Spraying paint on motorcycle fairings is not merely an aesthetic choice; it significantly impacts the motorcycle’s appeal and resale value. For business owners in the motorcycle industry, mastering this skill is paramount to delivering top-quality services that stand out in a competitive market. The journey to achieving a professional finish begins with thorough preparation, including careful surface cleaning and sanding. In the first chapter, we will delve deep into the essential steps needed to prepare motorcycle fairings. Next, we will explore effective masking techniques to ensure a smooth painting process. Finally, we’ll focus on applying primer and color paint, the heart of achieving that flawless finish that customers desire. This guide is designed to equip you with the knowledge to attract and retain customers through outstanding craftsmanship.

null

null

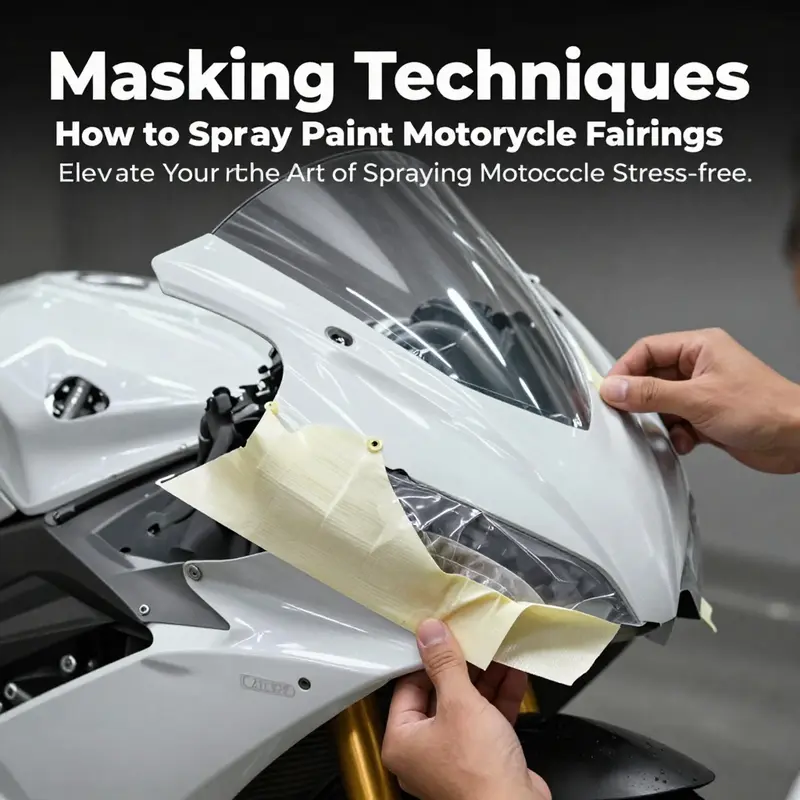

Masking Mastery for Motorcycle Fairings: Edges, Films, and Durable Finishes

Masking often goes underappreciated yet it determines if a paint job looks factory-fresh or DIY. For motorcycle fairings, masking is the boundary that controls edge sharpness, paint buildup, and finish durability. A careful masking plan protects unpainted surfaces, guides crisp color boundaries, and reduces post-paint touch-ups. When performed with care, masking yields a professional finish that stands up to UV, abrasion, and riding. When neglected, it can cause bleed, feathered edges, damaged decals, and a finish that reads sloppy.

Selecting masking arsenal begins with knowing the surface. Fairings are commonly polypropylene or ABS; tapes and films must tolerate plastic, resist lifting, and stay adhered through multiple coats. Low-tack tapes protect the surface with less residue, while automotive masking films offer greater coverage and curve conformity. The choice between tape and film is functional: edge control, overspray reduction, and speed through masking stage.

Preparation is foundational: clean the surface with a dedicated plastic or automotive cleaner to remove fingerprints, wax, oil, and dust. A clean surface ensures adhesive won’t lift and the tape will seat properly along every edge. After cleaning, wipe with a tack cloth to remove any remaining particles. A properly prepared surface is the bedrock on which masking rests.

Masking strategy balances coverage and accessibility. Cover what you don’t intend to paint, then refine for curves and features like air intakes and vent channels. Tape is ideal for edges and tight corners, while film provides broad shields for planes. Press edges firmly and seal corners with extra tape to prevent paint bleed. If a perfect edge isn’t possible with a straight line, extend masking slightly beyond the target edge to give yourself room to trim and keep paint from creeping during initial coats.

In complex shapes, masking becomes almost sculptural. Custom-shaped masking films can wrap contours and seal seams where straight tape balks at a curve. Liquid masking offers another option for hard-to-reach contours; apply a thin, flexible barrier, let it dry to a skin, and it peels away cleanly when you’re done. Treat masking as a shaping tool as well as protection so paint respects your design intent.

Adhesion is the quiet gatekeeper. Let masking materials seat on the surface for a few minutes before spraying. This patience helps in spaces with humidity or longer dry times and prevents lift as solvents escape or heat builds. If you remove masking too soon, you risk tearing wet paint. When in doubt, use a light pass of heat to soften edge adhesion for a clean release.

Edge handling decisions matter. For bold two-tone designs, use a narrow boundary tape to define the line and apply equal coats on each side. If you want a softer transition, you can slightly overlap borders and rely on the clear coat to blend. The masking plan must match the final aesthetic and be decided before coats go down.

Mask removal timing is surprisingly important. Many painters remove masking while paint is still tacky to preserve edge sharpness. Pull tape away from the painted surface at a shallow angle, about 45 degrees, in a single smooth motion. If a feathered edge remains, a light pass with masking can reestablish the line before recoating.

Overspray control and workspace discipline complete the technique. Use multiple light layers of tape and film rather than a single heavy layer to better conform to curves and textures. Maintain a dust-free environment: a spray booth or well-sealed space helps; airflow should be controlled, not aggressive. Wear gloves, a mask, and eye protection to guard against vapors and sprays.

With practice, you can map color zones on the fairing and sketch lines before laying tape, aligning color boundaries with confidence and keeping decals and logos ready for after-masking application. If you are tackling a multi-color design, plan boundaries first, then proceed with primer, color, and clear coats in a sequenced rhythm.

For those who want to practice, a scrap piece of plastic with similar texture provides a testing ground for tape adhesion, edge sealing, and the interaction between masking and spray. It is a practical hedge against costly mistakes on a valued fairing and a place to calibrate distance, speed, and coat thickness.

External resource: for broader context on painting motorcycle fairings, see Autocar’s how-to guide: https://www.autocar.co.uk/feature/how-to-paint-motorcycle-fairings/

null

null

Final thoughts

In conclusion, mastering the art of spray painting motorcycle fairings is a vital skill for business owners looking to provide exquisite service and product quality. By following the meticulous steps outlined in this guide—from the crucial preparation phase to effective masking and the thorough application of primer and paint—you establish a standard of excellence in your work. It is not only about the technique; it’s about creating an impressive final product that enhances the motorcycle’s appearance and increases customer satisfaction. As you implement these practices, you will elevate your business and attract a loyal clientele who values quality.