vent trims, and trim kits are shaped to sit flush, reducing the chance of looseness or rattling at speed. For riders who cover long distances and ride in varied climates, this predictability translates into less fatigue, steadier wind pressure at the chest and shoulders, and an overall smoother ride—qualities that become more valuable the longer the miles accumulate.

The range of OEM accessories mirrors the fairing’s dual mission: protection and personalization. Windshields are offered in several heights to accommodate rider stature, posture, and preference. A higher shield can dramatically reduce wind pressure and turbulence, especially on open highways, while a shorter one offers a more compact, sportier profile and potentially less weight or wind lift at high speeds. The 12 in. windshield, for example, is a popular choice because it preserves the classic look while delivering substantial wind deflection. A 10 in. option appeals to riders who desire a balance between protection and reduced helmet buffeting, especially for riders who sit a little higher in the seat or have slightly different riding styles. There is also a 5 in. wind deflector that helps tailor airflow without enclosing the entire front end. These choices demonstrate how OEM design anticipates a spectrum of rider preferences without requiring separate, incompatible components.

Integral to wind management is the concept of airflow optimization inside the fairing. A well-designed vent trim and, in some cases, a Splitstream Vent Trim, manage how air moves through and around the front-end structure. The aim is not to force a vacuum or create noise, but to guide air in a way that reduces turbulence, cools critical components, and supports rider comfort. This kind of airflow engineering matters even for riders who do not consider themselves “aero enthusiasts,” because stable wind flow reduces fatigue, which in turn improves focus and safety on longer rides. The vent trim works with the fairing’s internal channels to ease the path for air to move from the outside in a controlled manner, which can influence everything from helmet wind pressure to the acoustic signature of the cockpit.

In addition to the primary assemblies, the OEM ecosystem includes finishing touches that complete the look and protect the investment. A stainless steel windshield trim kit provides corrosion resistance and a clean, durable edge around the shield. The kit includes the screws, bolts, and trim pieces required for a secure, long-lasting installation. While it may seem like a small detail, a well-executed trim kit helps to prevent flaking paint, chipped edges, and rattles that can accompany a less thorough installation. The authenticity of these pieces matters because it preserves the visual integrity of the front end, a factor riders notice every time they walk up to their bike. Then there are the protective accessories, such as fairing bras, which shield the batwing from highway debris, dust, and minor scuffs that accumulate in daily use. These protective covers are not merely cosmetic; they preserve the finish on the fairing’s curves and paint, contributing to a look of well-maintained hardware for years to come.

The breadth of OEM options also speaks to the importance of fitment accuracy across different years and models. Even within a single product family, the exact mounting geometry, the position of mounting points, and the routing paths for wiring can shift with redesigns and updates. The OEM approach minimizes guesswork for the rider by providing guidance through official fitment checks and installation instructions. This guidance, coupled with dealer support, helps to ensure that a given windscreen height or vent trim configuration truly corresponds to the intended model and year. The result is a confidence that extends beyond mere aesthetics; it is about knowing that the front end of the motorcycle remains consistent in performance regardless of the riding scenario.

Riders who prioritize OEM components often value these elements as a unified system rather than a collection of standalone pieces. When a rider selects the batwing fairing windshields, they are choosing an integrated approach to wind protection. The shield’s curvature, the fairing’s sweep, and the angle at which the windshield meets the rider’s line of sight are all designed to work together. Switching to an aftermarket windshield that does not match the fairing’s original geometry can disrupt this balance, increasing turbulence or noise levels. OEM configurations address these risks by maintaining a set of relationships among parts that have been validated in real-world riding conditions. In turn, this fosters a sense of reliability that is often cited by riders who log long miles in varied weather, seasons, and road surfaces.

From a visual perspective, OEM batwing fairings preserve the brand language and the bike’s lineage. The sweeping profile of the fairing, the way its lines intersect with the fuel tank, and the manner in which the windshield integrates with the headlamp and instrument cluster all contribute to a coherent design story. Even small details—a precise gap between shield and edge, the alignment of the vent trim with the fairing’s grooves, the texture of the stainless finish—signal a commitment to a curated, factory-specified look. This unity matters to riders who want a motorcycle to convey not just capability but identity. In that sense, OEM batwing components do more than shield against wind; they reinforce a narrative about the bike’s heritage, its intended use, and the rider’s relationship to the machine.

For readers seeking a broader sense of fairing ecosystems beyond one brand, it is useful to consider the variety of fitments and categories that surround OEM batwings. A practical way to explore the landscape is to view the broader fairing categories available across brands and models, such as those offered in general fairing collections. The Honda fairings category, for instance, represents a class of products that share common goals with OEM batwing components: compatibility, protective function, and stylistic coherence with the motorcycle’s overall look. Exploring such categories can illuminate how different manufacturers approach wind management, mounting schemes, color-matching, and accessory ecosystems. This broader view helps riders appreciate the careful planning that goes into OEM batwing systems and the logic behind why certain shapes, heights, and trims are offered for specific bikes. See the Honda fairings category for a sense of how other marques structure their own fairing ecosystems and how fitment considerations are handled in practice. Honda fairings category.

As important as the mechanical fit is the rider’s interaction with the cockpit. The batwing fairing surrounds the rider, creating a defined cocoon that can influence posture, neck strain, and even breathing comfort at speed. The windshield height and curvature affect how air streams across the helmet, which in turn impacts hearing comfort and the ability to hear indicators and voices from a two-way radio or navigation prompts. The interior air pressure changes that occur behind the shield can influence the sensation of wind on the chest and shoulders. A well-sorted OEM setup reduces back fatigue by maintaining a more uniform wind pressure across the torso, allowing the rider to focus on the road rather than compensate for gusts and eddies. Even the placement of vent trims can guide slightly cooler air to the rider when sitting in a more upright posture for hours at a time. These subtle, often invisible effects accumulate into a more effortless, confident ride.

From a maintenance perspective, OEM batwing components are designed with serviceability in mind. Because these parts are intended to be serviced through authorized channels, they typically come with documented torque specifications, approved fastener types, and precise reassembly sequences. This standardization makes routine checks straightforward: ensure the windshield is tightened to the specified torque, confirm that the vent trim snaps are seating evenly, and inspect the stainless trim for signs of corrosion or micro-abrasions. Regular inspection of the mounting points during seasonal maintenance helps to prevent issues that could lead to misalignment or wind noise. In practice, a routine inspection is a modest investment that yields continued, consistent performance across riding seasons. The goal is not perfection in an isolated moment but sustained, year-after-year reliability that riders can count on when chasing miles and weather along a highway corridor.

The decision to invest in OEM batwing parts and accessories is, at its heart, a choice about longevity and predictability. It is a choice to preserve the front-end geometry that the engineers designed, to sustain the visual language of the bike, and to protect the rider from the capriciousness of wind and road spray. It is also a choice that recognizes the value of a dealer network, official fitment checks, and installation guidance that minimize the risk of misfit or warranty concerns. For many riders, these factors are not about brand loyalty alone but about establishing a dependable foundation upon which to personalize the bike without sacrificing the integrity of the original design. And while aftermarket options can expand the spectrum of style and performance, OEM batwing components provide a counterweight to the temptations of a do-it-yourself approach when the stakes are high: long-distance comfort, durable materials, and a front end that behaves predictably under diverse riding conditions.

To summarize, OEM batwing fairings and their accessories represent a holistic approach to wind management, aesthetics, and rider comfort. They reflect a philosophy that values exact fit, tested compatibility, and a coherent design language carried through every fastener and trim piece. The windshields in various heights, the deflectors, the vent trims, and the robust trim kits all exist to shape an experience as much as a silhouette. For riders who chart long miles and demanding weather, this is not simply about reducing wind resistance. It is about creating a reliable platform that supports the rider’s posture, shields critical components from harsh exposure, and preserves the machine’s identity mile after mile. In the broader landscape of motorcycle customization, OEM batwing systems set a high bar for fit, finish, and durability, inviting riders to consider how every angle, edge, and interaction within the front end contributes to a ride that feels as one with the road as it looks in the showroom mirror. The journey from windshield height to stainless trim and beyond is a pathway toward a more confident, better-supported ride that remains true to the bike’s enduring character as a touring icon.

External reference: https://www.harley-davidson.com/en-us/accessories/motorcycle-parts-and-accessories/custom-accessories-trim/fairing-trim/batwing-fairing-12-in-windshield.html

Final thoughts

Motorcycle batwing fairings serve as more than just aesthetic enhancements; they embody critical components for performance and rider comfort. For business owners in the motorcycle sector, understanding their design, exploring aftermarket possibilities, and recognizing the value of OEM parts can significantly influence customer satisfaction and business growth. This knowledge equips you with the tools to better serve your clients and foster loyalty in a competitive market.