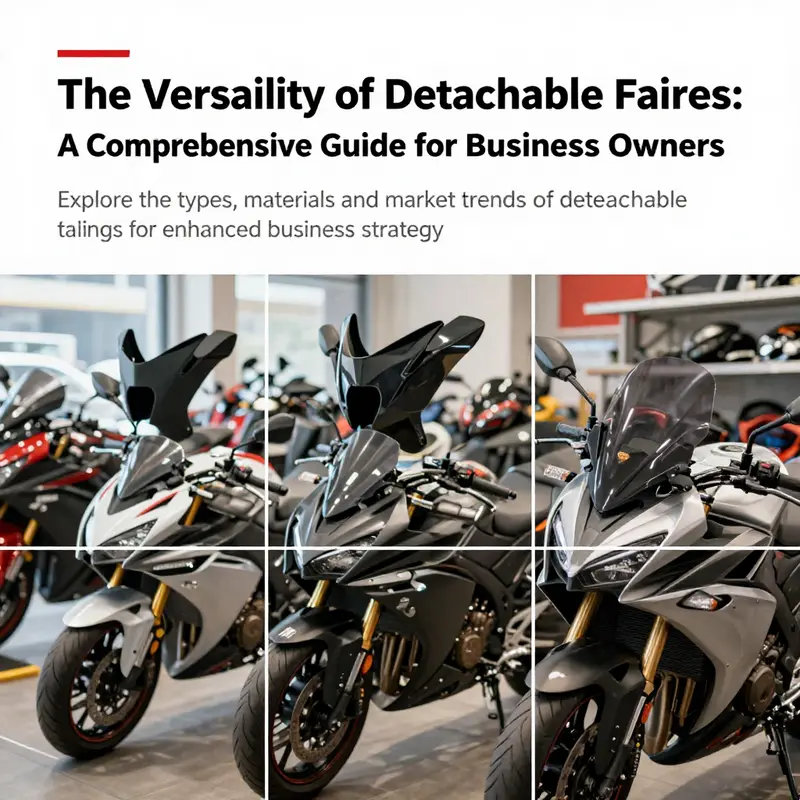

Detachable motorcycle fairings have emerged as a sought-after modification among riders looking to personalize their bikes while optimizing performance. For business owners in the motorcycle industry, understanding this trend can unlock significant opportunities for product offerings and customer engagement. This article delves into various aspects of detachable motorcycle fairings, from the different types available and the materials they are made from to installation and maintenance considerations. We’ll discuss the practical advantages these fairings offer in varying riding conditions and analyze current market trends and customer preferences—giving you the insights needed to capitalize on this lucrative segment.

Shaped for Every Ride: The Different Types of Detachable Motorcycle Fairings

Detachable motorcycle fairings sit at the intersection of form and function, a modular philosophy applied to the motorcycle’s front end. They are engineered to peel away or lock in place with minimal fuss, letting riders tailor wind protection, aerodynamics, and access to the machine itself. The appeal is simple and practical: a single motorcycle can morph from a wind-swept, exposed rider stance on a warm day to a sleek, shielded posture on a long highway crossing. The concept relies on a system of fasteners, clips, and mounting points that balance quick removal with steadfast security at speed. In this sense, detachable fairings are less a single product and more a flexible design language that accommodates riding styles, climates, and maintenance routines without committing to a permanent outer shell.

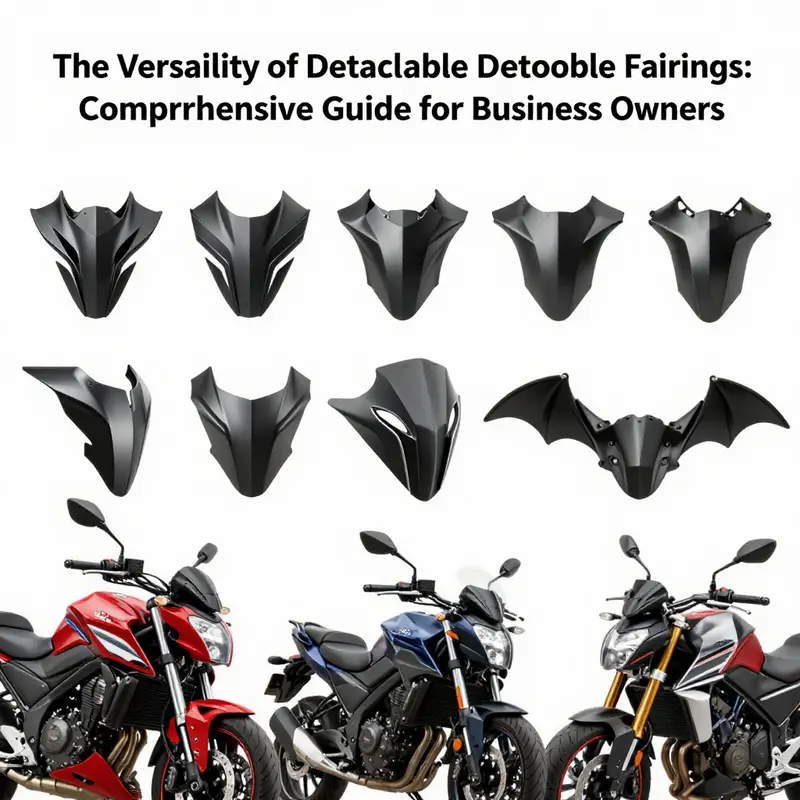

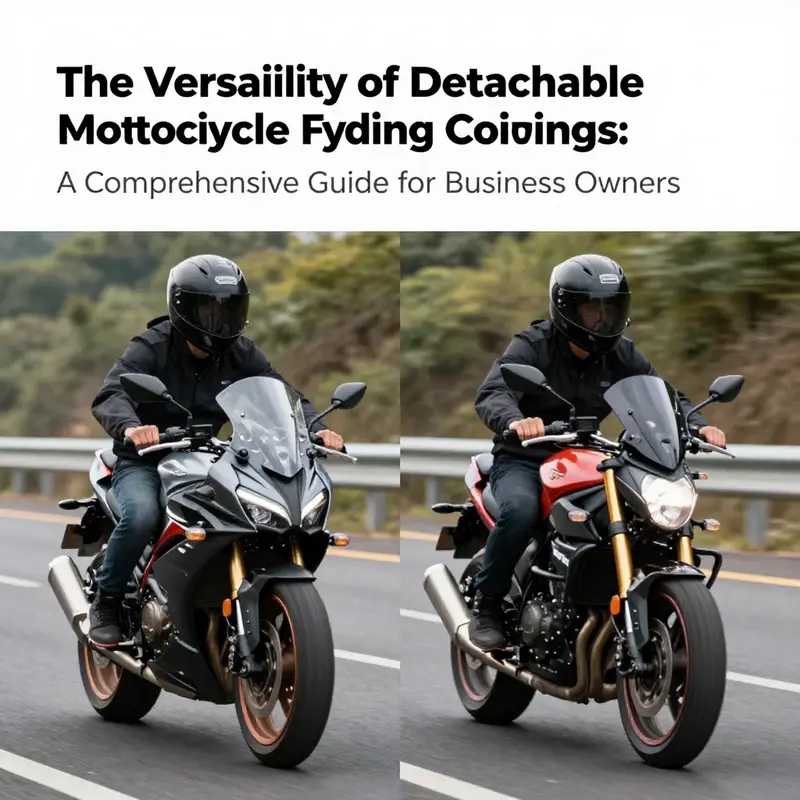

Within that flexible language, three broad families typically recur: full fairings, half fairings, and clip-on or modular configurations. Each type serves its own logical purpose, and the choice among them depends on rider priorities—whether one values comprehensive wind protection, aggressive aesthetics, or the ability to swap components quickly for track days or city riding. A full fairing encloses the front portion from the handlebars down to the engine, delivering the most complete wind block and the most pronounced aerodynamic profile. When correctly fitted and sealed, full fairings reduce fatigue on long rides by smoothing the airflow over the rider’s torso and the motorcycle’s chassis. They also shield sensitive components from debris and weather, which can translate into lower maintenance costs over time and a cleaner presentation for touring or sport-touring setups. Yet the trade-off is weight and the potential for more involved removal during maintenance or tuning, especially if the fairing surrounds complex fairing panels or integrates radiators and ducts that require careful alignment.

Half fairings—often referred to in the batwing configuration—strike a different balance. They cover the upper front end, typically from the handlebars to just above the fuel tank, leaving more of the engine and frame exposed. The result is a leaner, more aggressive silhouette that many riders associate with sport bikes and custom builds. Functionally, half fairings provide moderate wind protection while preserving a greater sense of air intake and cooling awareness. For riders who want the aesthetic edge of a full fairing but crave easier access for maintenance or quicker tire changes, detachable batwings offer a practical compromise. Their modular nature makes it simpler to experiment with different shapes and angles, which can fine-tune handling characteristics without a prohibitive investment in permanent bodywork.

Then there are clip-on or modular fairings, the lightest and most flexible option. These are smaller components that attach close to the handlebars or key frame mounts, sometimes incorporating wind deflectors, mirrors, or integrated lighting. Clip-on assemblies are prized by racers and riders who value precise cockpit geometry and rapid on/off adjustments. The modular approach means a rider can swap out a compact wind deflector for a larger shield, or replace a damaged panel after a track day, with a minimum of disruption to the bike’s overall balance. The downside is that these smaller pieces often need more frequent checks for alignment and fastener tightness, particularly after high-speed riding or aggressive cornering where vibration can loosen clamps and bolts. The key across all three families is that the hardware and mounting strategies are engineered to stay secure at speed while still allowing a clean release when needed.

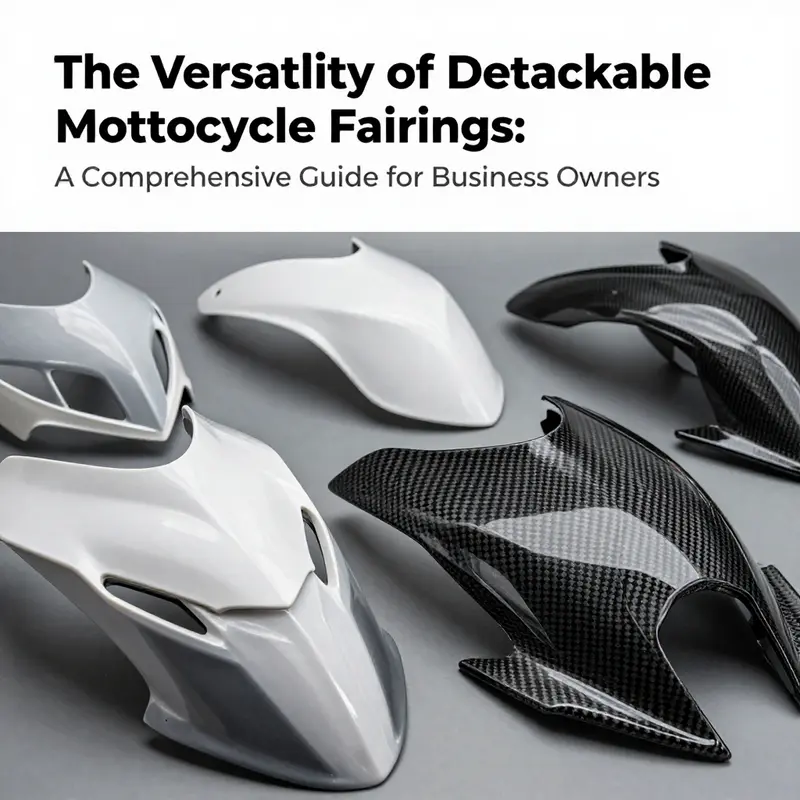

Material choices reinforce the performance differences among these types. Lightweight ABS plastic is common for many detachable fairings because it provides sufficient impact resistance at a reasonable weight, accepts clear coat finishes well, and can be molded into complex lines that echo the bike’s original design language. For riders who chase high-end rigidity and reduced mass, fiberglass and carbon fiber variants are appealing. Carbon fiber, in particular, offers a superior strength-to-weight ratio that can enhance acceleration response and cornering feel, especially on sport and race-inspired builds. But carbon panels can be more expensive and susceptible to UV-related degradation if not properly sealed and treated. The material selection influences more than just appearance; it affects vibration transmission, the ease of alignment during installation, and the long-term durability of the detachables under rock, gravel, and road spray. In practice, a rider might mix materials: a carbon top panel for a racey profile paired with ABS lower sections for rugged durability and easier replacements on rugged commutes.

Installation and removal dynamics are the practical heartbeat of detachable fairings. The goal is straightforward: a user should be able to remove a fairing section, perform routine maintenance, or swap styles within a short window without specialized tools or a full set of jigs. Quick-release fasteners and slide-in bolts are common solutions that support this objective. The fastening system must resist wind pressure at highway speeds, resist vibration, and still offer a clean, weather-tight seal when engaged. Good design also accounts for gaskets and mating surfaces to prevent wind noise, water ingress, and rattling. Precision is critical—misalignment, even by a few millimeters, can create gaps that undermine aerodynamics or lead to uneven panel wear. The best detachable fairings are accompanied by clear fitment guides and robust mounting hardware that remains reliable through repeated cycles of attachment and detachment.

A rider’s choice among full, half, or clip-on fairings is rarely about an isolated feature. It’s about how the whole system harmonizes with the bike’s geometry, the rider’s posture, and the intended tempo of riding. On long touring routes, full fairings can deliver consistent protection from wind shear and weather, helping to reduce rider fatigue and improve fuel economy by stabilizing the air stream. On a weekend sprint through mountain roads, a batwing or half-fairing might offer a sharper silhouette and improved access to the engine for quick tune-ups or mid-ride checks, while preserving enough wind protection to keep comfort levels high. In urban or canyon-carving scenarios, clip-on configurations give a lighter, more modular feel, allowing riders to swap in wind deflection for aggressive riding modes or to remove bulk entirely for a more direct, tactile connection with the machine. The design logic behind detachable fairings is, in essence, to give riders a toolset rather than a single, fixed aesthetic. It invites experimentation, allowing riders to learn how each configuration changes the motorcycle’s balance, how air flows around the rider’s torso, and how the bike responds when the frontal area shifts during lift and dive under braking.

The compatibility story matters just as much as the physical forms themselves. Not every fairing kit will fit every bike, which is why a thoughtful approach to fitment guides, mounting points, and the overall frame geometry is essential. A detachment system must align with the bike’s existing mounting architecture without forcing irreversible modifications. The best modular designs respect the integrity of the frame and the steering head, providing precise alignment references and robust, corrosion-resistant hardware. For riders who own bikes with significant aftermarket support, there are usually multiple pathways to a detachable setup, including panels designed to reproduce the bike’s original aesthetic while offering the convenience of removal. In a well-supported ecosystem, a rider can select among various panels, colors, and textures to tailor the bike’s look to a season, a race event, or a new personal style without altering the fundamental structure of the motorcycle.

The practical search for the right type often goes hand in hand with the rider’s maintenance and service routine. Detachable fairings should not turn routine checks into a scavenger hunt for hidden fasteners. Instead, they should simplify tasks such as valve checks, air filter maintenance, or radiator servicing, by providing ready access to vital components without requiring the entire fairing shell to come off. That ease of access is particularly important for sport-touring and racing-inspired builds, where quick pit-stop style maintenance might be routine. A robust system will also consider weather sealing around removable joints, because rain and road spray can find their way into seams if the panels aren’t tightly sealed. It’s here that the engineering discipline behind detachable fairings becomes most visible: the balance between secure, weatherproof attachment and the freedom to strip away a panel in minutes.

If you’re shopping for detachable fairings, you’ll encounter a spectrum of options that reflect this philosophy. Some kits emphasize a seamless, OEM-like finish, while others celebrate a bold, aggressive silhouette that signals performance. The modular nature means you can experiment—start with a simple half-fairing to test the wind line and cockpit height, then graduate to a full fairing for longer highway runs, or add a clip-on set for track days when you want minimal weight and maximum turn-in response. The market has grown to accommodate a wide range of bikes and riding cultures, with fitment guides and user reviews helping buyers gauge compatibility and quality before purchase. For riders who want a sense of place within a broader ecosystem, the idea of a dedicated fairing category becomes meaningful: it’s a way to maintain a visual thread across a lineup of bikes while preserving the ability to customize or revert to a stock look without a heavy commitment.

For riders who value brand-specific options, the ecosystem often includes dedicated categories that reflect the underlying bike’s design cues. In this context, it can be helpful to explore a bike’s fairing family in a dedicated category, such as BMW fairings. This internal link provides a sense of how manufacturers and aftermarket makers translate a brand’s distinctive lines into detachable pieces that still respect the machine’s geometry and aesthetics. The presence of such curated options underscores a larger point: detachable fairings are less about a single product and more about a modular strategy that honors both performance and style across a spectrum of models.

Looking ahead, the evolution of detachable fairings is likely to emphasize smarter fastening systems, better sealants that resist UV and heat exposure, and more sustainable materials that deliver strength without adding weight. As riders continue to demand adaptability—whether they commute, tour, race, or simply enjoy a changing look—the modular approach will remain central. A well-considered combination of full, half, and clip-on configurations can be tailored to a bike’s natural temperament, letting the rider cultivate a ride experience that remains faithful to the bike’s character while expanding what a single machine can do across seasons and miles. The chapter of detachable fairings is not about choosing one perfect type; it’s about embracing a design language that makes that choice a fluid, repeatable part of the riding journey.

External reading can broaden the concept of selection and fitment. For a broader framework on choosing the right type of fairing, a detailed guide provides useful insights into how different shapes influence airflow, weight distribution, and rider ergonomics. This resource complements the practical, bike-specific considerations discussed here and can help riders translate theory into a real-world setup that suits their riding goals.

External resource for further context: https://www.bikeexif.com/motorcycle-fairings-guide

Materials that Shape Detachable Fairings: ABS, Fiberglass, and the Quiet Edge of Carbon Fiber

The materials chosen for detachable motorcycle fairings do more than determine color and gloss; they dictate how easily a rider can swap skins, how the bike behaves at speed, and how the assembly endures the daily grind of vibration, weather, and the occasional spill. In a modular system designed for quick removal and reattachment, the material must marry form with function: it should be light enough to preserve the bike’s balance, tough enough to resist impact, and stable enough to hold fasteners and clips without sacrificing ease of service. Across the market, the talk centers on a few familiar players—ABS plastic, fiberglass, and, in more exclusive circles, carbon fiber. Each has distinct traits that suit different riding styles, climates, and maintenance habits, and the choice often comes down to the intended use of the bike, the rider’s budget, and the degree to which one values weight savings over impact resistance. ABS plastic stands as the workhorse of detachable fairings. Its appeal rests on a practical balance of strength, flexibility, and cost. ABS, or acrylonitrile butadiene styrene, is notably tough in impact and surprisingly forgiving when it comes to forming complex shapes. The same chemistry that gives it a smooth, shiny surface also makes it forgiving to heat and cold cycles that accompany day-to-day riding. Parts can be thermoformed or injection-molded into sleek, curvaceous profiles that cut a rider’s wind while preserving a curbside appeal that remains easy to repaint and repair. In the context of detachability, these attributes translate into a modular experience: fairings can be snapped on or off with quick-release fasteners or basic bolts without requiring exotic tools or specialized hardware. This is especially important for riders who want to alter the bike’s aerodynamics and protection on a whim—warmer days favor a lighter, more exposed posture, while highway miles benefit from a shield that smooths the wind and reduces fatigue. For many riders, ABS also offers predictable performance in the way it handles mounting points. The material’s surface tolerates repeated removal and reinstallation without developing the microcracks that can plague thinner plastics. Moreover, ABS finishes are highly compatible with standard paint and clear coats, making repairs and color-matching straightforward after hits or scratches. A glossy black finish, often used for detachable fairings, emphasizes the clean lines and modern silhouette of these modular sets while remaining practical in the face of road debris and sun exposure. This practicality—ease of manufacturing, ease of repair, ease of finishing—helps explain ABS’s dominance in detachable systems. It is cost-conscious enough to appeal to a broad spectrum of riders, from casual enthusiasts to those who view their bike as a canvas. Fiberglass represents a step up in durability and rigidity, often chosen by riders who want a more rugged, track-informed profile without resorting to full carbon composites. The material’s high strength-to-weight ratio is a key advantage; fiberglass skins can resist larger deflections and absorb impact energy more robustly than thinner ABS shells. This makes fiberglass fairings attractive for riders who push their bikes into sportier angles or who ride in environments where gravel, curbs, or minor collisions are a realistic concern. However, this durability comes with trade-offs. Fiberglass components tend to be heavier than ABS, and the resin systems used to bind the fibers can add stiffness that, if not properly engineered, translates into a more brittle response under sharp, concentrated impacts. The heavier mass also slightly alters the bike’s unsprung weight and rotational inertia, though in most street applications the difference remains modest. Another consequence of fiberglass is cost and repair complexity. While repairing a fiberglass panel is feasible, it is not as forgiving as ABS when it comes to quick fixes at the roadside or in a home shop. Repairs often require careful sanding, resin absorption, and curing time, which can be a barrier for riders who want an “install-and-forget” solution. Still, fiberglass shines in applications where the rider values a premium appearance and longer service life under demanding use. Its surface can be finished to a matte or high-gloss look, and the material accepts deep, museum-like finishes that can be difficult to achieve with cheaper plastics. For those who seek a balance between performance and aesthetics, fiberglass remains a compelling choice, especially in cases where a modular system must endure frequent removal and reattachment without showing excessive wear at the mounting points. While ABS provides the broadest coverage for mass production and quick-fit schemes, carbon fiber brings an edge that only a few riders will fully exploit. Carbon fiber is celebrated for its exceptional stiffness-to-weight ratio and its ability to create aerodynamically efficient shapes with minimal thickness. In the world of detachable fairings, carbon fiber can yield a dramatic reduction in overall weight, which translates to improved handling and slightly better acceleration characteristics. The downside is significant: carbon fiber sets are expensive, and their production requires specialized processes and skilled labor. The material’s high stiffness can make it more susceptible to surface imperfections that become visible at speed, and repairs—when necessary—can be costly and complex. Some riders also worry about compatibility with standard fasteners and mounting points, as carbon fiber panels can tolerate fastener loads and torque differently than multi-layer plastic shells. Moreover, carbon fiber’s aesthetics are sometimes a matter of taste; the distinctive weave and matte to satin finishes demand a careful integration with the bike’s color palette and line work. In the broad spectrum of detachable fairings, then, the choice of material often boils down to how a rider weighs cost, weight, and durability against repairability and finish. Beyond the primary materials, manufacturers sometimes blend plastics with reinforcing agents or pair ABS with glass fibers or other additives to tailor stiffness, impact resistance, and heat tolerance. These blends can yield a middle ground between the affordability of ABS and the ruggedness of fiberglass, offering a solution that satisfies daily riders who still want a performance-oriented look. The modular reality of detachable fairings places particular demands on every facet of the design. The snaps, latches, and quick-release hardware must work reliably across repeated installations, and the panel edges need to remain intact even after many cycles of removal. Temperature fluctuations during riding can cause differential expansion between the panel and the frame or substructure, particularly where metal hardware meets plastic or composite surfaces. Here, a careful attention to tolerances and mounting geometry becomes crucial. A well-engineered fairing system will use a combination of materials that complement each other: ABS shells for their lightness and ease of repair, fiberglass inserts or reinforcement where strength is needed, and selective carbon fiber elements in areas where heat and load transfer are most critical. The result is a system that preserves the bike’s aerodynamics and wind protection without demanding a permanent commitment from the rider. For those who want to explore compatibility with their existing bike family, a practical route is to browse model-specific or model-family pages where fairings are organized by chassis and year. For hands-on alignment with a specific model, riders often consult dedicated model categories such as the BMW fairings page, which provides a sense of how different materials and designs align with a particular motorcycle’s geometry and mounting framework. BMW fairings offers a glimpse into how a modular system translates into a model-focused lineup, including considerations about fitment, finish, and the relative emphasis on weight, rigidity, and protection.

In practice, the decision about material is rarely about a single factor. It is a balancing act that accounts for how the fairing interacts with the bike’s overall weight distribution, the rider’s riding environment, and the ease with which the panel can be swapped for a different look or a different aerodynamic profile. ABS remains the default for most riders who value broad availability and straightforward maintenance. Fiberglass serves as the preferred choice for those who demand durability and a premium look at a reasonable price, especially in mid- to high-end custom builds. Carbon fiber is a niche, performance-driven option reserved for riders chasing every possible advantage in weight reduction and stiffness, while accepting higher costs and more involved repair work. The modular philosophy behind detachable fairings makes these material choices more consequential, because the way a panel is attached and detached can magnify or dampen the material’s natural strengths and weaknesses. A fairing that is easy to remove but hard on fastener wear ends up being less practical in the long run. Conversely, a panel that resists impact but is stubborn to detach reduces the satisfaction of a customization routine. The optimal approach is to view material selection as part of a holistic system: form, function, and freedom all aligned to deliver a riding experience that is as adaptable as the rider’s intentions for the bike.

External resource: https://en.wikipedia.org/wiki/ABS_(plastic)

Modular Armor for Changeable Roads: Installing and Maintaining Detachable Motorcycle Fairings

Detachable motorcycle fairings are more than a cosmetic upgrade; they are a modular approach to riding that lets a rider adapt the bike to wildly different conditions without committing to a single configuration. When you choose a fairing system designed for quick removal and reattachment, you’re choosing a workflow as much as a look. In practice, the modular approach translates into a bike that can shed windshields and bulky panels for a lighter, more maneuverable feel on warm days, then return to full wind protection and aero efficiency for long highway miles. The value here lies in harmony between components and rider intent: the chassis, mount points, and the fairing panels must work together so that installation is straightforward, and maintenance remains predictable over time. This chapter examines how that harmony is achieved in real-world terms, focusing on compatibility, hardware, choice of fairing styles, mirror integration, and the ongoing care that keeps detachable systems safe at speed and reliable across seasons.

Compatibility starts where it all begins: with fitment. A detachable system is only as good as its compatibility with the motorcycle’s frame, subframes, and handlebar or steering assembly. The mounting philosophy behind these systems uses a combination of brackets, spacers, and guides that are designed to locate panels at precise angles while allowing for quick detachments. The first step for a rider is to verify that the chosen fairing set aligns with the bike’s mounting geometry and does not interfere with the operation of other components, electrical connections, or sensors. This is not a cosmetic decision but a structural one. When compatibility is uncertain, consulting the installation instructions and seeking guidance from an experienced technician is prudent. The wrong hardware or an ill-fitting bracket can create gaps, introduce vibration, or even loosen under high-speed wind.

Alongside fitment, hardware integrity matters just as much. A legitimate detachable system should include a complete hardware kit: mounting brackets, spacers, and a detailed installation guide. Each piece is engineered to distribute loads across the bike’s frame and fairing attachment points, reducing the risk of stress concentration that could crack a panel or strip a fastener. The hardware is designed to withstand typical vibrations and the occasional rough road surface, but it also depends on correct torque application. Riders should treat the fasteners with appropriate tightening procedures and, where recommended, a light threadlocker to maintain retention without resisting future removal. In practice, this means checking the torque specs, ensuring that quick-release mechanisms engage cleanly, and inspecting brackets for signs of wear or bending after intense riding or accidental impacts.

The spectrum of detachable fairings is broad, from full fairings that envelop the rider in a protective shell to half or quarter configurations that emphasize accessibility, lighter weight, and a sportier silhouette. Full fairings maximize aerodynamics and wind protection, making them popular for long-distance highway cruising and high-speed stability. Half fairings strike a balance, offering substantial wind reduction while preserving greater access to the engine and cockpit for maintenance or styling changes. Quarter fairings provide minimal coverage, which can be appealing for riders who prioritize a naked-bike aesthetic or who need unobstructed access to front-end components. Beyond these standard categories, aftermarket fairings offer customization that tailors protection, weight, and appearance. The material choice—ranging from reinforced ABS to composites such as fiberglass or carbon fiber—also dictates durability, impact resistance, and weight, which in turn influence handling characteristics and performance feel. When evaluating options, a rider should weigh the climate, typical riding speeds, and the level of protection desired against the added weight and potential maintenance demands.

Integral to the look and function of detachable systems is how mirrors are carried. Some fairing configurations include mirror mounts designed to maintain visibility while preserving the clean line of the panel. These integrated mounts can help minimize vibration and flutter while providing stable sightlines. Costs for mirror mounting solutions vary, reflecting differences in design complexity and materials. A careful assessment should consider not only the upfront price but how the mirror placement affects aerodynamics, field of view, and ease of disassembly when you switch between configurations. The goal is a cohesive package in which the mirrors remain secure and stable, even as the fairing panels are removed and reattached during routine maintenance or quick swap sessions on the roadside.

If you’re contemplating the installation process, the idea of a staged approach is useful without turning the discussion into a shopping list. Begin with a clean bike and a dedicated workspace that allows you to reassemble panels without marring paint or chrome. Remove any existing body panels in a controlled sequence to expose the frame mounting points. The next step is to set the new brackets in place, align the spacers so that the panels sit flush against the machine’s lines, and loosely fit the fasteners to verify alignment. With the fairing panels hung in place, you can check for clearance around the handlebars, the throttle, and any electrical harnesses. Only when alignment looks even and the gaps are symmetrical should you move to the final tightening phase. Torque should be applied in stages, following the manufacturer’s specifications, to avoid stressing an attachment point or distorting the panel edge. As panels are secured, it’s wise to test the system by lightly moving the bike and simulating edge loading in a controlled space; if anything binds or seems out of plane, it’s a signal to recheck the mounting geometry and perhaps revise the spacer arrangement.

Beyond installation, the maintenance routine for detachable fairings is a discipline in preventative care. Regular inspection is essential because UV exposure, temperature swings, and road debris can degrade both the panel surface and the mounting hardware. Look for cracks, warping, or fading on the fairing skins, and examine the edges where panels meet for chips or micro-delaminations that can expand with temperature cycles. Cleaning should be gentle and consistent, using mild soap and water and avoiding harsh solvents that can crack or dull finishes. While cleaning, inspect every fastener and bracket. Tighten any that have loosened from vibration and replace any that show signs of fatigue. If a bolt head has worn flats or threads appear stripped, the prudent choice is replacement rather than forcing a joint back together. UV exposure, moisture intrusion, and occasional impacts are invisible threats that accumulate over seasons, so a scheduled checkup—annually or after a season of heavy riding—helps catch issues before they become safety concerns.

The rider who values performance and longevity will also pay attention to alignment after each reinstall. A misaligned panel can not only look off but can also alter airflow and create unintended turbulence around the front of the bike. Realign the panels with care, ensuring uniform gaps and consistent contact with mounting points. A common trap is overtightening panels to compensate for back-and-forth fitment; this can warp the fairing edge or stress a mounting bracket. If you notice flutter at speed, recheck the bracket geometry and the fit of the panel against the frame. In cases where quick-release mechanisms are used, ensure they engage firmly and that the release lever seats completely into its housing when the panel is in place. A secure detachment could be a matter of a fraction of a turn, but that small movement matters a lot when you’re riding at highway pace.

Most manufacturers encourage riders to consult official installation guides and maintenance schedules. These documents—crafted to address model-specific interfaces, tolerances, and safety notes—offer the most reliable path to keeping a detachable system safe and functional. If you’re unsure about a step or encounter a conflict with wiring, fuel lines, or a cooling duct, seek professional assistance. An authorized technician can verify mounting geometry, test fitment under load, and confirm that the installation does not compromise electrical or cooling performance. Even with a solid skill set, the complexity of modern motorcycles means a second set of eyes can prevent mistakes that would be costly to rectify later. The aim is not to rush but to ensure a stable platform that preserves rider confidence across weather and miles.

For readers exploring the available styling and fitment options, a quick glance at current catalogs can be instructive. A catalog listing new products for 2023 showcases the range of detachable configurations and the evolving approaches to weight, strength, and aerodynamics. You can explore this curated set of options here: 2023 new products. This link offers a sense of how designers balance practicality with aesthetics while preserving safe mounting and maintenance workflows. The broader takeaway is that detachable systems succeed when they respect the bike’s core architecture and the rider’s need for flexibility, not when they aim to replace the bike’s fundamental design. The best setups feel invisible in operation—easy to attach and detach, smooth in wind noise, and predictable in how they interact with the bike’s balance at speed.

As you build your knowledge of installation and maintenance, keep in mind the broader ecosystem of resources that support safe aftermarket modifications. Official maintenance schedules, installation guides, and troubleshooting tips provided by the manufacturer remain the most dependable references. They help ensure that your detachable fairing system stays aligned with the bike’s structural design, and that your safety margins stay intact whenever you ride. While this chapter emphasizes hands-on steps and practical checks, the underlying principle is steady, deliberate care. A well-installed, well-maintained detachable fairing enhances aesthetics, adds comfort, and preserves performance, turning a modular accessory into a reliable extension of the bike’s identity. And when in doubt, a qualified technician is always a prudent ally in keeping the riding experience as safe as it is enjoyable.

External resource: https://www.harley-davidson.com/en_US/accessories.html

Advantages of Detachable Motorcycle Fairings Across Riding Conditions

Detachable motorcycle fairings act as a modular interface between rider, bike, and environment. They enable quick adaptation to weather, road texture, and riding discipline by allowing selective removal or swapping of panels. In urban riding, removing lower sections or side panels reduces weight and wind resistance, improving handling and reducing heat buildup around the engine bay. Access to critical components becomes easier for maintenance without disassembling the entire shell, which saves time in service scenarios. Reattachment restores full protection and aero stabilization for higher speeds or rain exposure. For long-distance touring, the option to strip down for light wind at highway speeds enhances efficiency, while reattaching the fairing during foul weather increases rider comfort and component protection, especially around the radiator and electronics. When track or high-speed riding is on the agenda, modular shells can be swapped for full race configurations to maximize downforce, brake cooling, and airflow management, then swapped back after sessions for street reliability. Material choices (ABS, fiberglass, carbon fiber) influence durability and weight, but the core principle remains: secure, repeatable attachment points and intuitive latching ensure safety at speed. Maintenance routines benefit from quick-release hardware, enabling inspections with minimal tools and downtime. The ecosystem around detachable fairings—fitment guides, community-driven recommendations, and standardized mounting—supports customization while keeping a consistent core geometry. In sum, detachable fairings provide a practical, scalable way to tune aero, protection, and usability as conditions evolve across city streets, long roads, and race days.

Adaptive Armor on Two Wheels: Detachable Fairings as a Mirror of Personal Style, Performance Demands, and Market Evolution

Riders have long treated the fairing not as a mere shield against wind but as a modular extension of their intent, mood, and riding environment. Detachable fairings exemplify this shift toward adaptive design, where the same motorcycle can transform from a wind-sculpted highway tool to a lean, airy machine suited for tight urban maneuvering or warm-weather jaunts. The appeal lies in the ease of reconfiguration: a few quick-release fasteners, bolts, or clips, and the silhouette, weight distribution, and wind management can be rebalanced to match the ride. This isn’t about a rigid, one-size-fits-all shell; it is about a system that invites riders to curate their machine in response to climate, terrain, and personal preference. The result is a motorcycle that feels less like a fixed object and more like a flexible platform that echoes the rider’s evolving needs and tastes.

The market’s growing appetite for modular components sits at the intersection of customization, performance optimization, and experiential riding. In the broader ecosystem of aftermarket parts, detachable fairings have found a premium niche among enthusiasts who demand both form and function without the permanence of a factory-specified silhouette. This trend toward personalization is not happening in a vacuum. It is reinforced by a consumer culture that increasingly equates vehicle components with identity—paint, texture, line, and fit all becoming visible statements of who the rider is and how they want to ride. In a landscape where style and performance are inseparable, modular fairings offer a pragmatic path to experimentation. Rather than committing to a single look or aerodynamics package, riders can assemble configurations that respond to a season, a tour route, or even a mood for speed on a mountain pass.

From a materials perspective, the spectrum ranges from lightweight ABS plastic to high-performance fiberglass and carbon fiber composites. Each material brings its own balance of strength, stiffness, weight, and cost. ABS is forgiving and economical, supporting mass customization and rapid prototyping. Fiberglass offers a middle ground with good shaping and durability, while carbon fiber delivers an elite strength-to-weight ratio that racing-oriented riders prize. The choice of material subtly reshapes performance: a lighter fairing can reduce unsprung weight and angular inertia, improving handling during quick transitions; a stiffer, better-sealed shell can deliver steadier airflow at speed, reducing buffeting and rider fatigue. Yet the conversation remains grounded in practicality. A detachable fairing must remain securely attached at highway speeds, resisting vibration, gusts, and the occasional lane-change maneuver, while still offering straightforward removal for maintenance or different weather conditions. The design challenge is to harmonize ease of use with secure retention, ensuring that modularity does not come at the expense of safety or reliability.

Within this design milieu, the common configurations—half, full, and batwing fairings—each have a cadence and purpose that influence rider choice. Half fairings provide a lighter, more exposed ride, inviting a sense of freedom in warm weather or spirited urban riding. Full fairings, by contrast, frame a more enclosed aerodynamic profile and wind protection, simplifying fatigue over long days on the highway. Batwing fairings, with their classic silhouette, offer distinctive aesthetics and air management characteristics that appeal to riders seeking retro flavor without sacrificing modularity. In detachable versions, these form factors maintain their essential lines while granting the flexibility to shed weight or modify the wind shield on demand. Such versatility aligns naturally with how riders actually use their machines: not all rides require the same wind protection or the same level of enclosure, and the ability to tailor those conditions quickly is a compelling benefit.

As with other segments in the premium and enthusiast tiers of motorcycling, the integration of technology and safety features is shaping the future of detachable fairings. Even though the current landscape emphasizes mechanical ease and material innovation, the longer horizon points toward smarter, more integrated solutions. Phase-change materials (PCMs) are cited in adjacent apparel and protective gear markets as a benchmark for thermal comfort, with penetration expected to rise markedly in the near term. The idea of combining smart materials with detachable aerodynamic panels is intriguing: a fairing that adapts its thermal management or microclimate in response to ambient temperature or airflow could offer riders a more comfortable experience without added bulk. Similarly, the trajectory of connected, intelligent clothing—aimed at improving rider awareness and safety—suggests a future where fairings themselves may incorporate lightweight sensors, communication systems, or adaptive lighting to improve visibility and situational feedback. While the data on smart fairings remains emergent, the underlying pattern is clear: performance and comfort are increasingly delivered not only through shape and materials but also through intelligent, interconnected components.

The American market remains a crucial engine for growth in detachable fairings. With more than 8.8 million registered motorcycles, the space is characterized by a diverse rider population that values both safety gear and aftermarket customization. The aftermarket ecosystem thrives on this diversity, offering a wide range of options to suit varied riding styles, climates, and aesthetic preferences. The scale of the market, coupled with a strong culture of modification, creates fertile ground for modular fairings to flourish. Riders in the United States are not seeking a single, permanent answer; they want a toolkit—an array of attachments and configurations that can be swapped in and out as their rides evolve. In this context, detachable fairings are not merely accessories; they are a language through which riders articulate how they intend to use their machines in different environments and moments.

The way consumers buy these components also signals a broader shift in the distribution of aftermarket parts. E-commerce dominates the sales channel for motorcycle fairings, with marketplaces and direct-to-consumer platforms shaping consumer expectations around selection, price, and delivery speed. Buyers increasingly expect reliable fitment guidance, transparent reviews, and quickly fulfilled orders. This environment rewards sellers who can provide exact fitment data, robust return policies, and authentic, test-proven parts that guarantee a secure attachment under high-speed conditions. Logistics have become a strategic differentiator; overseas warehouses enable faster fulfillment and responsive service, which in turn bolsters buyer confidence in a crowded marketplace. The net effect is a more dynamic, globalized supply chain where customers can access a broad spectrum of detachable fairing options without sacrificing assurance around quality and compatibility.

For readers exploring the latest in modular styling and wind management, a practical entry point is the 2023 new items category, which aggregates contemporary designs and innovations in detachable fairings. This page acts as a compass for those who want to compare form and function across recent releases, while still preserving the core value proposition of modularity: personalizing the ride without committing to a single configuration for the life of the motorcycle. See the 2023 new items category to sample how designers are balancing weight, aerodynamics, and ease of installation in ways that echo the broader market shifts described here. 2023 new items category

The chapter’s arc—of customization, technology, and logistics—maps onto the broader narrative of detachable fairings as a reflection of rider identity and market forces. Riders are no longer choosing between aesthetics and performance; they are integrating both through modular concepts that respond to weather, terrain, and personal preference. Brand distinctions fade into the background as the real differentiators become fit, finish, durability, and ease of use. This is not passive consumer behavior; it is a design philosophy that treats the motorcycle as a living platform, capable of evolving with its owner. As manufacturers and manufacturers’ partners invest in better fitment guides, stronger attachment mechanisms, and more durable materials, the threshold for safe, repeated removal and reattachment continues to rise. The result is a marketplace where customization is less a luxury and more a practical standard for riders who demand both control and creativity on the road.

In closing, detachable fairings illustrate how an ostensibly simple modification can serve as a microcosm of a larger pattern: riders seeking individualized experiences anchored by performance, safety, and reliability. The market responds with modular systems that respect the rider’s need for change, while suppliers optimize for the realities of online shopping, cross-border fulfillment, and evolving materials science. The chapter’s current snapshot—driven by customization, material choices, and the growing influence of smart design—points toward a future where detachable fairings are not just accessories but integral tools for shaping every ride. External research on broader export trends reinforces how this ecosystem is expanding in a global marketplace that values speed, trust, and versatility as much as style. For a broader industry perspective on how online marketplaces reshape availability and buyer confidence in aftermarket parts, see the external resource: https://www.ebay.com/press/2026-motorcycle-parts-export-trends

Final thoughts

Understanding detachable motorcycle fairings is essential for business owners looking to tap into the growing aftermarket industry. By recognizing the different types available, the varied materials used, and the installation and maintenance processes, businesses can better serve their customers. The advantages offered by these fairings can significantly enhance a rider’s experience, especially in diverse riding conditions. Additionally, staying updated on market trends and customer preferences will enable business owners to make informed decisions about product offerings and marketing strategies. Embrace the versatility of detachable motorcycle fairings to elevate your business in the motorcycle accessory market.