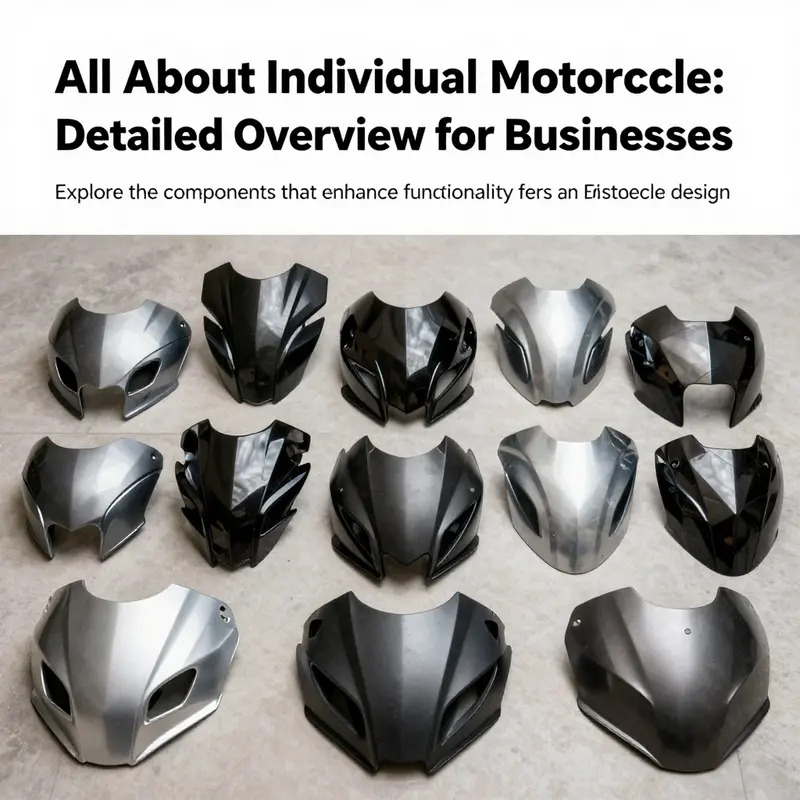

In the motorcycle industry, individual motorcycle fairings play a pivotal role beyond mere aesthetics. These specialized bodywork components not only improve the bike’s look but also enhance performance and rider safety. Understanding these standalone components—such as headlight fairings, half fairings, quarter fairings, side fairings, and rear fairings—is essential for business owners aiming to tap into the aftermarket and customization market. Each chapter in this article delves into the various types of fairings, the materials used, and the significant impact these parts have on motorcycle customization and upgrades, ensuring you’re well-equipped to meet customer demands and industry standards.

Inside the Shell: A Comprehensive Exploration of Individual Motorcycle Fairings, Their Functions, and Their Designs

When riders imagine the silhouette of a motorcycle, the first thing that comes to mind is often the fairing—the protective, sculpted skin that wraps around the bike’s nose and sides. Yet the fairing is more than a stylish cloak; it is a carefully engineered system that shapes aerodynamics, guards vital components, and influences rider comfort across a spectrum of riding styles. Understanding individual fairings means moving beyond the idea of a single, monolithic shell to see how distinct components work together or independently to tune a bike’s performance, feel, and personality. The concept of standalone fairings—parts that can be replaced or upgraded without reworking the entire bodywork—opens up a practical and creative pathway for riders who want to tailor their motorcycles in the same way they would choose a suit, a helmet, or a set of tires. It also entails a set of decisions that balance physics, safety, and aesthetics, all filtered through the rider’s purpose and budget. In this sense, the study of individual fairings reads like a geometry of speed: it maps not only how air moves around a machine but how a rider negotiates wind, visibility, and control while moving through space at varying speeds and weather conditions.

One can begin with the most visible and consequential categories: headlight fairings, wind-deflecting upper sections, and the more discreet panels that cloak sides and sometimes the rear. The headlight fairing, though modest in size, plays a dual role. It protects the lamp and electrical elements from road debris and weather while shaping the airflow around the front end. A well-designed headlight fairing reduces vortices that would otherwise shed turbulent air into the rider’s chest and torso, producing an almost immediate tactile improvement in ride quality. This is especially noticeable at highway speeds or when riding into a gusting crosswind, where even a small fairing can translate into steadier lines of air over the bike and more predictable steering feedback. In many motorcycle communities, headlight fairings also serve as a canvas for customization, contributing to a bike’s personality and stance without altering the powertrain. Universal headlight fairings exist precisely because riders want a broad compatibility that can be adapted to multiple models, a practical reminder that form can be decoupled from exact chassis geometry yet still deliver meaningful gains in function and flair.

Beyond the headlight sits the decision point between full, half, and quarter fairings—each with its own philosophy about protection, access, and artistry. Full fairings are the most ambitious in scope; they envelop the front, sides, and often bridge toward the upper rear area. Their design is a study in aerodynamic efficiency. By creating snug, continuous surfaces around the nose, you minimize the splash of turbulent air and carve a smoother path for the bike to slice through the air. At high speeds, the aerodynamic gains of a full fairing can improve fuel efficiency and stability, helping the rider maintain precise control with less effort on the handlebars and core. Aesthetically, full fairings deliver a race-ready presence that many riders associate with performance and discipline. However, they come with tangible trade-offs. The weight of a full shell, the complexity of installation and repair, and the potential for more restricted engine access during maintenance all remind us that every choice carries consequences. In practical terms, a full fairing often means a more careful approach to crash protection: the panel can absorb some energy in a tip or slide, but replacement costs and time can be substantial. These considerations become especially salient when a bike is used for touring or daily commuting, where easy maintenance and repair access may trump absolute edge in aerodynamics.

Half fairings, sometimes called windscreen fairings or clip-ons, present a more balanced proposition. They cover the upper front portion—typically including the headlight and the area above the handlebars—while leaving the lower engine and frame exposed. The large windshield that often accompanies half fairings is not just for style; it serves a practical purpose by redirecting wind away from the rider’s chest and shoulders, reducing fatigue on longer rides and improving control in gusty conditions. The exposure of the lower portion of the machine means maintenance tasks, inspection, and engine access are comparatively straightforward, a factor many riders weigh when choosing a setup for sport riding or everyday use. The half fairing sits in a sweet spot between efficiency and practicality, offering meaningful airflow management with less mass and less complexity than a full shell. For riders who crave a sportbike look, a certain sense of aggression, and robust wind deflection without the encumbrance of a full fairing, halves are often the preferred compromise. When it comes to the broader aftermarket ecosystem, half fairings frequently align with modular components, allowing riders to swap out windshields, inner panels, or upper shells to fine-tune the balance between drag reduction and tactile ride feel. In some markets, this approach has given rise to universal or model-agnostic fairing options, making the dream of a personalized, rider-specific contour more accessible.

Quarter fairings represent the most minimalist tier of fairing design. Usually attached to the front or near the handlebars, these small panels contribute to a smoother flow of air with minimal weight penalty and little intrusion into maintenance access. Quarter fairings appeal to enthusiasts who value speed-oriented aesthetics, café racer vibes, or a clean, stripped-down silhouette. They do not promise substantial wind protection and are not meant to shield a rider from the full brunt of the elements; rather, they deliver a taste of aerodynamic refinement and a dash of visual polish. In the crossover world of custom builds and retro-inspired machines, quarter fairings can be decisive in achieving the desired visual cadence while preserving the bike’s naked or lightly clad character. Because they are compact, inexpensive, and relatively easy to install, they invite experimentation—allowing riders to incrementally refine airflow, balance, and appearance. The way these small panels attach to the front end—the fasteners, the gaps, the joints—also speaks to a broader truth about fairings: small changes in surface geometry can have disproportionate effects on how air behaves around a machine and, by extension, how the rider experiences speed.

If we widen the lens to include side fairings and rear fairings, the narrative deepens further. Side panels, sometimes presented as distinct panels rather than a single shell, perform a routine but essential job: they guide air along the sides and help keep the rider shielded from wind and weather as it sweeps across the machine. Side fairings also protect critical components from debris and impact, offering an added layer of resilience without the bulk of a full wrap. In many builds—especially café racers and light sport bikes—the side panels are a canvas for color and texture, turning the bike into a moving sculpture as much as a tool for travel. Rear fairings carry their own logic. They tune the tail airflow, sometimes harbor taillights or license plate mounts, and in certain configurations contribute to a more integrated silhouette that reduces drag behind the rider. The rear portion of a bike can seem less conspicuous than the nose yet plays a vital role in airflow continuity and the overall aerodynamic profile. The interplay among these different panels—the headlamp housing, the upper shell, the sides, and the rear—creates a holistic geometry that can be tuned with significant effect by a mindful rider.

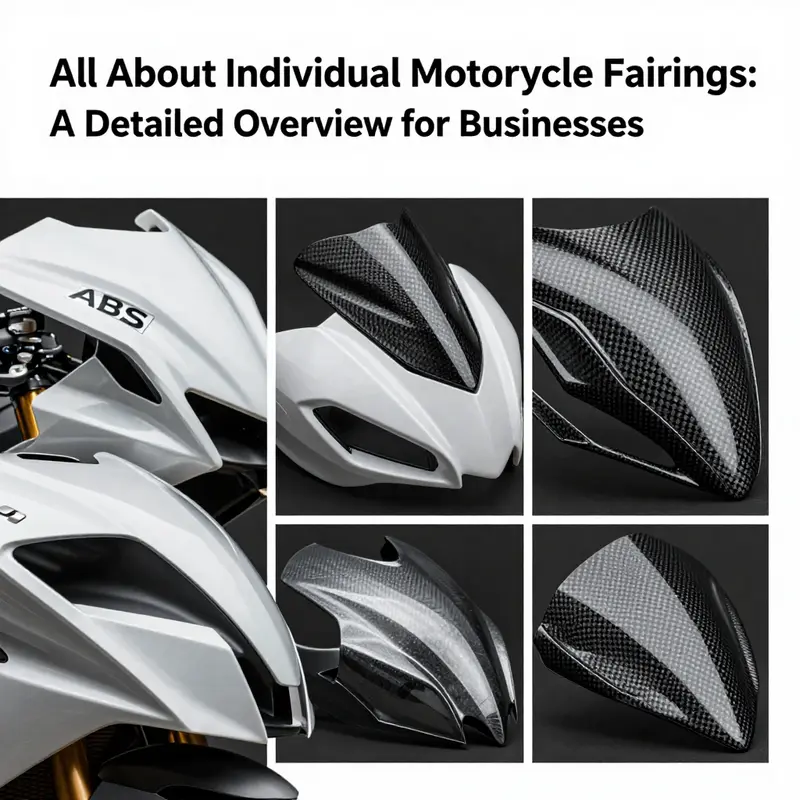

Material choices anchor these design decisions in reality. The industrial palette for individual fairings typically includes ABS plastic, fiberglass, and carbon fiber composites. ABS plastic is a common balance of cost, durability, and impact resistance; it tolerates everyday use, minor dings, and easy repair. Fiberglass offers a middle ground in stiffness and weight while remaining more affordable than carbon fiber. Carbon fiber, the premium option, delivers unmatched rigidity and a striking aesthetic coupled with weight savings, but at a higher price and with different repair considerations. Each material responds differently to heat, UV exposure, and road conditions, which means the decision to swap one panel for another isn’t only about appearance. It affects durability, weather resilience, and long-term maintenance. The manufacturing approach then becomes a practical concern: do you opt for injection-molded ABS, hand-laid fiberglass, or vacuum-bagged carbon fiber? The trade-offs touch on manufacturing tolerances, fit accuracy, and repainting needs. In a broader sense, material choice mirrors the rider’s relationship to the bike: a sport-focused rider may tolerate higher costs for lower weight and a sharper edge, while a commuter may favor durability and repairability with a more moderate price tag.

The practicalities of upgrading or replacing individual fairings extend beyond raw performance. A critical consideration is compatibility with the motorcycle model, frame, and other panels. Universal headlight fairings introduce flexibility by offering plug-and-play options across various makes and models, but the fit and aero intention can vary significantly. This is where the craft of selection, fitting, and sometimes minor modification comes into play. The rider’s objectives guide the process: is the goal to increase top-end stability, to reduce drag at cruising speeds, or to create a distinctive visual identity? This decision matrix is personal and technical at once, blending airflow theory with the reality of road surfaces, weather, and riding posture. Add into the mix the realities of crash protection and repair costs. In a crash scenario, fairings can absorb some energy, protecting more expensive internal components; but the cost and downtime for panel replacement can be steep, especially in regions where aftermarket supply chains favor certain models over others. For this reason, the choice between durability and ultimate lightness is not merely a fashion question.

A rider’s style casts a long shadow over all these decisions. Commuters and touring riders tend to value wind protection, weather sealing, and ease of maintenance. Sport riders and track enthusiasts seek sharper aerodynamics, reduced weight, and a cohesive front-end geometry that can improve steering response. Custom builders, meanwhile, use fairings as a language—a way to tell a story about speed, heritage, and personal identity. The café racer aesthetic, for example, often treats fairings as lean, poised lines that emphasize the silhouette of the bike rather than conceal it entirely. In such builds, even small quarter panels or a minimal rear fairing can transform the perceived purpose of the machine. It is this dialogue between function and form that makes fairings so compelling: their geometry is a map of riding intent, and the panels are the milestones on that map.

Where the literature converges is in a shared recognition that individual fairings are not isolated assets but parts of an ecosystem. Because each panel affects the aerodynamics, weight distribution, and access to the engine and electronics, changes here reverberate through the bike’s handling and daily usability. A thoughtful swap—perhaps upgrading to a carbon fiber rear fairing for weight savings, while retaining a robust ABS headlight fairing for durability and weather resistance—can harmonize performance with practicality. It is a reminder that the objective is not to chase maximum drag reduction in a vacuum but to craft an integrated package that serves the rider’s purpose. In this sense, the fairing becomes a bridge between the rider’s daily life and the machine’s engineered potential.

For readers seeking a more model-oriented perspective, the broader catalog of fairings offers a spectrum of options. A rider who leans toward a specific marque can consult dedicated fairing categories that tailor to that brand’s geometry and component attachment points. For example, exploring the Honda fairings category provides a sense of how model-specific panels align with factory-intended fitments, mounting points, and color schemes. This approach supports careful matching of panel lines, mounting hardware, and paint finishes to achieve a seamless result that respects original engineering while enabling personal expression. To facilitate this exploration in context, the Honda fairings category can serve as a practical reference point for readers who want to see how a brand’s styling language translates into replaceable, modular panels. Honda fairings invites readers to imagine how a single panel choice can reframe a bike’s appearance without requiring a full fairing overhaul.

The discussion naturally leads to standards and best practices. Designers and builders often consult industry standards to ensure safety, compatibility, and performance expectations are met. While the specifics can vary by jurisdiction and manufacturer, the underlying principles emphasize consistent attachment geometry, safe edge radii, and predictable airflow behavior. For those who want to dig into the formal framework that governs these aspects, general references to established standards provide a reliable anchor. See the external resource for a consolidated overview of how industry guidance translates into practice for fairings and related bodywork. In addition, riders and builders are reminded to verify model-specific documentation and local regulations, because what works in theory must withstand the realities of road conditions and testing protocols.

In closing, the world of individual motorcycle fairings is a dynamic field where science, art, and personal taste converge. The choice among headlight fairings, half fairings, quarter fairings, and the various side and rear panels reflects a philosophy about how a bike should meet a rider’s needs. It is a philosophy that recognizes that the shell around a motorcycle is not merely cosmetic but a functional instrument that can alter the machine’s response to air, weather, and fatigue. The most successful configurations are those that treat every panel as part of a coherent plan rather than as a set of isolated add-ons. They honor the rider’s goals—whether speed, comfort, touring resilience, or a distinctive visual identity—while respecting the bike’s engineering DNA. And as materials science advances, as modular mounting solutions evolve, and as the culture of customization continues to expand, the future of individual fairings promises even more opportunities to shape a machine’s character without sacrificing reliability or daily usability.

For readers seeking a straightforward entry point into the broader ecosystem of fairing options, exploring model-specific or brand-focused catalogs can be a productive next step. These catalogs illustrate how the language of form translates into specific curves, attachment methods, and colorways that harmonize with a motorcycle’s overall design. They also demonstrate how aftermarket panels can be integrated with stock components to optimize the ride for a particular mission, whether that mission is daily commuting through urban canyons or carving a winding road late on a Sunday afternoon. As you weigh your options, consider the story you want your bike to tell and the conditions under which you ride. The right single panel can alter the perception of speed, the sensation of wind, and the subtle interplay between rider and machine, turning a common ride into a personalized performance that remains faithful to the qualities you value most in two-wheeled travel.

External resource for standards and guidance: https://www.motorcycleindustry.org/standards/

Weight, Armor, and Attitude: How Material Choices Shape Durability and Performance in Individual Motorcycle Fairings

Individual motorcycle fairings are often treated as modular add-ons—the cosmetic shell that gives a bike its silhouette and a layer of protection against wind, debris, and the weather. Yet when you replace or upgrade a single panel, you encounter a deeper conversation about material science, engineering, and riding philosophy. The choice between ABS plastic, fiberglass, and carbon fiber is not merely about price or a glossy finish. It is a strategic decision that echoes through weight distribution, impact resistance, heat management, and the way a rider experiences the road. A single fairing panel can alter throttle response in the sense of wind pressure on the chest and shoulders, it can influence how the bike carries speed through a corner, and it can determine how easy or costly it is to repair after a tip-in or a stone strike. The narrative around material choices, therefore, deserves a careful, integrated treatment that connects fabrication realities with riding aspirations and maintenance realities, all while keeping the decision anchored to compatibility with the specific model and its intended use.

ABS plastic stands as the workhorse in the realm of aftermarket and OEM fairings because it offers a robust balance of durability, cost, and manufacturability. ABS is well known for its impact resistance; it absorbs and redistributes energy when a panel is bumped or lightly scraped, rather than shattering into shards. That resilience is crucial for daily riders who encounter the unpredictable: a driveway mishap, a parking lot misjudgment, or a stray rock on a rural highway. ABS also offers predictable behavior when subjected to typical temperatures and sunlight, which makes color matching and UV resistance manageable for most factory finishes and aftermarket coatings. Crucially, ABS lends itself to the integration of electronics and accessories. Modern motorcycles increasingly rely on sensor housings, audio interfaces for communication systems, and power-dedicated pathways within the fairing’s structure. ABS responds well to these needs because it accepts fasteners, adhesives, and molded-in channels without introducing excessive weight or expensive processing steps.

From a practical standpoint, ABS panels tend to be the most forgiving for a broad audience. They can be machined, drilled, and repaired with relative ease, and the repair ecosystem around ABS is familiar to many shops. A careful repair might involve sanding, fusing with heat, and applying compatible plastics to restore the surface. The result is a repair path that keeps downtime reasonable and costs predictable for riders who rely on their machine for daily transport or weekend sorties. The color stability of ABS is a factor too. While ABS accepts paint and clear coats well, the layer must be applied with attention to compatibility to avoid delamination or chalking under prolonged sun exposure. In this sense, ABS is the sensible choice for riders prioritizing longevity, repairability, and broad compatibility with accessories and model-specific mounting points. For those who want to explore model-oriented options around ABS, the path can be as simple as seeking one of the category pages dedicated to a specific brand’s fairings to confirm fitment and mounting alignments. For example, you can browse Honda fairings to see how an ABS-based panel integrates with the bike’s electrical, mounting, and cosmetic requirements.

Fiberglass, meanwhile, sits at a crossroads between ease of manufacture and performance ambition. Fiberglass panels can be molded into more intricate shapes than ABS and can reproduce complex contours with a high degree of freedom. This makes fiberglass attractive for amateur and professional custom builds where the visual language—sharp lines, pronounced scoops, or vintage cafe racer cues—needs a degree of sculpting that ABS cannot easily achieve. However, fiberglass is heavier than ABS, which translates into a different acceleration and handling feel when a panel is swapped. Its weight is not extreme in every case, but it is noticeable enough to matter for riders who track performance where every gram matters. More importantly, fiberglass is somewhat more brittle than ABS. A fiberglass panel might resist a direct impact without cracking in a robust way, but when it does crack it often requires more involved repair work and, in some cases, replacement of the entire panel. This brittleness calls for careful handling during installation and removal, as well as precise finishing work if you want to preserve a seamless aesthetic across multiple panels or a color-matched scheme. The repair workflow for fiberglass typically involves resin and reinforcement techniques; while skilled hands can produce excellent results, the process demands time, expertise, and materials that can drive up costs relative to ABS.

From a performance standpoint, fiberglass can be a stepping stone toward more ambitious builds where weight savings are desired but carbon fiber remains out of reach. For riders who want a degree of customization without fully committing to carbon fiber’s price point, fiberglass offers a path to achieve striking geometries and a distinctive look while maintaining a practical level of durability. It is a material that invites experimentation, but it requires responsible handling to avoid compromising structural integrity or the panel’s finish. For those considering a fiberglass solution, it pays to weigh the anticipated repairs against the aesthetic ambitions and to partner with reputable fabrication or restoration services that understand the material’s behavior when bonded, painted, or layered with clear coats. The choice of fiberglass is often a matter of balancing a bold, customized appearance with a willingness to invest in meticulous finishing work and careful maintenance.

Carbon fiber represents the aspirational apex of fairing materials for the performance-minded rider. Its extraordinary strength-to-weight ratio translates into a lighter bike with less inertial load, especially in the upper body and fairing assembly where wind pressure sits most heavily on the rider. Carbon fiber’s stiffness contributes to a more precise aerodynamic profile, which can translate into smoother turbulence management and a more confident feel at speed. The downside is equally clear: cost and repair complexity. Carbon fiber remains a premium investment, reflecting not only the material itself but the specialized processes required to shape, lay up, cure, and finish the panels. Repairs, when necessary, often demand skilled technicians familiar with resin systems, layup quality, and the intricacies of fiber orientation. A damaged carbon fiber panel may be repairable, but the repair can be costly and may not restore the original warranty or aerodynamic tolerance as reliably as a pristine panel. In addition, carbon fiber is sensitive to certain environmental conditions and needs appropriate protective coatings to prevent microcracking or UV-induced degradation of the resin matrix. The aesthetic payoff, however, is undeniable. The weave and finish can convey a sense of performance identity that resonates with riders who actively pursue weight reduction, acceleration feel, and aerodynamic refinement in a way that is visually unmistakable.

Choosing among ABS, fiberglass, and carbon fiber is less about a single universal truth and more about aligning material behavior with riding context. A commuter who spends long hours in the saddle will value impact resistance, color stability, and cost. A sport rider, chasing snappier response and marginal gains in aerodynamics, might lean toward carbon fiber or a tailored fiberglass build that balances weight and shaping complexity. A touring rider, weighing wind protection and ease of repair at remote stops, may prefer ABS for its robust, practical nature and predictable maintenance. A cafe racer enthusiast might prioritize the visual dialogue between form and speed, where fiberglass or carbon fiber can deliver a unique silhouette without compromising the required mounting integrity. In all these cases, the conversation about material choice is inseparable from the way the fairing panels are manufactured, finished, and installed, because each material sets up different pairing needs with mounting hardware, sealants, and edge finishing.

This is where the practicalities of installation and compatibility come into play. The decision to use a single panel rather than a full fairing package can influence how that piece interacts with the bike’s electrical cable routing, sensor housings, and mounting brackets. ABS panels tend to pair smoothly with standard fasteners and adhesives that technicians already stock, which reduces the risk of fitment surprises during installation. Fiberglass panels, with their molding flexibility, can be tailored to more aggressive lines or bespoke angles, but that customization comes with the caveat that fitment sometimes requires more precise alignment work. Carbon fiber demands careful attention to mounting tolerances, as even slight deviations can create issues with panel gaps, edge protection, and overall aero fidelity. The upshot is that the material decision feeds into a broader ecosystem of fitment knowledge: whether you’re swapping a headlight fairing, a quarter panel, or a side fairing, you need to check the model-specific fitment matrix, the mounting points, and the color or finish strategy that will harmonize with the existing bike’s lines.

Another layer to this discussion concerns finishing and long-term durability. ABS can be finished with a broad range of coatings, allowing riders to reproduce factory color matches or to experiment with custom tones. It responds well to clear coats that resist UV rays and weathering, preserving gloss and color depth for a reasonable duration. Fiberglass gains a similar opportunity for glossy finishes, but its surface may require more attention to resin-rich areas or sanding marks that can show through in bright light. Carbon fiber, when left exposed, offers an iconic look that can be a defining feature of a build. Even when coated, the clear protective layer must be chosen in concert with the resin system to avoid yellowing, hazing, or microcracking that could compromise both appearance and protection. In all cases, diligent surface preparation and careful coating application are essential to maintain a high-quality appearance and to preserve the panel’s integrity through temperature cycles and road use.

The conversation about material choices is also a conversation about repairability and lifecycle costs. ABS is typically the easiest and most economical to repair, which means more manageable upkeep and easier insurance or warranty considerations after a minor mishap. Fiberglass, while durable in many respects, can demand more specialized repair processes and may incur higher maintenance costs if repeated impacts are likely or if the panel sustains delamination. Carbon fiber’s repair landscape is the most complex. Small chips and surface scratches may be repairable with skilled services, but structural damage can require panel replacement and, sometimes, refinishing to restore aerodynamic performance. This reality naturally drives a budgeting strand into the decision process: upfront material costs versus anticipated repair costs over the bike’s life, plus the rider’s tolerance for downtime and the value placed on ultimate performance versus practicality.

The technical conversation about fairing materials is rounded by standards and best practices that govern how panels are manufactured, tested, and used. While the everyday rider may not dive into every specification, it is helpful to know that the industry prioritizes safety, predictable performance, and reproducible manufacturing results. These standards shape everything from the tolerances that govern fitment to the surface finishes that protect against environmental exposure. The material choice is thus part of a broader engineering conversation about how the fairing integrates with the bike’s aerodynamics, cooling paths, and rider protection, a conversation that continues to evolve as new composites and resin systems emerge and as riders push the envelope of what a modular panel can do.

In this integrated view, the best material for a given single fairing panel depends on riding style, budget, and the priorities you hold for performance versus practicality. For most riders who seek a durable, reliable, and affordable solution, ABS plastic remains the most sensible default. It delivers predictable behavior in everyday conditions, supports straightforward maintenance, and offers a wide range of color and finish options that can stay fresh for years under regular riding. For enthusiasts chasing maximum performance and the lightest possible construction, carbon fiber provides an impressive advantage, albeit at a premium price and with a repair discipline that requires specialized expertise. Fiberglass remains a compelling middle ground for those who want to explore more aggressive styling ideas or shapes while still keeping a tighter lid on weight than pure ABS can offer, all at a cost that sits between ABS and carbon fiber. The choice among these materials is not a statement about one being universally superior; it is a nuanced decision that aligns with what the rider values most—durability in daily life, the elegance of a race-ready silhouette, or the balance between aesthetics and performance.

For riders who want to connect this material decision to model-specific realities, there are catalog and category pages that help bridge the general material discussion with fitment accuracy. For example, those exploring Honda fairings can quickly confirm the fit and finish expectations, make sure the panel aligns with the model’s mounting points, and assess whether the chosen material will support any required mounting hardware or edge protection strategies. This alignment is essential because even a seemingly identical panel across different models can exhibit distinct fitment quirks, and those quirks can influence everything from the ease of installation to the quality of the final aesthetic. In short, the material choice informs the practical path to a flawless, durable upgrade or replacement, but the final result depends on careful alignment with the bike’s design language and the rider’s goals.

External reading can further deepen this understanding. For a comprehensive exploration of how to select the right motorcycle fairing material, many readers turn to detailed technical guidance that synthesizes performance data with real-world maintenance considerations. External resource: Choosing the Right Motorcycle Fairing Material.

Within the broader ecosystem of model-specific customization, the path to the right panel often involves glancing at the available categories for a particular brand to verify fitment nuances, connection points, and the alignment of the panel with the rest of the bike’s styling. If you are exploring options for a specific make, you can navigate to the Honda fairings category to understand how the panels are designed to integrate with the bike’s architecture and to anticipate the maintenance and installation considerations that accompany a swap from an OEM or aftermarket source. This approach helps ensure that the material choice—ABS, fiberglass, or carbon fiber—works in harmony with the bike’s structural realities, mounting geometry, and your long-term maintenance plan, rather than becoming a cosmetic afterthought that neglects fitment compatibility and practical upkeep.

In this sense, the material decision is really a decision about the rider’s relationship with the bike: how it breathes in wind, how it ages in sunlight, how it responds to a rock’s impact, and how easily it can be repaired after a mishap. It is about balancing the desire for a lighter, stiffer, more aero-ready profile with the realities of cost, repairability, and the everyday wear and tear of road life. When this balance is carefully considered, the result is not just a fairing panel but a coherent extension of the rider’s intent—a controlled blend of durability, efficiency, and visual identity that supports the bike’s overall character and performance.”

Shaping Speed and Style: The Craft of Individual Motorcycle Fairings in Customization and Aftermarket Upgrades

The appeal of motorcycle aesthetics often begins with form, but today it increasingly starts with function. Individual fairing components have moved from being mere cosmetic accents to essential tools for personal expression, performance tuning, and practical refinement. Rather than replacing an entire front end, riders can select, swap, and fine tune distinct panels—fronts, sides, and tails—to sculpt a bike that mirrors their intent. This modular approach to bodywork enables a precision of customization that aligns with riding style, weather, terrain, and even fuel strategy. It invites a shift in how people imagine upgrade projects. They become not a single, expensive overhaul, but a sequence of targeted improvements that accumulate into a transformed machine. The result is a motorcycle that looks, breathes, and behaves like a tailored instrument rather than a factory shorthand for a generic riding experience.

The modular philosophy behind individual fairings is inseparable from the economics of ownership. Full fairings can be costly, heavy, and demanding to fit when a rider wants only a small aerodynamic nudge or a fresh visual cue. With separate panels, a rider can invest incrementally, testing what effect a new shape or finish has on airflow, wind noise, and rider fatigue. The economics extend beyond the sticker price. If a single panel is damaged, replacement becomes simpler and cheaper than ordering a complete fairing package. This practical dimension matters in daily riding, where road debris, minor falls, or curb encounters are a part of life for many owners. In markets where shipping and import logistics complicate purchases, the ability to source only the necessary piece can smooth the journey from concept to installation. The impact of this approach is as much about timing as it is about cost; a rider can delay a larger project until the perfect color or finish becomes available, rather than being forced into a bundled decision that may not align with evolving tastes.

Materials selection lies at the heart of both performance and longevity. ABS plastics, fiberglass, and carbon fiber composites are the common triad that makes up individual fairings. Each material offers a different balance of rigidity, impact resistance, weight, and cost. ABS plastic is resilient enough for daily riding and relatively forgiving during minor impacts, which is helpful for a panel intended to cover the upper region or side sections near the rider. Fiberglass provides a stiffer, lighter option that can be molded into sharper lines for sportier aesthetics or race-inspired profiles. Carbon fiber, prized for its premium status, embodies the pinnacle of lightness and stiffness, with a visible weave that signals intent and performance. The choice among these materials is rarely about a single factor; it is a negotiation among weight, cost, and the perceived risk of damage. Lightweight composites often reduce the overall weight of the bodywork, subtly shifting the power-to-weight ratio and influencing handling characteristics. Even modest weight savings at the front of the bike can translate into crisper steering feel and quicker turn-in at high speeds or during aggressive lane changes. For riders who value fuel efficiency during high-speed riding, the reduced inertia of lighter fairings can contribute to less drag-induced energy loss in the critical portions of a corner or straight run.

Aesthetics play a central role, but style here does not preclude function. The visual language of a bike—its lines, gaps, and the way light catches a panel’s curvature—tells a story about rider intent. Whether a build leans toward a minimalistic, cafe-racer silhouette or a full-bore, wind-cheating profile, the chosen fairings help communicate that story before a wheel ever leaves the driveway. The ability to mix and match panels from different sources enables a high degree of creative experimentation. A rider can juxtapose a stealth-matte finish with a gloss stripe or swap a bold accent panel to create a one-off livery that is instantly legible as a personal signature. In practice, the customization process blends paint, finish, and texture with the geometry of the bike. A new front panel can redraw the perceived face of the machine, altering how air flows over the nose and how the rider sits within the wind stream. Side panels influence body angle and line through a curve, while a revised rear fairing can change the weight distribution and rearward silhouette. The result is a bike that does not merely exist in space but narrates a story of the rider’s evolving preferences.

Designing a set of individual fairings also invites a disciplined approach to fitment and compatibility. Unlike bulkier, complete fairing kits, modular panels come with a commitment to precision. The best products strive for model-specific compatibility, ensuring that panels align with the bike’s mounting points, instrument clusters, and headlight assemblies without requiring extensive trimming or improvisation. This is not just about a clean look; it is about safety and reliability. When a panel fits correctly, it maintains intended airflow management and reduces the risk of panel flutter or contact with moving parts at speed. MIC standards and other engineering guidance referenced in manufacturer documentation provide benchmarks for impact resistance, tensile strength, and chemical compatibility. While many aftermarket parts are designed to mimic factory geometry, intelligent design embraces tolerances that accommodate manufacturing variances while preserving critical mounting, sealing, and aerodynamic relationships. In this sense, individual fairings offer a pathway to a personalized aero profile that does not compromise the bike’s underlying engineering integrity.

Riders who explore aftermarket sources arrive at a landscape shaped by a combination of fitment accuracy and an openness to experimentation. Online marketplaces and specialty shops provide a spectrum of options that span door-to-door aesthetics and race-inspired performance. The modular approach invites ongoing upgrades—one panel today, another tomorrow—without forcing a single, irreversible decision. The ability to see, touch, and compare different textures, thicknesses, and finishes makes the process tactile as well as visual. It also raises considerations about color matching, UV resistance, and long-term durability. A panel that looks striking in a showroom or gallery might behave differently in real-world sun, rain, and heat exposure. The best manufacturers and suppliers acknowledge this reality, offering finishes and coatings that resist chalking, fading, and micro-cracking after exposure to sunlight and temperature cycling. Those choices matter not only for appearance but for the perceived value of the bike over time.

Market dynamics reinforce the practical, creative power of individual fairings. In a global ecosystem, riders access a broad array of options from diverse sources. Some projects focus on cost-effective, mass-market parts that deliver the essential aerodynamic function and a credible aesthetic at a modest price. Other projects chase higher performance with lighter materials and engineered curvature that reduces drag and improves stability at speed. The difference between these paths is rarely a mystery; it is a matter of expectations, budget, and tolerance for experimentation. Importantly, the freedom to source specific panels means a rider can tailor a bike for a particular riding context. A touring setup might favor fairings with robust wind protection and weather resistance, while a track-oriented configuration could prioritize minimal weight and aggressive angles that optimize air flow around the rider and chassis. A nuanced approach to material selection, panel geometry, and finish can yield meaningful, measurable differences in ride quality and confidence—without the need to abandon a beloved machine’s core identity.

The culture surrounding aftermarket and individual fairings is, at its heart, a conversation between rider and machine. It is a dialogue about how a bike’s bodywork should respond to a rider’s intent. Are you chasing sharper handling, more protection, or a bolder visual stance? Do you want to emphasize the bike’s core lines, or do you prefer to blur the silhouette with sculpted, high-gloss surfaces? Each question invites a different panel combination, a different layout of color and texture, and a different sequence of installation steps. The process is iterative: fit, ride, assess, adjust. It can involve refinishing a panel to match a newer color code, refining a mounting bracket to reduce vibration, or swapping a tail piece to alter seat height perception. This iterative nature is not a sign of indecision but a sign of precision, an ongoing calibration of a machine’s appearance and behavior to match the rider’s evolving goals.

For readers who want to explore concrete paths into this world, the reality is that model-specific compatibility and a broad ecosystem of suppliers make customization accessible. While some platforms emphasize large cataloging and quick color changes, others highlight authentic, race-inspired forms and premium finishes. The spectrum accommodates both pragmatic replacement and ambitious, bespoke artistry. Importantly, the digital dimension supports this movement as well. Online catalogs, dimensioned schematics, and interactive fitment guides reduce the guesswork that once characterized fairing swaps. A careful buyer can cross-check mounting points, confirm clearances around the headlight and instrument cluster, and anticipate how a new panel’s geometry will influence airflow. The aim is not to chase fads but to cultivate a consistent, coherent sense of the bike’s identity while honoring the rider’s functional needs. In this context, a fairing is less a single part than a statement about how the bike feels in the rider’s hands—the balance of aerodynamics, weight, and aesthetics that together shape the daily ride and the long weekend escape.

The practical and expressive benefits of individual fairings extend beyond the personal. They contribute to the broader culture of motorcycle care and stewardship. When a rider replaces a weathered or damaged panel, they are preserving the machine’s integrity and continuing its service life. This is particularly important for older or rarer models where OEM replacements are scarce or expensive. Replacing a single piece preserves the character of the bike while updating its performance envelope. It also invites a sense of community. Sharing panel designs, paint schemes, and mounting tips helps others navigate similar choices. The community aspect—whether through forums, social media groups, or dealer and shop networks—offers guidance on fitment challenges, paint prep, and finish durability. The end result is a more resilient culture of customization that values both craft and care, where each panel carries a story of a rider’s journey and a bike’s evolving role in that journey.

Ultimately, the story of individual fairings is a story about agency. Riders gain agency to sculpt how they move through space and interact with weather, road texture, and wind pressure. They gain agency to express personality in a mechanical form that historically favored uniformity. They gain agency to extend the life and utility of a beloved machine by replacing only the necessary parts rather than committing to a wholesale redraw. And they gain agency to participate in a global marketplace where materials, finishes, and manufacturing techniques continue to evolve. The result is a living, breathing ecosystem in which every panel, every seam, and every reflective surface contributes to a larger narrative of rider empowerment. For those who want to explore this path further, there is a practical, accessible route through cataloged options that emphasize model-specific fit and straightforward installation.

For readers who want a direct throughline to practical exploration, consider the Honda fairings category as a starting point. It offers a curated landscape of model-matching panels that help you visualize how a single piece can transform both stance and performance. This link provides a concrete sense of how design intent translates into mounting reality and aesthetic coherence: Honda fairings.

As the chapter moves toward broader context, it is important to acknowledge the external dimension of this ecosystem. The stories of aftermarket parts are anchored in global commerce, with platforms that connect riders to suppliers across continents. While the bodies of knowledge about fitment and materials are anchored in engineering standards, the daily practice of choosing, painting, and installing remains a craft. The skill set covers measurement discipline, surface prep, primer and coating techniques, and an understanding of how temperature, humidity, and substrate interact with paint and clear coats. A well-executed panel swap not only looks right but maintains protection against the elements, preserves the integrity of the rider’s cockpit, and ensures that the bike’s aerodynamics stay coherent with the rider’s posture. The hands that perform the swap become as important as the parts themselves, because the outcome depends on the care taken during removal, alignment, and securing of fasteners. The chapter points toward a future in which digital design tools, accessible 3D modeling, and printable mountings further democratize customization, allowing more riders to participate in shaping their machines without needing to rely solely on large, one-size-fits-all kits.

In sum, the role of individual fairings in customization and aftermarket upgrades is not merely about fresh looks. It is about modular optimization—carefully choosing which panel to replace, understanding how each piece affects the bike’s aerodynamics and rider comfort, and respecting the constraints and opportunities of the chosen materials. It is about delivering a riding experience that feels precisely tuned to a rider’s needs, whether that means dropping wind fatigue on a long highway run, sharpening the machine’s reflexes for a twisty back road, or simply making a visual statement that reflects personal taste. This approach reframes bodywork from a static shell into a dynamic interface between rider intent and machine capability. As the market continues to evolve, the possibility of achieving highly individualized configurations without sacrificing safety or reliability becomes less a dream and more a practical, repeatable practice—one fairing panel at a time.

External resource: https://www.aliexpress.com/item/1005005742958636.html

Final thoughts

Individual motorcycle fairings significantly influence not just the appearance of a motorcycle but also its performance and rider experience. Business owners who understand the diverse types of fairings and their material properties can better cater to their customers’ needs, whether they are seeking aesthetic upgrades or functional enhancements. As the aftermarket for motorcycles continues to expand, so too does the opportunity for businesses to thrive by offering customization options that leverage the benefits of high-quality fairings.