Inner fairings are crucial yet often overlooked components of motorcycle bodywork, playing a significant role in enhancing both performance and aesthetics. By streamlining airflow, these parts improve aerodynamics, contributing to better fuel economy and reduced rider fatigue. Additionally, the variety of customization options allows businesses to offer unique designs that cater to their customers’ preferences, enhancing the overall appeal of motorcycles. The durability of inner fairings helps protect essential motorcycle components, making them an invaluable inclusion for touring and sport-touring bikes. This article will delve into the aerodynamics and performance impact of inner fairings, explore aesthetic and customization options, discuss their protective qualities, and assess market availability and considerations for businesses in the motorcycle industry.

Inside the Shell: The Aerodynamic Precision and Practical Power of Motorcycle Inner Fairings

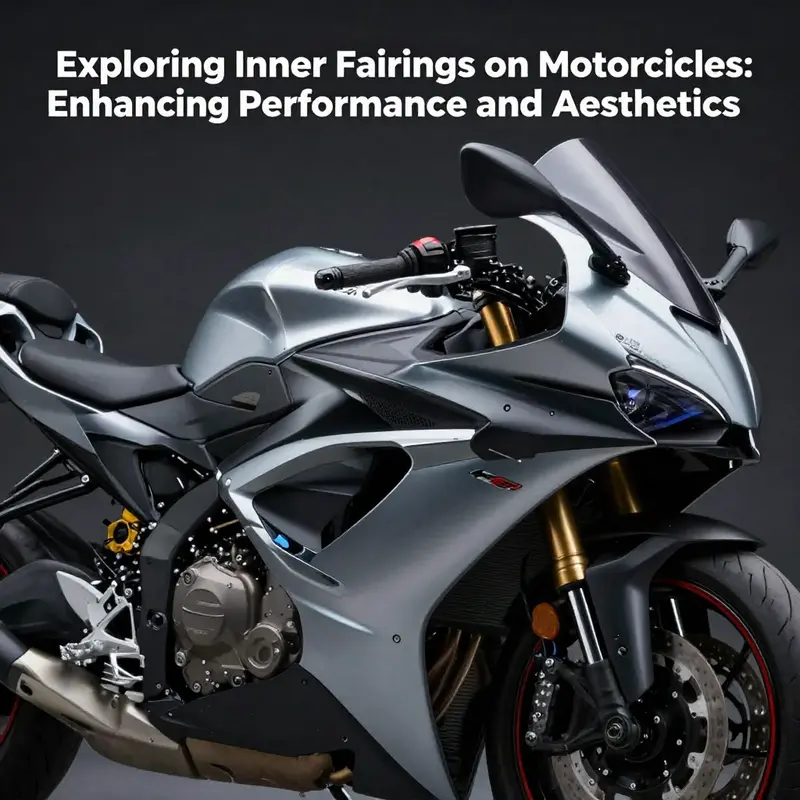

The inner fairing sits quietly at the heart of a motorcycle’s bodywork, yet its influence extends far beyond mere appearance. It is a carefully engineered channel within the broader skin of a machine, a component that shapes how air moves around the chassis, the engine, and the rider. When riders talk about an aero upgrade or a more comfortable long ride, they often focus on loud changes—a bigger windscreen, a bolder side panel, or a sportier exhaust. What tends to get overlooked is the inner fairing, the invisible conductor that orchestrates airflow and reduces the stray turbulence that can sap speed, stability, and stamina at high velocity. In a modern touring bike, in a nimble sportbike, or even in a cruiser with a refined touring posture, the inner fairing acts as a bridge between the exterior sculpting and the machine’s mechanical core. It is the place where design meets engineering, where the geometry of the air becomes a tool for efficiency, comfort, and reliability.

Aerodynamics begins with air entering the system in a controlled way. The inner fairing is shaped to guide that air along the frame, past the engine, and around the rider. Its contours are not just about a sleek silhouette; they are about steering air into a smooth, low-turbulence path. When airflow moves cleanly, drag drops and the front-pressure field balances more predictably. This is particularly consequential at highway speeds, where every small improvement compounds into measurable gains in fuel economy and rider endurance. The rider’s shoulders, neck, and wrists are then subjected to a calmer stream of air, reducing fatigue and allowing a rider to maintain posture and control for longer periods. A well-executed inner fairing can shave seconds off a lap time or stretch a long ride into the realm of enjoyably effortless cruising.

Material choice is a central determinant of how effectively an inner fairing contributes to performance. Modern production bikes commonly employ lightweight yet stiff materials such as ABS plastic and advanced carbon fiber composites. ABS provides the benefit of resilience against road debris and weather while maintaining a cost-effective manufacturing profile. Carbon fiber, by contrast, offers superior stiffness-to-weight ratios and the potential for more complex, aero-optimised geometries. The choice between these materials often hinges on the balance a manufacturer seeks between performance and cost, but the trend is toward lighter, stronger components that still protect the bike’s vital internals from the elements and from the abuse of gravel and rain splashes. The inner fairing also contributes to thermal management, gently guiding airflow where it can aid cooling for the engine and nearby electronics without creating hot spots or stalling the flow around the radiator or intercoolers in more complex setups. In practice, it is not simply a shell; it is a functional element that interacts with cooling channels, engine architecture, and mounting points to preserve overall efficiency.

The performance impact of inner fairings emerges most clearly when they are integrated with other aerodynamic elements of the bike. Front windshields, side panels, underbody structures, and even the bike’s overall geometry must work in concert with the inner shell to minimize drag and prick up the air where it matters most. A body of research and industry practice points to the importance of how inlet air interacts with fairing geometry while the bike moves in a straight line. That is a reminder that aero optimization is not just about a single component in isolation but about the harmony of a complete flow system. With careful CFD (computational fluid dynamics) analysis and wind-tunnel validation, manufacturers can refine how the inner fairing transitions air from the front of the bike to the sensitive regions behind the fairing’s core. The result is a smoother air curtain around the rider and a more coherent pressure field along the vehicle’s length, which translates into steadier handling at speed and a more predictable transition of forces during cornering and lane changes.

The design ethos behind inner fairings also emphasizes manufacturability and reliability. Standards in high-performance settings stress material quality and structural integrity because a fairing must persist through thousands of miles of exposure to heat, moisture, vibration, and impacts with small debris. In the realm of production and aftermarket kits, the inner fairing is typically offered as part of a complete kit that can include a fairing cap and a media door, ensuring that the installed piece looks finished and aligned with the rest of the bike’s aesthetic. The goal is a cohesive look in which the inner surface appears as a natural extension of the outer bodywork, rather than an add-on. This congruence matters because it influences how riders perceive the machine’s overall balance and quality—subtle cues that shape confidence and riding pleasure.

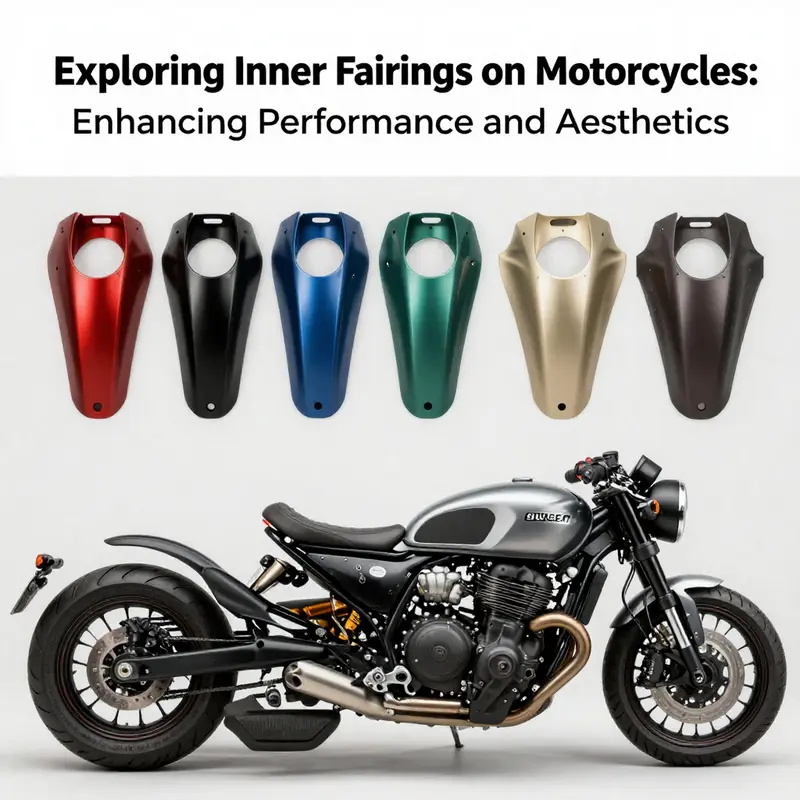

Customization is another dimension of inner fairings that deserves careful attention. Beyond the obvious color-matched finishes that can mirror or contrast with the main paint job, inner fairings offer opportunities for personalization that do not sacrifice fit or functionality. For riders who value a showroom feel, a color-matched inner fairing can create a cohesive visual theme when viewed from the cockpit or at a standing angle. The option to coordinate with the display touch screen and speaker grilles, for example, can yield an integrated interior look that complements modern infotainment setups without drawing the eye away from the rider’s controls. However, care must be taken to maintain correct fitment and tolerances; anything that disrupts the smooth line of airflow or interferes with cable routing and sensor placement can undermine the very aero benefits the inner fairing provides.

From a practical perspective, the inner fairing is a guardian as well as a gains-helper. It shields internal components—electrical harnesses, controllers, and other sensitive elements—from dirt, water, and road spray. In longer rides, this protective function is just as important as its aerodynamic role, because electrical reliability underpins performance and comfort. For touring and sport-touring configurations, riders demand reliability over days and across boreal climates. The inner fairing’s sealed interface and interior geometry contribute to that reliability by reducing exposure to the weather and by organizing internal channels in a way that minimizes the risk of abrasion or moisture ingress along critical wiring. This dual role—airflow management and component protection—helps justify the investment in inner fairings as more than a cosmetic upgrade. It becomes a core element of the bike’s capability to perform consistently over time and miles.

Another practical consideration concerns installation and compatibility. As with any major bodywork component, internal fairings are often supplied as part of a kit designed to fit specific platforms. Manufacturers and authorized outlets emphasize fitment accuracy as a key determinant of performance. Improper alignment can create micro-turbulence or contact with nearby components, which in turn can degrade the aero gains that the inner shell was designed to deliver. When riders evaluate options, they should consider the kit contents, the ease of installation, and whether the product aligns with the motorcycle’s original equipment specifications. This careful alignment reduces the risk of improper airflow and ensures that the fairing’s geometry complements the upstream and downstream features that shape the overall flow field around the bike. In this regard, the inner fairing is not a one-size-fits-all accessory. It is a tailored component that must harmonize with the bike’s geometry, the rider’s posture, and the intended riding regime, whether that is high-speed touring, endurance sport riding, or urban commuting.

In the broader context of aerodynamic innovation, inner fairings symbolize a move toward modular, designer-aware engineering. They reflect a philosophy in which aero performance is not an afterthought or a strictly race-derived feature, but a core attribute that can be tuned to different riding styles and climates. Computational tools have advanced to the point where the shape of the inner fairing can be iterated quickly, and wind-tunnel data can be translated into practical, repeatable manufacturing outcomes. The gains achieved through such iterations are often incremental but cumulative; they accumulate across the bike’s entire frontal area, the way air reattaches behind each curve, and the way pressure gradients influence lift and drag. The net effect is a motorcycle that feels more stable at speed, more efficient in long-range use, and more comfortable for the rider who spends hours in the saddle. The inner fairing, once a background feature, becomes a visible indicator of sophistication and attention to detail—an artifact of thoughtful engineering rather than a mere panel.

Riders who consider upgrades or new builds should also be mindful of the broader ecosystem in which inner fairings exist. A modular fairing approach anticipates future changes in styling and function. A well-designed inner shell can be paired with evolving external fairings and infotainment configurations without requiring a complete rework of the bike’s fundamental aerodynamics. This flexibility matters in a market where buyers increasingly expect customization without compromising performance. It also underscores why some riders prefer color-matched inner fairings or kits that integrate with the bike’s digital display architecture and audio system—finishes and details that reinforce a cohesive, premium impression rather than a hodgepodge of disparate pieces. When contemplating such upgrades, one practical route is to explore the 2023 new fairings category, which often highlights the latest shapes and finishes available to accommodate different riding visions. This reference point can help ensure that an inner fairing upgrade contributes to the overall aero strategy while staying compatible with the rider’s aesthetic goals and the bike’s mechanical layout. 2023 new fairings

The dialogue around inner fairings is not simply about speed or style. It is a conversation about efficiency, reliability, and rider experience. It asks how air moves in a machine that must perform across a wide range of speeds and road conditions, and how that movement can be controlled without adding undue weight or complexity. It asks how the tiny, hidden contours behind the visible surface can influence the ride’s feel, from the calmness of a sustained highway cruise to the precise feedback a rider cherishes during aggressive cornering. The answers lie in measured design, rigorous testing, and thoughtful integration with the bike’s other aero elements. They lie in a willingness to invest in materials that endure and in geometries that promote smooth, continuous airflow rather than abrupt, disruptive spillage. They lie in the understanding that the inner fairing is both shield and guide: a protector of precious components and a facilitator of a more confident, composed ride.

In summary, inner fairings matter because they embody a philosophy of motorcycle engineering where every line has a purpose, every curve is a decision, and every choice affects the rider’s feelings as much as the machine’s numbers. They are a reminder that aerodynamics is not a glitzy add-on but a practical discipline that touches comfort, efficiency, and safety. The future will likely bring even more refined materials, smarter manufacturing processes, and digital tools that make aero optimization accessible to a broader range of riders and builders. Yet the core idea remains timeless: the inner fairing is the engine of airflow control on the bike’s unassuming inside, turning a stream of air into a tailored environment that supports performance and long-haul comfort alike. For riders and builders, that is the sweet spot where science, craft, and riding passion converge.

External reading can broaden understanding of how these shapes translate into real-world benefits. For deeper reading on choosing motorcycle fairings for aerodynamics, see an authoritative external guide: https://www.motorcycle-riders.com/aerodynamics-fairings-guide.

Inside the Curve: Aesthetic Mastery and Personalization of Motorcycle Inner Fairings

The inner fairing is more than a hidden layer beneath the outer skin of a motorcycle. It is a conductor of form and function, shaping how a bike looks, feels, and performs at speed. In the broader story of bodywork, inner fairings blend refinement with practical value; they streamline the airflow around the rider, reduce turbulence, and contribute to a calmer, more efficient ride, while also offering a canvas for riders to express personality by echoing the bike’s color scheme, rider style, and the machine’s presence on the road. The discussion that follows explores how inner fairings become a bridge between aesthetics and engineering, a realm where appearance and performance collaborate rather than compete. Among the most noticeable aesthetic choices is the color-matched inner fairing: replacing a standard interior piece with a color that mirrors the paint or provides contrast can transform the rear silhouette as decisively as a new exhaust note or redesigned seat. The practical effect is a cohesive, factory-finished look that ties together the cockpit elements visible behind the handlebars, in front of the instrument panel, and around the display and grilles; the kit typically includes the inner fairing, a matching cap, and a media door, delivering a complete aesthetic that reads as purpose-built rather than aftermarket. Material choice matters as well: fiberglass offers durability and cost-effectiveness, while carbon fiber brings a premium edge with a higher strength-to-weight ratio and a distinctive weave that signals performance intent. The decision between these materials is rarely only about weight; it also concerns finish and maintenance. A well-executed fiberglass panel can mimic carbon fiber with the right resin and coating, while true carbon fiber delivers not just a lighter piece but a high-end manufacturing impression. Fitment accuracy is central: a fairing that does not align precisely with the frame, mounting points, or adjacent bodywork can undermine aerodynamic efficiency and rider comfort. The best outcomes arise when the inner fairing is designed to integrate with the bike’s original specifications, preserving the intended airflow path and ensuring that weather seals, cabling, and electrical connections remain protected. The functional upgrades embedded in inner fairings extend beyond aesthetics. They shield electrical harnesses, controls, and sensors from dirt, water, and debris encountered on longer rides or in varied climates, supporting fatigue reduction and comfort on touring or sport-touring machines. A smoother interior surface and a carefully contoured airflow path can reduce buffeting around the rider, dampen noise, and help maintain a calmer cockpit environment. In this sense, the inner fairing serves as a quiet partner to the rider’s ergonomics, adding subtle but real gains in perceived calm and efficiency on the highway. Some riders pursue refinements that nod to classic motorcycle aesthetics while preserving modern convenience, such as fairing-mounted mirrors with a polished chrome finish that offer a traditional look while integrating a modern reflective touch. This kind of upgrade blends with factory cues and demonstrates how the inner fairing can host refinements that are both visible and practical, contributing to a cohesive overall appearance that respects the bike’s design language. Installation and compatibility are real constraints: inner fairings are often sold as part of a kit, and upgrading hinges on precise fitment. Riders must verify whether a chosen piece aligns with their model’s geometry, electrical routing, and mounting hardware to avoid wind leaks, rattles, or interference. The most successful projects begin with compatibility checks, followed by careful, methodical installation that honors the bike’s original design intent. Beyond fitment, the inner fairing interacts with the bike’s broader aero profile; even modest changes to the inner surface can alter airflow around the rider’s torso and arms, guiding air toward the windscreen and smoothing pressure differentials to reduce turbulent eddies in the chest and shoulders. The effect is most noticeable at highway speeds, where real-world gains in rider comfort and fuel economy accumulate over long distances. The semi-fairing offers a lighter alternative that covers only the front portion of the bike, including the headlight and instruments, providing wind protection and a cleaner aesthetic without the full weight or cost of a complete fairing system. It presents its own visual language and a meaningful middle ground on the spectrum of fairing options. The path to personalization is often shaped by how owners acquire these parts: the inner fairing may come as a complete kit or as individual components integrated with existing bodywork. The purchasing journey typically includes fitment guarantees, material quality assurances, and compatibility with the motorcycle’s electrical and control architecture, helping ensure that aesthetics stay stable over time. The inner fairing thus becomes a bridge between the bike’s outer silhouette and the rider’s identity; it is where the line and the rider’s taste converge to form a visual statement that pairs beauty with performance. The best outcomes emerge when the aesthetic choice is paired with durability and fit, so the final result remains pristine after countless rides and exposure to weather and road grime. For readers seeking practical options, consider fairing categories that emphasize compatibility and design language, paying attention to mounting hardware, weatherproofing channels, and the ease of removal for maintenance. A well-conceived inner fairing maintains clean lines while offering a durable surface that resists scratches and scuffs, continuing to present a cohesive face of the motorcycle. Ultimately, the inner fairing’s potential is a dialogue between rider and machine—less about chasing trends and more about building a look that endures and aligns with the bike’s geometry and the rider’s expectations for a finished product that feels authentic and personal. External resources and related catalogs can broaden the search for compatible finishes and profiles, including Honda fairings, to illustrate the range of options available to riders.

Guardians Under the Skin: How Inner Fairings Fortify Protection and Endurance in Motorcycles

Inside the visible silhouette of a motorcycle lies a quieter, often overlooked layer that quietly does a heavy lift: the inner fairing. It is not the glossy shell that turns heads at a stoplight, nor the vented exterior that slices through wind. Instead, it sits between the outer bodywork and the bike’s core components, a discreet guardian whose job is to shape air, cushion structure, and preserve long-term durability. This interior layer, sometimes called an inner panel or liner, is where engineering meets everyday riding realities. Its value emerges most clearly not in dramatic photographs but in the steady performance it supports—less wind intrusion at speed, diminished transmission of vibration, and a shield for the components that keep a machine running mile after mile. The story of inner fairings, then, is a story about the marriage of aerodynamics, protection, and practical longevity that underwrites a bike’s reliability and rider comfort across a broad spectrum of riding styles.

Material choice is the first quiet negotiation that defines an inner fairing’s character. These panels are typically crafted from flexible, impact-absorbing materials such as foam or rubberized compounds. The reason is simple: a supple interior layer can absorb minor shocks and dampen vibrations before they travel into the chassis or into the cockpit where a rider sits. When the road throws gravel, potholes, or a stray twig, the inner fairing acts as a buffer, absorbing some of the energy that otherwise would transfer to the outer shell, the frame, and sensitive components tucked behind the panels. This buffering effect is not merely a matter of comfort; it contributes to preserving the integrity of the outer fairing, preventing cracks or deformation that could compromise fitment, alignment, and the bike’s overall aesthetic over time.

The protective value of inner fairings extends beyond simple cushions. They help shield a bike’s more rigid outer surfaces from a combination of impact, heat, and debris. Road dust, moisture, and minor road debris can eventually scour the edges of a fairing or loosen fasteners if those outer panels bear the brunt alone. By providing a secondary line of defense, inner fairings reduce direct exposure to these elements and help maintain a consistent, factory-like finish long after a ride through rough conditions. Beyond exterior protection, the inner layer also plays a careful role around the bike’s electrical systems and controls. Cables, connectors, and electronic modules hide behind the fairing’s interior. A well-designed inner panel curtails dirt ingress and water splash, which in turn supports reliable operation of instruments, switches, and cooling pathways. In this sense, the inner layer is as much a guardian of electrical reliability as it is a shield for cosmetic integrity.

Durability, in this context, is less about a single extraordinary moment of strength and more about resilience over countless cycles of temperature change, vibration, and load. Motorcycles operate across a spectrum of climates and road surfaces, and the inner fairing must endure repeated heating and cooling as engines and radiators cycle on and off. When metal or plastic outer skins expand and contract with heat, the inner panel helps moderate those stress transfers. Inadequate buffering can amplify flex in the outer shell, increasing the risk of micro-cracks, panel misalignment, or fastener loosening. A robust inner fairing mitigates those risks by providing a stable, compliant interface that distributes stress more evenly. This distribution matters not only for the longevity of the outer shell but also for the long-term performance of the entire bodywork assembly, including mounting points and the air intake geometry that depends on precise alignment.

Riding comfort is another practical dimension where inner fairings prove their worth, often in ways riders notice only when they aren’t noticeable. A quieter cockpit, reduced air buffet, and lowered tire or engine noise transmitted into the rider’s seat and hands can translate into reduced fatigue on long trips. The inner panel’s damping effect can help soften the harsh hiss of high-speed wind intrusion at head level, while also curbing vibrations that would otherwise travel through the fairing’s structure and into the rider’s posture. When you combine this acoustic buffering with the visual cohesion that inner panels help maintain—especially when color-matched options align with the bike’s paint scheme—the rider experiences a sense of continuity that reinforces confidence in the machine’s overall reliability and polish.

The inner fairing’s integration into the wider bodywork is a technical choreography. It sits within the footprint of the outer fairing and must be compatible with the bike’s frame geometry, mounting hardware, and the routing of wires, hoses, and components behind the panels. A well-conceived inner liner is designed to cooperate with the exterior’s aerodynamics, not to fight against them. It often includes features that improve airflow management from the air intake through to the radiator and behind the engine covers. A carefully shaped interior surface helps smooth the transition of air as it moves around the bike, reducing turbulence that would otherwise increase drag or create intrusive wind pressure on the rider. Even the profile of the inner panel can affect how air reaches the rider’s gridded display, speaker enclosures, or other cockpit elements that require consistent cooling and clean channels for wiring and ventilation.

From a maintenance and lifecycle perspective, inner fairings influence not only how a bike looks after a few thousand miles but how much work is required to keep it looking and performing well. Since many inner panels are installed as part of a complete kit that includes elements such as a fairing cap or a media door, the installation quality can determine how well the entire bodywork seals against weather and dirt. A precise fit means fewer gaps for dust to accumulate and for moisture to creep into the interior cavities where electrical components live. In this sense, the inner fairing becomes a steward of the bike’s enclosure’s integrity—helping maintain seal proximity, routing efficiency, and the ease of future service work. In a broader design sense, inner panels reflect the principle that durability is a function of both material resilience and intelligent assembly, where every interface is treated as a potential point of stress that must be managed with care.

The reality for riders is that inner fairings are often part of a broader strategy to balance performance with practicality. A touring or sport-touring setup benefits particularly from the interior layer’s dampening properties, as riders remain on the road for extended periods and must manage fatigue without sacrificing the bike’s protective envelope. Conversely, a light, city-oriented rider might value the inner panel’s role in enabling reliable operation in varied weather without adding excessive weight or complexity. In both cases, the inner fairing contributes to a long-term, predictable ownership experience by limiting the cumulative wear that comes from heat cycling, minor impacts, and routine road debris. Its presence helps preserve the crisp lines of the exterior panels, ensuring the bike keeps its intended silhouette and the panels continue to align with the cockpit’s controls and displays as designed.

When riders consider upgrades or replacements, practical questions arise about fitment, materials, and compatibility. Inner fairings are typically sold as part of a kit and may require careful selection to match the motorcycle model and generation. Correct fitment is crucial; a misaligned inner panel can create unwanted gaps, increasing wind noise and compromising the seal against moisture. Material choice and thickness also matter. A too-soft interior might compress over time under vibration, altering the panel’s ability to cushion and channel air. A too-stiff interior might transmit more vibration and contribute to a harsher cockpit feel. The design challenge is to strike a balance where the interior layer remains responsive to dynamic loads while retaining its protective and damping functions across a wide climate and road condition spectrum. This is why some riders prefer professionally fitted, model-specific options rather than generic add-ons—the aim is to maintain factory-level fit and finish while preserving the bike’s performance envelope.

The aesthetics of inner fairings also deserve attention, even if they occur out of sight for many observers. The interior materials are often color-matched to the surrounding panels to preserve a cohesive look if the inner layer is visible through any openings or if the bike uses translucent or clear fairing elements. Color matching preserves an unbroken line from the rider’s perspective, reinforcing the impression of a holistic, well-engineered package. This is not merely about vanity; color continuity signals that the interior and exterior work in harmony, which in turn reflects the broader design discipline—the intent to deliver a finished product that looks purpose-built and durable, from the tarmac to the showroom floor.

For readers who want to explore the breadth of fairing options and their fitment considerations, a useful starting point is to consult catalogs and category pages that index model-specific fairings and related interior components. These resources help map the terrain of fitment across generations, clarifying which inner panels align with which outer shells, and where color-matching and kit composition play a role in overall appearance and performance. In practice, such catalogs guide a rider from curiosity to a precise selection that preserves both aero efficiency and long-term durability without compromising the bike’s structural integrity. If you are scouting options online, you can begin with a comprehensive overview of Yamaha fairings to get a sense of how manufacturers present interior components alongside exterior panels, engineering notes, and compatibility guidelines. See the Yamaha fairings catalog for a starting point in understanding how inner and outer elements are designed to co-exist within a coherent bodywork strategy.

For those who want a broader technical context beyond the individual kit experience, the underlying design philosophy is well documented in manufacturer engineering resources that discuss how bodywork interacts with air, heat, and mechanical loads. These sources emphasize that every layer of protection serves a dual purpose: to shield critical components and to sustain the machine’s performance envelope over time. The inner lining is a practical embodiment of this philosophy, translating materials science and mechanical engineering principles into tangible benefits for riders who demand dependability on long rides and in varied weather. The result is a system where durability is not a single feature but a composite outcome born from thoughtful material choice, precise assembly, and an intimate understanding of the bike’s aerodynamics and thermal management.

External resources can provide deeper insight into these design principles, including official documentation and technical design discussions that illuminate how inner and outer skins are conceived as an integrated unit. For a broader, manufacturer-informed perspective on design and technology, see the official design and technology documentation from the design-focused engineering pages of the industry. This external resource offers context on how designers balance aerodynamic efficiency with durability, a balancing act that inner fairings embody in a practical, ride-ready form.

Internal link note: riders exploring the breadth of fairing options and their fitment considerations can consult the Yamaha fairings catalog for a model-aligned sense of interior and exterior compatibility. This internal reference can help map the landscape of inner panel options to specific frame geometries and exterior skins. Yamaha fairings catalog

External resource: for a broader manufacturer perspective on design principles and the role of bodywork in performance, see the official design and technology feature page. https://www.yamaha-motor.com/en/technology/design/

Inside the Shell: Market Realities, Fitment, and Practical Wisdom for Inner Fairings on Modern Motorcycles

The inner fairing is one of those components that rarely makes the rider’s eye catch instantly, yet it quietly governs a motorcycle’s vibe as surely as the engine itself. It sits beneath the outward curvature of the bike’s main bodywork, tucked against the frame, guiding air, shielding sensitive systems, and shaping how a machine feels when the wind becomes a constant companion. In the broader discussion of motorcycle bodywork, the inner fairing often functions as the invisible hand that steadies performance, comfort, and reliability. It is not merely a cosmetic addition but a carefully engineered element that blends aerodynamics, accessibility, and protection into a single, integrated module. The market for these parts reflects a delicate balance between OEM fidelity, aftermarket experimentation, and rider intent, a balance that presses riders to weigh fit, material, compatibility, and long-term maintenance against the immediate appeal of a color-matched finish or a lighter, less costly alternative.

When someone considers upgrading or refreshing inner fairings, they do not buy one part in isolation. They are often selecting a kit that promises a complete, cohesive look and a set of practical conveniences. Many inner fairing kits include the core inner panel itself, a fairing cap, and a media or access door, and some extend the promise with instrument housing or glove box doors, turning a cosmetic upgrade into a functional reorganization of the cockpit. The promise here is not just new plastics but a pathway to a cleaner wiring harness route, easier access to electronic modules, and a more streamlined environment for the rider. The fit must harmonize with the frame, the windscreen, the instrument cluster, and the lower fairings, creating a nest that reduces turbulence and noise while supporting the rider and passenger in comfort during extended miles.

The market for inner fairings is as much about fitment as it is about material selection. Two core materials dominate the conversations around durability and weight: ABS plastic and fiberglass. ABS offers impact resistance, resilience, and easier manufacturing, making it a practical choice for mass-produced kits. It is forgiving to work with during installation and repairs, a helpful trait for riders who take on do-it-yourself upgrades or who work with a trusted local shop. Fiberglass, by contrast, is prized for stiffness and potential for greater customization. It can be tailored with more aggressive shaping and finish, but its longevity under stress can prompt more careful handling and professional refinishing if cracks or stress lines appear. The trade-off between these materials—weight, rigidity, repairability, and cost—frames most buying decisions. A rider choosing fiberglass should be prepared for a longer path to perfect fit and potentially higher maintenance costs, while ABS buyers should expect a robust, service-friendly solution that holds up well to daily wear and occasional off-road encounters if the rider travels on mixed surfaces.

Beyond material, the crux of compatibility is where the conversation shifts toward the practical realities of ownership. Inner fairings are designed to integrate with specific motorcycles’ frames and bodywork. Even subtle differences in mounting points, cable routing, or instrument housing alignment can upset a seemingly straightforward swap. This means buyers must verify choices against their exact model and year. To some extent, the market acknowledges this with color-matched options and OEM-replacement offerings that preserve factory fit and finish. The value of color matching is twofold: it preserves the bike’s visual continuity and it also minimizes the labor and guesswork involved in painting and finishing. When a rider selects a color-matched inner fairing, the odds of a seamless installation rise, along with confidence that the finished look will align with the bike’s original design language. The reality, however, is that color options are often model-specific and time-bound by production runs, so the availability of a particular hue can depend on the immediate inventory and regional distributor networks.

The process of ensuring compatibility is often about more than the outer silhouette. The inner fairing houses or exposes specific control modules, protective doors, and mounting points that interface with the bike’s electrical and mechanical systems. A kit that includes instrument housing or a glove box door can simplify the reassembly and protect the electronics from dust, moisture, and minor road spray. In touring and sport-touring configurations, where riders spend long hours in the saddle and face variable weather, reliable access to gauges, switches, and media inputs becomes a tangible benefit. The requirement for easy maintenance is not a luxury but a practical necessity. If a design makes routine checks or component replacements more time-consuming, riders may pay a hidden cost in maintenance downtime. In this sense, the inner fairing is not only about how the bike goes fast; it is about how the bike endures heat, vibration, and the miles between service stops.

Market availability reflects a spectrum of riders, from those who prize OEM continuity to those who chase customization and weight savings. OEM-compatible inner fairings, often sold through authorized networks, guarantee a higher likelihood of factory-grade fit and a finish that aligns with the original paint and trim. For some riders, this alignment is worth the price premium and the wait associated with official channels. For others, a well-executed aftermarket alternative offers a tempting balance between cost and capability. The decision might hinge on the rider’s philosophy: maximize reliability and aesthetics through a factory-like package, or embrace modularity and personalization by exploring aftermarket variants. In either path, the choice should be anchored in a clear assessment of how the kit will perform in real-world riding—how it will handle at highway speeds, how it will resist water intrusion in rain, how it will withstand the occasional stone strike, and how it will age under sun and heat. The inner fairing is a long-term investment in the machine’s character and capability, not a short-term superficial upgrade.

The purchasing journey for inner fairings also highlights the importance of fit checks and compatibility guidance. Riders are well advised to consult manufacturer specifications or reputable guides to confirm exact fitment for their bike’s make and model. This is not merely a matter of matching a silhouette; it is about aligning with the bike’s frame geometry, mounting hardware, and electrical routing. A mismatch—even a minor one—can lead to rattles, misalignment of the instrument cluster, or problems with sealing against the elements. The market has responded with a variety of options designed to ease this risk. Complete kits that include all essential components reduce the chance of missing a part and simplify installation. In a well-managed kit, the fairing cap, the inner panel, and the media or glove box components are designed to work together, reducing the need for improvisation and the risk of incompatible parts arriving in the wrong order.

Color and finish hold significance beyond aesthetics. A color-matched inner fairing creates visual cohesion with the bike’s paint scheme, offering a sense of completeness and intentional design. It also signals to the owner that the upgrade was considered and deliberate, rather than a hasty swap. The interplay of color with the display, touch screen, and speaker grilles inside the cockpit adds to the overall impression of a well-integrated system. Yet color matching must be balanced with practical concerns: aftermarket colors may be offered in limited ranges, and the paint finish must be durable enough to withstand the exposure of road grime, UV radiation, and temperature swings. The best practice is to prioritize a tone that harmonizes with the bike’s overall palette while maintaining a finish that can endure long miles of sun and rain. For riders who value personalization, the ability to select a color-matched inner fairing becomes a compelling argument in favor of OEM or OEM-like options, even if it entails a longer lead time or higher price.

In discussing market availability, it is essential to acknowledge the role of installation ease. A kit that emphasizes straightforward removal of the existing inner panel and direct mounting of the new piece reduces the risk of misalignment and damage during the swap. A well-designed inner fairing will be dimensionally consistent with the factory piece, with pre-drilled holes and aligned mounting points that map onto the frame accurately. This is particularly important for riders who perform installations themselves or rely on a small shop for a quick turnaround. The more a kit looks and feels like a factory alternative, the more confident the rider can be that it will protect internal components, preserve wind flow behavior, and maintain the integrity of the bike’s electrical system. The installation narrative, therefore, is not only about mechanics but about preserving the motorcycle’s reliability and the rider’s peace of mind.

From a broader perspective, the inner fairing market mirrors the evolving expectations of riders who demand comfort during long rides without compromising performance at speed. The category has matured beyond a single function—wind protection—into a layered system that influences temperature management, acoustic comfort, and even electronics protection. In touring configurations, for instance, inner fairings can shield delicate sensors, control modules, and wiring harnesses from the elements, while also contributing to a quieter cockpit experience. In sport-oriented builds, the emphasis may shift toward optimizing airflow and reducing drag, with inner fairings shaping how air flows around the rider and the core mechanical components. The result is a nuanced ecosystem in which a small piece of plastic or composite material becomes a pivotal element of the bike’s broader performance envelope.

For riders who are contemplating a transition to an inner fairing upgrade, the market offers a spectrum of pathways. Some will opt for a direct OEM replacement that promises the most seamless integration. Others will explore aftermarket variants that promise customization, potential weight savings, or cost advantages. Few choices are universal; most will hinge on the rider’s priorities—whether that is ultimate compatibility, color coordination, or ease of maintenance. The practical approach is to assess fitment, material quality, and compatibility against the rider’s own riding profile. If a rider spends long hours on the road, the value of an inner fairing that contributes to stable airflow and reduced fatigue can be substantial. If the rider mostly commutes or enjoys weekend rides, the emphasis may lean toward appearance and ease of service. Regardless of the path, the decision should be anchored in a careful evaluation of how the inner fairing will perform under real-world conditions, not just in a showroom or online gallery.

To deepen the practical understanding of selecting the right inner fairing, an informed buying guide can offer a framework that balances performance, durability, and value. A reliable resource emphasizes considering fitment with the motorcycle model, the quality of the materials, and the ease of installation and maintenance. It also advocates evaluating how the inner fairing interacts with the rest of the bike’s bodywork and electronics, including the potential need for re-routing or re-sealing elements that interface with the air intake or instrument cluster. The guidance also highlights the importance of ensuring that any color-matched option aligns with the bike’s original design narrative, preserving not only aesthetics but the sense of a cohesive machine that was designed as a single unit from the factory.

In the end, inner fairings are about more than swapping panels. They are an opportunity to refine a motorcycle’s aerodynamics, protective envelope, and everyday usability. They allow riders to tailor airflow patterns, shield critical components, and align the machine’s appearance with personal taste while maintaining the integrity of the original engineering. The market’s breadth and depth reflect a healthy ecosystem that recognizes the rider as a partner in design—someone who values fit, finish, and function in equal measure. As with any meaningful upgrade, the key is thoughtful selection: verify model compatibility, choose a material that matches the rider’s climate and riding style, and consider the total system in which the inner fairing operates. When these elements align, the inner fairing becomes more than a cosmetic or protective layer; it becomes a functional instrument that enhances the reliability, comfort, and character of the motorcycle.

For readers seeking a practical starting point in this journey, the latest catalog of inner fairing options represents a convenient compass. In addition to factory offerings, many kits provide a complete package that streamlines installation and ensures unit compatibility. If you are considering a color-matched option, remember to check the availability of hues in your region and the expected lead time, as color choices can be limited by model year and regional supply. Finally, while exploring the market, it helps to consult a buying guide that emphasizes the essentials: fitment precision, material robustness, compatibility with your model, and ease of maintenance. By anchoring your decision in these criteria, you protect the investment you are about to make and maximize the likelihood of a satisfying outcome over many miles of riding ahead.

For additional context on choosing fairings that balance performance and practicality, see the comprehensive buying guide available online: https://www.bikeradar.com/uk/motorcycles/gear/accessories/how-to-choose-fairings-a-complete-buying-guide/. For a catalog of category options that can inform your search, you may also explore the broader fairings section in your preferred catalog, beginning with a dedicated category that aggregates 2023 new and updated pieces.

Final thoughts

Inner fairings represent an essential facet of motorcycle design, significantly enhancing both functionality and appearance. For business owners in the motorcycle industry, understanding the benefits of these components is crucial not only for product offerings but also for meeting customer demands for performance, customization, and durability. By focusing on inner fairings, businesses can tap into a niche market that enhances overall rider experience and satisfaction, ultimately leading to a loyal customer base. Investing in quality inner fairing options can provide a competitive edge in the dynamic motorcycle market.