Motorcycle fairing push pins, often overlooked yet essential, play a pivotal role in the maintenance and aesthetics of motorcycles. These small fasteners not only secure body panels and fairings but also contribute to the bike’s overall performance and durability. Understanding the importance of these push pins, their various types, and how to choose the right ones can significantly enhance bike maintenance and customization efforts. This article will delve into the importance of motorcycle fairing push pins, explore different types and their specific applications, provide a comprehensive buying guide, and discuss their role in customization and upgrades, ensuring that business owners are adequately equipped to meet their customers’ needs.

Tiny Fasteners, Lasting Integrity: The Crucial Role of Motorcycle Fairing Push Pins in Maintenance

A motorcycle’s fairing is more than a cosmetic shell; it is a carefully engineered enclosure that disciplines airflow, shields vital components, and plays a quiet but essential role in rider safety. Nestled at the heart of that protective skin are the humble push pins, sometimes called push rivets or retainer pins, tiny fasteners that do the heavy lifting of keeping plastic panels bonded to the steel or aluminum skeleton. They don’t scream for attention the way a polished exhaust or a glossy fairing segment might, yet their performance underpins everything from aerodynamics to vibration control. In the long view of bike maintenance, these small pieces emerge as keystones: when they’re present and sound, the bike breathes as designed; when they’re missing or worn, the entire bodywork becomes a potential source of risk and cost. The story of fairing push pins, then, is a story about the integrity of system design made tangible in a rider’s daily routine.

To understand why these pins matter, it helps to start with the primary function they fulfill: securing the fairing panels to the frame while resisting the twin adversaries of wind pressure and engine or road vibrations. At speed, aerodynamic forces press outward and downward on every panel, even when those panels are shaped to channel air smoothly around the motorcycle. A fairing that has loosened pins can begin to flutter. That flutter isn’t merely an annoying rattle; it translates into uneven load distribution, potential chafing against the frame, and a cascade of unintended deformations that can compromise the intended aerodynamic profile. In sport-oriented builds, where every millisecond of stability counts and weight is scrutinized, the difference between a rigid, sealed body and a loose, loose-fitting one becomes measurable in handling feel and efficiency. The danger becomes tangible when one or more pins fail completely: a panel can shift or detach, introducing new drag, shifting the rider’s line of sight or the air gap around lights and wiring, and, in a worst-case scenario, creating a hazardous situation at high speed.

Beyond safety, the push pin’s role in maintaining the bike’s aerodynamic envelope has a direct link to performance and efficiency. A well-seated fairing preserves a smooth stagnation line, minimizes parasitic drag, and keeps wind noise at bay. When a panel loosens, gaps can open where none existed before, and that is not just a whisper of air; it is a perturbation in the laminar flow that was carefully engineered into the design. The aerodynamic penalties aren’t always dramatic in everyday riding, but they accumulate: a rider may notice greater fatigue on long rides, a sport rider may feel a slight but persistent shift in stability at speed, and fuel economy can dip as the bodywork fights to maintain its intended cross-section. These effects underscore a broader truth: the fairing is not merely cosmetic; it is a system component that depends on secure, repeatable fastening to perform as engineered.

The protection the fairing provides for internal components cannot be overstated either. Behind those elegant sheets of plastic lie sensitive lighting assemblies, wiring harnesses, and, in many configurations, the engine’s peripheral plumbing. A loose panel can rub against a harness or scrape a connector, inviting wear, short circuits, or water intrusion in a way that looks minor until it isn’t. The push pins thus act as a shield, holding the cover in place and preventing the fairing from becoming a loose shield or a road-swept hazard. This protective function translates directly into maintenance economy: when the fairing remains intact, you’re less likely to encounter weather-induced corrosion, moisture ingress, or debris intrusion that could demand expensive repairs.

Another subtle but meaningful consequence of pin condition is the wear and tear cycle in the surrounding parts. Missing or broken pins allow panels to rub on the frame or substructures, generating scratches and even soft plastic deformation. Over time, these micro-abrasions accumulate into a misaligned skin that looks unkempt and, more importantly, alters the surface that interacts with wind. The visual impact is obvious, but the functional one is just as real: misalignment can compound with other fatigue in the fairing, loosening nearby fasteners and creating a chain reaction that escalates maintenance complexity and cost. In short, neglecting a handful of small fasteners can evolve into a bigger maintenance project that disrupts riding time and raises replacement expenses.

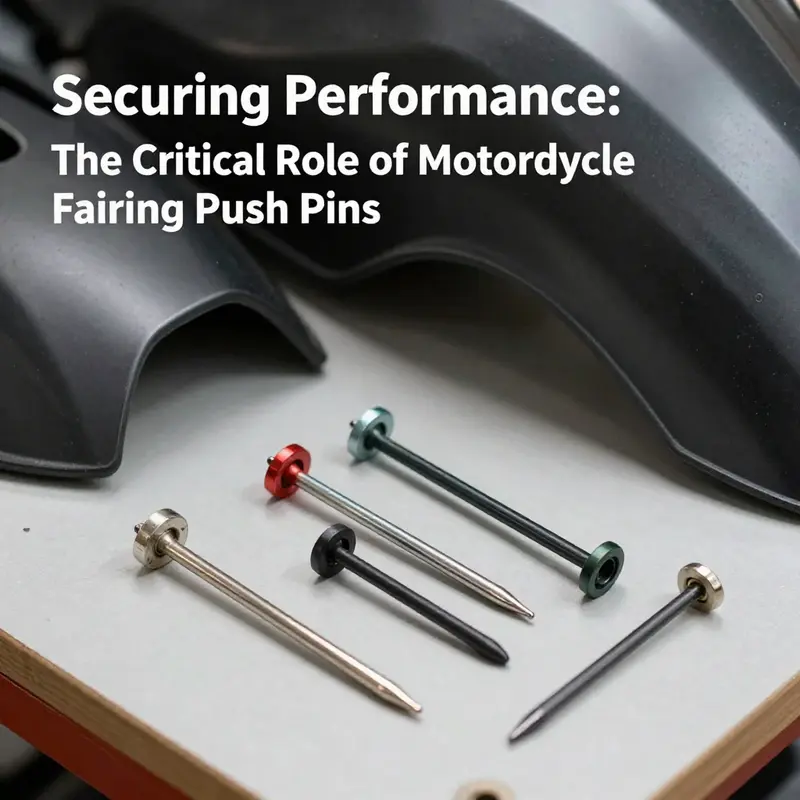

This practical narrative of fasteners naturally leads to questions of materials and selection. Push pins come in a few broad families, with nylon-based versions common for their color, flexibility, and resistance to vibration, and metal variants prized for superior strength and resistance to certain environmental stressors. Nylon pins often incorporate a little give that helps absorb vibration without cracking the surrounding plastic, a feature that can translate into longer service intervals between inspections. Metal pins, while typically more robust in raw pull-out resistance, may introduce a different wear dynamic where contact surfaces are involved or where exposure to road salt or certain solvents becomes a concern. The choice between these types is seldom a matter of raw strength alone; it’s about how the pin interacts with the fairing boss bosses, the thickness of the panel, and the climatic or riding context in which the bike lives. The head design—whether it’s a smooth cap, a ribbed grip, or a countersunk profile—also matters, because it affects seating depth and ease of removal during maintenance tasks.

Size matters, too. Most motorcycle fairing applications use pins in the range of several millimeters in diameter and assorted lengths, with common references to sizes such as M6, M7, and M8. The “M” designation is a reminder that these are metric fasteners, and the number offers a clue about the diameter and the corresponding boss hole size you’ll encounter on many modern fairings. The practical takeaway for a technician or a careful rider is to match both the diameter and the length to the fairing’s thickness and to the clamp force you expect the panel to resist. A pin that’s too short won’t grab enough of the boss to hold the panel flush; one that’s too long can bind against adjacent panels or protrude in ways that invite snagging or poor seating. Length and shoulder design influence how deeply the pin nests, which in turn affects how the panel sits against its mounting surface. In this sense, the push pin is not a one-size-fits-all component; it’s a tailored element that must harmonize with the period of maintenance cycles and the specific fairing kit you’re using, whether it’s OEM-inspired or aftermarket in nature.

When it comes to maintenance practice, the push pins should be integrated into a routine check as you inspect the bike’s fairing for any signs of wear, damage, or misalignment. A simple, methodical approach pays dividends: visually inspect every panel, run a casual tactile check along the edge to confirm it sits flush, and perform a gentle wiggle to detect any looseness. If you encounter a pin that moves freely, or if you notice increased air-gap or visible chafe marks on the surrounding plastic, that is a cue to replace. Replacement is typically straightforward but requires a careful eye for fitment: you want a pin that fits snugly in the mounting hole, anchors the panel without requiring excessive torque to seat, and leaves no visible gap between the panel and the underlying structure. It’s a small ritual with large consequences: it preserves the bike’s aero integrity, minimizes wear on surrounding plastics, and keeps the rider’s environment calm and predictable at speed.

In practical terms, riders and technicians tend to gather pins in sets that cover a few common sizes. Keeping a small spare kit on hand makes sense, partly because these pins can be damaged or lost during a minor collision, a tip-over, or even a routine wash when the scrubber or conduit touches a delicate area. A kit that spans M6, M7, and M8 variants gives you the flexibility to address the typical fairing bosses that appear across brands and generations. The choice between nylon and metal needs to be weighed against climate exposure, service life, and the potential for chemical exposure from cleaners or road salts. In a high-vibration environment, such as a sport bike or a touring machine encountering long highway legs, you might prioritize pins with robust retention features to resist loosening.

Caring for fairing push pins also means respecting the specifics of each fairing design. OEM panels often feature boss holes with precise diameters intended for particular pin types; aftermarket fairings can be a little more forgiving or perhaps more demanding, depending on the manufacturer’s tolerance stack. The consequence of a poor match isn’t just cosmetic. A pin that sits proud of the surface or that doesn’t fully engage the boss creates a stress concentration that can propagate micro fractures in the plastic, especially under the cyclical loads of vibration at speed. That is why a measured, thoughtful approach to pin selection, matching, and replacement matters as much as any torque spec you might apply to a fairing screw or bolt. It also reinforces the idea that the fairing’s assembly is a living interface: it changes with temperature cycles, with road conditions, and with maintenance history.

For readers who want to explore how this discussion translates into real-world practice, consider the broader ecosystem of fairing components. A well-crafted approach to push pins sits alongside decisions about gaskets, fastener finishes, and the mounting strategy for different panels across a bike’s fairing suite. It’s not just about keeping the surface clean and attractive; it’s about preserving the continuity of the design language that shapes how the bike behaves in wind, how it shields critical wiring, and how it supports the rider’s confidence. The balance between security and ease of maintenance is delicate: you want fasteners that hold up under vibration and weather, yet you want to be able to remove panels without destroying the tabs or the panel’s edge. The right pin, in this sense, is a link between engineering intent and practical, day-to-day service.

If you’re seeking a deeper dive into a brand-agnostic approach to fairing maintenance and selection, you can explore further through targeted pages that catalog fairings by category, including sections dedicated to specific brands and model lines. For a direct route into brand-specific fairings, a curated hub such as the Honda fairings page can provide a sense of how these components interact with the broader design language of a given family of panels. See the Honda fairings category for a concrete example of how a manufacturer’s approach to panel design often aligns with the fastening strategy employed by the corresponding push pins. Honda fairings category.

The small, almost invisible character of the push pin is precisely what makes it so compelling as a topic for maintenance and design discussion. It isn’t flashy, but it connects to every layer of the bike’s performance. It sits at the interface between aesthetics and engineering, between the rider’s tactile experience and the machine’s physical reality. A rider who understands that these pins are part of the system is a rider who can sustain better performance through proactive maintenance, who can preserve the fairing’s integrity over thousands of miles, and who can prevent the cascade of misalignments that would otherwise undermine the ride. The chain of attention required to keep fairing push pins in good shape is the sort of disciplined care that distinguishes a well-kept bike from a neglected one. In both track strip and daily streets, those small fasteners quietly influence the ride’s quietness, its efficiency, and its safety—the kind of subtle science that pilots the modern motorcycle forward with reliability and polish.

As this chapter glides toward its close, the emphasis remains clear: treat push pins not as disposable hardware but as integral elements of the fairing system. They deserve inspection, proper selection, and replacement when needed, because they are the line between a seamless panel presentation and a host of avoidable issues. The maintenance mindset you apply to these rivets shapes the bike’s overall resilience, the rider’s confidence, and the machine’s lasting appeal. The next time you wipe down the surface, pause for a moment at the edge where a panel meets the frame and imagine the small pin that holds that line steady. If you can hear the slightest rattle or detect a gap where there should be none, you’ve probably found your cue to assess and, if necessary, renew the push pins. It is a small task with outsized rewards: a fairing that remains true to its aerodynamic intent, a safer ride, and a bike that looks and performs like a well-tuned instrument rather than a hoped-for sculpture. The care you invest in these tiny fasteners translates into something much larger—the maintenance of trust between rider and machine, the preservation of performance, and the quiet certainty that the bike you ride is as sound as the road it travels on.

External resource for further practical guidance on maintenance and replacement practices: https://www.bikehacks.com/motorcycle-fairing-push-pins-maintenance-guide

Choosing the Right Fairing Push Pins: Types, Uses, and Practical Fitment Advice

Motorcycle fairing push pins do more than hold plastic to metal. They keep panels aligned, protect wiring, dampen vibration, and preserve the bike’s appearance. Each pin type is a compromise of ease, security, and aesthetics. Understanding how common variants work, and where they belong, saves time and prevents snapped panels, stripped mounts, and annoying rattles.

Standard snap-in pins are the workhorses. They rely on a split or expanding stem that compresses as it enters the hole, then springs outward to lock the head against the panel. These pins install quickly without tools, and they are the default on many motorcycles. Their main advantages are speed and convenience: a mechanic can remove and replace panels in minutes during routine service. They also tend to be forgiving of slight hole-size variations because the stem compresses. The trade-offs are clear: under heavy, sustained vibration they can slowly back out, and they rarely match the clamping force of a threaded fastener. For everyday street use and frequent maintenance, though, they strike a useful balance between reliability and serviceability.

Threaded push pins bring a different set of strengths. Instead of relying on spring tension, they engage by screw threads that bite into a mating, threaded boss or nut. This design provides higher clamping force and a far better resistance to loosening from vibration. Touring bikes, high-speed machines, and heavily loaded fairings benefit from threaded pins. When panels see strong aerodynamic forces, the extra security helps keep gaps tight and edges aligned. Threaded pins require a correct match to the motorcycle’s threaded inserts and a slightly longer service time to install and remove. That extra effort is rewarded with durability, especially on long rides and in rough conditions.

Tapered push pins are chosen when fit and finish matter. Their conical stems guide the pin into the hole and swell the surrounding material slightly as they seat. This design allows for a near-flush finish and precise alignment. Tapered pins are common on premium and custom fairings where visual continuity is a priority. They also help when panel holes are slightly misaligned; the taper nudges the panel into position during insertion. The downside is that repeated removals can enlarge or distort the hole, especially in soft plastics, so they work best where disassembly is occasional, not constant.

Retaining ring push pins combine the quick fit of snap-ins with an added mechanical stop. A small ring or external clip secures the pin’s stem from pulling through the boss. That extra safeguard prevents accidental ejection under shock or during off-road use. Retaining ring styles are ideal for areas that are difficult to inspect regularly, or near electrical connectors and harnesses where a lost pin could expose wiring. On sport and adventure bikes that see varied terrain, retaining rings provide peace of mind without requiring threaded hardware.

Weatherproof push pins incorporate seals and grommets to keep moisture and debris out of mounting points. On modern motorcycles, fairing mounts often sit close to sensors, electrical connectors, and wiring looms. A leaking mounting point can channel water toward vulnerable components, creating corrosion and electrical faults. Rubber-sealed push pins maintain a barrier, reduce wind noise, and cushion the panel. Use weatherproof pins near lights, under-cowl areas, and where the frame passes close to road spray. They are particularly useful for riders who face wet climates or frequent road grime.

Material choices matter as much as pin type. Plastic pins are light, inexpensive, and corrosion-free. They suit most fairings made of ABS, polypropylene, or fiberglass. Metal pins, often steel or plated alloys, add strength and harder wear surfaces. Metal is preferable in threaded applications and in places with repeated removal cycles. Some designs mix metal cores with plastic heads to balance strength with aesthetics and vibration damping. For carbon fiber fairings, avoid oversized or aggressive pins that can crack the laminate at stress points; choose pins with broader heads and soft collars to spread load.

Selecting the right pin size and head profile is a small detail that affects fit and finish. Head diameters determine how much of the panel edge is covered and influence overall looks. Low-profile heads sit flush and reduce wind drag. Larger heads conceal oversized holes and reduce stress at the mounting surface. Stem diameters must match the hole and boss; too small invites wobble, too large risks cracking the fairing. Measure hole diameters and arch back to the stem specs before purchasing. If a hole has been enlarged by wear or prior repairs, consider a larger head or a backing washer to regain clamping capability.

Installation technique reduces failures. Clean mating holes of paint, debris, and old adhesive. Inspect bosses for cracks or stripped threads. For snap-in types, align the panel precisely and apply steady pressure perpendicular to the surface. Avoid forcing a pin at an angle; it can shear the stem or deform the hole. For threaded pins, run threads slowly and stop if resistance spikes; cross-threading will ruin the boss. Use a hand tool rather than power tools to avoid overtightening, which can strip threads or crush plastic mounts. If a pin feels loose after seating, replace it; a loose fastener is a likely candidate for loss during a ride.

Maintenance and replacement strategy matter more than people expect. Keep a small kit of common types and sizes in your toolbox or tail bag. Bulk packs are inexpensive and convenient for riders who perform routine panel work. Replace push pins that show cracked heads, deformed stems, or significant corrosion. For older bikes, inspect every mounting point periodically; a seemingly secure pin may have lost friction due to heat cycling or ultraviolet exposure. When replacing, match the original type as closely as possible, especially on structural or load-bearing mounts.

Compatibility with aftermarket fairings is another consideration. Aftermarket panels may use different thicknesses, hole sizes, and boss locations. Before fitting new bodywork, compare the mounting pattern to the original and note differences. Adapters and spacer washers can bridge small mismatches. In some cases, switching from snap-ins to threaded pins improves long-term security when aftermarket fitment is looser than OEM. For model-specific parts and fairing kits, a product page like the one for fairings for GSX-R provides insight into how aftermarket panels are typically configured and which retaining methods they favor.

Aesthetics versus function often leads to compromise. Riders focused on show-quality appearance choose flush or low-profile heads and tapered pins. Track and touring riders prioritize retention and may use threaded fasteners or retaining rings. For riders who want both, a mixed approach works: use secure, threaded pins at critical load points and tidy snap-ins elsewhere. Also consider color matching; black pins vanish against dark plastics, while polished heads complement exposed edges. Silicone grommets or painted head caps can alter looks without changing mechanical behavior.

When troubleshooting common problems, start with vibration-related loosening. Replace fatigued snap-in pins with threaded or retaining-ring types in high-stress locations. For water ingress around mounts, swap to weatherproof pins with integrated gaskets. If panels sag or vibrate because the hole has enlarged, use larger heads or install backing plates. Cracked bosses often require repair or replacement of the subframe piece; temporary fixes rarely restore original strength. Keep a methodical record of which pins were changed and where; recurring failures at the same location point to design or structural issues rather than fastener choice.

For those ordering replacements, buying in bulk is cost-effective. Kits with varied diameters and head styles cover most needs. When matching older bikes, photograph the original pins and measure hole diameters overnight before purchasing. Labels and part codes help when sourcing OEM equivalents. Finally, consider environmental resistance: stainless or plated metal pins resist corrosion, while UV-stable plastics prevent brittleness and cracking under sun exposure.

Proper selection of push pins reduces maintenance time and prevents mid-ride surprises. Know the role each pin plays: quick-release snap-ins for service access, threaded pins for load-bearing retention, tapered pins for a refined finish, retaining rings for vibration-prone areas, and weatherproof designs near sensitive components. Attention to material, head profile, and installation technique ensures panels stay aligned and wiring remains protected. When in doubt, choose the style that prioritizes safety for the mounting in question, and keep a small assortment on hand for future repairs.

For detailed images and product listings, see: https://www.ebay.com

null

null

Pinned for Performance: How Motorcycle Fairing Push Pins Shape Aerodynamics, Durability, and Personalization

The smallest hardware often carries the heaviest weight in the design and upkeep of a motorcycle. Among the handful of fasteners that hold a machine’s silhouette together, the fairing push pins stand out as quiet workhorses. They do more than simply secure plastic panels to a steel or alloy frame; they influence aerodynamics, reduce noise and vibration, and provide a crucial avenue for riders to express their personalities through upgrades and customization. In a world where every curve and seam can be tuned for better performance, these unassuming pins deserve a closer look that blends engineering need with rider appetite for individuality. The journey from a stock assembly to a personalized, performance-conscious machine often begins with what might appear to be a trivial choice: the kind of push pin that anchors the fairing in place.

Fairings are not merely decorative shells. They are integral to the bike’s aerodynamics, engine cooling, and overall stability at speed. When a rider pushes the throttle on a smooth highway or leans into a high-G corner, the fairing’s position and integrity matter as much as the powertrain. The primary role of push pins in this system is to keep the fairing firmly attached to the frame, resisting the relentless vibration and occasional jolt that travel from the road into the bodywork. The pins must endure a spectrum of conditions—from the drag of air at velocity to the micro-impacts of pavement debris. The better their grip, the less wiggle there is, and in turn the less heat, noise, and material fatigue the system experiences. A secure fastener prevents rattles that can become magnified by wind pressure and vibration, which, if left unchecked, can frustrate a rider and undermine the perceived quality and reliability of the machine.

This functional duty sits at the heart of the push pin’s design. They are typically small in size, but their interaction with the fairing’s mounting points defines how well the panels stay aligned with the rest of the bike. The hole patterns in many fairings are a product of decades of incremental refinements—an echo of factory alternations and aftermarket tweaks alike. The pins must be compatible with these patterns, allowing a secure fit without introducing binding or misalignment. For riders who track their bikes or ride aggressively on social and scenic routes, maintaining exact alignment is not superficial; it preserves the intended airflow, reduces drag, and helps ensure that the fairing’s edge lines remain true to its aerodynamic design. In other words, the right push pins are part of the optimization of the bike’s external profile, an element that links engineering to experiential riding.

Beyond the structural duty, the aesthetic and tactile dimensions of push pins come into play. An OEM set may be unobtrusive, blending into the fairing’s color and texture. But a rider who seeks customization often views these fasteners as an opportunity for subtle distinction. Push pins can be swapped for aftermarket variants crafted from stainless steel, titanium, or anodized aluminum. These materials heighten durability, especially in regions with road salt exposure or frequent rain and humidity. The metallurgical choice also opens doors to color, finish, and a level of reflectivity that interacts with the bike’s lighting and paint. A rider who loves the visual discipline of a clean, cohesive look can choose pins that complement the bike’s colorway, or that stand out as a deliberate accent for an aggressive, performance-oriented stance. It is not about whimsy alone; color and material choices can harmonize with other hardware accents—levers, footpegs, exhaust heat shields, and even the chrome or matte textures of the engine covers.

From a practical standpoint, the ease of installation and maintenance that these pins afford matters more in daily life than many riders realize. The ability to install or remove fairing panels without drilling, without complicated tools, and without risking damage to the plastic is a meaningful convenience. For routine maintenance—checking the air filter, inspecting the radiator, or accessing the electrical connectors beneath the fairing—being able to pull a pin and re-seal with a quick push means less downtime and fewer chances of damaging fasteners or bodywork with improvised tools. This convenience also supports the ongoing process of customization. Riders who swap color schemes, upgrade windshields, or alter the mounting positions of various components can do so without confronting a complex disassembly ritual. The push pin becomes a small but reliable facilitator of broader mechanical and aesthetic experimentation.

These choices extend into the realm of performance upgrades. When fairings are secured properly, the bike’s intended aerodynamic shape remains intact, preserving edge geometry, gaps, and mating lines that influence how air flows around the bike at speed. Even minor misalignment caused by loose or ill-fitting pins can introduce unwanted turbulent flow that undermines stability, especially at higher speeds or on rough roads. A secure, well-tuned connection reduces the likelihood of panel shift that might otherwise produce flutter or fatigue over time. In this sense, push pins function as precision hardware within the broader optimization of a motorcycle’s aerodynamics. They are not the sole factor, but they are a critical enabler of consistent silhouette integrity, which translates into predictable handling, better wind management, and a rider’s confidence that the bike will behave as designed under varying loads and angles of attack.

The practical reality of sourcing push pins is a reminder that this hardware sits at the intersection of accessibility and performance. Riders who want to upgrade their fairings often begin with a simple purchase of a few replacement pins in a compatible size range. The common sizes—such as M6, M7, and M8—speak to the standardization that underpins fairing design across many OEMs and aftermarket kits. Sets that offer a mix of these sizes are common on major marketplaces, allowing builders to stock a complete solution for the typical mounting points encountered in fairing assemblies. The availability of these pins on platforms that the community already uses for parts and upgrades—whether for a quick replacement or a preventative refresh—speaks to their practical role in maintenance and customization.

For riders who want something a notch more robust or visually distinct, the market accommodates options beyond bare metal or plain plastic. A growing number of enthusiasts opt for aftermarket push pins manufactured from materials renowned for durability and resistance to corrosion. Stainless steel pins resist rust and maintain a polished look in damp or salty environments. Titanium variants push the balance toward lightness, high strength, and a modern aesthetic that can complement a bike’s performance-oriented persona. Anodized aluminum options add color while delivering a balance of weight and strength. The choice among these materials is rarely just a matter of looks; it reflects a rider’s priorities—whether they lean toward endurance in harsh climates, reduced weight for performance, or a particular visual language that speaks to their riding culture.

The discussion about push pins also touches on the broader ecosystem of customization that surrounds fairings. A fairing upgrade program might begin with a new set of pins but quickly expands to include a matching set of hardware for the entire mounting system, from screws and washers to clips that secure backup panels and vent flaps. The pins act as a gateway to a chain of decisions about fit, finish, and function. The rider who starts with a handful of new pins may find themselves revisiting the entire panel architecture, refining everything from seam alignment to the subtle interplay of light and shadow across the fairing’s curves. In this way, the humble push pin becomes a conduit for a larger narrative of transformation—from utilitarian necessity to personalized performance and visual identity.

The practicalities of sourcing such components are straightforward enough for most riders who navigate the online marketplaces and specialty shops that cater to motorcycle maintenance and customization. A typical starter kit might be an 80-piece set in a range of sizes—M6, M7, and M8—explicitly designed for fairing and bodywork applications. These assemblies promise a balance of compatibility and coverage, ensuring that most mounting points encountered on common fairings can be secured without improvisation. They also illustrate a broader theme: the ease with which riders can procure maintenance essentials alongside upgrade components. The same channels that supply a rider with a faster set of rotors, a lighter exhaust shield, or a new windscreen can also supply the tiny, high-leverage hardware that keeps those upgrades in place. It is a reminder that the journey from stock to customized is not solely about dramatic, expensive parts; it is about the cumulative effect of well-chosen, reliable components that sustain both performance and appearance over time.

In considering how to approach upgrading or maintaining fairing push pins, many riders find it useful to think about three guiding principles: compatibility, material choice, and serviceability. Compatibility is about ensuring the pin’s diameter and length fit the mounting hole pattern and the panel thickness. It is a reminder that not all push pins are created equal; a mismatch in even a fraction of a millimeter can translate into binding, misalignment, or a gap that gathers dirt and moisture. Material choice is about durability and aesthetics. Stainless steel or titanium may deliver superior fatigue resistance and a striking presence under certain lighting, while anodized aluminum can offer a spectrum of hues that echo the bike’s overall palette. Serviceability is about how easily the pins can be removed, replaced, and reinstalled during routine maintenance, winterization, or cosmetic updates. The knife-edge of performance in this space is the pin that can be snapped in without tools when needed, yet hold tight under pressure when the ride demands it.

To illustrate how this thinking translates into real-world practice, consider how a rider might approach upgrading a fairing on a mid-range sport bike. The first step is often a careful inspection of the current mounting hardware. Are any pins showing signs of looseness, wear, or corrosion? Are there visible gaps where panels meet around the edge of the windscreen or near the radiator shrouds? If so, replacing those pins with a more robust option can immediately improve panel integrity and reduce noise. The rider may also choose to tune the appearance by selecting pins with a color that harmonizes with the bike’s colorway or by selecting a finish that mirrors other metal accents on the machine. This kind of deliberate substitution is a small investment that pays dividends in confidence, ride quality, and the perception of care that surrounds the bike. As part of this process, it can be valuable to consult the bike’s specific model documentation or community forums to confirm pin sizes and hole patterns that have proven reliable for that particular chassis. For those seeking model-specific guidance, exploring dedicated pages that present fairings for a given brand or model can help ensure that the subtle details—down to seam positions and grill vents—are respected during upgrades. If you’re exploring the nuances of a particular model such as a Honda CBR, for example, you can explore the dedicated collection of fairings and mounting hardware for that line here: Honda fairings for CBR.

The broader, enduring takeaway is that push pins are an unglamorous but essential part of any fairing strategy. They are the hinge on which practical maintenance, aerodynamic fidelity, and aesthetic expression pivot. A rider who treats these pins with the same care they give to oil changes, air filter inspections, or brake fluid checks is investing in durability and performance that accumulates across miles and seasons. It is a quiet form of engineering discipline—recognizable only to those who understand how much the wrapping skin of a motorcycle matters for both function and feel. In this sense, the push pin is a tiny ambassador for the rider’s approach to the machine: practical, prepared, and precise about the details that add up to a better ride.

To sustain that level of commitment, riders often assemble a small toolkit of those essential fasteners and keep a rotation of spare pins at the ready. The convenience of having a ready supply means that a rider can respond quickly to minor panel maintenance, dramatic cosmetic upgrades, or a mid-season refresh that keeps the bike looking as sharp as its performance suggests. In practice, a few spare push pins can save hours of downtime when a fairing clip or pin fails during a ride or a garage session. It is a simple, pragmatic behavior that supports longer-term reliability and a continuous flow of upgrades that align with evolving rider needs. The result is a bike that not only performs well but also wears a sheen of intentional customization that speaks to the rider’s philosophy about maintenance, care, and style.

For readers who want to explore the broader ecosystem of fairing customization and purchase options, there is a spectrum of models and configurations that accommodate various brands and styles, including sections dedicated to specific manufacturers and model lines. This range highlights how push pins fit into a larger strategy of personalization without forcing a single aesthetic or performance path. The opportunity to align hardware with the bike’s character—be it understated and functional or bold and eye-catching—transforms maintenance from a routine obligation into an ongoing conversation between rider and machine. In this ongoing dialogue, the fairing push pin acts as a quiet, reliable interlocutor, ensuring that every decision about shape, angle, and color remains true to intent and performance expectations.

As with any element that sits at the interface of form and function, the best practice is to stay informed about compatibility and quality. When choosing replacement pins or planning a fairing upgrade, seek options that emphasize secure retention, resistance to vibration, and compatibility with your bike’s subtle tolerances. It is not merely a matter of aesthetics; it is about preserving the delicate balance that keeps the fairing aligned, the airflow undisturbed, and the rider confident in the machine’s behavior at speed. The result is a cockpit of precision—where even the smallest fastener earns its keep by contributing to a more efficient, more personal riding experience.

For readers who want to deepen their understanding of how these tiny components influence broader performance considerations, a deeper dive into the topic, including practical purchase guidance and comparative considerations, is available in industry-focused coverage. The article explores what riders should consider when selecting push pins for fairings and how these choices relate to the bike’s overall aerodynamic performance and maintenance ease. You can read more about the practicalities of motorcycle fairing push pins here: BikeRadar’s overview of what you need to know about motorcycle fairing push pins.

And for riders who want to explore model-specific options and related fairing pieces, the internal linking resource can be a valuable starting point. If you’re curious about fairing options for a particular brand, a good place to start is the dedicated Honda fairings category, which offers access to fairings and associated components tailored to the CBR line and other Honda models. The link provides a direct path to model-specific configurations and mounting considerations that can guide your decisions as you plan upgrades or replacements, ensuring compatibility with the distinctive geometry of your bike’s fairing system. Honda fairings for CBR.

In sum, push pins are more than fasteners; they are enablers of performance, durability, and personal expression. They bridge the gap between engineering goals and aesthetic ambitions, supporting the bike’s aerodynamics while inviting riders to shape their machines’ look and feel. Their role in maintenance and upgrades makes them a practical focal point for anyone planning a fairing refresh, a color-coordinated upgrade, or a broader performance-focused build. When chosen with attention to compatibility, material properties, and serviceability, these tiny anchors help ensure that every panel sits correctly, every line remains true, and every ride feels as deliberate as the rider intended. In that sense, the humble push pin is a cornerstone of the modern sport-cycle philosophy: small, reliable, and perfectly aligned with the rider’s pursuit of speed, control, and personal style.

Final thoughts

Motorcycle fairing push pins may be small in stature, but their impact on maintenance, safety, and customization is immense. By understanding their importance, the various types available, and making informed purchasing decisions, business owners are better positioned to meet customer needs and promote the longevity of motorcycles. Integrating high-quality push pins into service offerings not only enhances bike performance but also fosters a culture of thoughtful customization within the motorcycle community. As this industry continues to evolve, fairing push pins will remain a crucial element of motorcycle care and personalization.