Motorcycle enthusiasts understand the inherent risks that come with riding, especially in urban and off-road settings. One crucial accessory that every motorcycle owner should consider is the fairing guard. Designed specifically to protect the motorcycle’s fairing—the vital bodywork that shields critical components—these guards serve as a first line of defense against impacts, scrapes, and road debris. The relevance of fairing guards extends beyond mere aesthetics; they can significantly influence safety, repair costs, and overall riding experience. Each chapter of this article delves into distinct aspects of fairing guards, including their protective role, material composition, key features, market trends, and installation compatibility, providing comprehensive insights for business owners in the motorcycle industry.

Guardians of the Frame: How Fairing Guards Shield Motorcycle Bodywork and Boost Rider Confidence

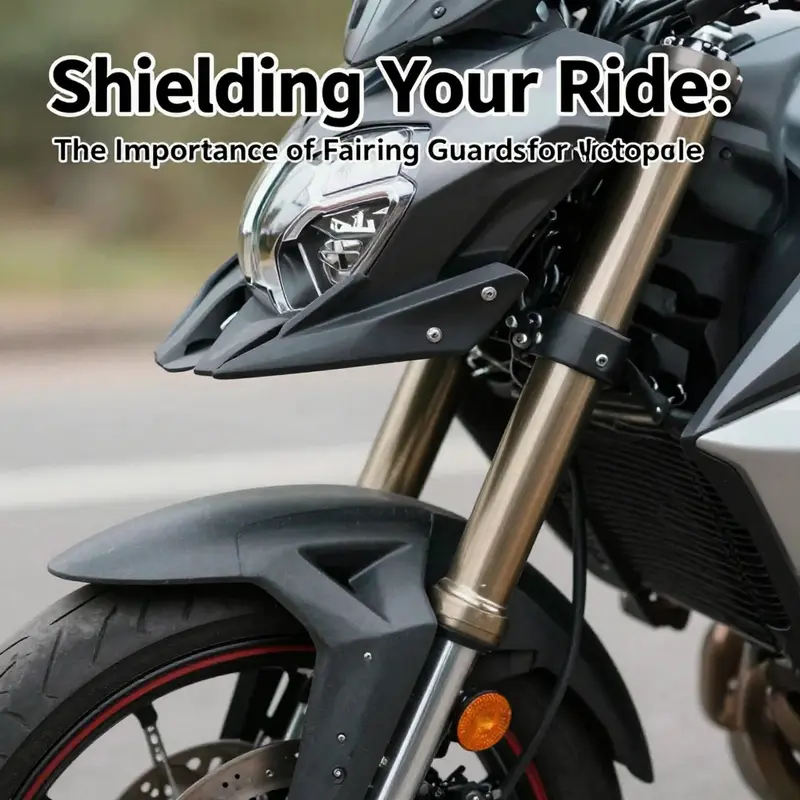

The surface-level appeal of a motorcycle is tempting to call aesthetic, but the true value of a bike’s bodywork lies in its ability to withstand the realities of riding. Fairing guards sit at the intersection of protection, performance, and practicality. They are purpose-built barriers that shield the most vulnerable parts of the bike—the front and lower edges of the fairings—from the kinds of misadventures that urban traffic, gravel, and misjudged lines on a curve tend to deliver. In the moment of a low-speed fall or a glancing scrape with a curb, these guards act as sacrificial armor, absorbing and redistributing energy that would otherwise crack, bend, or gouge the plastic or composite skin that defines a motorcycle’s silhouette and aerodynamics. The result is not only a preserved appearance but a preserved integrity of the bike’s aerodynamics, mounting points, and, crucially, its structural and mechanical alignment.

Within the design space of fairing guards, two ideas dominate: durability and gentleness of impact. Durable guards are crafted from high-impact plastics, polycarbonates, or reinforced composites that resist abrasion and resist shattering when subjected to grit and impact. Yet the best solutions maintain a light touch; they deliver enough stiffness to deflect debris and cushion impacts without introducing excessive weight or altering the bike’s balance and handling. Engineers in this field aim for a careful equilibrium: a protective shell that tunes energy dissipation while remaining unobtrusive to the rider’s experience and the bike’s overall performance envelope. The result is a component that does not merely look rugged but behaves like a dynamic part of the motorcycle’s protective system, working in concert with other safeguards rather than as a standalone add-on.

For riders who spend time on rough surfaces, or who frequent twisty tracks and the unpredictable reality of city streets, guards become the first line of defense for the fairing itself and the junctions where panels meet the frame. The impact path of a fall often concentrates around the front lower areas, where a stone, a curb, or a footpeg misstep can create a cascade of damage. A properly engineered guard distributes that force across a broader surface and channels it away from the most brittle points. That distribution—not just the raw hardness of the material—defines how much fairing can be saved in the moments immediately after a slip or the instant a bike kisses the ground in a corner entry. The rider feels this as a quiet form of reassurance: a sense that the machine is protected, that the investment in metal, plastic, and engineering remains intact, and that the bike can be returned to the road without a lengthy, complicated repair.

In practical terms, the role of fairing guards extends beyond mere defense. They contribute to the motorcycle’s longevity by protecting downstream components that live near the fairing’s outer edges. When an impact is absorbed by the guard, the force is less likely to travel to engine covers or cooling ducts, reducing risks of oil leaks, coolant damage, or misalignment that could affect cooling efficiency. For sport-touring and adventure-oriented machines, in particular, this protective layer can be a decisive factor in keeping the machine ride-ready after a rocky gravel section or a routine track day where the margins for error are slim and the stakes are high. Because many adventure bikes and sport-tourers run substantial fairings that shelter radiators, air intakes, and mounting hardware, a guard that behaves like a shield rather than a simple cosmetic trim is a meaningful upgrade in both protection and peace of mind.

The material conversation is not only about toughness. It is also about compatibility with the bike’s geometry and its aesthetic. A guard must mate cleanly with mounting points and not interfere with heat shields, lower fairings, or other protective elements. Installers need to consider how a guard affects ground clearance during full steering lock and how it behaves when the bike is leaned over in a corner. Some designs contour around frame rails and wrap in a way that feels integrated rather than bolted on. For riders who care about color and finish, many guards come in a spectrum of finishes that can echo or contrast with the bike’s original paint scheme. The goal is to blend function with form so the protective accessory complements the machine rather than competing with its lines.

For riders who use their bikes as daily transports, the emotional and financial calculus matters as well. The knowledge that a guard has already absorbed the brunt of various encounters makes the prospect of a minor crash less daunting. The rider can decide to push through a challenging segment or attempt a tricky descending line with slightly more confidence, knowing that the fairing’s edges are not a fragile compromise but a safeguarded asset. In this way, guards influence not only the restoration cost after a spill but the rider’s behavior on the road and track alike. This subtle shift in mindset can translate into a more composed riding style, better line choice, and a willingness to test limits within reason, all while the protective layer quietly does its work beneath the surface.

A thoughtful approach to choosing a guard also considers integration with other protective components. Many riders complement fairing guards with frame sliders or crash bars that bracket the bike’s most vulnerable junctions. In combination, these elements form a network of protection that shields the engine isolators, brackets, and mounting hardware as well as the delicate outer shell of the fairing. The philosophy here is not to overbuild but to create a coherent, layered defense where each piece supplies a portion of the overall energy management. The guard absorbs and deflects, the sliders diffuse and translate, and together they reduce the probability of extensive repairs and the downtime that accompanies them. This approach is particularly appealing to riders who frequently ride in environments where debris is common, where tracks demand aggressive lines, or where urban roads present a constant barrage of surprises.

Of course, maintenance remains a practical consideration. Like any protective component, a fairing guard will accumulate scratches, impact marks, and grime over time. Regular inspection is prudent: check for cracks or deformation after a heavy impact, verify that mounting points remain secure, and replace worn sections before they compromise adjacent parts. Cleaning should be gentle to preserve the material’s integrity and finish, and any color finish should be checked for chips that could propagate through the layer and into the underlying fairing. The long-term value of guards lies not only in resisting the first hit but in maintaining the aesthetic and functional alignment of the entire bodywork assembly over the motorcycle’s life.

Riders contemplating the integration of guards into their machines will also find it useful to view the broader ecosystem of fairing protection. Guards are part of a family of protective solutions that includes dedicated lower fairings, protective extensions, and integrated anti-crash pads that reinforce the critical juncture between fairing and frame. For those who want to explore compatible fairing pieces in relation to a specific bike, the category of fairings available in the market provides a useful map of how protection can be matched to model lines and riding styles. For example, enthusiasts looking to align protection with a Yamaha-styled fairing can explore the relevant category to see which pieces are commonly paired with guards and how color, fit, and finish are coordinated to preserve the bike’s overall look while enhancing its resilience. Yamaha fairings can serve as a reference point for riders who want to understand how guards interact with the surrounding fairing panels and how a cohesive ensemble can be achieved without sacrificing performance.

In the end, the value of a fairing guard is measured not only by the number of scratches it prevents but by the larger story it tells about riding with confidence. It reflects a philosophy that protection can be smart, targeted, and aesthetically mindful. It recognizes that a bike’s bodywork is not just skin but a critical interface that balances protection, aerodynamics, and rider feedback. When chosen and installed with care, a guard becomes a quiet partner on every ride—a physical reminder that, even when the road throws a curveball, the frame and its protection system have the resilience to keep the journey going. For riders who navigate everyday streets, rougher back roads, and occasional track sessions, that reassurance translates into the willingness to ride farther, push a little deeper into corners, and enjoy the ride with the knowledge that the bodywork is safeguarded by a well-integrated defense system.

External reference: https://www.motea.com/en/products/fairing-guard-motorcycle-motoguard-dk1811

Material Choices and Performance in Motorcycle Fairing Guards: From ABS to Carbon Fiber

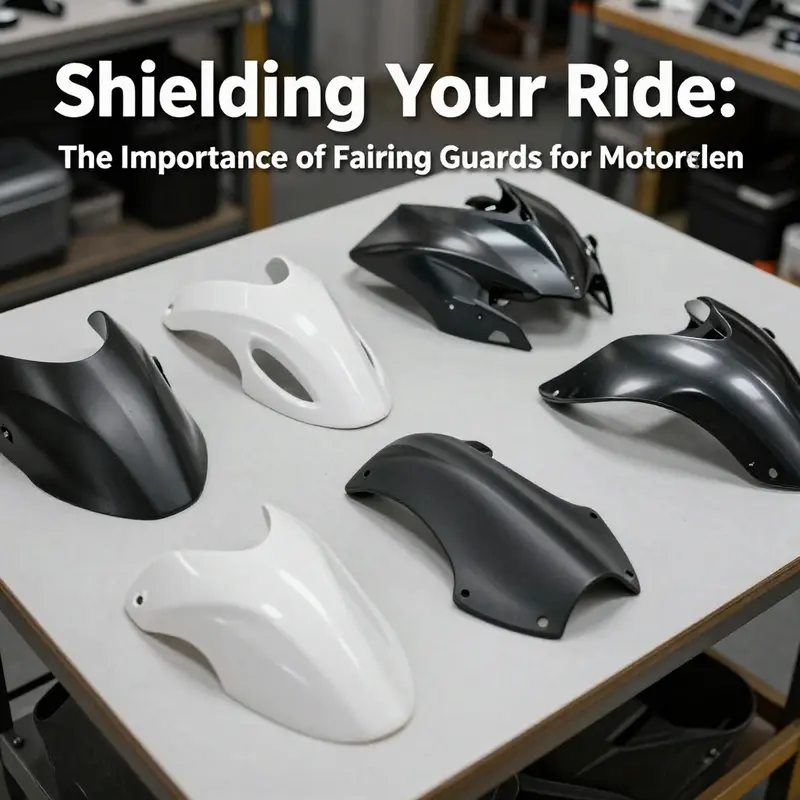

Material choices in motorcycle fairing guards shape every aspect of how well a bike survives a tip, a slide, or a stray stone kicked up by a passing car. A guard may feel like a simple shield, but its performance rests on a careful mix of properties: energy absorption, stiffness, weight, weather resilience, and how easily it can be repaired or replaced. For riders who log urban miles, dedicate track days to pushing limits, or venture along rough back roads, the material under the surface translates into lower repair costs, shorter downtimes, and better resale value. The three most common options—ABS plastic, fiberglass, and carbon fiber—each tell a distinct story about how a guard behaves in the real world. The choice often comes down to how a rider weighs affordability against performance goals and how much protection is deemed necessary for the bike’s fairing and underlying structure. In practice, the material is not a mere shell; it governs how energy is managed when a guard meets a sharp curb, a misjudged line through gravel, or the glancing impact of a close encounter with another vehicle. A well-chosen material can also influence how a guard tolerates repeated minor impacts and how its edges hold up after a low-speed fall, where the goal is to preserve the integrity of the fairing and avoid costly repairs downstream.

ABS plastic is the default for mass-market production and, for many riders, the most sensible starting point. It delivers a compelling balance of cost-effectiveness, impact resistance, and manufacturability. ABS can be molded into complex shapes to match the lines of modern fairings, and it holds paint well enough to produce bright, durable finishes. In day-to-day riding, it easily withstands minor scrapes, rain, and UV exposure, while keeping weight modest enough not to alter handling dramatically. For guards that must be replaced after a tumble, ABS pays back its cost through straightforward, field-friendly repair and relatively quick production turnaround. The tradeoffs come in the form of fatigue and heavier impact energy transfer when the guard is struck at speed or by sharp-edged debris. In those moments, the plastic can crack or deform, but the price to fix is typically low, and replacements are widely available. Thickness, typically around one to two millimeters in common production, helps balance stiffness and impact distribution without creating unnecessary bulk around the fairing lines. The appeal is clear for riders who value predictable performance, ease of repair, and compatibility with a wide range of bikes at a modest price point.

Fiberglass sits between ABS and carbon fiber on a spectrum of stiffness, strength, and cost. Custom or aftermarket guards often use fiberglass because it can be shaped into bespoke geometries without the complexity of carbon fiber layups. It offers good rigidity and better impact resistance than many thin ABS skins, which can translate into more forgiving energy absorption during a drop. Weight increases relative to ABS, but still remains modest enough for practical street use. Resin systems and layup quality matter more for fiberglass than for molded plastics, and improper curing can introduce porosity or micro-cracking that undermines long-term durability. Repair and refinishing are feasible, though it takes more DIY skill or professional service than a flat ABS panel. Enthusiasts who want a personalized look or a more robust protectant that can be tuned with different laminate schemes may gravitate toward fiberglass for its balance of toughness and customization potential. The ability to add thicker sections to high-wear zones or to reinforce edge guards without a prohibitive cost makes fiberglass a popular middle ground for riders who want a sturdier shield without venturing into carbon fiber’s price band. Color matching and texture can be excellent with fiberglass, offering a semi-permanent stripe of personality while preserving functional protection against scuffs and cracks that would otherwise expose the fairing’s core material to the road.

Carbon fiber represents the premium edge for those who measure performance in weight savings and stiffness. Its strength-to-weight ratio is unrivaled, so carbon-fiber guards can deliver similar protection with noticeably less weight than both ABS and fiberglass. For riders chasing sharper throttle response and lighter steering effort, every gram saved in the nose area can feel meaningful, particularly on lighter sport bikes. Carbon fiber also carries a high-end aesthetic that complements premium builds and can elevate the perceived value of the entire machine. Yet carbon fiber has its drawbacks. It is considerably more expensive and often requires more careful handling, because impacts can cause micro-cracks that are not always visible. Repairs are specialized and can be costly, and the finish must be protected with a clear coat or resin layer to resist UV damage and chalky weathering over time. The resin matrix and weave pattern demand meticulous workmanship to avoid finishing flaws that show up as gloss changes or micro-dimples. If a guard is used in environments with sharp, chiseling debris such as certain rural roads or track debris, the risk of localized failure increases unless the layup and protective coatings are designed with those hazards in mind. In practical terms, carbon-fiber guards make sense when weight savings are prioritized alongside a clean, performance-oriented look and when the rider is prepared for higher maintenance and cost. The material also demands considering the bike’s overall balance: excessive stiffness in the guard can transfer vibrations or stress elsewhere, so the weave orientation and edge protection must be coordinated with the fairing’s design language and the mounting scheme. The result is a shield that can feel almost part of the bike’s chassis, especially on machines that already emphasize precision and speed.

Beyond the raw material, the guard’s geometry, edge protection, and compatibility with other safety features matter. Some designs integrate crash bars or frame sliders that help distribute impact energy across a broader area and shield both fairing and engine components. The connection points, mounting hardware, and the overall stiffness of the guard influence how well it performs in a slide. A too-flexible guard can deflect and transmit more energy inward, while an overbuilt shield adds weight without proportional benefit. The interplay between the guard material and mounting system is critical, because even the strongest polymer can fail at a weak joint if the installation isn’t precise. For riders who tweak their bikes with aftermarket fairings, it is essential to confirm that the material and the chosen mount points align with the bike’s frame geometry and the lower fairing sections. Proper fitment reduces gaps where debris can lodge and improves the guard’s longevity in realistic riding conditions. In addition, the choice of finish—polyurethane clear coats, UV-stable paints, or gloss laminates—can influence how well the guard resists sun exposure and road salts, a practical consideration for daily riders who park outside and ride in a variety of climates. When done thoughtfully, a well-designed guard does more than protect the fairing; it preserves the bike’s lineage of performance, aesthetics, and reliability across seasons of use and miles of asphalt and dirt alike.

Choosing the right material is a balancing act between budget, riding style, and practical needs. Urban commuters who mainly contend with curbs and incidental road spray may prioritize cost and ease of replacement, leaning toward ABS or simple fiberglass skins. Track enthusiasts, who demand minimal weight and maximum stiffness, might lean toward carbon fiber, accepting the higher price and maintenance diligence that entails. Off-road riders facing rocks, branches, and unpredictable terrain may prefer fiberglass for its ruggedness and the ease of field repairs. Regardless of material, attention to edge treatments helps: rounded edges reduce snag risk, while reinforced lips or sacrificial sections can absorb edge impacts and prevent cracks from propagating. Finishes should be UV-stable and compatible with the bike’s color scheme, since sun exposure can dull or fade plastics and fibers over time. Routine checks should include inspection of fasteners, mounting brackets, and the seal between the guard and the fairing to prevent moisture ingress that can compromise the underlying structure. The maintenance footprint varies with material: ABS might require occasional refinish, fiberglass demands attention to moisture management and resin integrity, and carbon fiber benefits from careful cleaning and protective coatings that guard against micro-impacts and resin wear. In all cases, the goal remains clear—keep the fairing intact, preserve the bike’s aerodynamics, and minimize downtime when the unexpected happens on the road or the track.

For readers exploring how fairings are categorized across brands and to see related styling, see the Yamaha fairings page. Yamaha fairings

To deepen understanding of carbon fiber properties and composite materials, consider external resources that detail weave patterns, resin systems, and the science of stiffness and damping. For a comprehensive overview, visit https://en.wikipedia.org/wiki/Carbon_fiber

Guarding the Ride: Key Features, Fit, and the Balance of Motorcycle Fairing Guards

A motorcycle fairing guard acts as a practical shield for the bike’s bodywork, absorbing rocks, gravel, and curb scuffs before they reach the fairing. It is not merely cosmetic protection: it helps protect critical panels, preserve resale value, and can support stable airflow around the front end. Materials range from high-impact plastics to polycarbonate shells with reinforced inserts; the goal is a light, stiff barrier that resists cracking while keeping weight down. Modern guards emphasize modularity, allowing easy installation, maintenance access, and straightforward upgrades without dismantling the entire front end. Fit matters: guards should align with mounting points, windscreen edges, and lower fairing contours to avoid rattles and preserve cooling paths. When properly chosen, a guard can enhance handling by reducing front-end chatter and maintaining steady steering feel through corners. A balanced selection respects the bike’s geometry, supports reliable maintenance access, and complements other protective devices like crash bars or frame sliders for a cohesive protection strategy.

Guarded by Design: How Market Trends and Leading Brands Are Shaping Modern Motorcycle Fairing Guards

The rise of the motorcycle fairing guard as a staple of rider protection embodies a shift in how people think about safety, performance, and personal expression on two wheels. What began as a simple shield to guard against curb scuffs and loose gravel has evolved into a design element that blends protection with aerodynamics, weight management, and customization. Riders now evaluate guards not only for how well they resist impact but for how they influence the bike’s balance, airflow, and even its overall silhouette. In busy city streets, a guard can keep costly panels and paintwork intact during the inevitable low‑speed contact with obstacles; on winding roads or at the drag strip, it can manage energy transfer during a slide or a gentle topple. The best solutions feel invisible when the motorcycle is upright and moving, yet tangible in the reassurance they provide when a rider leans into a corner or steers through a narrow gap. This dual role—protection without overburdening the machine—drives the continuous refinement of materials, geometry, and mounting systems, and it makes the guard a meaningful part of the rider’s relationship with the bike rather than a mere add-on.

Market momentum mirrors this shift in priorities. The global motorcycle fairing market was valued at about 6.84 billion dollars in 2025 and is projected to grow at a robust compound annual growth rate of roughly 12.8 percent through 2033, crossing the 15 billion dollar threshold toward the end of the period. This trajectory is propelled by riders who seek modest protection paired with comfort and efficiency across a range of use cases—from lengthy touring sessions to daily commutes and spirited weekend rides. Touring bikes, sport‑tourers, and commuter motorcycles represent the core demand, not because they require heavy armor, but because their owners value predictable protection that integrates with a long service life and predictable maintenance. With more riders clocking long hours in the saddle, the market is increasingly driven by the desire for a fairing system that reduces drag, stabilizes airflow, and preserves the ease of cleaning and repainting after a scratch or a drop. The numeric signal is clear: riders want guards that work with the bike’s geometry, not against it, and that remain faithful to the rider’s preferred balance between protection and performance. The result is a push toward modularity that lets riders tune depth, coverage, and finish to their model and to their riding philosophy, making the guard a personal extension of the motorcycle’s design language.

Material science advances have kept pace with this demand. High‑impact ABS plastics remain a practical workhorse for everyday applications, offering resilience against impact and abrasion at a reasonable price. In premium lines, carbon fiber composites enter the frame, delivering lightness and stiffness where it matters most. The most effective guards blend these materials, using ABS for the outer shell and strategic carbon fiber reinforcements where stress concentrates, so the guard can absorb energy without becoming a heavy paddle that weighs down steering. The result is a system capable of withstanding routine encounters with curbs or rocks while preserving the rider’s sense of control and the bike’s precise handling. In many configurations, guards are designed to work in concert with integrated crash pads or frame sliders. This coordination helps disperse impact forces not just across the guard but toward components that are engineered to take it, reducing the likelihood of damage to the engine, radiators, or mounting points. The best solutions therefore combine protective performance with a lightweight footprint and a clean integration that does not disrupt cooling airflow or the bike’s frontal geometry.

Design philosophy today embraces customization as a core value. Riders want to express their personality through the very armor that stands between metal, plastic, and paint on the outside. A modular guard system that can be swapped, upgraded, or color‑matched to the rest of the fairing appeals to enthusiasts who care about aesthetics as much as impact resistance. When a rider changes color schemes, switches to a different riding setup, or adds a new set of lower panels, the guard should adapt with ease. That flexibility is supported by mounting schemes that accommodate a variety of configurations without forcing a wholesale disassembly of the bike. The end result is a cohesive look in which the guard, fairing, and chassis form a single, well‑considered entity. Beyond appearance, modularity also simplifies maintenance and repair. If a panel is scratched, a part can be replaced without affecting the rest of the fairing, and if a rider wants a different level of protection for a track day, the guard can be adjusted without replacing the entire fairing assembly. This philosophy keeps the guard in step with the rest of the bike’s ecosystem, rather than standing apart as a separate, optional add‑on. In this light, the guard is not just a probability of damage control; it is an organ of the bike’s overall design maturity, a statement that safety and style can travel together.

Smart technology is weaving its way into the guard altogether. The most forward‑looking guards integrate LED elements that enhance daytime visibility and contribute to the bike’s lighting language without adding heavy electrical loads. Some models feature discreet USB‑C ports positioned for convenient charging on long trips, a practical nod to riders who count on devices for navigation, communication, or media. More sophisticated configurations explore sensor channels and interfaces that align with cornering safety systems. In this sense, guards become part of the bike’s electronic ecosystem, offering value not only in impact resistance but in utility and data collaboration. The integration is not about turning a guard into a gadget; it is about making it a thoughtful piece of a rider’s broader safety and convenience architecture. The narrative here is consistent with a broader industry trend: accessory components are increasingly designed with electronics and sensors in mind, enabling a richer user experience without compromising the core function of protection or the bike’s aerodynamic integrity. Even as these features proliferate, the comfort and confidence of the rider remain the central priority, with form and function synchronized to deliver a seamless riding experience.

Brand ecosystems and the market’s competitive landscape shape how this evolution unfolds. Established manufacturers emphasize aerodynamic efficiency, structural integrity, and the preservation of the bike’s design language from the fairing to the chassis. In such cases, guards are engineered to work with factory or official crash‑protection systems to form a coherent protective envelope, rather than functioning as an isolated add‑on. At the same time, a vibrant aftermarket sector tests ideas, shares findings, and develops parts for a wide range of models. From a rider’s perspective, this creates a spectrum of choices: one can stay within a single brand family for predictable fit and finish, or explore cross‑brand compatibility with careful attention to mounting points and tolerances. The popularity of certain styling cues—thin leading edges, integrated undercuts, or slender side panels that maintain airflow—highlights how protection and aesthetics are increasingly inseparable. The guard becomes a visible thread in a rider’s personal narrative about how a bike should look and what it should endure. When riders discuss their builds in forums or showrooms, the emphasis often turns to fit, finish, and the sense that the guard contributes to the bike’s overall stance while reducing inevitable costs associated with minor crashes.

For readers curious about how a specific machine’s geometry accommodates guards without sacrificing its character, a practical example lies in the space dedicated to certain OEM and aftermarket options within the rider community. The area that focuses on fairings for a well‑known performance platform illustrates how a guard can synergize with the bike’s lines, maintain the intended airflow, and preserve maintenance accessibility. See the dedicated area for BMW S1000RR fairings to understand how a guard can harmonize with OEM geometry and the designer’s intent.

As the market expands, the industry anticipates continued growth driven by practical needs and the desire for personal expression. The most enduring guards will be those that keep pace with riders’ ambitions, whether they are crossing continents on touring setups or pushing apexes on a spirited weekend ride. The future of fairing guards lies in tighter integration with aerodynamics, electronics, and ride‑control systems, enabling guards to adapt to new powertrains, smarter riding modes, and evolving lighting strategies. The data points toward sustained momentum, a trend that honors safety without compromising style, and a willingness among manufacturers and riders alike to treat the guard as a purposeful component rather than a cosmetic afterthought. The chapter ends with a reminder that this is not a static category but a living facet of modern motorcycling—one that grows stronger as design, materials, and technology converge around the humble yet vital shield around the bike’s most vulnerable surface. External resource: https://www.marketresearchfuture.com/market-reports/global-motorcycle-fairing-market

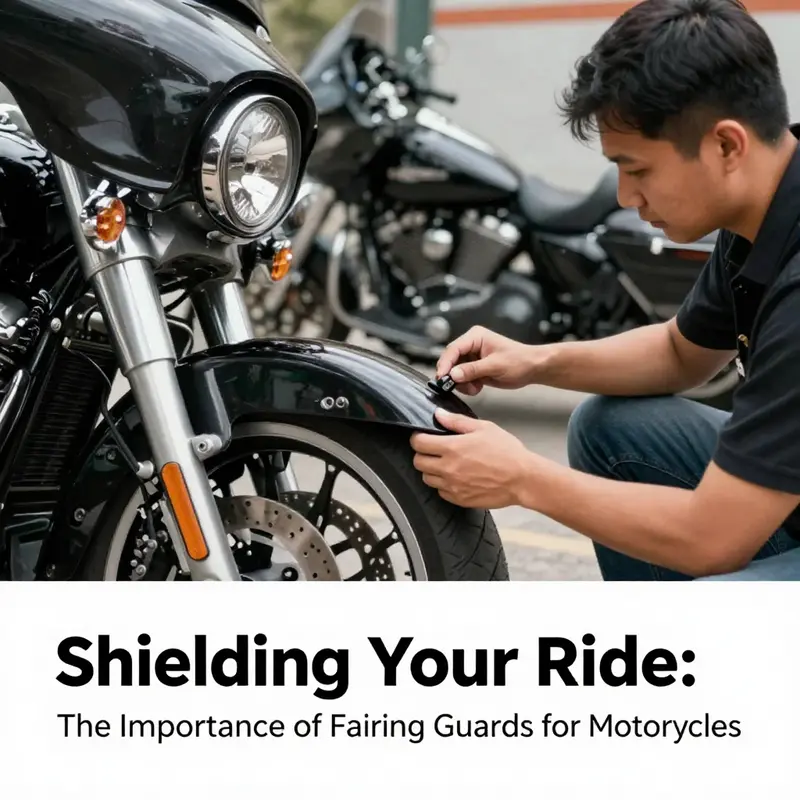

Fit, Finish, and Protection: Mastering Fairing Guard Installation Across Popular Models

A fairing guard is more than a simple shield for the bike’s bodywork. It is a carefully chosen layer of defense that helps absorb the first blows from curbs, gravel, and the occasional low-speed tumble, while preserving the clean lines and performance feel riders expect from their machines. The guard’s purpose becomes particularly clear when you ride in patterns that bring you into close contact with road debris, or when you spend long hours in environments where the bike’s lower edges lead a double life as a shield against the grit of the road. Materials matter here: high-impact plastics, polycarbonate, and reinforced composite polymers offer a balance of stiffness, weight, and resilience. Lighter guards tend to preserve acceleration feel and fuel efficiency, while sturdier configurations deliver real-world protection in scenarios that leave lesser shields singed and scarred. The best guards also play nicely with the bike’s aerodynamics, with smooth profiles that don’t intrude on cooling air or steering geometry. In this light, a well-made fairing guard becomes less a vanity accessory and more a crucial part of the motorcycle’s resilience. And for riders who travel varied roads—from city streets to back roads and light off-road trails—the guard must perform across this spectrum without demanding an overhaul of the bike’s appearance or handling. The dialogue between protection and aesthetics continues here, as many guards come in a range of colors and finishes intended to harmonize with the bike’s paint scheme, so the protective function does not have to clash with style. When installation is done correctly, the guard reads as an extension of the fairing rather than a separate add-on; misalignment, on the other hand, can create gaps, rubbing, or heat-related issues that undermine both protection and rider confidence. The best outcomes occur when riders approach selection with a clear sense of their typical riding environments and a careful eye for how a particular guard’s geometry will relate to the bike’s underlying structure. This becomes especially important for riders who park in tight lots, navigate narrow lanes, or ride aggressively on twisty pavement, where any protruding edge could catch on a curb or a rock and transfer force directly into the fairing rather than into the guard itself. The protective value then expands beyond the surface; it can influence repair costs and downtime after minor mishaps, which is a meaningful consideration for those who rely on their bike for daily transport or weekend adventure alike. A practical way to frame the decision is to imagine how the guard interacts with a bike’s other protective elements, such as engine guards or frame sliders. In some configurations, the fairing guard integrates with or supplements these features, spreading impact forces across a broader portion of the frame and reducing the likelihood that a single point bears the brunt of a collision. This integration can also influence maintenance routines, as mounting points and hardware must remain accessible for inspection and eventual replacement. Compatibly designed kits often include the necessary hardware and mounting brackets tuned to a specific family of bikes, making fitment more predictable and installation less invasive. Still, even with a complete kit, compatibility is never a guarantee. The geometry of fairings changes with model redesigns, trim levels, and even minor year-to-year updates. The result is a simple truth that guides most informed riders: verify the fit against official specifications and cross-check with trusted retailers or installation guides before buying. Some models share nearly identical platform dimensions, while others require custom brackets or alternate lower fairing components to ensure a clean fit without interference with the engine, cooling system, or suspension. In practice, this means looking beyond the appearance of a guard and toward its relationship with every nearby feature—the radiator shrouds, the exhaust routing, the fairing’s edge contours, and the space between the guard and the crankcase. In this sense, the installation becomes a careful alignment task rather than a quick click of a rivet gun. For riders who want to gauge options without committing to a single kit, a helpful approach is to study compatibility notes from reputable sources and then inspect real-world fitment images. A well-documented installation path shows how a guard’s curves align with the bike’s fairing lines, where the mounting points sit relative to the engine mount brackets, and how the guard’s corners clear condensation channels or intake openings. It also helps to consider the impact on serviceability; some guards are designed to come off easily if needed for routine maintenance, while others are meant to stay on and simply hinge aside when required. The balance between permanence and serviceability is part of the broader conversation about maintenance practicality and the long-term ownership experience. When discussing compatibility, the conversation inevitably touches on model specificity. A guard that is marketed as universally “fit-for-all” typically under-delivers in either protective capacity or cosmetic integration. Conversely, a model-specific design promises a cleaner silhouette and a more seamless attachment, yet may limit flexibility if you change bikes or alter trims. The most thoughtful choices emerge when riders weigh their personal riding calendar—the urban commute, the weekend canyon run, and the occasional off-road foray—against the guard’s profile and attachment strategy. For those who want to explore options tailored to a particular bike, a useful reference starts with a dedicated catalog that groups fairings by model families rather than by generic category. This focused approach helps riders see at a glance how the guard’s mounting points align with the bike’s frame and how it will look once installed. For riders seeking direct product cues within a specific brand ecosystem, the Honda fairings category offers a curated view of panels and guards that share mounting philosophies and interface with common hardware layouts, providing a practical baseline for compatibility checks. You can explore that resource here: Honda fairings catalog. Beyond visuals, the installation narrative benefits from a calm, measured approach. Start by assessing the bike in a parked, upright position, noting where the lower edge of the fairing sits relative to the ground and identifying any potential contact zones with the wheel or fork crowns. Check the available clearance for the guard’s profile in all steering angles and when the suspension compresses under load. Prepare the hardware in advance, ensuring you have the correct bolts, spacers, and quick-release options if the kit employs them. As you begin mounting, work from the most rigid anchor points first and then snug secondary fasteners to avoid warping the plastic or stressing a mounting bracket. A careful sequence, paired with modest torque, preserves both the guard’s integrity and the surrounding bodywork. The dynamic payoff is clear: a guard that is correctly installed protects the fairing, contributes to a more forgiving crash energy distribution, and preserves the bike’s appearance over time. In the end, compatibility is less a checkbox and more a process of aligning intention with engineering. It is a conversation between the owner, the shop technician, and the bike’s design language. It asks you to look at how the guard will perform under the pressures of daily use and how it will complement the bike’s silhouette, rather than disrupt it. For readers who want to extend their exploration, the linked resource provides a gateway to a broader marketplace of compatible panels while additional guidance on installation practices can be found in trusted retailer guides. External resource: https://en.wikipedia.org/wiki/Fairing_(motorcycle)

Final thoughts

Fairing guards are an essential investment for motorcycle owners looking to protect their bodywork and enhance safety on the road. With the increasing awareness of these protective accessories, business owners in the motorcycle industry should prioritize stocking and promoting high-quality fairing guards. Understanding the materials, key features, market trends, and installation processes can help businesses provide valuable recommendations to customers while also fostering loyalty. As riders continue to demand both safety and style, fairing guards will hold their place as a must-have accessory for any motorcycle enthusiast.