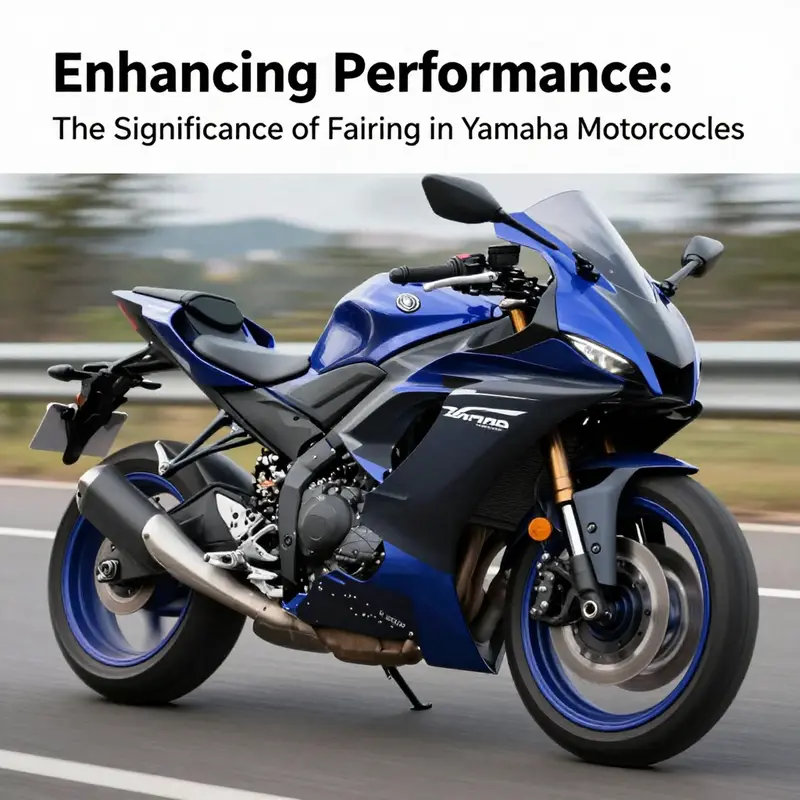

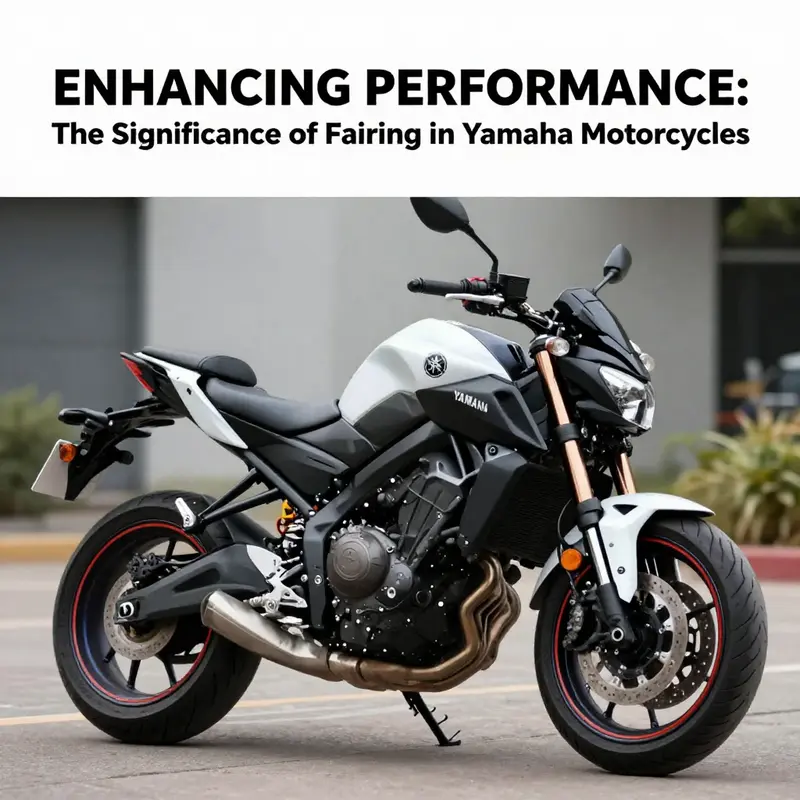

The design and functionality of motorcycle fairings play a pivotal role in providing Yamaha riders with enhanced performance and aesthetic appeal. Yamaha motorcycle fairings, designed to protect internal components and improve aerodynamics, are integral to both sport and touring models. Through this exploration, we will delve into the unique design features and functionalities of Yamaha fairings, the material compositions that make them resilient yet lightweight, and the marked performance benefits they offer. We will also look at the current market availability of Yamaha fairings and the various customization options to suit individual rider preferences, addressing the needs of business owners in the motorcycle accessory market. By the end of this article, the reader will have a comprehensive understanding of Yamaha motorcycle fairings and their application in business endeavors.

null

null

Under the Skin: Materials, Craft, and Construction of Yamaha Fairings for Performance and Style

The fairing is more than a shield for the engine and a splash guard for the rider. On Yamaha motorcycles, it is the skin that shapes performance, dictates sound, and communicates the machine’s intent to the rider and onlookers alike. The material choices and the way those materials are put together determine how a bike handles at speed, how it breathes through the air, and how it keeps a rider comfortable and protected when the road gets rough. In this sense, the fairing is a study in balancing competing demands: lightweight strength, aerodynamic finesse, and long-term durability, all while preserving the machine’s identity. The journey from raw polymer or carbon fiber to a finished, precise-fit fairing begins long before the first part is bolted onto the frame. It starts with the fundamental decision about material chemistry and ends with the meticulous articulation of joints, seals, and mounting points that maintain integrity under real-world riding loads. In Yamaha’s ecosystem, the standard approach leans on high-quality engineering polymers, with occasional forays into premium composites for riders chasing weight savings and stiffness gains. The standard fairing kits widely used across models are typically molded from impact-resistant plastics that strike a careful balance between rigidity and resilience. These engineering polymers, often a class that includes ABS or ABS-like blends, are chosen for their toughness, their ability to absorb energy in a crash, and their resilience against outdoor exposure. The result is a shell that can stand up to rock debris and weather while keeping the rider’s cabin reasonably quiet at highway speeds. The plastic’s light weight translates into tangible benefits: the bike responds more readily to steering input, throttle response becomes more forgiving, and fuel efficiency benefits from reduced inertia as the bodywork becomes easier to move through the air. The certifications that are frequently cited in these products—CE marks, for example—signal that the fairing has been tested for impact resistance and structural integrity to a standard that is meaningful across European markets. When riders seek reassurance about the long-term performance of a fairing, that CE label is not merely bureaucratic theater; it is a practical promise that the part can withstand the kinds of incidental impacts it might encounter on public roads and in light off-road use. Yet even within the broad world of plastic fairings, there is a spectrum of design philosophy. Some riders are drawn to the cost and practicality of conventional plastics that are easy to replace and repair; others pursue the cleaner, more aggressive lines that carbon fiber can deliver. Carbon fiber, with its renowned strength-to-weight ratio, appears most often on higher-end applications and sport-oriented configurations. A carbon fiber lower front fairing, for example, demonstrates how the same silhouette can be realized with an entirely different material system. The allure is not merely aesthetic—though the visual weave and high-gloss finish deliver a premium look—but also functional. Carbon fiber layers reduce mass at critical points and increase stiffness, which helps maintain shape under high dynamic loads. But there is a price to pay. Carbon fiber parts demand more precise manufacturing controls, specialized layups, and longer production cycles, all of which translate into higher costs. This reality pushes carbon fiber toward models that demand maximum performance and present a longer-term ownership calculus: the weight saved is meaningful in cornering and stability, but the sticker price is higher and the repair ecosystem is narrower. For most Yamaha riders, the default remains high-quality plastics, engineered for durability and modularity. The manufacturing process for these plastic fairings relies on injection molding or thermoforming, followed by precise trimming and assembly. The process ensures consistent wall thickness, smooth interior surfaces, and repeatable alignment of mounting points. Inside the shell, engineers design channels and recesses that manage heat from the engine and protect sensitive components. The aesthetic aspect—the way a fairing looks when the rider first catches sight of it in a showroom or after a wash on a weekend ride—depends on how these channels are integrated into the outer surfaces. Subtle curves, angular facets, and ventilation intakes must all be sculpted so that they not only look right but also behave predictably at speed. This is where air flow meets material science. The surface finish matters as much as the core material. A well-chosen surface texture reduces drag by guiding the boundary layer in a controlled way, while a smooth, polished exterior may offer marginal improvements in top speed at the expense of impact resistance in a crash. In practice, engineers often rely on a combination of surface treatments, from textured sections that manage airflow to glossy coats that emphasize the bike’s lines. The construction goes beyond the skin. Behind the outer shell lies a network of internal braces, mounting bosses, and fasteners that hold the fairing in place as the bike accelerates, decelerates, and encounters the terrain. These internal structures must be robust enough to withstand torsional forces from cornering and vibrations from the engine, yet not so heavy as to erase the weight advantages achieved through the skin material. The interfaces between fairing panels, the windscreen, and the rest of the bodywork demand careful tolerances. Poor alignment can lead to rattles, gaps, and increased drag, especially at high speed. A well-executed assembly plan considers not only fitment but serviceability. The rider should be able to access bulbs, fuses, or the radiator with reasonable ease. This is why many fairing designs include modular components or removable segments that simplify maintenance and upgrades. From a design perspective, the fairing is an integration exercise. It must accommodate electrical harnesses, headlights, and signaling devices with clean, deliberate cutouts. The geometry has to account for thick lips around the edges that act as shields against impact while still allowing the fairing to flex in the event of a light fall. The result is an artifact that looks seamless and integrated but must actually tolerate stress, heat, and moisture. This integration is reinforced by the availability of OEM-compatible parts and, in many markets, by aftermarket modular sets. For riders who want to tailor their machine to a particular aesthetic or performance target, modular design means they can swap sections without replacing the entire kit. This approach reduces maintenance time and encourages customization without compromising safety or fit. When we examine sourcing and compatibility, the landscape is shaped by marketplaces that promise OEM compatibility and a broad range of options. The notion of compatibility is not merely about matching a hole pattern; it is about ensuring the parts align with the bike’s frame geometry, mounting points, and electrical routing. Reputable sources stress the importance of checking fitment against the exact model year and regional specifications. The emphasis on compatibility becomes even more important for riders who rely on the fairing to protect critical components such as the engine, lights, and cooling system. It is precisely this attention to fit that makes a seemingly simple shell a critical performance component rather than a mere cosmetic add-on. For those who pursue a blend of style and performance, the conversation often turns to the aesthetic and mechanical synergy achieved by pairing a carbon fiber upper with plastic lower sections, or by selecting a complete set that preserves the bike’s color identity and aerodynamics. The visual continuum—from the gloss of a full plastic shell to the matte weave of carbon fiber—reflects an intention to balance lightness with rigidity and to present a coherent silhouette to the wind. A rider who contemplates this choice is weighing the benefits of stiffness against the realities of cost, maintenance, and repair. There is also a practical dimension to the decision: aftermarket and OEM-compatible options enable riders to refresh or upgrade their machines without sacrificing safety or performance. The availability of complete accessory sets means a rider can preserve the bike’s original design language while extracting improvements in aerodynamics or protection. In this broader ecosystem, the fairing becomes a facet of the motorcycle’s identity, signaling not only speed and agility but also care and preference for precision engineering. For readers who want to see the range of Yamaha-focused fairings and related components, a convenient entry point exists in the Yamaha fairings category, which collates many of the options manufacturers and retailers provide. This centralized resource helps ensure that fitment and styling align with the specific Yamaha model in question, reinforcing the idea that the fairing is a deliberate, integral choice rather than a casual add-on. Yamaha fairings offers a curated view of the possibilities and serves as a practical starting point for riders exploring material options, installation nuances, and compatibility checks. While the category highlights the breadth of choices, the underlying message remains consistent: the material and the construction method chosen for Yamaha fairings shape the riding experience as much as the engine horsepower. Looking ahead, the trajectory of fairing technology is likely to tilt further toward advanced composites and thermoplastic composites that combine impact resistance with easier manufacturing and repair processes. Innovations in resin systems, lightweight core materials, and rapid production techniques could enable more riders to access high-performance aesthetic packages without prohibitive cost. The goal is not simply to shave grams but to achieve a coherent balance where every panel contributes to stability, protection, and comfort. As with any performance-oriented upgrade, the decisions about materials and construction must align with the rider’s priorities—whether that is corner speed, highway efficiency, or the simple satisfaction of owning a machine that feels precisely shaped to the rider’s intent. In the end, the Yamaha fairing is a marriage of form and function, where choices in polymer chemistry, composite layup, and panel architecture converge to deliver an experience that goes beyond the sum of its parts. External considerations—such as weather exposure, impact scenarios, and maintenance routines—shape the practical reality of ownership. The materials chosen determine how the fairing ages, how well it resists UV degradation, and how easily it can be repaired after a bash against a barrier or a mishap in crowded streets. The method of construction—whether injection-molded plastic or layered carbon fiber—determines the panel’s stiffness, its resistance to flexing, and its response to heat generated by an air-cooled or liquid-cooled engine. These are not theoretical concerns; they translate into real-world outcomes—confidence at speed, predictable handling in gusty conditions, and the knowledge that the bike remains a reliable partner through miles of open road. For those who study and ride Yamaha motorcycles, the fairing emerges as a core element of the machine’s character. It is a tangible manifestation of engineering discipline, material science, and the rider’s personal taste. It is the first thing that meets the wind and the last thing that one might replace when chasing a new look or improved performance. When approached with a thoughtful understanding of material properties and construction techniques, fairings become more than a shell—they become a design philosophy about how speed, balance, and aesthetics arrive at the rider together. External resource: https://www.alibaba.com/product-detail/Yamaha-FZ16-Full-Fairing-Kit-plastic1600547298355.html?spm=a2700.1.usemainsearchbar.1.1f7a5d9bPnFjXm

Aero-Driven Edge: How Yamaha Fairings Shape Speed, Handling, and Durability

When riders talk about the speed and feel of a sport bike, they often mention more than the engine and tires. They discuss the skin that cloaks the machine—the fairing. For Yamaha’s sport models, the fairing is more than a cosmetic shell. It is a carefully engineered envelope that subtly but decisively influences riding dynamics from street to track. A well-designed fairing reduces wind resistance, channels air to cooling systems, and sculpts the silhouette that becomes a rider’s identity in motion. The right fairing blends form and function, turning a bike into a responsive instrument whose character is defined by the air that flows around it.

Material choices carve the balance between weight and strength. Modern Yamaha fairings are built from carbon fiber, fiberglass, or high-grade ABS plastics. Carbon fiber offers exceptional stiffness and a dramatic weight reduction; fiberglass provides robustness at a reasonable cost; ABS delivers versatility and impact resistance for everyday riding. On race-oriented variants, weight savings matter most. A lighter shell translates into a sharper power-to-weight ratio, quicker acceleration, and more immediate handling. The bike feels lighter in the hands, even when the rider is tucked into a lean angle and the wind hisses past the fairing.

But lightness alone does not win on the track. The aerodynamic form of the fairing shapes airflow around the motorcycle, reducing drag and smoothing turbulence. A well contoured shell lets the wind slip cleanly along the bike’s lines, promoting higher top speeds with less engine effort. The contours also stabilize the front end in corners and during heavy braking by minimizing lift. Cooling is enhanced too: air is guided toward the radiator and engine compartments in a controlled stream, supporting sustained performance under intense, hot-lap conditions. In short, the fairing is an active participant in the bike’s thermal and aerodynamic balance, not merely a passive cover.

Protection forms the quieter but essential duty of the fairing. Behind the skin lie the engine, radiator, and wiring harnesses, which fairings shield from road debris, weather, and the occasional slide. In competitive riding, the difference between a scuffed panel and a damaged component can mark the end of a session. A sturdy shell absorbs minor impacts, keeping critical systems intact and reducing downtime between runs. Performance-focused fairings are designed with this protective role in mind, offering reinforced attachment points and resilient edges that stand up to the stresses of high-speed riding and repeated pit-stop checks.

The link between fairing design and engine technology is a story of true cooperation. On platforms that feature advanced engine layouts, bodywork is developed in tandem with the engine to optimize motion, balance, and thermal management. The fairing does not merely surround the engine; it directs air to match cooling demands and exhaust dynamics. This collaborative approach yields a machine where every millimeter of shaping supports predictable throttle response, stable cornering, and consistent performance lap after lap. When the chassis and the powerplant move as a single system, the aerodynamic shell becomes a partner in the machine’s precision driving.

Beyond raw performance, the fairing becomes a canvas for personal expression and functional customization. Modern kits enable riders to apply graphics and color schemes without altering core structural panels. This allows branding, team colors, or personal motifs without compromising performance integrity. The modular nature of many Yamaha fairings adds another layer of practicality: riders can swap sections to adjust aerodynamics or aesthetics, or to repair a damaged piece without replacing the entire shell. The outcome is a motorcycle that can be tuned visually and aerodynamically to suit track conditions or street riding preferences.

From a maintenance perspective, modular design matters in real-world use. Quick-release fasteners and standardized mounting points mean a fairing swap or repair can be completed in a fraction of the time. This saves minutes during a race weekend and hours over the life of the bike. The spread of aftermarket options means riders can tailor the balance of weight, drag, and protection by choosing different materials and thicknesses for specific panels. Even on high-end consumer bikes, the sense of a purpose-built, track-informed shell remains tangible in how well the panels fit and feel when the rider is perched in the saddle.

When evaluating aftermarket fairings, compatibility and safety matter. Some producers emphasize safety by including certifications that signal compliance with recognized standards. This matters because a shell that fails under wind pressure or heat can create new points of weakness or malfunctions on the road. At the intersection of sport performance and reliability, certification provides reassurance that the shell will perform as intended under real-world stresses and high-speed conditions. This careful attention to standards helps ensure that the investment in performance does not come at the expense of safety or longevity.

A practical note on marketplace options underscores the reality of a global supply ecosystem. For Yamaha riders seeking a blend of weight savings, aerodynamic fidelity, and value, the market offers a range of OEM-inspired, aftermarket, and hybrid solutions. Some sellers offer modular sets designed to fit a broad range of Yamaha platforms, prioritizing weight savings and optimized airflow. The best choice depends on the rider’s goals—street comfort, track days, or more aggressive racing—and on the willingness to invest in a shell that can withstand the rigors of intended use. This is where fitment data, mounting precision, and a clear warranty become deciding factors.

Riders should also be mindful of compatibility and serviceability when ordering. A fairing designed for one platform will not always align with another’s mounting points, clearance, or radiator layout. This is where the recommended path through official authorized channels or reputable cross-border platforms matters. A well-vetted kit will come with precise fitment data, protective coatings, and installation support. The right fairing improves not only aerodynamics but also maintenance access; thoughtful shaping preserves or enhances access to radiator caps, hoses, and sensors, reducing time spent during servicing and calibration.

For industrial and applied contexts, there is a parallel benefit. Instrumented testing, wind tunnel trials, and other research projects can use lightweight yet robust shelling to mirror real-world airflow conditions without adding unnecessary mass. In testing environments where durability and repeatable geometry matter, fairings function as controlled boundary surfaces. They help engineers study pressure distributions, heat transfer, and drag coefficients with higher fidelity. In this sense, Yamaha fairings translate racing engineering into practical lessons for product development, automotive wind research, and even aerospace-adjacent applications that require compact, robust aerodynamic enclosures. The outcome is a set of design cues that inform both street and lab work.

In sum, the value of Yamaha fairings extends beyond their visual appeal. They embody a carefully tuned blend of weight, aerodynamics, protection, and adaptability that aligns with the physics of speed and the realities of riding. They enable riders to push the envelope with greater confidence, whether crossing a finish line or navigating a city boulevard. The equipment becomes not just armor but a partner in performance, shaping the bike’s throttle response, cornering balance, and the rhythm of wind at speed. As track performance analyses and consumer feedback converge, a well-chosen fairing elevates heat management efficiency, reduces rider fatigue by smoothing the air around the body, and enhances ride predictability across a spectrum of speeds and conditions.

For those curious to explore further, a catalog of Yamaha fairings offers a spectrum of choices that cater to different goals. To see the breadth of Yamaha fairings available, explore Yamaha fairings at UltimateMotorX.

External resource: https://www.motorcyclefairings.com/yamaha-r6-fairings-performance/

Shields in the Marketplace: Availability, Materials, and the Craft of Yamaha Fairings

A fairing on a Yamaha motorcycle is more than a cosmetic shell. It is a carefully engineered interface between rider, machine, and the air that wraps around the bike at speed. In this light, the fairing acts as a guardian for the engine bay, a sculpted conduit for airflow, and a mood-setter for the bike’s presence on the road or the track. When riders step back to assess performance and style, the fairing’s influence is immediately tangible: the silhouette is sharpened, the wind is controlled, and the sense of direction becomes crisper as the bike carves through air rather than battling it. The effect extends beyond aesthetics. Aerodynamics play a central role in handling at higher speeds and in how the bike behaves in crosswinds, while a well-designed fairing helps manage heat by guiding airflow to critical components. The most successful fairings emerge from a balance between protection, efficiency, and the rider’s comfort, taking into account how air moves around the bike and how that movement translates into stability and energy efficiency over long rides or aggressive laps on a circuit.

Materials are the foundation of that balance. Modern fairings pivot between high-strength plastics and advanced composites. ABS plastic is common for its impact resistance, flexibility, and capacity to hold a smooth, glossy finish with reasonable cost. Carbon fiber, celebrated for its exceptional stiffness-to-weight ratio and its striking visual appeal, comes with a premium price tag and requires careful handling during installation to preserve its pristine weave and gloss. The choice between these materials is a negotiation: ABS can absorb impacts and be forgiving in imperfect installations, while carbon fiber shines in weight savings and rigidity—qualities riders feel in the precision of steering, the consistency of straight-line stability, and the bike’s response to quick changes in direction. Beyond material choice, the manufacturing approach matters. Thick, rigid shells reduce flutter at speed, while lighter, well-supported panels reduce unsprung weight and improve the bike’s ability to respond to the rider’s inputs. In all cases, the goal is to deliver a shell that can sustain UV exposure, weathering, and the occasional abrasion while preserving form and the finish that makes a bike recognizable from afar.

As the market for aftermarket and OEM-inspired fairings has evolved, modular designs have gained prominence. Rather than one monolithic piece, many kits offer replaceable front panels, side sections, and lower cowls that can be swapped to reflect racing liveries, personal color schemes, or simply to replace a damaged section without replacing an entire shell. The modular approach lowers downtime and simplifies repairs, meaning a rider can return to the road or track more quickly. It also enables a staged approach to customization: a rider might start with a full front fairing swap for improved aerodynamics and then expand to side panels or a tail section as needs and tastes evolve. This flexibility is especially appealing to owners who use a bike across different environments—daily commuting, weekend laps, or exhibition displays—because the same bike can visually transform while preserving the core geometry that keeps fitment predictable and straightforward.

Yet with a broad market comes the responsibility of choosing wisely. Compatibility is central to a successful upgrade. Fairings designed to fit a particular generation or model family often rely on standardized mounting points and common interfaces, but there are notable exceptions where slight variations can affect fit, gaps, and aerodynamics. Riders should verify model compatibility with the seller, review fitment guides, and, when possible, consult installation resources or professionals who understand both the bike’s anatomy and the fairing’s engineering. The market reflects a spectrum of offerings—from complete front-and-side replacement packages that promise a cohesive look and improved airflow to modular components that let a rider pick and choose which panels to replace. The best options deliver a cohesive surface that sits flush with the bike’s lines, minimizes buffeting, and preserves the rider’s line of sight and instrument visibility. They also acknowledge practical realities, such as how the fairing affects access to maintenance points, routing for cables and wires, and the ease of cleaning and care in various climates.

The online marketplace ecosystem has made Yamaha fairings more accessible to a broader audience. Large-scale platforms host a range of full-fairing kits and component panels that span materials, finishes, and price points. For riders seeking to modernize the look of an older machine or to tailor a current ride to a personal aesthetic, there is a practical path between preserving original mounting geometry and adopting contemporary design cues. The procurement process benefits from clear product specifications, real-world fit notes, and user feedback that illuminates how a panel aligns with the bike’s contours in real-world conditions. In the end, the choice rests on a combination of how the bike will be used, the rider’s tolerance for maintenance effort, and the importance placed on weight savings and visual impact. When a rider balances those priorities, the fairing becomes not just a protective cover but a flexible tuning element that complements the chassis, the suspension, and the rider’s stance.

Within this marketplace, a curated sense of direction helps. A rider who values a blend of performance and personality can look for full front-and-side kits that promise a unified geometry and a clean wind profile, while still allowing the freedom to mix finishes and colors. For riders who prize weight savings and a race-grade look, carbon-fiber options provide a visible expression of how engineering choices translate into feel and response at speed. Those who are more concerned with durability and cost-effectiveness might lean toward high-strength plastics with reinforced edges and pre-scored mounting zones that offer a forgiving installation process. Across all preferences, the core considerations remain constant: how the fairing interfaces with the bike’s frame and fasteners, how it channels air to reduce drag and buffeting, and how it protects what lies beneath—from the engine bay to cooling ducts and fast-moving components.

To guide this exploration, it helps to think of the fairing as a shape-shaping tool that exists at the intersection of aerodynamics, aesthetics, and serviceability. A well-chosen fairing respects the bike’s natural silhouette while steering airflow into a pattern that stabilizes the bike at speed, reduces fatigue on long rides, and gives the rider a confident sense of control. On the aesthetic side, the fairing communicates a rider’s taste—whether toward a classic, restrained look, or toward a bold, high-contrast, track-inspired stance. On the practical side, the right panels make maintenance more straightforward by keeping access points accessible and by reducing the risk of damage to sensitive components during of riding and maintenance sessions. The result is a motorcycle that not only looks the part but also behaves with greater composure under a range of wind and ride conditions.

For riders who want to explore options with a view to both form and function, a practical step is to examine a comprehensive catalog of Yamaha fairings that aggregates styles, materials, and mounting schemes. This approach helps ensure that the chosen fairings align with the bike’s geometry and the rider’s goals, whether those goals center on improved top-end stability, a more aggressive stance, or a restoration project that seeks to refresh the bike’s appearance without compromising compatibility. As with any significant modification, taking the time to understand the mounting framework, the need for any reinforcement, and the potential impact on service intervals pays dividends in long-term satisfaction. An informed choice translates into a smoother installation process and a more harmonious integration with the bike’s existing components.

For a curated overview of options, explore the Yamaha fairings catalog. It provides a sense of what modern aftermarket and OEM-inspired panels offer in terms of materials, finishes, and fitment. While no single kit guarantees universal compatibility, many offerings are designed to align with broad family traits and mounting conventions, making it easier to choose a cohesive set that respects the bike’s lines and enhances its air-handling characteristics. As riders navigate the market, the key is to balance the aspiration for a striking appearance with the practical realities of weight, protection, and maintenance ease. In doing so, the fairing becomes a reliable partner in the rider’s ongoing relationship with their machine, ensuring that the love of speed is matched by the discipline of thoughtful, informed upgrading.

External reference: https://www.amazon.com/dp/B0CQ1XZV4K

Beyond Aesthetics and Aerodynamics: The Craft of Customizing and Fitting Yamaha Fairings

The fairing on a Yamaha motorcycle is far more than a glossy shell. It is the interface between rider, machine, and road—a carefully contoured surface designed to tame air, protect vital components, and create a visual language that speaks the rider’s intent. When riders begin to seek more from their machine, they often turn first to the fairing as a lever for performance and personality. The case for customization rests on a simple truth: each bike’s bodywork is a precise balance of geometry, weight, and airflow. Alter one element, and you shift how the bike breathes, settles into cornering, and even how confidently a rider sits at highway speed. This is where the craft of Yamaha fairing customization shows its depth. It is not merely about slapping on a new look; it is about choosing a pathway that respects the original design while expanding the bike’s expressiveness and practical capabilities.

Riders pursue fairing upgrades for a spectrum of reasons, from the aesthetics of sharper lines and a cleaner silhouette to the measurable gains in aerodynamics and rider comfort. A well-chosen fairing kit can transform how wind interacts with a rider’s torso, shoulders, and helmet, reducing fatigue on longer rides and smoothing the buffeting that can jar the spine at speed. At the same time, these kits offer an opportunity to align the machine with a rider’s personal identity—whether that means a stealthy, understated look or a bold, race-inspired stance. The fascination with fairing customization grows because it sits at the intersection of form and function. The bodywork is not only an expression of style; it is a functional component engineered to complement the bike’s frame, engine, and chassis geometry. It studies how airflows separate from the surface, how pressure fields coalesce around the rider, and how those forces influence stability at speed. The outcome is a more cohesive riding experience where aesthetics reinforce performance rather than merely decorate it.

What makes Yamaha fairing customization particularly compelling is the breadth of options that are purpose-built to match the brand’s bodywork language. Kits are designed to align with the unique curves, panel alignments, and mounting points characteristic of Yamaha’s sport and street models. The design process behind these kits reflects a blend of precise engineering and creative sculpture. Engineers often begin with advanced CAD modeling to capture every contour, then test the models in wind tunnels or high-fidelity computational simulations. The goal is not simply to lower a number on a drag coefficient but to harmonize the fairing’s shape with the bike’s profile, the rider’s posture, and the suspension’s travel. The result is an aerodynamic package that smooths the flow around the rider and engine, contributing to greater high-speed stability and improved cooling efficiency by guiding air toward radiators and vents in a controlled manner.

Material choice sits at the center of this balancing act. Manufacturers tend to favor high-strength plastics, such as ABS, for cost-effective durability and impact resistance, especially for full replacement sets. Carbon fiber is often the alternative when weight reduction and stiffness are prioritized, though its higher cost means it is typically reserved for lighter, performance-oriented builds or track-focused projects. The material decision influences not just weight but also how the fairing behaves under wind pressure, how it handles UV exposure, and how it ages over time. A well-made ABS kit with robust surface finishes can offer long life with reasonable replacement costs, while carbon fiber injects an unmistakable lightness and rigidity that can alter the bike’s perceived balance. In both cases, the objective remains the same: to preserve the integrity of the mounting structure and ensure that the surface provides predictable feedback to the rider, rather than introducing instability or misalignment under load. The interplay of materials and geometry also speaks to durability and weather resistance, ensuring that the fairing remains serviceable in varying climates and road conditions.

Compatibility is perhaps the most crucial thread in the tale of Yamaha fairing upgrades. Yamaha models share a family resemblance in their basic mounting geometry, but each model line exhibits its own subtle taper, panel gaps, and connector locations. The right kit must map precisely to the bike’s model year and variant, not just to a general “Yamaha” shape. This is why many riders consult official parts catalogs or trusted aftermarket suppliers who provide verified fitment information. The emphasis is on a seamless, plug-and-play experience that minimizes guesswork during installation. A proper fit reduces the risk of misalignment, rattling, or contact between panels and moving parts, which could compromise aerodynamics or even create safety concerns. It is here that the philosophy of compatibility—model-specific design, exact panel counts, and secure mounting points—meets the craftsmanship of customization. The most successful upgrades feel as if they emerged from the factory, with consistent gaps, precise alignments, and integrated windshields or venting that contribute to a coherent aerodynamic narrative.

Integrated design also touches on the modularity some riders crave. Modern fairing kits often offer modularity through replaceable sections or a combination of full-coverage panels and smaller inserts. This approach lets riders tailor their bike for different uses—subtle street appearances for daily riding, or a more aggressive, track-flavored silhouette for weekend rotations—without committing to a single, rigid configuration. The modular concept supports faster service timelines, as panels can be swapped with minimal disruption to the rest of the bike’s bodywork or its electrical harnesses. Yet modularity also demands attention to detail during assembly. The interfaces between panels must be consistently tight, with gaskets and fasteners positioned to preserve aerodynamic continuity and weather sealing. Any misalignment can disrupt airflow, introduce noise, or invite water intrusion, which erodes both performance and comfort. The best modular systems balance ease of swap with a high degree of precision, ensuring that each panel remains a native extension of the bike’s original geometry when fastened into place.

The rider’s position and experience are inseparable from the fairing’s character. A fairing that looks striking on the stand must also contribute to a stable, comfortable riding posture. Wind pressure acts on the torso, shoulders, and helmet, and the fairing’s shape helps guide that pressure in ways that minimize fatigue and maintain control. Careful attention to the cockpit area—how the windshield interfaces with the rider’s line of sight, and how the fairing’s lower edges protect the hands and knees from gusts—can transform a bike from a mere machine into an instrument of controlled expression. This is not only a matter of speed but of sustained confidence. When a rider feels the bike responds predictably at speed and in gusty crosswinds, the relationship with the machine deepens. The rider is less likely to fight the bike and more likely to ride with intention, carving smooth arcs through corners rather than wrestling at the handlebars.

Sourcing decisions are equally important for a well-balanced upgrade. The market hosts a spectrum of options, from manufacturer-backed replacement sets to aftermarket kits that promise aggressive styling and reduced drag. Prospective buyers are urged to verify compatibility and read user feedback to gauge fit quality and long-term durability. Safety and quality standards can be signaled by certifications or by the credibility of the supplier. For those who want to explore the landscape online, a practical route is to visit a dedicated catalog that aggregates Yamaha fairing options and presents model-specific guidance. This ensures that the chosen kit not only looks right but also aligns with the bike’s intended performance envelope. Within this landscape, a well-curated catalog can illuminate the differences between full-body replacements and partial enhancements, and explain how each choice affects weight distribution, center of gravity, and the bike’s overall balance. An informed purchase becomes less about chasing the newest trend and more about preserving the bike’s integrity while expanding its capability to perform and to express.

In the pursuit of customization that resonates with the rider’s ambitions, it helps to anchor decisions in the broader ecosystem of representation and function. The aesthetic goal—sharp lines, clean gaps, and a silhouette that reads clearly from a distance—must harmonize with the engineering goal: to reduce drag and buffeting, to protect the engine and rider from debris, and to sustain reliable operation under a variety of weather and road conditions. When those aims align, the bike achieves a coherent presence that speaks to both the eye and the hand that steers it. And because the fairing is the largest, most visible body component, it becomes a veritable ambassador of a rider’s philosophy on speed, protection, and personal style. A well-executed upgrade tells a story about intention: a rider who respects the machine’s design language while shaping it to meet individual needs, a bike that remains faithful to its Yamaha lineage even as it embraces a personal frontier of performance and identity.

For readers who want to explore the range of Yamaha fairings and to see how the community curates fitment information, a comprehensive catalog remains a valuable starting point. The catalog helps ensure that the chosen kit aligns with the bike’s geometry and mounting points, supporting a seamless installation that preserves performance, safety, and aesthetics. As a final note, many riders look to trusted resources and official materials to confirm that a chosen kit is appropriate for their model and year. This careful vetting reduces the risk of misfit and reinforces the overall goal: a fairing that integrates with the bike as a single, coherent system.

Internal link for deeper exploration of model-specific offerings and to view the broader Yamaha fairings category can be found here: Yamaha fairings category. This resource helps riders assess compatibility, view different styling options, and compare the relative merits of various designs in the context of their specific Yamaha model and riding goals.

External reference for a practical example of a batwing-style fairing and its impact on ride dynamics can be found here: https://www.customcraftride.com/products/batwing-fairing-for-yamaha-xvs-1300. This resource offers a concrete illustration of how a particular fairing concept translates into fit, aerodynamics, and rider comfort, underscoring the broader themes of customization and compatibility discussed in this chapter.

Final thoughts

In summary, Yamaha motorcycle fairings are not merely aesthetic enhancements but integral components that enhance performance, durability, and customization. Their advanced design, material choices, and ability to personalize have made them crucial for motorcycle enthusiasts and business owners alike. Understanding the specifics of Yamaha fairings equips business owners with the knowledge to cater to an evolving market, ensuring that they offer products that meet the highest standards of performance and style. As the demand for high-performance accessories continues to grow, investing in quality fairing options can lead to greater customer satisfaction and expanded market reach.