Polishing motorcycle fairings is an essential process that not only enhances their visual appeal but also preserves their structural integrity. As business owners, understanding the meticulous steps involved can set you apart in the highly competitive motorcycle service industry. This comprehensive guide will delve into the key aspects of polishing motorcycle fairings, outlining the necessary preparation steps, effective wet sanding techniques, polishing methods, and final inspection processes. Together, these chapters will equip you with the knowledge needed to provide high-quality polishing services that meet customer expectations.

Laying the Groundwork: Thorough Preparation for Polishing Motorcycle Fairings

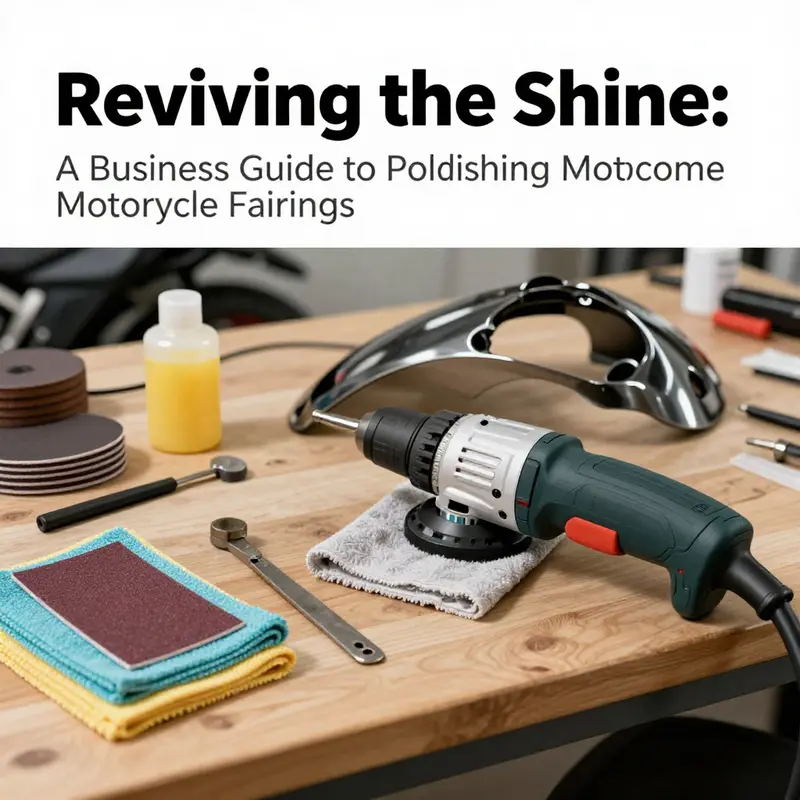

Polishing motorcycle fairings is more than chasing a showroom glow. It is a careful ritual that starts well before any paste meets the surface. The preparation phase is the quiet work that determines whether the final finish will be a glassy mirror or a tired, dull look that swirls under the light. When the surface has been thoughtfully prepared, the polishing stage becomes a precise, controlled dance rather than a guessing game. A well-prepped fairing responds to each pass with consistent luster, and the risk of introducing new scratches or heat damage is dramatically reduced. In this sense, preparation is not simply a prelude; it is the real foundation of the outcome you want to achieve. The steps that follow—thorough cleaning, careful inspection, and then assembling the right tools—form a seamless flow that sustains momentum from the first pass to the final wipe.\n\nCleanliness is the starting line. Begin with the simplest, most accessible rule: a clean surface will respond predictably to sanding and polishing. Use a mild detergent and a soft microfiber cloth to wash away dirt, grime, oil, grease, and any leftover wax build-up that may have accumulated in seams and along edges. Dirt trapped in texture or along creases can act like sandpaper on your finish, embedding particles that will become visible as you begin sanding. It is tempting to rush this step if the sun is warm or the bike is on display, but skipping or skimping here almost always leads to micro-marring later. A meticulous wash, followed by a thorough rinse, is the cheapest, most reliable form of insurance you can have before you introduce any aggressive abrasives to the surface. The goal is to reach a true, uncontaminated canvas so that each subsequent action, from sanding to buffing, behaves as intended.\n\nAfter washing, the inspection begins. A bright light or the natural daylight you intend to use for the finishing check will reveal flaws that the unaided eye might miss. Look for scratches of varying depth, chips in the paintwork, or even slight deformations that could indicate underlying damage. The difference between a superficial scratch and a deeper defect can be the deciding factor in whether you proceed with polishing alone or you need a repair step first, such as applying a body filler and sanding back to a smooth plane. For minor imperfections, the polishing itself can be enough to blend and erase the marks, but deep gouges or structural issues may require a different approach to avoid chasing problems that would reappear once you begin the polishing cycle. The inspection should also consider the type of fairing material you are working with. ABS plastics, fiberglass, and composite parts each respond a little differently to sanding and polishing, so the plan you make must align with the material, not merely the color or gloss you hope to achieve. In this moment of assessment, you are setting expectations for the finish and the workload, and you are determining where the hard limits lie. If you’re sourcing replacement components or seeking matching parts, a reference point like the Honda fairings catalog can help you verify fit and compatibility as you map out the restoration path. Honda fairings catalog\n\nWith the surface clean and the condition understood, you assemble the tools and materials that will carry you through the preparation phase. The core kit remains consistent across most guides: a dual-action (DA) or rotary polisher, a range of progressively finer sandpapers, a polishing compound or paste, a soft polishing pad, and clean microfiber towels for final wipe-downs. The sandpapers commonly used are 800-grit for initial flaws, 1500-grit for smoothing the coarser lines, and 2000-grit for the final refinement. Each grit serves a specific purpose in the journey from rough to refined, and the order matters because it preserves the integrity of the paint or clear coat while reducing the risk of heat buildup. The pads—foam or wool depending on your preference and the level of compound aggressiveness—should be clean and free from any old residues that could contaminate the surface during the polish. The towels must be lint-free to prevent fibers from becoming embedded in the finish, particularly when you are close to the final glaze. The idea is to create a workflow that is repeatable and controllable, not a sequence of random nags that leaves you chasing dust and residues in every corner.\n\nOnce the tools are gathered, you turn to tool preparation with the same care you gave to the fairing itself. Ensure that all equipment is in good working order and that you have ample supplies within reach before you begin. A miscalibrated speed, a worn pad, or a clogged pad can turn a routine pass into a source of heat that could melt or soften the surface. Check the polisher’s speed range to keep it in a safe zone for each stage of the process. Condition the pads so they conform to the contours of the fairing, and make sure the backing plate and power connections are secure. The preparation phase is where fatigue often hides; a small misstep at this stage can ripple through the entire job, so give yourself a moment to verify everything is ready. Since you are preparing to work with plastic or composite materials, you want to avoid harsh solvents that could degrade the surface or soften the plastic, especially near edges and mounting points. The goal here is not to rush through the setup but to construct a reliable, repeatable baseline from which you can move forward with confidence.\n\nThe environment matters almost as much as the tools themselves. Polishing needs to be done in a cool, shaded area, away from direct sun, heat, or strong drafts that could cause rapid evaporation of lubricants and drying compounds. Heat is a subtle enemy in this work, capable of magnifying swirl marks or causing uneven patches if the surface temperature climbs too high. If you are working in a garage, you may want to park with some shade or bring a portable canopy to maintain a steady working temperature. Cool air helps the compound perform consistently and prevents the pad from glazing or loading with material too quickly. Even the most carefully chosen products can fail to deliver their best results if the environment is unbalanced. You might notice that the surface finishes differently in a room with high humidity, which can be a clue to adjust your technique to maintain uniform contact and pressure. In this way, you are not just preparing the surface; you are preparing the entire working environment for success.\n\nA crucial aspect of preparation is planning the approach. The fairing can be large and contoured, which means you need to divide the work into manageable sections. Rather than attempting to polish the whole piece in one go, imagine the surface as a mosaic that you will treat piece by piece. Working 6\” by 6\” patches is a practical rule of thumb, enabling you to maintain even pressure and consistent motion. This tissue-like segmentation helps manage heat buildup and ensures that each area receives equal attention, reducing the risk of hot spots where the polish might burn or haze. As you plan the approach, keep in mind the curve lines and camera angles you aim to preserve. You want to enhance the surface without flattening the character of the fairing, so you must respect the contour and the way light plays across it. The preparation phase, therefore, becomes the map of your polishing journey, guiding you toward a uniform gloss that reveals the shape rather than erasing it.\n\nTo weave these elements into a cohesive whole, think of preparation as a single, continuous action rather than a checklist of isolated tasks. Cleanliness and visibility feed into the decision to repair or skip repairs; the choice of tools and the condition of those tools guide the technique you will use. The environmental considerations influence the pace and the pressure you apply, while the division of labor across the surface keeps you from overworking any one spot. If you encounter a stubborn scratch that demands more intensive attention, you know where to allocate your resources without compromising the rest of the panel. And if you need to search for parts or refer to a matching kit, the Honda fairings catalog can help you verify compatibility and fitment while you map your remediation plan. Honda fairings catalog\n\nAs you transition toward the wet-sanding phase that begins the actual refinement of the surface, the preparation work you have completed becomes the quiet confidence that carries you through the rest of the process. The initial cleaning loosens the grip of contaminants, the inspection defines the scope, the tools and environment are aligned, and the surface is mapped into sections that ensure uniform treatment. This cumulative preparation is what makes the later steps smoother and more predictable. It also gives you a reference point for evaluating progress in natural light once you move into the polishing phase. The goal is not to create a flawless patch of shine overnight but to develop a consistent, long-lasting finish that can withstand exposure to sun, rain, and road grime. The path you set during preparation—methodical, patient, and safeguards-driven—will determine how well the fairing stores and displays gloss over time. When you pause to wipe away a residual film after a test pass, you will appreciate how much preparation has already influenced the result, even before the final polish is applied.\n\nIn closing, the preparation phase is the unseen but essential work of polishing motorcycle fairings. It is a discipline that rewards patience, careful attention to detail, and a willingness to adjust as you learn the specifics of the surface you are treating. The steps—thorough cleaning, detailed inspection, gathering and preparing the proper tools, ensuring a calm and controlled environment, and planning the work in logical, evenly spaced sections—form a unified narrative. They bring you to the moment where the fairing’s surface is truly ready to begin the wet sanding and polishing journey with confidence. By treating preparation as a deliberate craft rather than a series of tasks to check off, you invest in a finish that not only looks spectacular in the short term but endures through miles of road and seasons of weather.\n\nExternal resources can supplement the practical steps outlined here. For readers seeking a broader perspective on polishing plastics and maintaining a glossy surface on various automotive components, a comprehensive external guide provides deeper insights into technique and material-specific considerations. Polishing plastics guide

Refining a Mirror: Wet Sanding and the Path to Flawless Motorcycle Fairings

Wet sanding is more than a technique; it is the bridge between a consumer paint job and showroom gloss. It matters because fairings are highly visible, and even tiny imperfections can stand out at the curb of a rider’s eye. The process relies on patience, steady hands, and an understanding that the surface preparation determines the final result. Before the first glide of sandpaper makes contact, the fairing must be clean from edge to seam, free of wax, oil, and any lingering residue that could melt or smear under polish. A mild soap wash followed by a careful dry with a lint-free microfiber cloth sets the stage for the delicate work to come. The goal is to create a true, uniform canvas where the light can reflect cleanly, not just a glossy layer atop scratches and oxidation. When done right, the fairing will respond to polish with a depth that feels almost tactile, as if the finish could be touched and still remain glassy. The preparation is not merely a step; it is the foundation for the entire transformation, and it guards against heat buildup, which can mar the paint in the very moment you seek brilliance.

Wet sanding is often described as the key step to remove the more stubborn flaws in a controlled, conservative way. The water acts as a faithful lubricant, carrying away abrasive particles and keeping the surface cool. This is crucial on plastic substrates common to motorcycle fairings, where heat and abrasion can quickly degrade the finish. The approach balances the need to flatten imperfections with the discipline to avoid cutting through the clear coat or color layer. In practice, this means choosing the right range of grits and applying light, even pressure with a soft foam block that floats over the contours rather than locking in with a rigid grip. The block helps maintain consistent contact across curves, corners, and recessed panels, turning what could be a patchwork of dull patches into a single, luminous field. The subtle magic of wet sanding is that it reveals what lies beneath the surface—the micro-scratches that define the true texture—and then it erases them with successive, finer steps.

The narrative of the wet sanding journey often begins with an honest assessment of the depth of the flaws. Deep scratches and heavy oxidation may require a slightly more aggressive start. In such cases, stepping down to 800-grit (used with water) can begin the process of evening out the surface. The goal is not to grind away large swaths but to remove the most evident defects without introducing new damage. From there, a controlled progression through 1500-grit resolves the coarser lines left behind by the initial pass. This transition is not dramatic; it is a careful, measured work that returns the surface to a matte uniformity. The final shaping occurs with 2000-grit or finer, which prepares the field for polishing. Each stage is performed in small sections, typically no larger than a 6 by 6 inch square, to keep heat, friction, and drying risk under control. The process invites frequent rinsing and inspection; a quick rinse reveals how evenly the surface responds to the last pass, and it helps identify any low spots that might require another pass. The discipline here is to resist rushing through grits for the sake of time. A patient, deliberate pace often yields the most dramatically even results, with fewer swirl marks and a deeper clarity when the light returns from various angles.

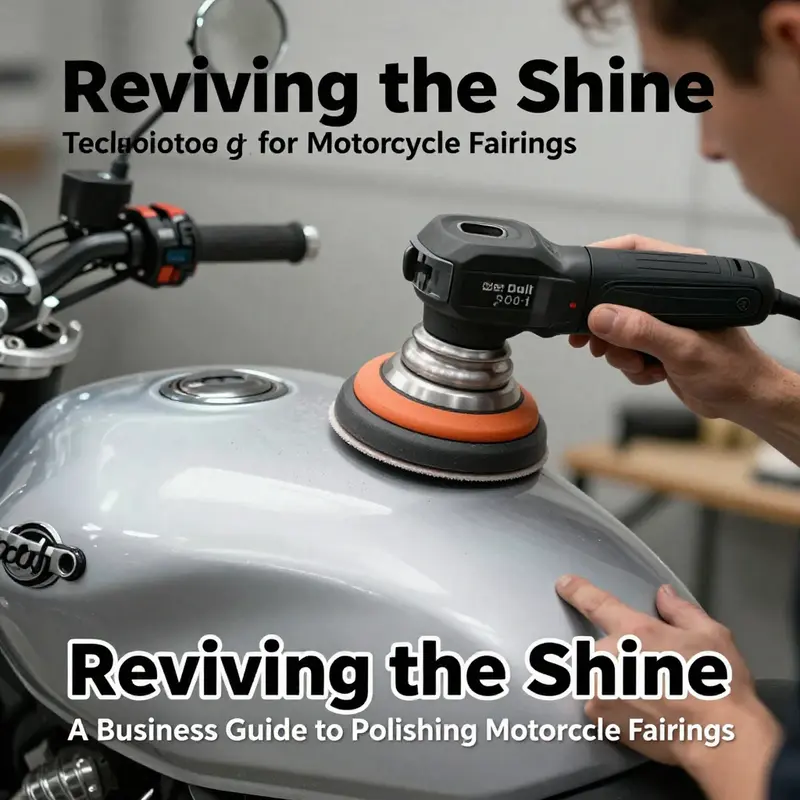

As the layers of abrasion are refined, the transition to polishing becomes the natural next chapter. Wet sanding paves the way by delivering a truly smooth base, and polishing then elevates that base to a mirror-like finish. A generous but not excessive amount of polishing compound is applied to a clean, soft pad, and the pad is mounted on a polisher set to a modest speed. The motion should be slow and steady, whether you prefer a figure-eight pattern or straight passes, with attention paid to not lingering in one spot where heat could accumulate. The real discipline is sectioning the work, ensuring that each panel breathes the same finish and that the pressure remains light and even across all surfaces. The pad should glide rather than dig; excess heat can burn through delicate layers or soften the finish in a way that undermines gloss. The finish emerges as the compound cures and is subsequently buffed away with a clean microfiber cloth, revealing a depth that looks almost liquid in bright daylight. This is where patience and technique converge—the result is a consistent, high-gloss field rather than a patchwork of micro-swirls.

In the realm of wet sanding, the details carry weight as much as the broad strokes. The water itself is a silent partner in the process, and its cleanliness matters. Impurities in the water can be ground into the surface just as much as dirt on the pad can leave micro-scratches. Keeping the surface continually damp during sanding reduces friction, but it also reduces heat spikes that might otherwise soften the plastic or clear coat. It is important to rinse the area frequently and wipe the surface clean before advancing to the next grit. The foam block is more than a tool; it is a guide that helps distribute pressure evenly and prevents the formation of low spots or hazing across convex or concave shapes. The fairing’s geometry should guide your technique, and curved panels often benefit from more frequent, gentle passes to avoid scalloping and uneven textures. The intention is to achieve a uniformly smooth plane that invites light instead of scattering it into a thousand tiny reflections that reveal the roughness beneath.

The journey does not end with polishing alone. A thorough post-polish inspection under natural light is essential to verify uniformity and to catch any areas that might require a touch more attention. If any panel looks dull or uneven, the approach is not to leap to a harsher treatment but to re-engage with the polishing step in the affected area, sometimes returning to 2000-grit and refining once more. The broader goal is not mere shininess but a robust, durable sheen that resists micro-marring from road debris and weather exposure. In this sense, wet sanding becomes part of a larger philosophy of care for plastic fairings: meticulous preparation, controlled abrasion, and deliberate polishing yield longevity and aesthetic clarity that stand up to daily riding.

For riders and builders thinking about compatibility and customization, there is value in recognizing how different fairing families respond to these methods. Some designs are more forgiving, while others demand extra care around edges and seams where resin or understructure can telegraph into the finish. If you are exploring panel swaps or decorative updates, the Honda fairings catalog is a practical reference point for understanding fit and finish across a range of models. This internal reference can help you anticipate how your chosen panels will respond to the same wet sanding and polishing sequence, revealing whether a particular shape will respond with the same depth of gloss or require minor preconditioning before the smoothing process. For readers who want a direct route to such options, the link to the Honda fairings catalog provides a useful context while you plan your project: Honda fairings catalog.

The discipline of wet sanding also carries with it a mindset about the environment in which you work. A cool, shaded space helps control the heat that can otherwise creep into the plastic during long sessions. Humidity and temperature affect how the polish and abrasive interact with the surface, so choosing a time and place that minimizes these variables is part of achieving a consistent finish. The surface should never dry out between passes; re-wetting is part of the process, not an interruption. In practical terms, this means you keep water on the surface throughout the process and frequently reapply more polish as needed, always removing the residue with a clean microfiber towel before assessing the next area. It can be tempting to chase a perfect shine with very aggressive passes, but true quality comes from measured steps, controlled heat, and a deeper understanding of how light plays across the clear coat and base color.

As you close the loop on the wet sanding journey, you appreciate what this technique is not. It is not a shortcut to a flawless finish without effort, and it is not a process that substitutes for good prep or appropriate repair work. It is, instead, a careful, methodical bridge that connects the rough to the refined, the dull to the gleam, and the ordinary panel to something that catches the eye with quiet authority. The fairing, once dull from overspray, oxidation, and micro-scratches, becomes a canvas that reflects the rider’s care. The magic lies in how small, repeated acts—clean, wet sand, rewash, polish, recheck—add up to a surface that feels as smooth as glass and shines with a depth that seems to hold a small, private glow in any light. The technique respects the plastic’s integrity, avoids overzealous abrasion, and rewards patience with a durable, showroom-quality finish that looks right on the bike when parked or in motion.

For readers seeking a broader frame of reference on painting and finishing, the wet sanding principles outlined here align with more comprehensive guides that explore the preparation, execution, and protection of painted fairings. A reliable external resource provides a broader perspective on the culture of refinishing and the practicalities of color, gloss, and enduring protection. See the widely cited guide for painting motorcycle fairings like a pro for additional context and techniques that complement the wet sanding approach described here. External resource: https://www.motorcycle.com/how-to-paint-motorcycle-fairings-like-a-pro/

Polishing Motorcycle Fairings: A Practical Guide to Clarity

Shine on a motorcycle fairing is the result of an intentional workflow. It is not accidental but the product of careful planning, patient execution, and respect for the plastic that protects the bike and connects rider to road. A fairing reflects the rider and the machine when it is clean, uniform, and free of heat haze and scratches. The polishing process described here emphasizes method over bravado and aims to restore visible clarity while preserving the integrity of the material. The goal is not a showroom mirror at the expense of material life but a dependable, durable gloss that withstands sun, rain, and ride after ride.\n\nPreparation is the door through which every successful polish must pass. Start with a thorough wash using a mild soap and water solution to remove oil, wax residues, and fine grit that could be ground into the plastic during sanding or polishing. Dry the surface with a clean microfiber towel to lift contaminants rather than smear them. Inspect the panel for damage and masking needs. Use painter’s tape to protect edges, decals, lights, and seals. A well protected perimeter reduces the risk of accidental abrasion and keeps your work predictable.\n\nTools and materials are chosen for safety and consistency. A dual action polisher with a soft backing plate helps control heat and swirl formation. A set of sandpapers—800, 1500, and 2000 grit—provides a graduated path from defect removal to surface refinement. A high quality polishing compound designed for plastics or clear coats, along with clean soft microfiber or foam pads, completes the core kit. Keep water spray, microfiber towels, and a clean workspace handy to wipe and inspect as you progress.\n\nStep one uses controlled abrasion with 800 grit in small sections. Keep the paper hydrated by wetting it and periodically rinsing the surface. Move the polisher in a slow, overlapping pattern and avoid staying in one spot too long to prevent heat buildup. Target a uniform satin texture that reveals remaining deeper defects without creating new scratches. If deep scratches persist, repeat the pass with care and check alignment between grains.\n\nStep two continues with 1500 grit. The goal is to erase the scratches left by the 800 grit and begin to approach a smooth, even surface. Maintain light pressure and consistent speed, and use overlapping strokes to avoid visible ridges. Rinse and dry between steps so you can feel the change in texture as the surface becomes progressively smoother.\n\nStep three finishes the abrasion with 2000 grit. This stage removes micro marks and creates a near glass-like feel that accepts polishing more readily. A final rinse ensures no grit remains that could dull the finish during polishing.\n\nPolishing is the next act. Apply a small amount of polishing compound to the pad and work on small sections with light to moderate pressure. Use a steady, overlapping pattern and keep the pad moving to prevent heat buildup. The aim is to bring up reflection and clarity without creating holograms or discoloration. The surface should begin to reflect light as a smooth, uniform plane rather than a collection of lifted speckles.\n\nAfter polishing, wipe the surface with a dry, lint-free microfiber towel to remove oil and residual compound. Inspect under good lighting for any dull patches or halos. If needed, perform a targeted rework on suspect areas with a light reapplication of polish and another wipe down.\n\nProtection is the final layer. Choose a wax or sealant compatible with plastics and painted finishes. Apply evenly and buff off according to the product directions, ensuring no residue remains that could cloud the gloss. A protective layer helps resist UV damage, minor chemical exposure, and subsequent road grime, while also making future cleaning easier.\n\nMaintenance keeps the finish honest. Regular light polishing sessions or schedule a light wipe-down and top-up sealant every season to maintain gloss without overheating the plastic. By approaching maintenance as a ritual rather than a chore, you preserve both aesthetics and durability for many rides to come.

The Last Polish: Final Inspection, Gentle Cleanup, and the Promise of Lasting Shine on Motorcycle Fairings

Polishing motorcycle fairings is not just about a single bright pass of the pad. It is a careful ritual that begins long before the last wipe and ends long after the shine has settled. The true test of a job well done comes in the quiet, almost clinical review that follows the final pass. This is where intention meets technique, where what you see under natural light confirms what you felt in your hands during the polishing. If the surface looks like glass and feels perfectly smooth to the palm, you have earned the right to call your work finished. If not, you know exactly where to return, what to adjust, and how to protect what you’ve just coaxed back to life. While the steps may feel like the tail end of a process, they are in fact the bridge between immediate gratification and lasting durability. The finish you’ve achieved deserves nothing less than a meticulous, deliberate final inspection and cleanup that sets the stage for protection and long-term beauty.

Begin with a calm, unhurried mindset and a willingness to examine the surface from multiple angles. Visual inspection is not just a glance; it is an active dialogue between your eyes and the bike’s curves. Stand back, step closer, and tilt the fairing ever so slightly to catch reflections. Natural light is a friend here, because it reveals the micro-scale realities that studio lighting can mask. Look for swirl marks that flirt with the surface as you move, hazy residues that cling to recessed lines, or any patch that seems a touch dull compared with its neighbors. Swirl patterns, even if faint, can be telltale signs of carelessness in the earlier stages or lingering hazing from polishing residues that weren’t fully removed. The presence of orange-peel texture is another clue that demands a closer look. A true showroom gloss should be uniformly smooth, with reflections that run cleanly across the contour of each panel rather than bouncing in a dozen tiny directions. A small flashlight held at grazing angle can help expose the micro-marring that daylight alone might overlook. The point is not to nitpick for its own sake, but to ensure the surface behaves predictably under sunlight, streetlights, and the shifting angles of daily riding.

Once the visual audit is complete, turn your attention to cleanup—the practical, hands-on step that keeps dust and remnant polish from becoming a recurrent problem. Even a perfectly polished surface can be betrayed by a careless wipe with a dirty cloth. Gather a clean, lint-free microfiber towel and a fresh sheet of air as you approach your final wipe-down. With this cloth, gently remove any remaining polish residue or fine dust. The cloth should glide without dragging grit across the surface. If you encounter streaks or a faint haze, switch to a fresh section of the cloth and re-wipe. This is not a moment to rush. The goal is to remove every trace of residue so the next stage, which sets the finish in place, has a clean canvas to work with.

In the corners of hard-to-reach areas—crevices around the mounting points, under edge lips, and along seam lines—the cleanup can require a little extra care. A soft-bristled brush helps lift dust from those nooks without requiring you to press the cloth into vulnerable areas. A gust of compressed air can also dislodge stubborn particles, but use it sparingly and from a safe distance to avoid blowing grit into vents or into gaps where it could later abrade the surface. The brush should be kept dry and free of any hardened particles that could scratch. The aim is to leave every inch of the fairing free of debris so that the final gloss you’ve coaxed out does not fight against hidden contaminants. If you notice a stubborn speck that won’t budge with brushing, do not attempt to rub it away with more pressure. A light mist of cleaning solution on a fresh microfiber can help, followed by a careful re-wipe with a dry section of cloth.

A second pass at inspection may reveal micro-scratches or slight hazing that the first sweep missed. This is not a failure of the process; it is a natural part of refining a delicate plastic surface. In those cases, address the affected patch with a targeted, conservative approach. Do not reintroduce the entire panel to heavy cutting or new sanding. Instead, you can rewarm the area gently with a hair dryer set to low heat or simply allow it to acclimate to room temperature. If needed, apply a touch more polishing compound on a fresh pad and rework the zone with slow, deliberate motions, maintaining a light touch. The goal is to blend the corrected area seamlessly with its surroundings so the patchwork is invisible to the casual observer and remains durable under normal riding conditions. Throughout this, maintain a cool environment that prevents rapid evaporation of solvents and avoids heat buildup that could warp or mar the surface.

As you near the end of the cleanup, the notion of protection must begin to crystallize in your mind. The polished appearance is delicious, but without a protective layer, it can be short-lived in the face of UV exposure, rain, road grime, and bird droppings. The final stage is not a replacement for the earlier work but a complement to it. A well-chosen wax or sealant can extend the life of your shine, making future maintenance easier and less time-consuming. The preparation for protection begins with one critical habit: ensure the surface is completely dry and free of oils left behind from your skin or from any cleaners. Oils will create an uneven bond with protective coatings, resulting in streaks or patches that dull rather than deepen the gloss. Apply your chosen protection with the same respect you gave to the polishing stage. Work in small sections, apply a thin, even layer, and allow the coating to cure for the recommended period. Then, buff with a fresh microfiber until the surface gleams in a way that feels effortless and smooth. If you decide to use wax, do so in a shade, cool area, away from direct sun. If you prefer a sealant, follow the product’s curing timeline and instructions for layering. Either option, when applied correctly, creates a sacramental edge to the finish: a barrier that resists contaminants and makes future maintenance even more straightforward.

The chain of care does not end with the application of a protective layer. A few minutes of mindful handling after finishing can preserve the moment when the fairings caught that perfect reflectivity. That means finishing the job with clean hands only, ideally wearing light gloves to avoid transferring fingerprints and oils back to the surface. It also means staying mindful of how you wipe or polish any residual areas during the final pass. The last wipe should feel almost ceremonial—soft, complete, and confident—because you are telling the surface, and yourself, that this is the finish that will endure. In practice, it is this discipline—the patience to do the inspection properly, the care to remove every speck of residue, the restraint to avoid overworking a single patch—that determines whether your work lasts through a season of highway dust, rain showers, and sun-baked days.

If you are stepping into the realm of maintenance and compatibility with aftermarket parts, a practical reminder can be valuable. When you consider replacement panels or accent pieces for a specific brand, it is helpful to compare options that honor the same curvature, mountain of vents, and panel lines you’re polishing. For readers exploring replacement or enhancement options for a broad range of models, the following catalog provides a useful reference point for various fairings: BMW fairings. This internal link offers a sense of how aftermarket panels align with a polished finish and how a cohesive look across multiple panels can contribute to a showroom-ready result.

As the chapter closes, it is useful to reflect on the rhythm of the process you have followed. Preparation, initial cleaning, measured wet sanding, thoughtful polishing, final cleanup, and careful protection—each step is a turn of the same screw. Skipping any one step risks compromising the final appearance or, more importantly, the durability of the finish. The final inspection is more than a pass or a glance; it is a deliberate act of confirmation. The cleanup is more than tidying up; it is an assurance that all future maintenance will be easier and more predictable. The protective layer, whether wax or sealant, is not a decorative flourish but a shield that preserves the shine against the daily onslaught of weather, road grit, and ultraviolet radiation. And so, with the fairings polished to a deep, glassy luster and a protective veil in place, you are ready to ride with confidence, knowing the finish has been earned through careful, repeatable work that respects the material, the geometry, and the environment in which it exists. For broader context on surface care practices and how they relate to trim work, an external resource on related surface maintenance provides additional perspective and validation of these approaches: https://www.musee-motorcycle.com/retours-et-echanges-devenir-concessionnaire-musée.

Final thoughts

Polishing motorcycle fairings is not just about aesthetics; it’s about delivering quality and care in every service your business provides. By mastering the preparation steps, wet sanding techniques, effective polishing methods, and meticulous final inspection, you enhance not only the bike’s appearance but also your reputation as a trusted service provider. Implementing these strategies will improve your service offerings, attract more customers, and ultimately lead to greater success in the motorcycle business.