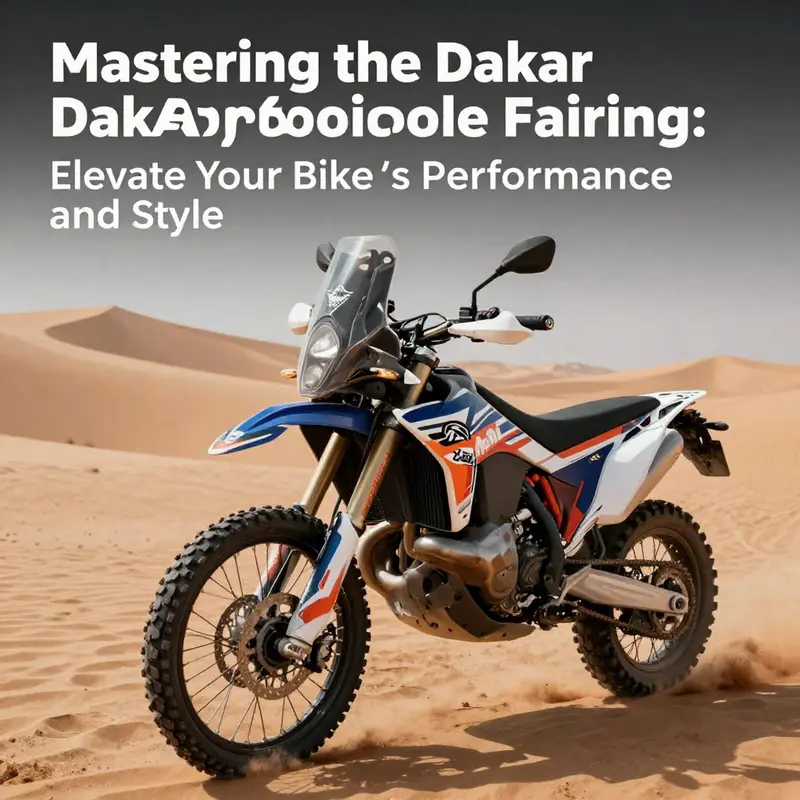

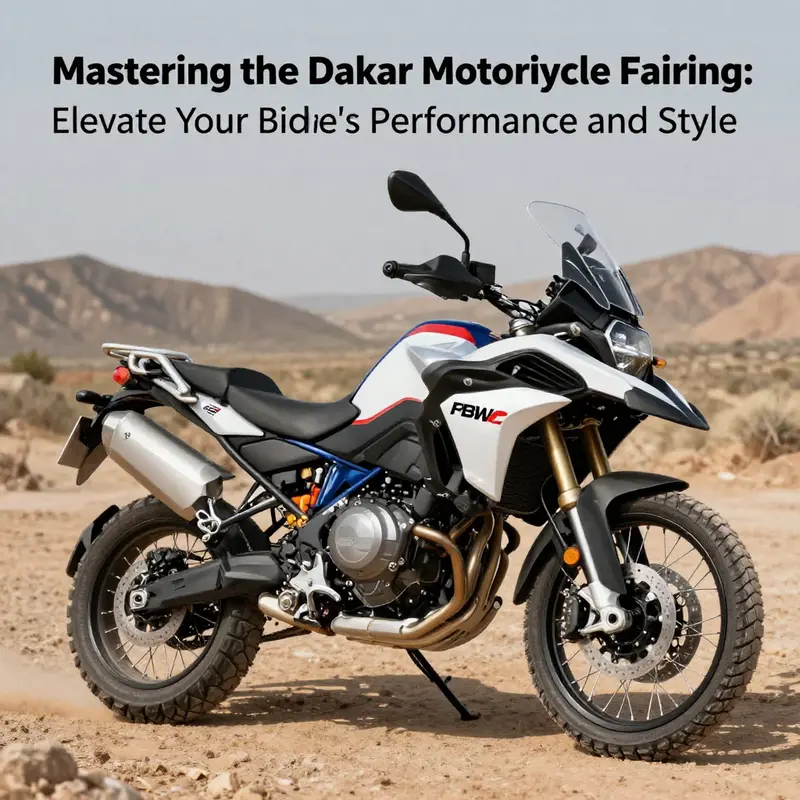

The Dakar motorcycle fairing is not just an accessory; it is a fundamental upgrade for many riders seeking improved performance and style. Especially relevant for models like the BMW F650GS Dakar and G650GS Sertão, these fairings incorporate advanced aerodynamic features while providing the rugged aesthetic that embodies the spirit of the Dakar Rally. This article will delve into four key areas: how these fairings enhance aerodynamic performance, their adaptability and customization potential, their role in rally styling, and the current market trends affecting their availability. Together, these chapters will illustrate the importance of Dakar motorcycle fairings as essential components that can significantly impact a business’s product offerings in the motorcycle aftermarket segment.

Rally Silhouettes: Aerodynamics, Protection, and the Dakar-Influenced Fairing

The Dakar Rally is a test not just of rider stamina, but of how a machine slices through air, dust, and a shifting horizon. In this harsh theater, the motorcycle fairing becomes more than a cosmetic shell; it is a carefully crafted interface between machine and environment. A Dakar-inspired fairing embodies a philosophy that blends rugged endurance with a pared‑down, race‑ready silhouette. It aims to manage the tempo of airflow around the rider, shield vital components from grit and debris, and present a visual statement that echoes the grit of the rally itself. Even without formal wind tunnel data dedicated to Dakar challenges, riders and builders intuitively recognize that shaping the front of the bike can influence stability at speed, reduce fatigue, and improve confidence on long horizons of heat, sand, and dust.

In practice, the fairing serves a triad of functions. First, aerodynamic efficiency is pursued by sculpting the air path so that the rider experiences less buffeting and the machine remains predictable at speed on open desert flats. Winglets and lobe-like extensions are not merely flashy add-ons; they are small, focused tools. They coax air to travel along surfaces rather than collide with the rider’s torso, and they create subtle vortices that help keep the front end steady as the wind shifts from quartering gusts to straight-ahead blasts. This is especially relevant on rallies where sections stretch into hundreds of kilometers of straight line running, and even small gains in stability can translate into steadier handling and reduced fatigue for the rider over multi-day stages.

Second, protection is a foundational concern. Desert environments throw rocks, grit, and brush at speed. A well‑designed Dakar-inspired fairing covers more of the vulnerable heat exchangers, wiring, and critical junctions than a minimalist shell would. It acts as a shield for radiators, wiring looms, and the cockpit, while still allowing quick access for maintenance between stages. The protective logic extends to headlight guards, lower belly guards, and pump protectors—equipments that became popular not as fashion statements but as practical safeguards against the kind of debris that can transform a routine ride into a roadside repair job. The same protective logic informs mounting points, attachment durability, and finish choices that resist cracking and impact damage without becoming brittle in extreme sun or dusty abuse.

Third, the fairing carries a deliberate aesthetic. Dakar styling signals an identity: it says that the rider does not merely commute; they participate in a tradition of endurance, of weathering long distances with a sense of purpose. The look is unapologetically rugged, with a geometry that echoes the lines of rally motorcycles yet remains adaptable to a wide range of adventure and dual-sport machines. This visual language matters not only to enthusiasts who want their bike to exude a rally vibe, but also to builders who use it as a bridge between function and form. The result is a bodywork palette that ranges from clean, race-inspired profiles to more complex, multi-piece assemblies designed to be retrofitted onto existing platforms. The common thread is a fairing that communicates resilience while offering practical improvements in daily riding, touring, and off-road abuse alike.

Designing for the Dakar mindset means embracing a balance between openness and coverage. Exposed radiators, exposed handlebars, and exposed cables may be lighter and easier to service, but they invite heat, dust, and damage to sensitive components. A well conceived fairing minimizes drag without leaving the rider exposed to the windblast that can accompany a fast desert cross. Every edge, intake, and curve is a negotiation: reduce drag and buffeting, protect internals, and maintain access for maintenance while still delivering a coherent, rally-inspired silhouette. The outcome is not a single perfect shape but a spectrum of configurations that can be tailored to the rider’s priorities, weather conditions, and the specific demands of a route. That is why the aftermarket ecosystem surrounding Dakar-style fairings remains diverse, offering options that can be tailored to different models, climates, and budgets.

To understand how this translates in real-world terms, consider how airflow interacts with a rider seated in a forward-leaning position. The rider’s torso disrupts a portion of the boundary layer—a thin veil of air hugging the bike—and this disruption can cause a cascade of pressure differences along the fairing’s surface. A well shaped fairing helps keep the boundary layer attached longer, smoothing transitions from the nose to the sides and toward the rider’s chest. When airflow adheres more cleanly to the surface, the rider experiences less turbulent pressure against the chest and arms, which in turn reduces fatigue over thousands of kilometers of desert, gravel, and pavement. It also helps with heat management by guiding warm air away from the rider’s torso and toward exhaust paths or ventilation cutouts that are designed to work with the overall geometry.

Aesthetics aside, the materials chosen for Dakar-inspired fairings reflect a practical calculus. Carbon fiber remains a favored material for many builders because of its high strength-to-weight ratio and stiffness. Lightweight composites help preserve handling and reduce the unsprung load that can affect suspension behavior and steering feel. But carbon fiber also raises considerations about impact resistance, repairability, and cost. Fiberglass or composite blends offer more forgiving impact performance and easier repair for riders who ride aggressively off-road or who frequently bend fairings during a rally’s rocky stretches. The choice of materials thus becomes a dialogue between lightness, durability, and the realities of maintenance between stages. The final assembly often encompasses a combination: a carbon or composite shell with reinforced mounting points and strategically placed impact shields to absorb energy where hits are most likely.

The installation journey for a Dakar-inspired fairing is itself a story of craft. The goal is a seamless look that appears factory‑like, but the path to that finish requires careful alignment, fitting, and paint matching. Because many of these wings, chin sections, and side panels are designed to adapt to a family of platforms rather than a single model, some trimming and reshaping can be necessary. The fitter must consider gaps, alignment with the tank, and the intersection with the windscreen. A misalignment can ruin both the aerodynamics and the visual harmony that rally-inspired styling seeks to convey. The process often includes precision trimming, careful smoothing to eliminate sharp threadlines, and a paint job that not only matches but reinforces the intended rugged identity. The result is a cohesive surface that hides the joints and reinforces the perception of a purpose-built machine rather than a modification.

The broader ecosystem surrounding these fairings testifies to a community that places equal emphasis on performance and aesthetics. Riders who lean toward authentic rally styling often seek not only the fairing but a matching suite of protective and functional accessories. Headlight guards and pump protectors, for example, appear in many riders’ gear kits because they address real-world threats in rally-style riding. The combination of protection with aerodynamic shaping is what enables a rider to tackle long gravel downs or dune sections with a steadier hand and a steadier heart. It is this blend that keeps the Dakar story alive on modern street bikes and dual sports alike, turning a weekend ride into a narrative of endurance and capability.

Within this context, the option to explore a broader spectrum of fairing shapes becomes meaningful. A rider may choose a minimalist approach that preserves the bike’s original silhouette, or they may opt for a more aggressive, fully faired stance that channels the rally spirit. Either path benefits from a sensibility about maintenance and serviceability, because rally-grade gear must perform under strain and still be repairable in the field or back at base camp. The logic is not merely about speed or wind drift; it is about reliability, comfort, and the confidence that comes from knowing the bike is protected from the dust of remote stretches while presenting a controlled, predictable aerodynamic profile.

For riders curious about the breadth of options, the following resource category offers a look at various fairing styles that can complement Dakar-inspired aims. The range includes configurations designed to integrate with existing lines while preserving function and access. It is worth noting that while some configurations are quite model-specific, others are adaptable with trimming and finishing to achieve a factory‑like finish. The key is to balance coverage with accessibility, to preserve service intervals, and to maintain the rider’s sense of control, no matter the terrain.

To see how designers and builders approach these decisions across platforms, enthusiasts can explore a broader catalog of fairing styles and their fitting considerations. For those seeking a concrete model of the approach, a closer look at the BMW fairings category reveals how different shapes and lines can pair with rally-inspired aesthetics while preserving essential performance characteristics. This example illustrates the principle that a single design language — defined by a sense of purpose, responsibility for protection, and respect for airflow — can translate across bikes and riding styles. It is this continuity that makes Dakar-inspired fairings more than a niche accessory; they are a philosophy of engineering that appreciates the desert as a testbed for efficiency, durability, and identity. BMW fairings provide a concrete window into how these principles materialize in the wild, offering a sense of scale for what is possible when form and function converge.

In contemplating installation and usage, riders also weigh the trade-offs between airflow optimization and heat management. The desert sun beats down, heat climbs from the engine, and air must be moved efficiently not only around the rider but through the radiators and engine bay. An effective fairing design helps guide air toward the radiators while shielding the rider from the majority of direct wind pressure. Yet the rider must still feel connected to the bike’s dynamics; an overbearing fairing can create an artificial wind pressure that makes the bike feel less responsive in tight corners or rough, off-camber sections. Consequently, many builders favor a modular approach, where fairings can be added or removed with relative ease to adapt to the conditions of a particular rally stage or a weekend ride. The ability to tailor the footprint of the front end without sacrificing structural integrity becomes a practical virtue when a rider moves between dusty backroads and highway stretches.

The discussion above points to an underlying truth: while the Dakar Rally supplies a dramatic backdrop, the core ideas behind the Dakar-inspired fairing are broadly applicable. Any rider who spends long hours in exposed environments — whether cross-country travelers, adventure riders, or desert racers — can benefit from a fairing that respects air flow, shields important components, and communicates a rally‑ready personality. The fairing becomes a partner in the ride, not an ornament, and the rider gains a degree of control that translates into steadier handling, reduced fatigue, and a sense of preparedness that makes every mile feel purposeful. The narrative of these components is thus not about a single shape or a single achievement, but about a philosophy of construction that treats air as a collaborator rather than a force to be merely endured. In that sense, the Dakar-inspired fairing is a living bridge between rally heritage and everyday riding, a testament to how design can translate the grit of a desert crossing into the predictable, confident motion of a well‑prepared machine.

External reference: https://www.aliexpress.com/item/1005002839472898.html

Rally-Derived Armor: Adaptability and Personalization of Dakar-Style Motorcycle Fairings

Rally-inspired fairings sit at a fascinating intersection between function and form. They emerge from a lineage of endurance racing where riders press on through dust, heat, and shifting light, relying on every aerodynamic edge and every protective shield their bike can offer. In the context of the broader topic of Dakar motorcycle fairing, these shells are not merely cosmetic upgrades; they are statements about how riders want to engage with their machines when the road turns rough or the weather turns hostile. The Dakar-style fairing, with its distinct silhouette and its promise of practical benefits, has become a versatile aftermarket choice that can transform a wide range of motorcycles into candidates for long-haul exploration or competitive riding, depending on how they’re mounted, trimmed, and finished. The core appeal rests on a blend: a modular design that invites adaptation, and a design language that communicates endurance and grit even when the bike remains street-legal and cleanly styled for daily use.

At its most practical level, Dakar-inspired fairings are engineered to improve aerodynamics and rider comfort. The bodywork is shaped to deflect wind, reduce fatigue, and manage turbulence around the rider’s torso and arms. The aerodynamic punch comes not from a single feature but from a constellation of design choices: smoother transitions around the cockpit, carefully sculpted side panels that streamline flow without obstructing control inputs, and a windscreen that blends protection with visibility. These principles clearly recast a sport or adventure bike’s line into something more purpose-built for long hours on uneven surfaces, where wind pressure can sap strength and visibility can waver. Yet the same features that reduce wind resistance also contribute to a more controlled ride, where aggressive accelerations or sudden changes in direction are easier to handle because the rider and the machine move as a coherent unit with less air-driven wobble.

What makes Dakar fairings particularly compelling is their adaptability. They are often designed as modular systems, giving riders the choice to mix, match, and tune according to the bike they ride and the conditions they expect. A modular approach means components such as winglets, side panels, and mounting brackets can be swapped or adjusted. Adjustable winglets, for instance, provide a way to fine-tune the aerodynamic balance. Depending on riding style or terrain—high-speed highway swoops, loose gravel, or a steep climb through wind—these small surfaces can alter how air is directed around the fairing and around the rider’s torso. For the seasoned rider, the ability to tailor these elements means the bike can feel more responsive in track-like turns or more stable when negotiating a bumpy straightaway. The beauty of this modular logic is that it frees the rider from a one-size-fits-all approach and invites experimentation within safe, repeatable parameters.

Another cornerstone of adaptability lies in the universal mounting brackets that accompany many Dakar-inspired fairings. These brackets are not passive fasteners; they are the interface through which a fairing can be coaxed to fit a variety of frames and handlebar geometries. In the hands of a skilled technician, these brackets become an enabling technology. They accommodate small variances in frame alignment, fairing width, and even cable routing under the dash. The result is a finished appearance that looks factory-like, with clean gaps, tight seams, and consistent lines where the fairing panels meet the tank and the headlight cluster. The ability to adapt, trim, and repaint is what makes these fairings attractive beyond strictly racing contexts. For riders who want a Dakar-inspired look without compromising street legality or daily usability, this flexibility is essential.

With adaptability comes the practical matter of fitment. Compatibility confirmation is not a mere checkbox; it is a critical step in ensuring the fairing serves its aerodynamic goals rather than undermines them. Even small differences in frame geometry, steering-head angles, or handlebar position can change how a fairing aligns with the rider’s line of sight or how it interacts with the radiator, headlight, and turning signals. Rivet lines and mounting points that seem to align on a showroom tailpiece may shift once the fairing is brought near a different engine cradle or a different subframe. This is why many riders begin with manufacturer specifications or compatibility checkers offered by reputable aftermarket suppliers. The careful comparison of measurements—wheelbase length, dash height, bar clamp spacing, and the distance between mounting bosses—helps prevent misfit, which can lead to vibrations, wind noise, or even safety concerns if a panel interferes with steering or cable movement.

The design intent behind these fairings often includes a balance between performance and aesthetics. The Dakar ethos is as much about endurance and resilience as it is about speed. Consequently, the visual language of the fairing tends toward rugged, rally-inspired lines that communicate readiness for rough terrain. The result is a shell that not only reduces wind pressure but also signals to onlookers a rider’s affinity with an adventurous discipline. For many, the appeal goes beyond speed and protection; it is a way to forge an identity on the bike, to echo the uncompromising spirit of the rally. Custom painting becomes a natural extension of this identity, transforming a practical shell into a personal statement. In practice, this often means color matching, careful edge finishing, and the choice to retain or alter gloss, satin, or matte finishes so the fairing harmonizes with the bike’s tank and seat geometry. The interplay between protection and personality is where the Dakar fairing gains its most durable value: it is as much about how the bike looks as how it performs.

The aftermarket ecosystem surrounding Dakar-inspired fairings reflects a broader trend in motorcycle customization. Riders are not simply buying a shell; they are curating a system that can incorporate additional accessories and protective measures. It is common to see compatibility with a range of auxiliary components—air filtration upgrades, protective tubes, headlight guards, and shielded cable routes—so the bike can venture beyond smooth pavement without inviting needless damage. In practice, this means the fairing acts as a hub for a suite of protective and performance-oriented parts. The integration process requires planning: where will the air intake route through the new geometry? Will the radiator be shielded enough without impeding airflow? How will the headlights and indicators be re-seated to preserve visibility and legal compliance? Answers come not only from the fairing’s own engineering but also from the installation practices and finishing touches performed by professionals or seasoned enthusiasts who understand the delicate balance between aesthetics, aerodynamics, and rider comfort.

Aesthetic and functional thinking also extends to maintenance and longevity. The reflective surfaces, the joins between panels, and the paintwork all demand routine care if the fairing is to maintain its factory-like finish over time. Trim work may involve removing burrs and smoothing edges to reduce wind noise, while paintwork requires attention to UV exposure and stone chipping on off-road sections. Protective films and careful masking during long rides help preserve the gloss and preserve edge lines. This ongoing care underscores a broader truth: customization is not a one-off purchase but a dialogue between rider, machine, and environment. Each ride teaches a lesson about air management, ergonomics, and the durability of the installed panels. With that knowledge, a rider can revisit winglet angles, adjust mounting tension, or refine the color scheme to keep the bike looking as purposeful as it feels when the throttle is twisted wide.

To illustrate the practical path from concept to a finished, integrated system, the narrative often starts with a clear compatibility check, then proceeds to measurement and fitting, and finally to finishing and tuning. A rider might begin by confirming that the chosen fairing kit will align with the bike’s frame and cockpit openings. Next, professional fitting becomes a prudent step, particularly when the fairing needs to be aligned with the windscreen and headlight assembly. The process may involve trimming certain panels, relocating fasteners, or re-routing cables so that everything sits flush and operates without interference. Once the shell is mounted, attention shifts to trim and paint—color matching or color blocking can transform the whole look, while edge sealing and seam smoothing produce a seamless, factory-like appearance. The combined effect is a bike that not only breathes better through improved aerodynamics but also presents a coherent and rugged stance that resonates with Dakar-style aesthetics. In essence, the adaptation and personalization of Dakar fairings are as much about careful, repeatable craftsmanship as they are about the initial purchase.

For readers seeking further technical grounding on the adaptability of this kind of fairing, a utility-minded listing can be a helpful primer. Many retailers publish compatibility notes and installation considerations that lay out practical steps and caveats for different models and subframes. These resources often emphasize the importance of verifying fitment before ordering and highlight the kind of modular options that make the system forgiving to imperfect matches. They also tend to showcase the breadth of customization possible—from subtle trim to bold color schemes—while warning potential buyers about the need for professional finishing work to ensure a seamless, durable result. The broader point is that Dakar-inspired fairings function best when treated as a modular, evolving system rather than a fixed, one-size-fits-all accessory. The rider’s goals—whether they are endurance-ready performance, rugged aesthetics, or a balanced blend of both—will guide choices about winglets, brackets, and paint, and will shape how the bike evolves over time through subsequent upgrades and refinements.

As the landscape of customization continues to evolve, the conversation around Dakar fairings remains anchored in two enduring ideas: adaptability and identity. Adaptability ensures that the fairing can be coaxed to fit different machines and riding philosophies without demanding wholesale frame changes. Identity is the sense of purpose a rider feels when the bike looks and behaves the way they want it to. The fairing thus serves as a tactile bridge between the rally’s uncompromising spirit and the rider’s daily life. It is a reminder that a bike is not a static collectible but a living platform for experimentation, performance, and self-expression. For anyone who has ever stood over a partially assembled, wind-cupped silhouette and imagined how it would feel to ride it across a dust-churned desert or along a misty coastal road, Dakar-style fairings offer a compelling pathway from concept to execution. They invite you to test fitment, to refine geometry, and to finish with care—so the final machine stands not only as a piece of engineering but as a personal manifesto on wheels.

For readers who want to explore more about how these fairings can fit into a broader catalog of options, a practical touchstone is the collection of fairings from established brands and categories. The online catalog of a well-curated parts retailer can be a starting point to compare how different fairing pieces relate to each bike’s silhouette and to the rider’s expectations. For instance, some pages focus on a dedicated BMW fairings lineup, which can illuminate how a brand-heritage approach translates into modular, adaptable components that cross model boundaries. This perspective helps explain why a rider might choose a framework of winglets, brackets, and panels designed to accommodate a spectrum of bikes while still delivering a cohesive, rally-inspired look. It is this blend of shared engineering language and personalized execution that makes Dakar fairings a durable, repeatable approach to upgrading a motorcycle’s performance envelope and its personality on the road.

If you want to dive deeper into the broader ecosystem around these parts, you can explore related content through the catalog that focuses on a range of brands and model families. A representative entry within that catalog guides you toward a dedicated subset of fairings that share common mounting logic and visual appeal, making cross-model adaptation more straightforward. For readers who prefer a hands-on path, the practical takeaway remains: verify compatibility, plan your fitment, and then approach the finish with a careful blend of precision and artistry. The result is a machine that not only performs better in wind and terrain but also communicates a rider’s willingness to push the limits of what a street-legal bike can endure and express. In this spirit, the Dakar-style fairing is less a single product and more a philosophy of modular engineering paired with personal storytelling on two wheels.

For those seeking a concrete, external reference on fitment and winglet options that align with this approach, an external resource provides in-depth guidance on how winglets and related components can be integrated with mid-sized adventure bikes. It offers practical notes on compatibility, installation steps, and finishing considerations that complement the insights shared here. [External reference: https://www.motorcycleaccessories.com/bmw-f650gs-dakar-fairing-winglets]

Internal resource note: to see how a major rider-focused catalog frames the available fairings for a BMW-focused lineup and to compare how these components are presented and organized, you can explore the dedicated BMW fairings category in the retailer’s catalog. This page aggregates several related fairing pieces and accessories, helping you gauge how a modular system appears in a real-world shop context. BMW fairings catalog. The accessible layout and cross-referencing across models can illuminate how a kit intended for one application may inspire a creative adaptation for another bike family, while still maintaining a coherent aesthetic and aerodynamic logic.

Rally Form, Endurance Shield: The Dakar Fairing as Aerodynamics, Armor, and Identity

The Dakar motorcycle fairing is more than a shell set to cover the bike; it is a deliberate statement about what speed, endurance, and grit look like in motion. In rally-style builds, the fairing acts as a practical apparatus and a cultural emblem, a synthesis of wind, dust, heat, and the unspoken promise of capability. When a rider sits astride a bike fitted with a Dakar-inspired fairing, there is an immediate sense of purpose: the machine is prepared to face long days, harsh terrain, and the relentless grip of sand and stone that define the Dakar-like experience. It is a design that respects the physics of travel at speed while acknowledging the realities of off-road endurance. In this sense, the fairing becomes the hinge between human endurance and mechanical robustness, a locus where aerodynamics, protection, and identity converge.

From a functional perspective, the fairing’s primary role is to shield both rider and critical components from the barrage of dust, debris, and weather that accompany high-speed desert and off-road sections. Dust is not merely an annoyance; it can abrade seals, clog filters, and distort air intake. A well-crafted fairing channels air to minimize interference with the engine’s cooling flow, reduces the impact of crosswinds, and cushions the bike against debris that might otherwise ride up the front of the chassis. The result is a more predictable handling profile, where the rider can concentrate on line, throttle, and terrain rather than fighting with gusts or blurred vision. This protective function extends to the radiator and fork areas, where strategic shaping and shielding help maintain steady cooling and suspension control through long, unyielding miles.

But the Dakar fairing is not simply a shield; it is a projection of aerodynamic intent. Its sculpted forms work to reduce wind resistance and harmonize the rider’s profile with the bike’s body, a pairing that translates to steadier high-speed stability and reduced rider fatigue over hours of riding. The physics are intuitive: when air flows smoothly around a bike, drag losses drop and the machine can maintain momentum with less energy leakage into turbulent wake. In endurance racing, even small gains compound over the course of a day, week, and season. The fairing’s lips, air ducts, and side panels are not decorative flourishes but elements tuned to minimize buffeting, stabilize steering at speed, and maintain rear-wheel traction on loose surfaces where a slightest gust can unsettle a line. The visual language of the Dakar fairing—the broad stance, the aggressive rake lines, the confluence of curves and sharp angles—also signals that the bike is built for resilience as much as it is for speed.

Styling matters because rally-inspired aesthetics carry a story. The distinctive silhouette of a Dakar-style fairing has become shorthand for a bike that has embraced the spirit of the rally: relentless, rugged, and ready for anything the track or the trail might throw. The fairing’s proportions—large, sculpted surfaces, a pronounced nose, and a sweeping cockpit area—convey a sense of purpose that transcends mere appearance. This design language has helped create a visual identity that separates rally-raid machines from ordinary sport-touring configurations. It is a language that communicates not just speed but the belief that endurance riding demands a machine designed to weather long horizons while still feeling alive and responsive to rider input.

In practice, the integration of a Dakar-style fairing is a three-part equation: form, function, and finish. The form dictates how air will flow around the bike, which in turn supports both cooling and stability. The function encompasses protection, seal integrity, and mounting geometry, ensuring that the fairing remains reliable under the stress of rough terrain, dust, and vibrations. The finish ties the look to the bike’s overall posture and paintwork, often requiring trimming and professional spraying to achieve a factory-like flush. This last step is not cosmetic vanity; it is about unifying the fairing with the rest of the machine to prevent gaps that collect dust, or seams that flutter at speed, disrupting the aerodynamics and the rider’s comfort.

The role of the fairing in rally styling extends beyond pure performance. It has become a defining element of how a bike is perceived in the wider riding community. A Dakar-inspired fairing signals commitment to durability and a certain allegiance to the sport’s archetype—the rider who embraces rough routes, long stages, and the artistry of mechanical repair in the middle of nowhere. It creates a common visual shorthand that connects riders across continents, a shared vocabulary of rally grit expressed not just through speed but through the careful sculpting of air and shield. This cultural resonance helps explain why the fairing remains a staple within aftermarket and custom-build scenes: it is as much about storytelling as it is about reducing drag or protecting the bike.

The cross-pollination between form and function is evident in the way designers and builders approach these fairings. When a fairing is designed with endurance in mind, it considers a rider’s line of sight, control inputs, and the likelihood of debris’s trajectory across different terrain. The wider stance and more enveloping profile can improve rider protection in the event of a tip or a slide, while still providing access to essential servicing points. In the more stripped-down iterations, builders focus on trimming and shaping to achieve a clean, factory-like finish that preserves the original lines of the chassis while delivering rally-ready impact resistance. This philosophy—to honor the bike’s core geometry while adding a protective, performance-oriented extension—has informed countless restorations and modern interpretations of rally styling.

The practical realities of installation and integration are a constant part of this conversation. While some fairings are tailored to specific platforms, many can be adapted to a broader range of bikes through careful trimming, mounting adaptations, and refinishing. The goal is not to create a one-size-fits-all solution but to craft a seamless, cohesive look that preserves the machine’s proportions and the rider’s ergonomics. When done well, the fairing reads as a natural extension of the bike’s silhouette rather than a bolt-on add-on. It sits flush, its joints align with existing panels, and the transition between fairing surfaces and the bike’s original lines reads as an intentional design choice rather than a field modification. Such outcomes require professional fitting and finishing work to ensure the look is impeccably integrated and the performance benefits—airflow, shielding, and stability—are fully realized.

The broader aftermarket ecosystem that supports Dakar-inspired fairings echoes the rally’s ethos: a blend of performance, customization, and personal expression. Builders seek out materials that balance strength with weight, craft joints that resist vibration and dirt ingress, and pursue paint and finish schemes that capture the rally’s rugged glamour without sacrificing durability. The result is a spectrum of configurations—from clean, minimalistic fairings that emphasize function to more aggressive enclosures that project a bold, rally-raid stance. Across this spectrum, the equity is clear: a well-executed Dakar-style fairing is more than a visual upgrade; it is a modular platform for extending comfort, reliability, and confidence when distances grow long and the route grows unpredictable.

For riders who want to explore practical options, a curated entry point is available in the fairings catalog that groups items by compatibility and style. This catalog offers a gateway to understanding how different lines of fairings can complement a rider’s preferred geometry, riding position, and climate. The catalog’s architecture reflects the reality that a fairing must harmonize with the bike’s chassis, the rider’s stance, and the terrain’s demands. It acknowledges that adaptation—whether by trimming, reshaping, or repainting—can transform a standard machine into a rally-inspired companion without sacrificing daily usability. The emphasis remains on achieving a cohesive visual and functional whole, rather than merely selecting a visually striking shell.

In the end, the Dakar fairing is a study in disciplined design. It embodies why rally styling endures as a compelling lens through which to view motorcycle aesthetics and performance. It respects the desert’s harshness and the endurance rider’s long horizon while acknowledging that the machine and rider must feel integrated, comfortable, and controllable at the edge of grip. The fairing’s large, sculpted surfaces and sharp lines are not just about looking the part; they are about making the bike behave better under the most demanding conditions. They signal a willingness to invest in the bike’s resilience, a belief that speed is not solely about acceleration but about maintaining momentum through consistent, controlled effort over thousands of kilometers. This is the essence of rally styling: a fusion of aerodynamic purpose, pragmatic protection, and a visual identity that travels with the rider wherever the road or the rumor of a rally might lead.

For readers curious about practical sources that illustrate how these elements come together in real-world builds, a representative starting point in the broader catalog of fairings can be found at the bmw-fairings category, where you can explore how different designs approach fitment, aerodynamics, and finish. bmw-fairings.

External resource: Dakar Rally Official Website – Technical Insights: https://www.dakar.com/en/technical-insights

Rally Lines on the Road: Craft, Performance, and Market Dynamics of Dakar-Style Motorcycle Fairings

The Dakar motorcycle fairing sits at the crossroads of endurance history and modern customization. It is more than a decorative shell or a wind shield; it is a compact statement about the rider’s intent to chase rough roads with the efficiency of a rally prototype and the personality of a well-tuned street machine. In the wake of the Dakar Rally’s legendary terrain—sand, dust, heat, and sudden gusts—the fairing evolved from practical protection into a versatile tool that shapes air, shields the rider, and frames the bike with a purpose-built silhouette. When a rider chooses a Dakar-inspired fairing, they are not merely buying a cosmetic layer; they are selecting a system that influences aerodynamics, protection, and the very feel of riding in open, unpredictable environments. The appeal lies in the balance between function and heritage: a purposeful profile that hints at off-road grit while still serving the daily grind of city commuting and weekend exploration. The result is a familiar, almost iconic, look that signals both capability and commitment to endurance.

Designers have long studied how a fairing can manage the air that streams around a motorcycle at speed. A Dakar-style fairing typically emphasizes a clean, forward-leaning line that channels air to reduce drag without creating turbulent pockets near the rider’s chest and helmet. Slender radii and careful transitions help the bike slice through headwinds, while a thoughtfully shaped windscreen works in concert with the rider’s posture to minimize fatigue on long, high-speed stretches. Yet the draft is not the sole concern. The Dakar look carries a rugged, protective aura. The fairing must shield limbs, wiring, and gauges from spray, dust, and occasional impacts with branches or rocks on rough tracks. In this sense, the fairing becomes a shield as much as a sail.

The functional side of the equation cannot be separated from the aesthetic, because the Dakar influence is as much about identity as it is about performance. The silhouette—tall, assertive, and boldly angular—evokes a narrative of endurance and exploration. For riders who spend weekends chasing off-road trails and weeks commuting through urban canyons, that narrative carries tangible value. It communicates intention at a glance. The same panel that deflects grit from the rider’s visor also frames the bike in a way that others recognize as ready for challenge. This dual role—protection plus personality—helps explain why Dakar-inspired fairings persist as a popular aftermarket choice across a wide range of bikes.

A fairing of this kind is constructed with a view to modularity and extendability. The core purpose remains protection and aerodynamics, but the modular nature of modern fairings makes it possible to adapt a design to different frames with relative ease. In practical terms, this means riders can trim, tune, or reshape the panels to fit a particular chassis, then blend the edges with custom painting to achieve a factory-like finish. The process often involves precise trimming at mounting points, careful alignment of the nose and side panels, and a finishing pass that eliminates gaps and reveals clean lines. It is not unusual for enthusiasts to work with professionals on the final fitment and paint, ensuring a seamless integration that looks intentional rather than improvised. The end result is a fairing that marries form and function—wind management and rock protection on the one hand, and a cohesive, rally-inspired look on the other.

Beyond fitment, the aftermarket ecosystem surrounding Dakar-style fairings is notable for its breadth. A typical rider’s shopping cart might include related components that complement protection and performance, such as air filtration, suspension-related parts, and headlight guards. The market in this space tends to favor items that can be installed with a reasonable degree of customization, allowing riders to tailor the overall package to their bike and riding style. Availability remains robust, with large online catalogs and specialist shops offering a range of materials—from durable plastics to lightweight composites and, in some premium applications, carbon fiber. This broad spectrum helps keep the Dakar look accessible to riders on various budgets while preserving the essence of the rally’s rugged aesthetic.

But access to a Dakar-style fairing does not erase the realities of installation. A seamless finish and optimal performance require careful mounting, alignment, and sometimes professional finish work. The mounting points must be compatible with the bike’s frame and headstock geometry, and the panels must integrate with existing electrical routing, radiator shrouds, and instrument clusters. Poor fitment can result in rattles, excessive vibration, or misaligned lines that undermine both aesthetics and aerodynamics. For many riders, the path to a factory-like finish includes a collaborative process: selecting the right base panels, performing precise trimming, and then coordinating paint and clear coat work to achieve a uniform surface with consistent color depth. The payoff is a look that reads as intentional and engineered, not merely inherited from a generic off-road style.

In the broader market, trends that shape Dakar fairings echo the wider motorcycle industry. The authoritative currents of 2026 describe a shift from price competition toward value creation. Consumers increasingly expect better service ecosystems, longer-lasting materials, and features that justify a higher upfront investment. For fairings, this translates into reinforced durability, improved mounting hardware, and streamlined installation guides that shorten the path from box to ride. It also prompts designers to consider integration: where can a fairing accommodate auxiliary equipment without compromising rigidity or aerodynamics? The answer often involves smarter bracket systems, better gaskets to limit dust ingress, and more forgiving tolerances that help riders achieve a clean, factory-like finish even when the bike uses a nonstandard frame. In this sense, Dakar-inspired fairings become more than a skin; they are an interface that connects the rider to the bike’s underlying geometry and performance ethos.

The macro trends also point to the evolving landscape of propulsion and power. Electric motorcycles, supported by government policies in several markets, are expanding the horizon for aftermarket accessories. For Dakar-styled fairings, electrified platforms bring new considerations: how to route cables neatly, where to place sensors or cooling ducts, and how to maintain a low unsprung weight with composite materials. The growth of electric options does not rewrite the aesthetic rules of rally-inspired design; it simply adds a layer of engineering discipline to the fabric of the fairing. The result is a market where the same fairing can be part of a daylight commuter or a weekend explorer that pairs wind protection with efficient urban charging. The Dakar look endures because it remains a faithful symbol of resilience, while the engineering around it continues to adapt to new powertrains and new expectations from riders who value both capability and a pronounced identity on two wheels.

The discussion of market dynamics would be incomplete without acknowledging how distribution channels shape what riders can actually acquire. Aftermarket fairings have found receptive homes on global marketplaces, specialty retailers, and DIY project forums. The appeal of the Dakar style is enhanced when buyers can pair a fairing with a compatible range of accessory pieces—brackets, guards, and trim pieces—that help create a coherent, rally-ready package. For riders who want the look without sacrificing reliability, the availability of tested, installation-friendly kits helps reduce the guesswork that can accompany a project bike. The practical reality is that the Dakar-inspired path from concept to road-ready reality is smoother when shops and makers provide clear mounting guides, tolerant tolerances, and options for different thicknesses and materials that suit a variety of bikes. In a marketplace that increasingly values not just cost but confidence and post-purchase support, the Dakar fairing stands as a case study in how aesthetics can align with practical improvements in protection, efficiency, and longevity.

For readers curious about current catalog entries and new-category developments, there is a route to explore the latest entries in related accessory lines. The catalog can provide a snapshot of how 2023 entries and ongoing refinements influence what riders expect from a rally-inspired setup. See the 2023new category for an overview of recently added items and design directions that may inspire a Dakar-style build. This glimpse into the catalog reinforces the sense that the Dakar fairing is not a static relic but a living, evolving interface between rider ambition and engineering capability. 2023new category

The cultural dimension is equally important. Dakar-inspired styling carries with it a heritage claim: the willingness to push a machine beyond standard boundaries and to embrace a look that announces, without words, a readiness to tackle challenging terrains. This symbolism resonates with riders who value character as much as speed, who see their bikes as canvases for a personal narrative about endurance and adventure. The fairing, in this sense, becomes a portable emblem of that narrative. It invites questions about the kind of riding one aspires to do—whether the journey is a long horizon on a desert plain or a weekend loop through forested trails. The resulting conversations in rider communities, in turn, influence how fairings are designed, marketed, and installed. The dialogue between function and image remains vibrant, ensuring that Dakar-inspired fairings stay relevant as technology, regulations, and rider expectations continue to evolve.

In sum, the Dakar-style motorcycle fairing stands as a focused, multi-dimensional product category. It carries forward a heritage of endurance, delivers tangible aerodynamic and protective benefits, and invites riders to participate in a shared narrative of exploration. Its evolution—driven by material advances, modular design, and a growing emphasis on value and service—speaks to a broader pattern in the motorcycle world: enthusiasts want gear that performs, protects, and tells a story. The installation experience—often requiring careful fitting, finishing, and color work—remains a crucial part of that story, reminding us that the best renditions of rally lineage ride true not just because they look the part, but because they integrate with the bike and the rider’s goals with coherence and confidence.

Final thoughts

In conclusion, business owners in the motorcycle accessories market can harness the potential of Dakar motorcycle fairings to meet the growing demand for both performance enhancements and stylish aesthetics. Understanding aerodynamics, customization options, and market trends will empower your business to cater effectively to customers looking to upgrade their bikes. By offering quality fairings that resonate with the iconic rally spirit, businesses can appeal to passionate riders looking to improve their motorcycle’s performance while making a strong style statement. Embrace the Dakar motorcycle fairing for a competitive edge in today’s evolving market.