Removing motorcycle fairings is a crucial skill for business owners in the motorcycle industry, whether you’re managing a repair shop or selling parts. Understanding the intricacies of fairing removal not only enhances service quality but also boosts operational efficiency. This comprehensive guide will delve into essential tools and preparation, providing a step-by-step disassembly process, and offering reassembly and maintenance tips to ensure a holistic mastery over motorcycle fairings. With careful handling and knowledge, you can foster a culture of excellence in your business and offer unmarred service to your customers.

From Frame to Finish: A Thoughtful, Methodical Journey to Remove Motorcycle Fairings

Removing motorcycle fairings is less a dramatic sprint than a deliberate, practiced negotiation with plastic, screws, and silence. The panels that shape a bike’s silhouette are more than cosmetic; they protect wiring, ducts, and delicate components while guiding airflow and cooling. Treat the process as a careful conversation between you and the machine. Preparation, patience, and a steady hand will pay off with clean panels, intact fasteners, and a reassembly that feels like you never left the saddle. The approach outlined here builds a quiet confidence by grounding every motion in stability, organization, and respect for the bike’s underlying architecture. It starts with the right stance and a few essential tools, then moves through the sequence of removal in a way that keeps the panels pristine and the bike’s inner workings undisturbed.

Begin with preparation that honors the bike’s design and your own safety. Stability is not optional; it is the governing principle of every action. Position the motorcycle on a center stand or paddock stand if possible. This raises the bike to a comfortable working height, reduces wobble, and exposes attachment points that might otherwise hide behind fuel tanks or seats. A stable base makes it far less likely that you’ll slip or put uneven stress on a panel as you pry, unclip, or lift. While stability is the frame on which this procedure rests, the next layer is protection for the finish. Lay down a soft cloth or mat on the floor, and keep a clean workspace where removed parts won’t contact dirt or dust. It’s amazing how quickly a blurred edge or a speck of grit can turn a simple panel into a scratched souvenir of a weekend project.

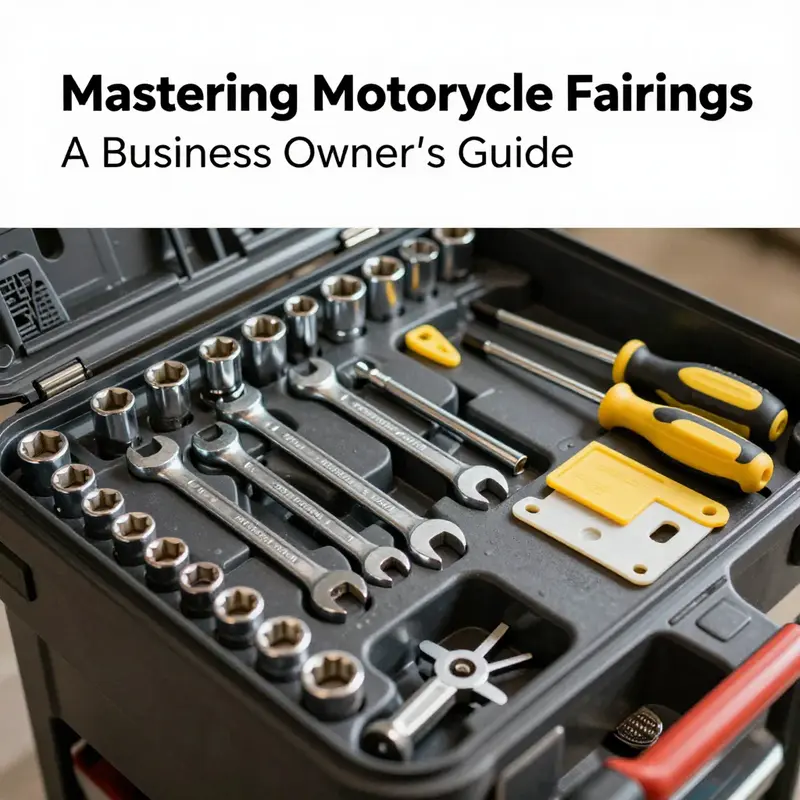

With the stand secured and the work area prepared, gather the tools you’ll need. A socket wrench set with a selection of sizes—commonly 8, 10, and 12 millimeters—will cover many fasteners. A screwdriver, either Phillips or flat-head, will handle trim screws and small caps that hide bolts. A plastic trim removal tool is essential; metal tools can mar the paint or nick the surface of a panel, and once a scratch appears, the whole job loses a little of its resilience. A soft cloth protects the paint when you rest parts during the job, and a small container or labeled bags keep screws and clips from wandering into the wrong corners of the toolbox. Finally, a labeling system—tags, painter’s tape, or color-coded stickers—makes reassembly a straightforward mirror of disassembly. When you set out with these protections in place, you’re not just removing fairings; you’re preserving the integrity of the entire assembly.

Disconnection of the electrical system follows safety as a non-negotiable step. The negative terminal should be disconnected before you reach for any wiring harnesses or electrical connectors. This is a compact insurance policy against accidental shorts that could ripple through lights, sensors, and control modules. A moment of caution saves you hours of troubleshooting later. When the battery is disconnected, you can inspect the fairings with less concern about unintended power draws or shorts. Make a mental note of the bike’s electrical layout as you proceed, but avoid dwelling on the specifics of any one wire. The goal is to reduce risk and maintain clean separation between chassis metal and living, energized circuits.

You’ll soon find that the removals begin in earnest with identification of fasteners and trim. Begin by recognizing all the main bolts that anchor the fairing panels to the frame. Look for screws that sit under the front fender, behind the headlight housing, along the edges of side panels, and in the often overlooked air intake zones. Plastic push pins or clips are common in modern designs and can be stubborn when you try to release them with brute force. A plastic pry tool is your best friend here; it slides under the head of the clip with minimal resistance and gradually raises the clip without gouging the surrounding plastic. Small plastic covers or caps hide screws from view; don’t neglect removing these before you attempt to separate any panel. A tip that repeats with every fairing job is to move slowly and work methodically. If you choose to label each fastener type and its location as you go, you’ll save time on reassembly and avoid mixing parts that look similar but belong to different panels.

The moment comes when the panels begin to yield. Pry cautiously along the edges with the trim tool, working in gentle increments. Start at a corner where the panel clearly meets the subframe or another panel, and move along seam lines rather than attempting to lift a whole section out in one forceful yank. Even pressure matters here; too much pressure on a small area can crack a corner, while uneven pressure can warp the panel at the point where it meets the frame. If the edge resists, there may be hidden fasteners still attached, or a clip that has not yet released. In all cases, resist the urge to brute-force the panel away. The goal is a controlled separation, not a demolition job.

Some fairings are linked to more than their own geometry. Electrical connectors, lighting harnesses, or air ducts may pass behind or through a panel. When you encounter resistance, pause and search for these connections. A release tab, little lever, or clip may be waiting just behind a seam. Have a clean flashlight ready to illuminate crevices that aren’t obvious in normal room light. If a panel resists, double-check that every visible fastener is removed and that you’re not working against a hidden clip. It’s easy to misread a tight seam as a single point of resistance, whereas the real obstacle is a clip seated in a pocket you can’t immediately see. The patient approach here saves you from bending or snapping panels that are meant to be flexible under normal operation.

As you determine that a panel is free from fasteners, turn your attention to the electrical realm. If the fairing houses headlights or turn signals, you’ll find connectors tucked behind the panel’s inner surface. Locate the release tab, a small lever, or a clip that holds the connector in place. A careful press on the release while gently pulling the two halves apart will separate the connection without damaging the pins or the housing. The act of labeling behind the panel remains valuable; it ensures you will reconnect the right wire to the right socket later. This moment of disconnecting is not simply a pause; it is the transition from the external layer to the internal choreography of the bike’s wiring. Treat these connectors with the same respect you give the screws themselves, and you’ll avoid the tangled debugging that can come from mismatched plugs.

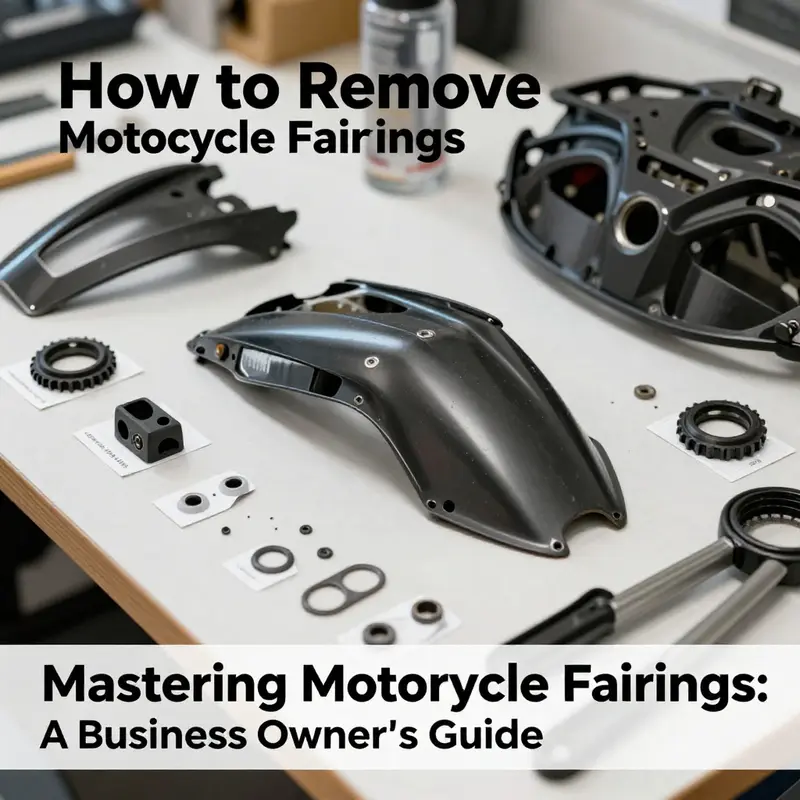

With all fasteners removed and connectors released, the next step is to lift and remove the panel. The method of removal varies by design: some fairings lift outward and then pivot away from the bike; others hinge upward or slide along a defined track. In every configuration, lift gradually, supporting the panel with both hands. A panel can feel surprisingly heavy, especially once it’s detached from the lanes of air that held it in place while you rode. Place the panel on a soft surface, keeping the mounted side away from dirt, dust, and other potential abrasives. The moment you lower the fairing onto the mat, you’ll feel the tension in your arms ease. The panel is now within reach for inspection, and the bike has gained a pause that will let you consider the next panel with a calm, systematic approach.

Now that the fairings are off, take the opportunity to inspect the surfaces that mounting points contact. Look for signs of wear on rubber gaskets, seals, or cushions that seal the join between panels and the frame. Warping or cracking in the plastic may appear after years of heat and vibration; small cracks can develop along seams where stress concentrates. If gaskets show wear or damage, replace them during reassembly to maintain weatherproofing and reduce rattle. Clean the mounting surfaces thoroughly so the reinstalled panels sit flush. A clean contact surface prevents misalignment, creaking, and future rubbing that can lead to panel damage or a compromised seal. This is not a cosmetic check; it is a functional step designed to preserve the bike’s structural integrity as much as its appearance.

Reassembly is the inverse of removal, but it is not merely a reversal of steps. Reassembly begins with the careful prep work you performed before removal. Have a soft mat, the labeled fasteners, and the connectors ready. When you begin to rejoin the pieces, start at the top and work downward, following the reverse order of removal. This approach minimizes the chance of misalignment and helps ensure that each fastener slides into its intended hole without forcing. As you reinstall screws, tighten them in a gradual, cross-pattern sequence to avoid distorting the panel or creating uneven compression along the seam. If a torque specification exists for your specific model, use a torque wrench rather than guesstimating. A panel overtightened is as harmful as a panel that is too loose; the right balance preserves fit and keeps the weather seals functional.

The process is almost complete when the wiring harnesses are reconnected and the final panel is secured. It is worth a final pass to verify that all connectors are fully seated, clips snapped in, and screws snug but not over-torqued. A visual check across seams should reveal a uniform line with no gaps where a panel sits unevenly. If a panel seems misaligned, back off a touch and reseat it before continuing. This is the moment when care pays for itself in both aesthetics and function. The bike should feel solid and aligned, as if the fairings were never removed—except you’ll be the one who knows the work you invested to reach this place and complete the task with precision.

While the core technique is universal, you may find model-specific quirks that require adaptation. Some bikes place the main fasteners behind the seat or under the fuel-tiller area, while others rely on clips that demand a particular sequence of removal. The best practice is to consult the service manual for torque specs, step-by-step diagrams, and any model-driven cautions. A good manual offers diagrams and notes about connector pinouts, the order in which panels are removed, and special care points, such as delicate bracing in the air ducts or the location of a rain seal that keeps moisture from the internal electronics. If you need broader, model-oriented diagrams or step-by-step visuals, you can turn to a dedicated catalog that organizes parts by year and category, which can help you align the correct approach with the bike’s architecture. A link to a catalog section is included here as a convenient reference: 2023new. For a deeper dive into model-specific diagrams and torque guidance, the official manuals provide diagrams and tool requirements that can be invaluable in more complex disassembly tasks.

Once the fairings are reattached, take a moment to reconfirm the bike’s overall integrity. Reconnect the battery, verify that all indicators illuminate correctly, and listen for any unusual creaks or rattles as you gently swing the bike from side to side. If you notice anything amiss, stop and recheck the panels and their fasteners. The goal is not speed but confidence—the confidence that your work will stay intact through next week’s ride and through many miles to come. The fairings should look as if they belong to the machine, with lines that align and surfaces that reflect light evenly. A well-executed panel removal not only makes maintenance easier but also preserves the bike’s aerodynamic profile, the integrity of air intake pathways, and the reliability of the electrical system that hides behind the skin.

This chapter has walked you through a deliberate, skillful approach to removing motorcycle fairings without damage or drama. It emphasizes a calm, data-informed sequence—stability, disconnecting power, identifying and removing fasteners, careful edge-prying, disconnecting electrical connectors, lifting panels with balance, inspecting for wear, and reassembling with measured torque. It is a craft that rewards patience and a methodical mindset. The minute you replace the battery and admire the restored alignment of panel seams, you’ll sense that the effort was not merely about separating plastic from steel but about preserving the bicycle’s anatomy—its geometry, its weatherproofing, and its future potential for upgrades or repairs. As you continue to perform more disassemblies, the process will feel more intuitive, and the bike will respond with the familiar, confident resilience that comes from a job done right.

If you want a broader reference for this kind of work that goes beyond general guidelines, a catalog of model-year resources can offer diagrams and procedural details aligned with specific builds. For a general sense of structure in these references, see the catalog’s 2023new section, which serves as a hub for updated diagrams and related coverage. While every bike presents its own nuances, the core discipline remains: work with intention, protect the finish, and respect the internal systems you expose. In the end, removing fairings should feel like a controlled, almost meditative task rather than a rushed or reactive one. And with the right approach, you’ll return to the road with a bike that looks as pristine beneath the skin as it did when it rolled into your garage.

External resource for deeper diagrams and official guidance: https://www.haynes.com/motorcycle-repair-manuals/

Shedding the Shell: A Thoughtful, Wiring-Savvy Approach to Removing Motorcycle Fairings

Fairings are more than decorative armor; they are the first line of defense for delicate internals, a canvas for the bike’s silhouette, and a complex network of fasteners, clips, and connectors that keep electrical systems and air paths working in harmony. Removing them, when done with patience and care, can open a window into the heart of the machine without leaving scratches, cracks, or electrical headaches in your wake. This chapter threads together a practical, narrative approach to disengaging the body work, balancing the need for access with the respect the panels deserve. It emphasizes preparation, respect for the hardware, and a calm, methodical rhythm that keeps you in control from the first turn of a screwdriver to the moment the last clip is seated again. The goal is not merely to extract panels but to understand how they are held together, how the wiring is organized, and how to reassemble with the same care that kept the bike looking pristine in the first place.

Begin with a quiet collect-and-prepare phase. Stability and safety are the quiet prerequisites that unlock a smooth disassembly. Park the motorcycle on a level surface, ideally on a firm stand or center stand if your model supports it. A gentle, deliberate stance matters here: you don’t want the bike to tip or rock as you maneuver panels and connectors. Wear gloves with a light grip to shield your hands from sharp edges and edge-biting plastic trims, yet maintain enough tactile feel to sense the subtle give of a plastic fastener or a clip. Now, assemble the toolkit in a way that mirrors the pathway you will follow on the bike. You will want a set of wrenches or sockets sized to your model’s fasteners, a selection of screwdrivers for plastic trim screws, a plastic trim tool or a soft pry tool to avoid scratching, a clean cloth to set the panels on, and a labeling system—small tags, tape, or markers that let you record where each piece came from. The labeling is more than a courtesy; it becomes your map for reassembly, preventing mismatched fasteners or skewed gaps later on.

With the bike stable and your materials ready, the disassembly begins in a logical sequence that respects the way the panels are assembled. A common approach is to start with ancillary pieces that give access to the core fairing panels. Often the seat is attached with screws hidden beneath a trim cover or a small panel. Removing the seat first can clear space and reveal mounting points for the side panels, which are typically secured by a mix of screws and plastic clips. As you work, approach the fasteners with careful respect for their function. Bolts and clips are chosen for particular tolerances and materials; forcing them can deform plastic or shear a clip, leaving you with more work and potential rework later. The same courtesy you show to the fasteners should extend to the clips that hold the side panels in place. Use the plastic trim tool to gently release clips, lifting them just enough to free the panel without bending the surrounding structures. When screws are encountered, turn them with the appropriate screwdriver and store them in labeled containers so nothing goes astray during reassembly.

The sequence continues forward, toward the front of the bike where the fairing often meets the headlight assembly. In many designs, the front fairing is secured by fasteners around the headlight housing, along the lower edge near the fender, and in corners that tuck into the air ducts or intake channels. The key here is to identify all visible fasteners first, then scan for hidden clips that may be concealed behind trim covers or under edge panels. A slow, methodical sweep is far more reliable than a quick, forceful pull. If a panel resists, resist the urge to yank. There is almost always another fastener or a hidden clip waiting to be found. This is the moment to pause, retrace your steps, and verify you have addressed every attachment before applying further leverage.

As you approach the moment of separation, you will often encounter electrical connections trailing from the fairing’s inner edges. The wiring harnesses for headlights, turn signals, and possibly instrument clusters can weave through the fairing’s inner channels, riders of their own internal map. Disconnecting these safely requires a tactile approach as well as a bit of memory. Find the release tabs or clips on the connectors themselves, usually designed to be pressed or lifted with a finger or small tool, and gently pull apart. Once a connector is free, label it if you haven’t already. A simple system—one tag per connector or per wire harness segment—will save you from a tangle at reassembly and protect against cross-connections that could cause misrouted signals or a nonfunctional light kit.

With the fasteners released and the electrical connectors disengaged, the moment of actual removal arrives. Lift the panel with even, deliberate pressure, moving away from the frame and toward a soft surface that won’t scratch or mar the paint. Placing each panel on a clean cloth or a soft mat ensures the finish remains pristine while you work on the bike’s inner life. It’s not unusual for some panels to rely on rubber gaskets, seals, or weatherproofing layers that can resist separation slightly. If you encounter resistance in a corner, recheck for hidden attachments rather than forcing the panel. When a panel clears, take a breath and set it down gently. The process becomes almost meditative at this stage—a cadence of release, lift, set, and move to the next piece, always mindful of the slight tension from wiring ducts, air routing components, or light housings that may still be linked to the fairing.

The broader landscape of the disassembly becomes visible as the panels withdraw. Now is a good time to inspect the mounting surfaces and the edges of the fairing for any signs of wear or damage. Cracks or deep scratches are a reminder that even small misadventures during removal can leave a lasting impression. Check the rubber gaskets, seals, and the air-channel interfaces for signs of deformation or wear; these elements contribute to weather resistance and cooling when the fairing is reinstalled. Cleaning the mounting surfaces at this stage makes life easier down the road. A mild detergent solution and a soft cloth can remove dust and old residue, letting new clips or gaskets seat more cleanly when it’s time to tighten back in. This inspection phase is not mere housekeeping; it is part of ensuring the bike’s integrity remains intact after any fairing work.

When the time comes for reassembly, the playbook is the reverse of what you just did. Begin by reconnecting electrical connectors, making sure each is fully seated before you proceed. If a connector has a locking tab, you should hear or feel it click into place, confirming a secure connection. Then reattach the fasteners in a methodical sequence, tightening them gradually to avoid deformations or misalignment. A torque wrench is ideal if you have model-specific torque specifications on hand; if not, tighten to a snug feel that respects the panel’s ability to hold firmly without overdriving the fastener into the plastic. Your goal is even clamping across the panel, with no gaps or high spots that betray misalignment. Finally, replace any trim covers or caps that hide screws, ensuring each piece seats as snugly as it did at the outset. A careful reassembly leaves the panels looking as if they never left, with uniform gaps and a consistent, factory-like finish.

The practice of fairing removal is, in the end, an exercise in respect—for the bike, for the panels, and for the systems that rely on careful assembly. It is also an act of preparation for the next stage of maintenance or customization, whether you are swapping panels for a fresh appearance, replacing a damaged piece, or simply gaining access to underlying components for inspection. This mindset—patience, method, and an organized workspace—reduces the risk of damage and speeds up the workflow when you know exactly where to look and what to expect. It also frames the broader understanding that the fairing is not a single piece but a composite of connections. Each screw, clip, and plug is part of a larger map that guards electrical reliability, fluid routing, and structural integrity. When you approach the task with this awareness, you are more likely to complete the job without unintended consequences and to re-create a clean, visually appealing, and mechanically sound result.

For riders seeking model-specific diagrams and torque specs, it helps to consult the dedicated catalogs and guides that organize information by system and chassis. You can explore a focused collection of parts and diagrams in the honda-fairings category, which provides a targeted resource for those who want to preview how a particular fairing assembly is supposed to fit together. The path to this resource is straightforward: honda-fairings. While the panels themselves vary by model, the general logic of removal remains consistent across similar designs: identify fasteners, release clips, disconnect the harnesses, and handle each piece with care. The catalog helps you anticipate specialized fasteners or unique clip styles that may not be present on every bike, reducing surprises during the actual operation.

As a final note, the practical discipline of fairing removal carries with it a broader obligation to consult official references when uncertainty arises. Manufacturer manuals and service guides are designed to address the specific torque values, clip types, and wiring harness routing for each model. When in doubt, pause, consult the appropriate service materials, and proceed only with the precise instructions for your bike. This approach protects the longevity of the fairings and the reliability of the electrical systems that lie beneath. The aim is not to rush but to ensure that every action is deliberate and correct, so the project advances with clarity rather than risk.

In the larger arc of maintenance or customization, the fairing removal process—careful preparation, a steady sequence of detachments, mindful handling of panels, and meticulous reassembly—becomes a hallmark of skilled bicycle care. It teaches you to value the delicate balance between accessibility and protection, between the allure of a new look and the quiet assurance that the work has not compromised the bike’s fundamentals. The steps described here echo across many models and setups, and they translate into a confident workflow that you can apply whenever you need to access the interior or update the external shell. The result is not merely a set of removed panels but a deeper competence: the ability to treat the bike with respect while you pursue mechanical clarity, aesthetic updates, or performance refinements. Whether you are swapping a set of panels for a fresh appearance, replacing a damaged piece, or simply performing routine checks, the method stays the same: patient preparation, careful disengagement, and precise reassembly. And the next time you approach the project, you will bring the same calm focus, knowing that the shell can come off without compromising the heart beneath, and that it can go back on with the same degree of care that kept the bike looking flawless in the showroom lights.

External resource and reference suggestions can further ground your practice. Accessing general repair manuals and service guides—ideally official, model-appropriate documents—can provide diagrams, torque specs, and clips that your specific model requires. For readers seeking broader access to repair diagrams and model-agnostic guidance, the official service manuals portal is a trustworthy destination. It is a reminder that while the practical steps above cover standard disassembly, the safest path for model-specific nuances remains the authoritative manual that matches your bike’s year, variant, and trim. This adherence preserves not only the bike’s aesthetics but its reliability over time.

In sum, removing motorcycle fairings does not have to be a high-risk or high-stress operation. With deliberate preparation, a clear understanding of fasteners and clips, mindful handling of electrical connectors, and a structured approach to reassembly, you can gain access to the bike’s internals or switch up its appearance without compromising anything valuable. It is a practice grounded in patience, respect for materials, and the discipline of careful documentation. When you adopt that mindset, the fairing removal process becomes a reliable tool in your maintenance repertoire—one that empowers you to care for your bike and pursue the custom or diagnostic work you envision with competence and confidence. And with a simple nod to model-specific guidance when needed, you ensure that every panel you remove or reinstall continues to serve you well on every ride ahead.

External resource: https://www.honda.com/service/manuals/

Skin Reunited: Mastering Reassembly, Maintenance, and Safe Care After Removing Motorcycle Fairings

When you set out to work with a motorcycle, removing the fairings is only half the journey. Reassembly is the other, more intricate half, where precision, patience, and a methodical mindset become the difference between a flawless finish and a panel that never sits right again. The chapter that follows treats reassembly and maintenance not as a hurried afterthought but as a careful extension of the original disassembly. It invites you to approach the process as a coordinated sequence rather than a series of isolated tasks. In this light, fairing removal and subsequent reattachment share a single purpose: to restore the bike’s integrity, protect its sensitive components, and preserve aesthetics while keeping electrical systems, seals, and fasteners in a state that supports reliable performance. A solid reassembly rests on preparation, disciplined execution, and ongoing inspection, all rooted in respect for the materials and the engineering that keeps the machine aligned with both safety standards and rider expectations.

Begin with a calm map of the work ahead. The removal steps you’ve already completed will guide you back, but the reassembly phase often reveals details that were easy to overlook in the first pass. The panels you took off sit in a specific order and orientation to the frame, with a network of fasteners, clips, dampers, and seals that must re-engage with the same precision. In practice, this means returning to a clean, stable work surface and confirming that every fastener from the disassembly has a known counterpart on the bike and a designated home on a panel. A labeling scheme—simple tags or color-coded tapes placed near each fastener or clip—can save hours of confusion when you begin to reinstall. The method is almost ritualistic: you approach the bike with the same care you would give a delicate sculpture, knowing that plastic components can be brittle if rushed and that wiring harnesses, when misaligned, can trap or pinch in ways that create electrical faults or heat buildup later on. If you paused to reflect during removal, you will find that reflection pays dividends during reassembly, because it sharpens your sense of how things should fit together and what normal resistance feels like when you push a panel back into place.

The first contact you’ll establish with the bike during reassembly is the readiness of the mounting surfaces. While the panels are off, you’ve likely inspected the engine side of the fairings and the frame for nicks, burrs, or corrosion that could interfere with a clean seating. A soft cloth becomes your first ally here. Wipe away any dust, grease, or small debris that might have found its way into the mounting pockets or along the edge seals. If you notice a rubber gasket or seal that appears compressed or cracked, replace it before you proceed. Weatherproofing, even in mild climates, depends on these little gaskets holding their shape and elasticity. Remember that fairings, while primarily cosmetic and streamlining in function, also contribute to aerodynamics, air routing to the engine and intake points, and in some cases, to the alignment of lighting and sensor modules. Any misalignment can ripple into performance issues, such as incorrect air density at the intake or stray vibrations that hatch into rattles when the bike is running.

Tools come into play in a disciplined, almost ceremonial way. Gather the same sockets and screwdrivers you used for removal, but now with the intent to tighten in a controlled, incremental pattern. If you’ve kept track of fastener types and locations, you’ll want a small torque-spec guide on hand. Torque is a friend when used correctly; too little and the panel can vibrate loose, too much and you risk stripping threads or cracking plastic. If a torque wrench is available, reference the model’s service manual for the exact values. Where manuals are not at hand, adopt a conservative approach: tighten progressively in a crisscross or star pattern for large panels, and snugging in key positions for smaller trim pieces. This approach ensures even seating of the panel against the frame and reduces the chance of warping at corners or seams.

The reassembly rhythm is not simply about bolts. It begins with re-engaging the more permanent mountings—the biggest panels that define the bike’s silhouette and the core around the engine. Start with a main body panel that defines the central plane of the machine. Align its mounting posts with the frame and slide it gently into position. If you encounter resistance, stop and double-check that you’re not binding a clip or misaligning a hole. It’s far better to back up a few millimeters and adjust than to force a panel back into place and create a chipped edge or a peeled mold line. The plastic is forgiving up to a point, but it does not react well to brute force. You will, in many cases, hear a faint click as snap-fit clips seat into their anchors. That sound is not a victory cry—it’s confirmation that the panel is really engaging its mounting points and not just resting on top of them. For panels secured with screws, use a light touch at first, and only apply final torque after confirming the panel sits evenly along its entire length.

Electrical connectors are one of the most delicate aspects of reassembly. During disassembly, you may have labeled every wire or connector, but labeling becomes even more critical during reattachment because the geometry of the harnesses changes as panels are remounted. Start by reconnecting the main harness cluster or the longest connectors first, ensuring they snap fully into their housings. Look for a distinct “click” as the release tab seats, then gently tug on the connector to verify it’s locked in place. Don’t rely on a single latch; some connectors have secondary locks or retaining clips that must be re-engaged. If you encounter a connector that won’t seat, back up and inspect the mating surfaces for debris, misaligned pins, or a protruding harness that is obstructing proper engagement. After all electrical connections are reestablished, it’s wise to perform a quick systems check before the entire reassembly is complete. Reconnect the battery only when you’re sure the harnesses and clips are secure and that no panel is under pressure from wires.

One of the more tactile aspects of reassembly involves the clips that hold the panels to the frame. Plastic clips can be deceptively fragile; a clip that looks intact may have lost its bite and fail to hold a panel firmly. Move around the panel while you seat it and listen for those same reinforcing clicks that signal the clip has engaged. If even a single clip feels loose, consider replacing it. Clip integrity matters not only to aesthetics but to the long-term resilience of the fairing alignment. A loose clip can permit slight movement of the panel, which over time can rub against a metering device, a sensor, or a fastener and eventually cause wear. When a clip breaks, it is often a simple, inexpensive replacement, but it can save far more labor and potential damage later. The goal is an even, quiet mounting that can withstand road vibrations without presenting a visible gap along the seams.

As the fairing edges begin to meet the frame again, you will have opportunities to reassert weather sealing and reduce wind noise. Inspect the rubber gaskets along the mating surfaces, particularly around the headlight area and the lower edges of the panels. A slightly deformed gasket will not seal properly and may trap moisture or allow rain ingress. If you find a gasket that lacks proper resilience, replace it or compress it with a minimal amount of compatible sealant if the manual permits, and only in the specified locations. This is not a broad invitation to crowd the edges with adhesive; rather, it is a targeted step to preserve weatherproofing and the structural integrity of the panel assembly. The careful application of sealant should be guided by the service manual, which explains where and how much to apply, usually in folds or grooves that are designed to accommodate it.

In the busier, more complex fairing systems, you may also have to re-align air ducts and internal channels that route air to the engine or to sensors on the bike. The alignment here is subtle. Even a small tilt or shift in an air duct can alter airflow patterns, influence engine cooling, or change the way air reaches a sensor. Re-check these pathways as you re-seat adjoining panels. Make sure that there are no kinks or pinches in hoses that could cause blockage or reduced performance. If a duct or hose is held by a clip or a small bracket, reattach it in the same location and verify that the associated clip aligns with its mounting hole, then secure it with a light, even pressure.

With the major panels in place and the electrical and air pathways confirmed, you move toward the final cascade of smaller trim pieces and covers. The trim is the last mile of the journey and often where riders notice the difference between a factory-perfect fit and a makeshift reassembly. These small pieces can hide an array of fasteners or sit in recessed pockets that require careful alignment. Gaps along the seams are a visual cue of misalignment, not just a sign of poor aesthetics. So, as you reinstall, pause to scan the entire perimeter of each panel for uniform gaps and consistent alignment with the adjacent panels. The goal is to achieve a continuous silhouette and a uniform line that follows the bike’s geometry. A common pitfall is to push a trim piece into place without verifying its relationship to surrounding parts. To avoid this, fit the piece loosely at first, then gradually apply final pressure as you confirm alignment with neighboring panels. This approach minimizes the risk of deforming the trim or the panel and helps preserve a seamless look that will endure the rigors of road testing and the cycles of heat and cold.

Beyond the physical fit, reassembly is a moment to re-validate function. Before you finish, slowly rotate the engine by hand to ensure there is no unexpected contact that could hold back movement. If you have LED or other lighting elements wired through the fairing, a quick ignition test can help confirm proper operation after reassembly. Reconnect the battery and switch on the ignition, observing the indicators and lights for any anomalies. This test is not about full system diagnostics, but a quick check to catch obvious issues such as a loose connector or a panel that obstructs a light or sensor. If something fails to illuminate, pause and trace the wiring again, focusing on connectors that may have been disturbed during panel seating. It is far easier to repair a loose connection at this stage than after the bike has ridden for miles with a hidden fault.

Maintenance is not a separate afterthought but a continuous practice that begins the moment the last screw is tightened. With the fairings back in place, examine the mounting points for signs of stress, cracks in the plastic, or any movement in the panel that suggests a clip or screw is becoming loose. The frame and the mount points should show no signs of fatigue, and the fasteners should sit snugly, not overtightened. Keep a small supply of spare clips, screws, and a soft cloth for routine checks. Periodic inspections are especially prudent after long or rough rides, where vibration and temperature changes can reveal hidden weaknesses. If the bike is used in damp conditions, check for corrosion around any exposed metal fasteners and treat those areas as you would any other corrosion risk—clean, dry, and protected. When you’re satisfied with the structural integrity, mask off large surfaces from dust, and perform a gentle polish to restore the finish, preserving the visual continuity that fairings contribute to the machine’s overall presence.

In most cases the reassembly process will be straightforward if you have kept to the disciplined approach of labeling, mapping, and verifying each connection. There is no substitute for patience here. A rushed job often leads to a panel that sits slightly askew, a clip that fails to engage, or a gasket that doesn’t seal. The aim is not to rush through a celebratory moment of finishing a task; it is to ensure the work stands up to the tests of time and the environment, so the bike looks and performs as it should for countless miles ahead. The formal etiquette of this task is simple but powerful: take your time, check your work, and only move to the next step when the current one is clearly complete. If a step is unclear, pause, consult the manual, or seek the guidance of a professional. There is value in asking for clarity before forcing a panel into place, and there is wisdom in recognizing when a job is beyond your current skill level and warrants professional support. This respectful approach not only protects the bike but also guards your own safety and investment.

For readers seeking a compact, model-spanning guide that complements this narrative, there exists a detailed step-by-step resource that outlines the general process of fairing removal in a clear, practical way. It can serve as a convenient reference while you work toward a confident reassembly. How to remove motorcycle fairings.

As you finish the reassembly, you should also consider how you’ll maintain the fairings going forward. The occasional removal of panels for routine checks becomes a positive habit when you plan for it. Develop a simple maintenance routine that includes inspecting fasteners for tightness, testing electrical connectors for security, and listening for unusual rattles that might indicate a loose clip or a misaligned edge. The habit of regular inspection helps catch small issues before they evolve into more significant problems, preserving both performance and appearance. In addition to these checks, consider a light, periodic cleaning of the internal mounting surfaces. Dirt and dust can gradually accumulate in mounting pockets, making future removal more cumbersome. A clean mounting plane reduces the likelihood of debris causing misalignment or chip marks during future service.

A final note on the broader practice of fairing care: if you are restoring a bike to a near-original condition or undertaking a high-end customization, the stakes of proper reassembly rise accordingly. Small deviations in alignment, seal integrity, or clip condition will be more visible when the bike has a tuned appearance or when you are aiming for a particular aerodynamic profile. In those cases, follow the precise torque specs and reassembly procedures outlined in the official service manual for your model. The manual not only provides numbers; it also documents the intended seating sequence, the recommended order for panel installation, and any model-specific quirks that affect how the fairings integrate with wiring or sensors. If you are uncertain or face a unique configuration, professional help becomes a sensible consideration to avoid mistakes that could compromise safety or performance.

In sum, reassembly after removing motorcycle fairings is a careful, deliberate act that honors the design and engineering of the machine. It demands organization, attention to detail, and a patient approach to both the mechanical and electrical systems. When you succeed, the result is more than an aesthetically pleasing exterior; it is a reliably sealed, correctly aligned, and functionally sound architectural shell around the bike’s inner workings. This is how you protect your investment, maintain riding confidence, and extend the life of your fairings and the systems they protect. The process, though exacting, becomes a routine you can master with practice, preparation, and a steady hand. External references can further illuminate the shared principles across models and years while preserving the individual nuance each bike demands. For continued reading on practical steps and best practices, consult the external reference linked above, which delves into common scenarios and cautions that riders frequently encounter during fairing work.

Final thoughts

Successful removal and reassembly of motorcycle fairings entail precision, knowledge, and proper practices. As a business owner, mastering this process not only enhances your service offerings but also reinforces customer trust in your expertise. The efficiency gained from utilizing the right tools and following a step-by-step approach can lead to improved turnaround times and increased customer satisfaction. Equip your team with these insights and deliver excellence with every motorcycle you service.