Motorcycle fairings are vital for enhancing aerodynamics, comfort, and aesthetics. For business owners in the motorcycle industry, understanding fairing templates is essential for custom designs that meet rider needs. This article explores the significance of motorcycle fairing templates, detailing types, design considerations, materials, manufacturing processes, and future trends that can bolster your business’s competitive edge. Each chapter provides insight that connects to overall market demands and the technical advancements in the industry.

null

null

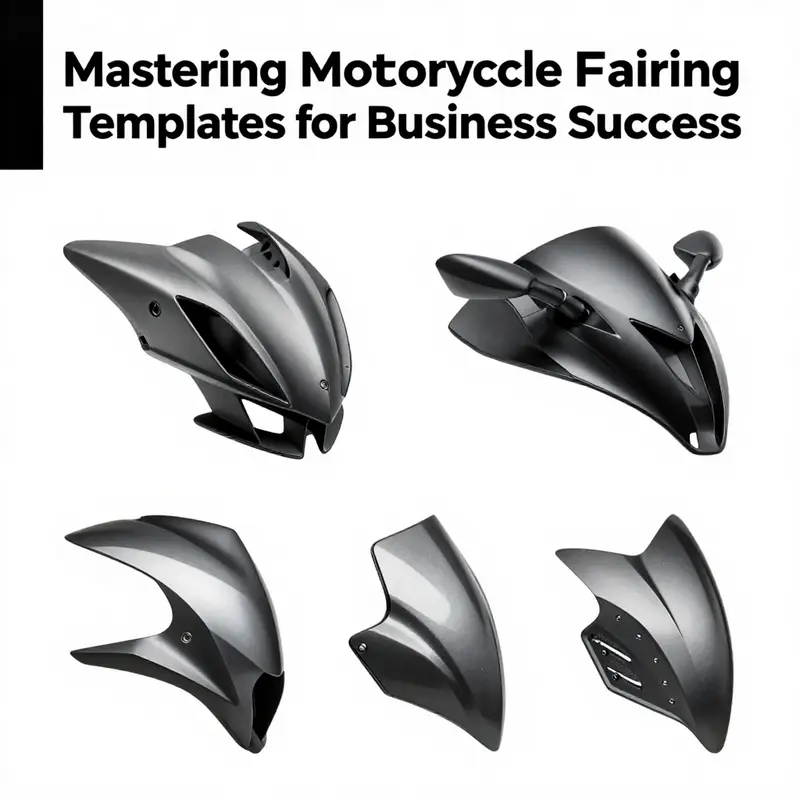

Blueprints of Wind: Navigating Full, Half, and Hybrid Motorcycle Fairing Templates

A template in motorcycle fairing design is the bridge from intent to tangible panel: a dimensional and functional map that translates aerodynamic goals, rider ergonomics, and serviceability requirements into cut lines and attachment points. Templates are rarely one-size-fits-all. They grow from chassis geometry, cooling and intake targets, and the expected usage of the motorcycle, and they must be interpreted with care so that fit, visibility, and maintenance are not sacrificed for a marginal aerodynamic gain.

Full fairings aim for continuous, integrated surfaces that channel airflow around the bike and rider. A full-fairing template defines interlocking panels that meet precisely at the headstock, radiator shrouds, and side mounts. Key concerns when developing this template are access for routine maintenance, placement of inspection panels, internal reinforcement to resist vibration and wind loads, and preserving the rider’s sightlines and range of motion. In practice, designers start with accurate chassis and component locations, then iterate with digital modeling and physical mockups to ensure panels assemble into a smooth, serviceable shell.

Half fairings favor modularity and accessibility. The template focuses protection where it delivers the most rider benefit—a screen and upper cowling—while leaving lateral areas more exposed for easier access to the engine and frame. Half-fairing templates usually depend on a few strong mounting interfaces and standardized attachment points to simplify installation and service. The trade-offs are lower weight and easier maintenance at the cost of reduced high-speed wind management, so designers test and refine curve radii and shoulder coverage to find the appropriate balance for intended speeds and riding conditions.

Three-quarter and hybrid fairings sit between full and half solutions, offering graduated coverage that increases long-distance comfort without fully enclosing the bike. Templates for these fairings are often conceived as a base envelope with optional extensions or add-on fingers to tune protection for different climates or rider preferences. Important template inputs include radiator orientation, exhaust routing, and how panels will nest against crash protection or luggage mounts to avoid interference with routine checks and repairs.

Naked-bike templates are less about a continuous shell and more about targeted shielding and ergonomics. With mechanicals exposed, the priority becomes protecting heat-sensitive zones, mitigating buffeting around the torso, and ensuring the simplest possible access for routine service. The template approach is therefore pragmatic and minimal: small, robust pieces that resist vibration and abrasion while keeping the machine easy to inspect and maintain.

Across all types, the recommended workflow is consistent: gather precise frame and component data, articulate aerodynamic and ergonomic goals, model panel families digitally, and validate with physical prototyping and on-road or wind-tunnel testing. Designers commonly consult official dimensional data and parts catalogs for reference and interoperability. While universal, downloadable templates for every model are not generally available, the method and measurements needed to create them are accessible through manufacturer specifications, material science guidance, and iterative practice. For practical references and product families that illustrate design approaches, consult manufacturer fairing categories and comprehensive guides on fairing selection and optimization: https://ultimatemotorx.net/product-category/honda-fairings/ and https://www.carinterior.com/motorcycle-fairings-guide/.

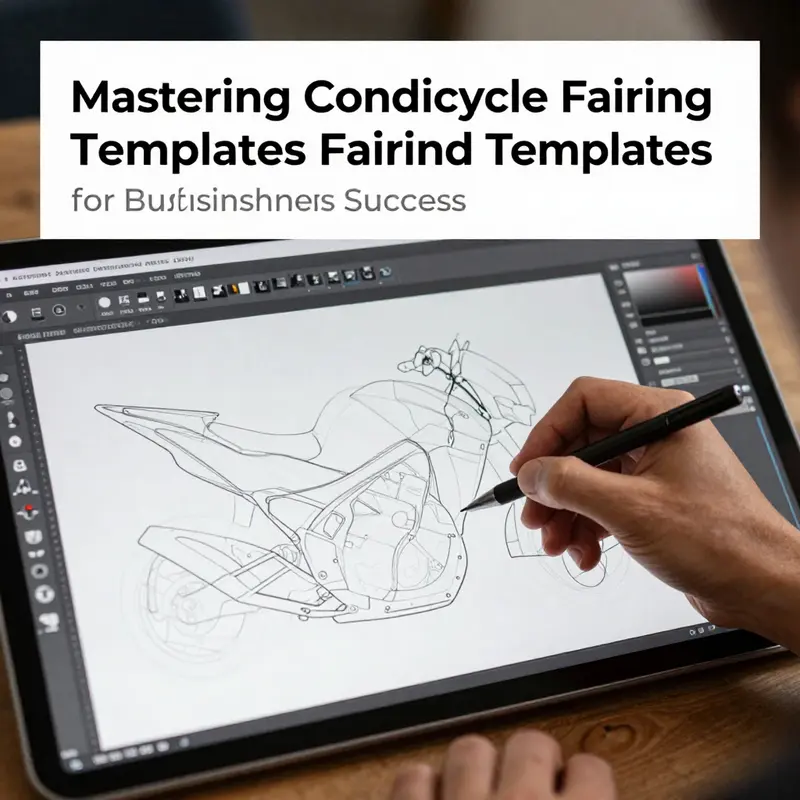

From Form to Fit: Designing High-Performance Motorcycle Fairing Templates

Designing motorcycle fairing templates is a craft that sits at the intersection of aerodynamics, manufacturability, and rider experience. It is a discipline that demands both disciplined engineering and a sensitivity to the nuances of real-world riding. In practice, a template is more than a two-dimensional guide; it is a blueprint for a three-dimensional relationship between the bike’s frame, the rider, and the air that sweeps around the machine at speed. The chapter that follows treats design not as an abstraction but as a lived process—one that begins with precise measurement and ends with finishes that can survive exposure to sun, rain, and road grit while preserving the rider’s comfort and the vehicle’s reliability. To understand how to craft fairing templates that perform well, it helps to start with the core questions that any strong design must answer: fit, durability, aerodynamics, integration, and compliance with safety expectations. Each question threads into the next, guiding a designer from data collection to a finished, install-ready template that can be used for manufacturing or custom fabrication. The result is a coherent narrative of how to move from measurement to model to measurable performance on the road, rather than a collection of isolated tips.\n\nFitment accuracy lies at the heart of every successful fairing template. The template must mirror the motorcycle’s frame geometry with a level of precision that prevents misalignment during mounting and reduces the risk of unintended stress on mounting points. Even small deviations in contour or offset can translate into paint chipping, panel misalignment, or awkward gaps around the headlight and instrument cluster. Precision begins with meticulous data gathering: high-resolution measurements of mounting points, attachment interfaces, and clearance to nearby components; it continues in the digital realm with CAD models that reproduce the bike’s geometry at the intended scale. Digital prototyping allows designers to simulate fit across multiple tolerances, to test how a panel will behave under clamping forces, and to verify that removal and reattachment will not require excessive force or time. In this light, the template becomes a standard against which every upstream manufacturing choice is measured. When the fit is right, the rider’s perception shifts from “this panel is on” to “this panel belongs here,” a subtle but meaningful distinction that underpins both aesthetics and performance.\n\nMaterial durability is the next critical thread. The choice of material—whether ABS, fiberglass, or carbon fiber—carries consequences that ripple through the entire design workflow. ABS provides a reasonable balance of stiffness, impact resistance, and cost, making it a common baseline material for many production and aftermarket applications. Fiberglass can offer rugged resistance and ease of repair, which matters when a template is used in small-batch fabrication or workshop settings. Carbon fiber, while more costly, delivers superior strength-to-weight performance that can influence handling by altering weight distribution and moment of inertia. Each material interacts with the template in distinct ways. The layer thickness, the joint strategy between panels, and the method of attachment all influence how the final part behaves under UV exposure, temperature swings, and abrasion from road debris. Durability testing—simulated weather cycling, impact tests, and long-term aging studies—helps to anticipate issues such as thermal expansion mismatches, warping, or color migration. A well-chosen material not only endures but also preserves the integrity of the geometry the template prescribes, ensuring that the finished fairing maintains its precision across the bike’s service life.\n\nAerodynamic efficiency elevates the template from a fit-focused artifact to a predictor of performance. Modern fairings are designed to sculpt airflow around rider and engine, channeling air to reduce drag and minimize turbulent wake that can destabilize the machine at speed. Even modest geometric refinements—gentler radii, tighter trailing edges, or integrated deflectors—can produce measurable gains in drag reduction and high-speed stability. The design process, therefore, must include airflow reasoning early in the prototyping cycle. Computational fluid dynamics (CFD) helps identify where air leaks or separations occur, while wind tunnel validation can confirm whether a proposed contour performs as expected in real-world conditions. The result is not merely a sleek silhouette but a panel set whose lines and contours contribute to a smoother, faster ride. Yet, there is a balance to strike: overly aggressive contouring can complicate manufacturing or degrade visibility for the rider by altering light paths or glare. Designers must weigh these trade-offs, using a systematic approach to optimize drag reduction without compromising visibility, cooling, or overall ride quality. Recent insights in the field remind us that small design missteps can increase air resistance by noticeable margins, underscoring the importance of disciplined, data-driven iteration.\n\nCompatibility with existing components represents the practical spine of the template. A fairing must accommodate the headlight assembly, mirrors, instrument cluster, and the steering interface without forcing compromises elsewhere. Universal, off-the-shelf shapes offer flexibility but can introduce compromises in fit and aesthetics. Custom templates tailored to specific models tend to deliver superior alignment and a cleaner finish. The integration challenge extends to maintenance: panels should be removable to facilitate engine access, wiring checks, and routine service without requiring disassembly of multiple fixtures or risk of damage to fasteners during reassembly. The design conversation, therefore, must include thoughtful decisions about access panels, clip strategies, and finish techniques that balance serviceability with the desire for a seamless, uninterrupted exterior. The template must also anticipate the rider’s daily use: during a long ride, vibration and thermal cycling can stress fasteners and joints, so provisions for robust mounting hardware and secure, repeatable attachment are essential. In this spirit, the template becomes a guide not only for shaping panels but also for specifying a reliable, serviceable assembly that can be reproduced in workshops with consistent results.\n\nCompliance with technical standards and regulations ties the design to the broader safety and legal landscape. Fairings must respect headlight visibility requirements, reflector placements, and other lighting considerations that influence both safety and lawfulness. A well-conceived template supports this by incorporating mounting interfacing features, recommended cutouts, and tolerances that align with regulatory expectations. The challenge lies in reconciling aggressive aerodynamic goals with the constraints of visibility and illumination. The best templates anticipate regulatory checks and include documentation or references that help a technician verify compliance during installation. This alignment is not only about avoiding penalties; it is about guaranteeing rider safety and ensuring consistent performance across different geographic markets where standards may vary. The design workflow thus expands beyond aesthetics and performance into the realm of responsible engineering practice.\n\nThroughout this process, designers must be mindful of the realities of manufacturing and customization. In practice, there is value in reverse engineering an existing, well-functioning fairing to understand how components satisfy fit, alignment, and attachment requirements. This approach can inform the geometry of new templates, particularly when exploring new materials or manufacturing methods. It also invites a conversation about tolerances and surface finishes that translate well from digital models to physical parts. The path from digital prototype to physical part is not a straight line; it involves iterations that factor in tooling, paint, and assembly processes. These considerations shape the final design, the speed with which it can be produced, and the ease with which a rider or shop can reproduce the same results elsewhere. The template thus embodies a practical compromise among theory, material behavior, and the realities of the workshop floor.\n\nTo illustrate how the design principles translate into actionable steps, consider the typical workflow in which measurement data feeds a CAD model, which then informs a prototyping phase that includes both virtual and physical validation. The CAD model must capture the exact attachment interfaces and clamp geometry, while also encoding tolerances for panel gaps and join lines. A digital prototype may reveal potential interference with nearby components or show how panel thickness interacts with mounting hardware. Physical prototyping—via 3D printing or hand-laid composites—lets the designer test fit and determine whether cosmetic finishes meet expectations before committing to a full-scale production or fabrication run. This end-to-end process ensures that the final template delivers the intended fit, the anticipated aerodynamic benefits, and the necessary resilience for everyday riding. The narrative of design becomes a story of iteration, where each cycle resolves new questions about geometry, material behavior, and integration with the rider’s experience.\n\nFor readers who wish to see how professional workflows translate into practical choices during real-world fabrication, a useful reference is available in contemporary design literature that emphasizes a holistic view of fit, form, and function. As you explore options for expanding or validating your own template work, you may find it helpful to consult a widely cited guide on fairing selection and customization. This resource discusses how to choose appropriate materials and how to balance aerodynamic goals with practical installation and maintenance considerations. It also highlights the importance of clear documentation and standardized interfaces, which help ensure that templates can be used reliably across different projects and teams. Honda fairings provides an accessible example of how category pages present typical mounting interfaces and installation data, illustrating how a well-organized catalog can support designers who are reverse-engineering or designing from scratch. While the specific product names are not the aim, the underlying principles—accurate fit, durable materials, aerodynamic awareness, and seamless integration—remain the same across manufacturers and custom shops.\n\nIn the broader context of the article on motorcycle fairing templates, this chapter emphasizes that templates are living documents. They must be revisited as new materials become available, as computational tools evolve, and as regulations or rider expectations shift. A robust design approach treats templates as contracts between form and function—agreements that specify how a panel is shaped, how it attaches, and how it ultimately performs on the road. The outcome is not merely a piece of plastic or composite; it is a precise, repeatable instrument that helps riders realize smoother, safer, and more efficient rides. The journey from measurement to finished template is not a line but a loop, where each pass improves accuracy, resilience, and the rider’s sense of connection with the machine. As this process matures, the resulting templates enable more consistent production, easier customization, and clearer pathways for technicians to achieve professional results without sacrificing the bike’s integrity or the rider’s experience.\n\nExternal reference for further reading: https://www.carinterior.com/custom-motorcycle-fairing-guide

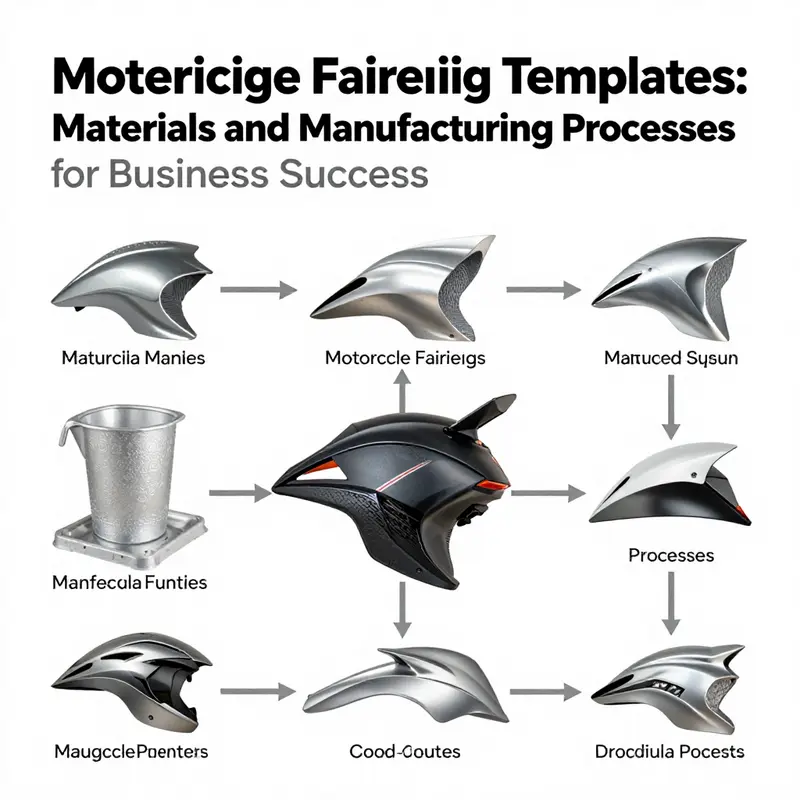

From Form to Flight: How Materials and Manufacturing Shape Motorcycle Fairing Templates

Motorcycle fairings are more than decorative shells; they are the interface between aerodynamics, rider comfort, and the engineering realities of the machine beneath. In the context of designing and using templates for fairings, this chapter moves beyond the cosmetic to explore how material choices and manufacturing processes dictate what a template must capture, preserve, and enable. The template, in essence, is a translator between a bike’s geometry and the manufacturing world that will produce a part. It must reflect not only the external silhouette but also the internal interfaces, mounting points, and the tolerances that ensure a snug, durable fit at speed and under vibration. When viewed through this lens, the study of materials and processes becomes central to any meaningful discussion of fairing templates, because those decisions ripple through every design decision a engineer or designer makes later in the workflow.

Materials sit at the heart of the template’s behavior. Each option—polycarbonate, ABS, fiberglass, carbon fiber, and the growing space of 3D-printed resins—carries a distinctive set of properties that shape how a template should be drawn, supported, and tested. ABS, the workhorse of mass-produced fairings, offers a favorable blend of rigidity, impact resistance, and cost. It tolerates bending and production-line automation well, and it accepts paints and UV coatings without dramatic loss of color fidelity over time. A template derived for ABS-based parts must emphasize smooth contours and precise edge radii, because the surface finish that the downstream painting and coating lines expect is tightly coupled to the molding process and subsequent post-processing. In contrast, polycarbonate, renowned for its impact resistance and optical clarity in windshields and related components, invites a template that accounts for its tendency to scratch with gloss-reducing micro-abrasions unless a protective coating is employed. The template must enable accurate replication of surface features even when minor surface imperfections could propagate into visible or tactile flaws once the fairing is assembled and painted.

Fiberglass (GFRP) and carbon fiber-reinforced (CFRP) variants occupy a different end of the spectrum. GFRP offers a high strength-to-weight ratio and versatility for custom or racing-oriented projects where the geometry may be less forgiving and more bespoke. The template in such cases often has to consider more complex lay-up geometries, patching, and post-cure dimensions that are sensitive to resin content, mold stiffness, and environmental conditions during cure. CFRP pushes weight savings and stiffness even further but demands greater precision in the mold, resin content, and lay-up sequence. A template intended to support CFRP production must encode not just the outer profile but also subtle thickness gradients, ply orientations, and alignment guides for pre-impregnated materials. These details, while invisible to the eye on a finished bike, become critical during the transfer from digital design to actual parts. For both CFRP and GFRP, the template should help the fabricator anticipate fiber coverage, resin-rich zones, and potential delamination risks by clearly marking critical zones, seam lines, and access points that influence cure and post-processing.

The expanding frontier of 3D printing further complicates the template conversation. Resins and thermoplastics such as PETG, PLA, ASA, and related materials enable rapid prototyping and highly customized forms. A design team can explore fit, line-of-sight improvements, and ergonomic refinements without committing large tooling budgets. Yet, 3D-printed fairings—especially when deployed as a primary structural component for high-speed riding—must meet stringent mechanical and thermal criteria. A 2026 guide on additive manufacturing cautions that 3D-printed fairings can be viable at speed only when they pass rigorous structural and thermal testing; otherwise, they carry unacceptable risk. Consequently, templates for these parts should emphasize test-fit areas, mounting interfaces, and rapid iteration points so that a rider can validate fit and form while developers can still adjust geometry before committing to more expensive molds or composite tooling.

The manufacturing processes themselves shape what a template must depict and how it should be conditioned for real-world production. Injection molding dominates the ABS and PC landscape for mass-produced fairings because it yields high precision, repeatability, and fast cycles. The template for injection-molded parts can afford to be highly detailed in curvature and edge precision, because the downstream mold and automation do the heavy lifting of consistency. The process, however, imposes constraints. Wall thickness must be uniform to avoid sink marks and warping, so the template must incorporate controlled thickness guidance, ribbing patterns, and suggested draft angles that help produce reliable molds and consistent final parts. A well-crafted template will also include assembly interfaces—where fasteners, clips, and mounting points attach to the bike frame or subframes. These interfaces are not merely cosmetic; misalignment at these loci can cause rattling, poor aero performance, or even structural compromise at speed.

Vacuum forming presents a different set of constraints. It excels for lower-cost fairings, prototypes, or niche runs and is prized for speed and flexibility. Templates crafted for vacuum-formed parts often emphasize large surface areas, gentle curvature transitions, and minimal undercuts that could complicate removal from the mold. Precision is still essential, but the tolerances tend to be looser than injection molding, with the caveat that the downstream assembly must compensate for any dimensional drift through careful fit checks and, if necessary, post-form trimming. Hand lay-up and resin transfer molding (RTM), sometimes used for fiberglass and carbon fiber components or premium aftermarket kits, demand templates that capture the exact lay-up geometry, fiber orientation cues, and cure-through dimensions. The human skill in lay-up processes makes templates more a guide than a guarantee; they should incorporate clear indicators for ply orientation and prescribed resin regimes to minimize variability.

When templates team up with additive manufacturing, the dynamic changes again. Quick-turn prototyping benefits—such as validating ergonomics, cockpit ergonomics, and lines of sight from the rider’s position—depend on the template’s ability to translate digital surfaces into build instructions with fidelity. The risk, of course, is that a print can misrepresent a real-world load path if the material properties or the printer’s resolution fall short. Therefore, the template for 3D-printed parts must balance a realistic representation of the intended print material with a pragmatic acknowledgment of its limits. In practice, designers often use multi-stage templates: a coarse, geometry-first version for layout and fit checks, followed by a higher-fidelity template for structural regions intended for final production in ABS, PC, or composite materials. Each stage reveals new constraints—thicker sections for strength, cutouts for cooling channels, and edge finishes that improve aerodynamic interaction with the rider’s line of sight and wind protection.

Beyond the material and process specifics lies a set of shared design imperatives that templates must respect to remain useful across models and brands. First, the template must faithfully capture mounting points, bolt patterns, and fastener recesses so that the fairing aligns not just with the bike’s outer silhouette but with its underlying frame and fairing stays. Second, surface continuity matters. Radii, blends, and edge conditions have a direct impact on aerodynamics, which in turn influence ride stability at high speeds. A template that omits the subtlety of a rounded fillet or an intentional chamfer risks producing a part that traps turbulent flow or causes undesirable buffeting. Third, change control is essential. As new standards emerge—whether in regulatory testing, material certification, or manufacturing automation—the template must be updated to reflect revised tolerances or new tooling interfaces. This is why the organizational approach to templates matters as much as the geometry itself: change control, versioning, and clear documentation ensure that designers, machinists, and assembly technicians stay aligned as products evolve.

The global manufacturing landscape adds another layer of complexity. By early 2026, production and development activity around fairings was heavily concentrated in Guangdong and Zhejiang, China. These hubs offer advanced polymer injection molding, automated painting and UV coating, and integrated logistics that can shorten lead times dramatically. For buyers and OEMs seeking scalable supply, the evaluation criteria extend beyond geometry to include material certifications, quality control processes, and compliance with international technical standards. This broader view of the template’s context helps teams anticipate downstream challenges, such as surface finish uniformity after painting, compatibility with UV-resistant coatings, and the practical realities of producing consistent repeat parts at high volumes. When a template is used in a supply chain, it doubles as a protocol for how parts should be produced, finished, and tested, reducing miscommunication between design studios and manufacturing floors.

For practitioners who need a concrete anchor point while navigating these considerations, an accessible reference is to look at brand-aligned fairing catalogues and category pages that illustrate typical geometries, mounting schemes, and common interface patterns without relying on free downloadable CAD files. A practical destination for brand-relevant references is the Honda fairings category, which provides a sense of how official data is organized and what interface conventions look like in practice. See the Honda fairings category for context on fitment, interface patterns, and common geometry traits that recur across models. Honda fairings category

As a counterpoint to OEM-anchored references, designers can consult industry-wide sourcing guides that discuss how suppliers approach the supply chain, material selection criteria, and production capabilities in 2026. An external resource that captures these dynamics offers a wider lens on how templates must be adaptable to evolving manufacturing technologies and regional capabilities. For readers seeking deeper industry insight into supplier ecosystems and procurement best practices, the Motorcycle Fairing Supplier Guide provides a grounded overview of how modern factories evaluate tooling, process stability, and material performance when turning digital designs into physical fairings. External resource: https://www.b2bsourcingguide.com/motorcycle-fairing-suppliers-china-2026.

In sum, a well-conceived fairing template does more than map a surface; it embeds manufacturing reality and material behavior into a guide that can survive iterations, supply chain shifts, and evolving standards. It aligns geometry with mounting realities, surface treatment requirements, and the inevitable trade-offs among weight, strength, and cost. It anticipates the needs of downstream processes—from injection molding to hand lay-up, from RTM to 3D printing—and it preserves a record of decisions that connect a design’s intent with the physical realities of producing the part. When a template is treated as a living instrument—one that reflects the material science, process capabilities, and assembly constraints of a given project—it becomes a powerful bridge between the idealized form imagined in a CAD session and the tangible performance delivered on the road. The ultimate aim is not a perfect, static replica of a bike part but a reliable, adaptable framework that supports innovation while safeguarding fit, durability, and rider confidence across models and years.

Riding the Template Frontier: The Next Wave of Motorcycle Fairings in Materials, Digital Design, and Personalization

Designing and shaping motorcycle fairings has always sat at a crossroads of performance, aesthetics, and practicality. The chapter that follows journeys into a near horizon where those crosswinds become part of a larger, more integrated design language. As the search for faster, lighter, and smarter motorcycles continues, the idea of a universal, downloadable fairing template fades into a more nuanced reality. The future lies not in one universal file but in a suite of adaptable templates—material, geometric, and digital—that riders, shops, and manufacturers can tailor to specific models, riding styles, and regulatory contexts. This turn toward customization does not negate the need for discipline; it reframes it. The fairing becomes a living interface, a boundary layer between machine and human experience, rather than a static shell. In this sense, the template is less a fixed blueprint and more a live framework that supports performance, protection, and expressivity in equal measure.

Material innovations are the first, most tangible tide reshaping fairing templates. Sustainable materials have moved from niche experiments to practical options for mass production. Lightweight advanced composites perform the dual role of reducing overall vehicle weight and enhancing stiffness in the critical zones of the structure. When paired with recycled polymers, these materials create a balance between environmental responsibility and mechanical reliability. The result is not merely a lighter shell, but a more resilient one that can absorb impacts, reduce fatigue in mounting points, and maintain aero integrity across a wider range of speeds and weather conditions. The aesthetic payoff is equally meaningful. The surface finishes achievable with new materials—whether high-gloss, matte, or textured—offer a broader palette for personal expression while preserving the performance characteristics of the underlying composite layups. Riders no longer need to trade form for function; they can have both simultaneously. The integration of these materials into standard production practices also means that concept-focused design ideas can migrate into real-world bikes with fewer compromises, enabling more faithful translation from digital concepts to the road.

Alongside material advances, the smart integration of sensors and data pathways is redefining what a fairing can do. The modern shell becomes a conduit for real-time information about aerodynamics, cooling, and even rider posture. Embedded sensors may monitor local pressure differentials to map how a particular fairing shape performs at varied speeds, or collect temperature data where the engine or exhaust system interacts with the rider’s windscreen and airflow. This knowledge feeds back into the design loop, allowing subsequent iterations to optimize airflow, reduce drag, or mitigate heat transfer to the rider. In addition to sensing, there is growing potential for embedded communication systems within the fairing itself. A fairing can host compact transceivers that integrate with the motorcycle’s broader electronics, providing updates on aerodynamic efficiency, environmental conditions, and even maintenance alerts. The fairing thus shifts from a passive protective and aesthetic layer to an active participant in the riding experience. The challenge remains ensuring that such integration does not introduce new heat or EMI concerns, and that it respects serviceability. But the trajectory is clear: the boundary between structure and intelligence continues to blur, opening possibilities for safer, faster, and more enjoyable rides.

Digital design tools are the second major propeller in this evolution. The democratization of design workflows means more people can participate in shaping the visible and aerodynamic character of a motorcycle without becoming a CAD expert overnight. The narrative here is less about one-size-fits-all templates and more about flexible, parametric workflows. Designers can start from established form families that reflect the geometry of a given model or riding purpose and then push variations with minimal steps. The concept of templating expands to include both geometry and graphic identity. In practice this means scalable digital canvases and modular design elements that respect mounting geometries, ventilation channels, and clearance zones at the wheel and radiator. A rider may experiment with colorways, branding elements, and stylized airflow lines within safe design boundaries before committing to any physical part. The result is a more iterative, responsive process that shortens the cycle from concept to prototype to production, while reducing waste and rework. At the same time, digital tools foster more precise alignment with regulatory and safety guidelines. In a landscape where fast-turnaround customization is prized, having reliable, model-specific templates that reflect the actual mounting interfaces can save time and avert fitment issues during installation.

The role of digital platforms in customization is remarkable for its social dimension. Platforms are increasingly seen as launchpads for personalization that do not require professional studio resources. The idea that a rider can sketch out a personal graphic theme or try a few color palettes on a modern fairing via a user-friendly interface is not science fiction; it is becoming common practice. Even as the underlying geometry remains constrained by the physical world, the surface design layer can be explored in depth. This shift—toward user-driven, visually expressive customization—has a practical upside. Riders are more invested when they see a direct link between visual choices and their impact on the vehicle’s appearance and perceived performance. The digital-to-physical bridge is strengthened when platforms incorporate accurate previews and downstream specifications that align with the chosen geometry and bore tolerances. The broader implication is a more inclusive design ecosystem in which the rider’s voice becomes part of the development narrative rather than a post-purchase afterthought.

3D printing, or additive manufacturing, accelerates the ability to materialize bespoke fairings. It is no longer about printing entire shells but about generating highly tailored parts and extensions that fit precise model tolerances and rider preferences. The advantage is twofold. First, printers enable rapid prototyping, letting designers test fit, interference with components, and airflow behavior before committing to expensive tooling or molds. Second, additively manufactured parts can accommodate unique geometries that are hard to realize with traditional subtractive methods, opening opportunities for niche models, limited editions, or individualized rider configurations. The constraints mostly revolve around material choices, print resolution, and post-processing requirements, but these challenges are increasingly manageable as polymer and composite printing technologies mature. The forward-looking vision is a blended manufacturing approach: base-shell geometries produced through conventional methods, augmented with additively manufactured inserts, vents, or attachment features that support customization while preserving structural integrity and serviceability.

In the broader sense, the future prospects for fairing templates are dynamic and interactive rather than static. Dynamic shaping concepts could involve reversible or tunable aerodynamics, where certain sections of the fairing adjust in response to speed, wind direction, or rider posture. Interactivity might extend to digital dashboards that sync with the bike’s telemetry, giving riders real-time feedback on how their design choices affect performance. The core promise is a higher degree of control for riders, not only over appearance but also over function. This confluence of form and function invites a more holistic design discipline that respects airflow, rider comfort, structural durability, and ease of maintenance.

For those just entering this space, a practical starting point exists in digital design as a gateway to physical realization. Platforms like Canva provide accessible entry points for creating custom graphics and branding visuals that can be mapped onto fairing surfaces. While Canva does not replace the need for engineering-grade templates, it lowers the barrier to experimentation and helps riders articulate a cohesive aesthetic identity before engaging engineers or fabricators. It is worth noting that the path from graphic concept to a finished part typically involves cross-disciplinary collaboration—from industrial designers to mechanical engineers to fabricators. The objective is not to invent everything from scratch but to assemble a well-structured design language that can be translated across models and manufacturers, with proper attention to mounting interfaces, material behavior, and regulatory compliance. For those curious about how official market offerings align with these ideas, a look into specific model families and their fairing configurations can be informative. For instance, a rider may explore the official catalog of a well-known model line to understand how fairing shapes historically translated into performance benchmarks and rider protection. See the Honda fairings catalog for a sense of the traditional interface language and mounting geometry that modern customization workflows must respect. Honda fairings catalog.

The path forward will demand careful coordination among design intent, engineering constraints, and rider expectations. It will require disciplined testing—both computational and physical—so that increasingly complex skin designs do not compromise the fairing’s core responsibilities: reducing drag, shielding from the elements, and maintaining safe clearance with moving parts and the ground. As technology evolves, new materials will demand updated testing protocols to quantify durability under real-world riding conditions. Smart features raise questions about power budgets, EMI, and reliability in vibration-prone environments. These considerations underscore the essential balance between innovation and practicality. The challenge is not simply to imagine advanced capabilities but to weave them into a coherent process where digital intentions convert into printable, manufacturable, and serviceable parts that riders can trust.

In this sense, the chapter is less about forecasting a single, monolithic template library and more about describing an ecosystem. An ecosystem where the template—whether geometric, material, or graphic—serves as a modular toolkit. Each rider can select a set of modules appropriate for their bike, riding style, and local regulations. The toolkit grows richer as new materials become available, new sensors are integrated, and new digital workflows emerge. The rider, the fabricator, and the designer co-create within a shared language that respects the physics of air flow and the artistry of personal expression. This is not merely customization for customization’s sake; it is a disciplined form of personalization that enhances performance, protection, and pride of ownership.

As this frontier unfolds, the practical steps to engage with customization remain straightforward. Start with a clear brief: what model, what riding style, what performance priorities, and what aesthetic story you want the bike to tell. Gather authoritative data about mounting points, ventilation needs, and weight distribution. Use digital canvases to sketch visual themes and generate a preview that aligns with the model’s geometry. Move to prototyping, either through 3D-printed components or mockups in a virtual build, to validate fit and feel. Finally, translate the design into a manufacturable plan with input from engineers or fabricators who can translate concepts into real-world parts while maintaining safety and compliance. This iterative loop—concept, test, refine—captures the spirit of the future in motorcycle fairing templates: a flexible, rider-centric approach that honors the machine while inviting personal expression. External resource: https://www.canva.com/templates/ .

Final thoughts

In summary, motorcycle fairing templates serve as a cornerstone for innovation and success in the motorcycle industry. By understanding their types, design considerations, and manufacturing processes, business owners can better serve their clients and enhance their offerings. Embracing future trends will ensure sustained relevance and competitiveness in a rapidly evolving market. Investing in comprehensive template designs not only benefits product performance but also enhances rider experience, ultimately leading to greater customer satisfaction and business growth.