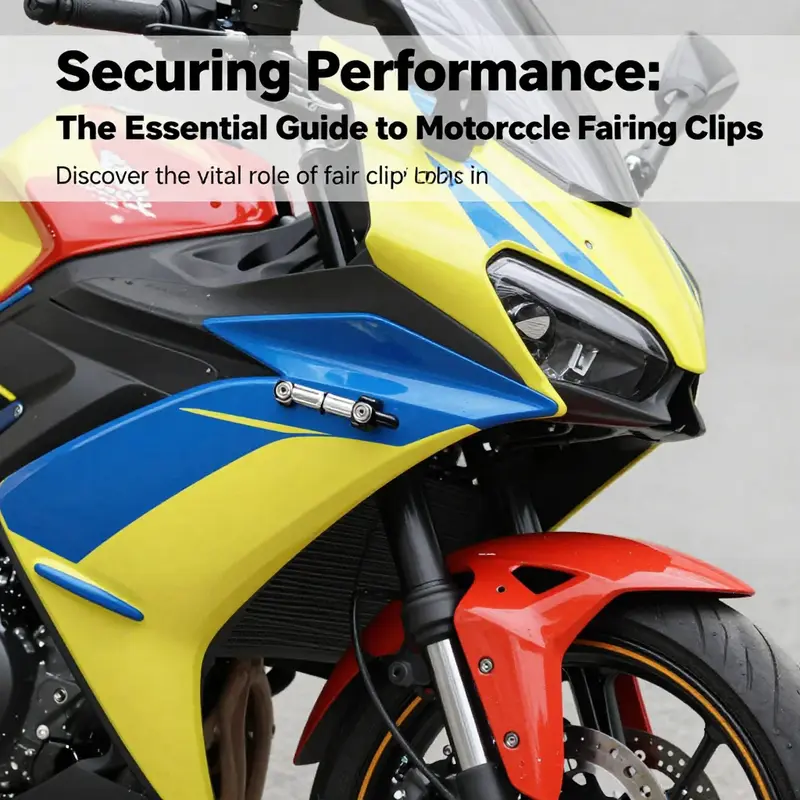

Motorcycle fairing clips play a pivotal role in connecting the fairing panels to the motorcycle frame, ensuring stability and protection against vibrations and environmental stress. Understanding the different types, installation methods, and performance benefits of these clips is essential for motorcycle business owners who want to offer quality service to their customers. The first chapter delves into the various types of fairing clips available in the market, highlighting their distinct features and applications. The second chapter will cover important installation and maintenance strategies that can enhance the longevity and functionality of fairing clips. Finally, the third chapter will explore the performance advantages that come with using high-quality fairing clips, ultimately contributing to improved motorcycle performance and rider satisfaction.

Holding It Together: The Subtle Science of Motorcycle Fairing Clips and How They Shape Ride Quality

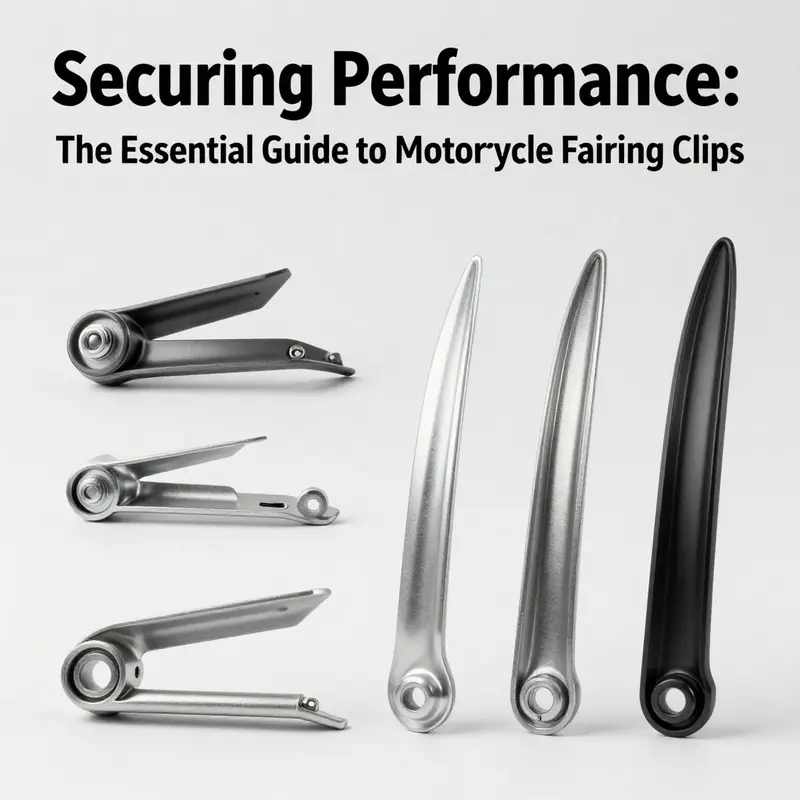

On a motorcycle, the fairing is more than a cosmetic shell. It is a crafted interface between rider, aerodynamics, chassis dynamics, and the very air the bike slices through at speed. The clips and fasteners that hold those panels in place are the quiet guardians of performance. They manage fit, control vibration, and influence how clean the bike looks when it sits in the garage or rolls down the road. The right clips do more than keep panels in place; they contribute to smoother airflow, reduced wind noise, and a stable cockpit that stays aligned with the rider’s line of sight. When a clip fails or wears out, the result can be a subtle flutter at highway speeds, a rattling panel at 60 when the wind shifts, or a panel that shifts just enough to catch on a leg or boot. In other words, fairing clips matter, even when they aren’t the first thing a rider notices. They are the unsung parts that translate design intent into real-world stability and comfort.\n\nThe landscape of fairing clips is a spectrum rather than a single solution. Across brands and model lines, engineers have defined families of fasteners and retainers that balance ease of service with durability. The most common families include spring clips, rubber or silicone grommets, plastic push-in clips, threaded fasteners, and, in some newer kits, magnetic holders. Each family brings its own story of how a panel is held, how it responds to vibration, and how a rider can access the internals of the bike without wrestling with stubborn pieces. The goal is not to pick one universal tool but to understand how each type fits into the architecture of a bike’s fairing system and what that means for riding dynamics over miles of road and a lifetime of weather.\n\nSpring clips, sometimes called retaining clips or T-clips in maintenance circles, are the backbone of many fairing assemblies. They are designed to snap into a pre-drilled hole or groove on the frame or mounting point and exert a gentle, continuous spring force against the panel. The flexibility of metal or reinforced plastic means they absorb a portion of the vibration that would otherwise travel through the fairing and echo into the cockpit. The benefit is twofold: a snug fit that resists rattling and a degree of compliance that prevents the panel from becoming a rigid, souring source of resonance as the engine and road surface interact with the bike. For riders who regularly take their machines out on winding roads or long back routes, the spring clip’s resilience translates into fewer creaks, less wind noise, and a consistent panel alignment that stays true as the bike warms up and cools down. Their installation is typically straightforward and tool-light, making routine maintenance or reforming a damaged panel a task within reach for many riders.\n\nRubber or silicone grommets play a more subtle but equally important role. They are soft, flexible inserts placed around fasteners where the bolt or screw passes through the fairing and frame. Their primary job is vibration damping. By isolating the metal path and adding a layer of compliance, grommets reduce the buzz that travels from the engine through the chassis and into the fairing. A well-damped fairing demonstrates reduced cabin noise and less rattling that can otherwise become a magnet for dirt and moisture. This becomes particularly meaningful at high speeds where aero loads and engine-induced vibrations combine, especially for sport-touring riders who spend hours in the saddle. Grommets also contribute to a longer service life by reducing the fretting wear that can occur where metal parts slide against each other. They are not the primary retention method but rather a crucial secondary mechanism that adds stability and comfort over the long haul.\n\nPlastic push-in clips offer a cost-effective path to a secure fit, especially on lower-cost or OEM fairings. They rely on a simple principle: a protruding barb or tab is pushed into a socket or hole, and the material’s elasticity keeps the panel in place. For lightweight panels or non-structural sections, plastic push-ins can deliver quick, tool-free service and a reasonably durable attachment in normal operating conditions. However, plastic has its limits. In extreme weather, temperature fluctuations can make the material brittle or overly pliable, compromising retention if a panel experiences repeated flexing or significant aero load. Riders who mothball their bikes for winter or park them in damp environments may see grommeted or spring-based solutions outlast push-in clips in the long run. Still, for certain sections of the fairing where a quick release or replacement is a priority, plastic push-in clips provide a practical balance of cost, convenience, and performance when paired with compatible mounting points.\n\nThreaded fasteners—bolts and nuts—represent a different category altogether, one that emphasizes strength and repeatable torque. While not technically a “clip,” these fasteners anchor larger sections of the fairing, particularly around critical junctures like the headlight housings, instrument clusters, or the main body panels that define the bike’s silhouette. They are the workhorses of long-term structural integrity. The trade-off is clear: they require tools, and their use invites a meticulous approach to torque, thread engagement, and over-tightening risk. When a rider wants a panel to resist high aero loads or when panels need to be aligned with precise gaps for aesthetics and function, threaded fasteners prove their worth. For daily riders, the ability to access internals with a handful of tools is valuable, especially during maintenance or upgrades. For those who chase lightweight builds or high-speed stability, the interplay between clips and screws becomes a design conversation: where to rely on spring or push-in retention for speed of service, and where to secure a more robust threaded connection that stands up to miles of road and heat cycling.\n\nA newer, more exploratory approach to fairing attachment has begun to surface in aftermarket ecosystems: magnetic fairing holders. These are not typically used as the sole permanent attachment in a race-ready setup, but they can offer a convenient, temporary hold during alignment, assembly, or the installation of lightweight accessories. The magnetic approach simplifies the stage of fitting a panel in place for final checks before a more permanent fastening method is engaged. While not a cure-all for every mounting scenario, magnetic solutions illustrate how designers are rethinking the interaction between ease of service and structural integrity, especially for riders who value rapid access to panels for cleaning, customization, or hobbyist maintenance.\n\nBeyond the individual types, the material science behind these clips and fasteners matters as much as the geometry. Metal clips, often stainless or coated alloys, deliver strength and durability in a wide range of temperatures and weather conditions. They resist deformation, provide predictable retention, and support the repeated cycles of assembly and disassembly that riders perform during maintenance. Plastic variants, including reinforced polymers, reduce weight and cost but must balance toughness with UV resistance, heat deflection, and chemical stability from fuel vapors and cleaners. Rubber and silicone grommets are prized for their damping properties, yet their performance hinges on resistance to oil, ozone, and long-term compression set. The best setups use a blend: a metal clip in high-load, critical connections; grommets at vibration-prone junctions; and plastic or composite fasteners in zones where ease of service takes priority without compromising safety. This balancing act is the essence of a well-engineered fairing system, where the goal is to maintain a precise panel fit across a wide envelope of riding styles and environmental conditions.\n\nA practical truth emerges when riders evaluate their own machines: the fit of the fairing, and the resilience of its attachment system, reflects the rider’s maintenance habits as much as the original design. Regular inspection is not a luxury but a necessity. Visible cracks, widening gaps between panels, or abrupt changes in the panel alignment can signal fatigued clips or grommets that should be replaced before they fail entirely. A fairing that whistles or creaks at highway speeds is not just a nuisance; it is a sign that the attachment system is shifting under load. The rider who stays ahead of this problem by checking mounting points, replacing worn grommets, and ensuring fasteners are torqued to spec prevents more serious consequences down the road. The best riders adopt a mindset of proactive care: they treat the fairing as a system with moving parts. It is not enough to buy a kit that includes clips; one must understand how those clips will behave across thousands of miles and across the different seasons.\n\nThe choice of clips and fasteners also intersects with the broader ecosystem of the bike’s fairing family. The rider who is curious about how a particular system manages interaction with the frame and the surrounding fairing panels will benefit from exploring the repair and replacement pathways offered within their bike’s community. Compatibility across brands and models is a practical concern. While many fairings across manufacturers share a similar logic—panels fastened near the headstock, around the fuel tank, and along the sides—the exact shapes, hole spacings, and mounting depths vary. The result is a modular truth: some riders will find that their preferred clip type and mounting strategy works across several models, while others will need model-specific clips carved by engineers who understand the geometry and tolerances of that particular chassis.\n\nThe aesthetics of a bike intertwine closely with function here as well. A clean, gap-free panel line is not just about looks; it is a display of careful engineering that supports better aerodynamics and reduced drag. The more precise the panel alignment, the less air leaks into the cockpit or under the bike’s belly, where stray air can disrupt airflow and increase parasitic drag. In sport and sport-touring contexts, riders may opt for clips and grommets that strike a balance between a secure hold and the possibility of rapid panel removal for track days or on-road tuning. Cafe racer builds, with an emphasis on a streamlined, vintage-inspired silhouette, often lean toward clip configurations that emphasize a tight, minimalist mounting system while still preserving ease of access for maintenance. Daily commuters, who place a premium on reliability and noise suppression, may favor clip types that stay quiet at speed and resist weather-induced changes in fit across the seasons. In all these scenarios, the underlying principle remains the same: the fairing’s attachment system should disappear behind the rider’s focus on the road, while still delivering consistent performance and easy maintenance when needed.\n\nThe practical implications of choosing the right clip family extend into the realm of maintenance planning and resource allocation. Riders who prepare for service intervals will find it helpful to maintain a small stock of common items: a few spare spring clips, a couple of grommets, and a modest set of fasteners in different lengths and thread pitches. These essentials enable quick field fixes, panel realignments after a run through heavy rain, or a swap that accompanies an upgrade to a higher-performance fairing configuration. Kits that bundle bolts, studs, and clips in two or more pieces provide flexible options for different mounting points, and they are especially useful for riders who customize their bikes or perform frequent panel removals. While the specifics of what to stock will depend on the model and the rider’s goals, the ethos stays constant: preparedness reduces downtime and preserves the bike’s ride feel.\n\nFor riders who like to keep an eye on broader ecosystems, a practical reference point helps anchor decisions. This is not about chasing a single perfect solution, but about understanding how different clips integrate with various fairing geometries and how that integration shapes ride quality. A scope that considers OEM guidelines, aftermarket adaptability, and rider preferences offers the most resilient approach to choosing and maintaining fairing clips. The Honda fairings category provides a useful illustration of how a manufacturer’s design language translates into mounting points, hole spacings, and panel profiles across a family of models. For a practical sense of how these elements come together and to situate your own setup within a broader ecosystem, you can explore the Honda fairings category, which showcases how mounting points and panels align in a coherent design language. Honda fairings category.\n\nAs riders weigh the options, the question often turns to the balance between ease of service and the fidelity of the panel fit. A well-chosen system delivers both. It enables quick maintenance, precise panel alignment, and a ride experience that feels solid and connected rather than sloppy or rattly. It also supports the bike’s overall performance envelope by preserving aerodynamic integrity, reducing wind noise, and maintaining a stable cockpit that helps the rider stay focused on the road rather than on intermittent snaps or rattles from the fairing. In the end, fairing clips are not merely fasteners; they are a living interface between engineering intent and riding reality. They carry the weight of design decisions about how a bike should feel at speed, how it should respond to the rider’s inputs, and how it should hold up under the vagaries of weather and mileage. The rider who understands this can approach maintenance and upgrades with a sense of purpose, knowing that the right clips contribute to a more enjoyably controllable machine and a more gratifying ride.\n\nExternal resource for deeper technical context: Technical Guide on Motorcycle Fairings.

null

null

The Quiet Leverage: How Fairing Clips Shape Aerodynamics, Comfort, and Safety

Motorcycle fairings are more than a sculpted exterior; they are a purpose-built interface between rider, bike, and environment, and the clips that fasten them are the quiet workhorses that keep airflow where it belongs. When panels stay in the intended planes, the airflow remains smooth, transitions between riding conditions are predictable, and the overall drag, buffeting, and noise stay low. But if clips loosen, crack, or fail to seat correctly, tiny panel movements can create micro-vortices, disrupt pressure distribution, and degrade handling and efficiency. The role of fairing clips extends beyond mere attachment: they define the panel alignment, maintain sealing against wind and water, and help protect rider comfort by reducing flutter that would fatigue arms and helmet. Design matters, too: clips must withstand engine vibration, heat cycling, and the repeated flex of aggressive riding, while remaining compatible with the panel system, frame geometry, and mounting bosses. Materials range from high-strength polymers to metal variants, chosen to resist fatigue and corrosion while staying lightweight; the best choices balance secure retention with the ability to service the bike quickly during maintenance or track days. Installation is not cosmetic; it is a critical step that, if done correctly, preserves the fairing’s aerodynamic shape and seals. The correct clip type must align with the panel’s mounting points, fit snugly without over-tightening, and avoid creating stress concentration on bonding bosses or sharp edges. In practice, riders may favor quick-release variants for easy panel swaps or race preps, while others rely on traditional bolts for maximum torque stability; the decision should reflect riding environment, expected loads, and the panel system’s design. Maintenance habits matter as much as the initial choice: inspect clips for wear, cracks, or deformation, replace those that show fatigue, and check the surrounding bosses for signs of elongation or fatigue. A small lag in one clip can allow a panel to flutter or separate under side wind, accelerating wear elsewhere and inviting more drag or noise. Ultimately, a well-fastened fairing contributes to rider confidence by preserving predictable steering feel, steady air pressure on the helmet, and a more comfortable ride in wind and weather. It also reduces the risk of loose panels becoming road hazards, so annual or semi-annual inspection combined with after-a crash clip replacement after a heavy impact is prudent. When considering upgrades or aftermarket options, the goal is compatibility and reliability: choose clips that integrate with the existing panel system and frame geometry, verify the clips’ tolerance to vibration and temperature, and ensure the hardware does not introduce stress or misalignment. In track or sport-riding contexts, retention systems that resist vibration and rapid temperature cycling can prevent panel movement at high speeds, protecting the fairing’s aerodynamic shape and the rider’s line through cornering. For everyday street use, a balance between ease of maintenance and secure fit can guide the choice toward robust, serviceable designs that endure sun, rain, and road debris. In the end, the best clips are not flashy; they are dependable, compatible with the bike’s design language, and installed with care. They enable the fairing to do its quiet work—ensuring clean, consistent airflow, maintaining seal integrity, and supporting safety and comfort across a wide range of riding scenarios. For riders who want to learn more about how fairings integrate with the bike’s overall robustness, a careful look at the mounting system, panel fit, and the relationship between clips, studs, and bolts will reveal why these small parts matter as much as the visible shapes that define a motorcycle’s silhouette.

Final thoughts

The significance of fairing clips in motorcycle design cannot be overstated, as they not only secure the fairing but also enhance the overall performance and appearance of the bike. By offering a variety of high-quality clips and ensuring proper installation and maintenance, motorcycle business owners can build loyalty among riders who appreciate practicality and style. Investing in the right fairing clips will ultimately benefit both the motorcycle’s functionality and the rider’s experience, reinforcing the importance of these seemingly small yet vital components in the world of motorcycles.