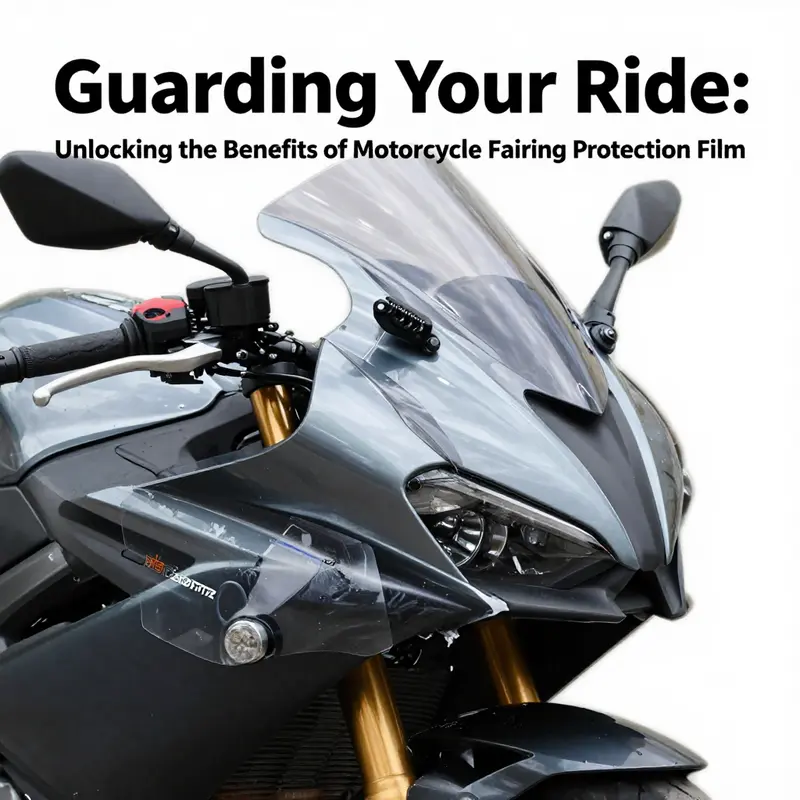

Motorcycle fairing protection film offers an innovative solution for business owners looking to maintain the aesthetics and value of their fleet. This specialized film acts as a transparent shield against road debris, environmental factors, and minor scratches. Understanding its importance not only aids in preserving the physical condition of bikes but also influences long-term profitability through enhanced resale values. Our exploration will guide you through crucial reasons why this protection is essential, key features to look for, top recommendations, installation and maintenance tips, and the economic impact on resale value.

null

null

The Invisible Shield: Preserving Form, Function, and Value with Motorcycle Fairing Protection Films

The fairing is more than a sculpted shape that slices through the wind. It is the bike’s face, a first impression of its condition, and a repository for the miles, weather, and road debris that every rider accumulates in the saddle. A motorcycle rides through this world wearing a thin, transparent layer between its pristine finish and the raw realities of pavement, gravel, insects, and the occasional stray branch. A high-quality protection film acts as an invisible shield, an engineered barrier designed not to alter the look of the bike but to preserve it. When we lean into the idea that a fairing is a valuable investment—part art, part alloy of plastic or composite—it becomes clear why riders increasingly seek a solution that balances protection with aesthetics, durability with maintainability, and longevity with ease of care. The right film delivers this balance by performing its duties without drawing attention to itself, allowing the bike’s lines and colors to speak for themselves even after thousands of miles of exposed, exposed, and sometimes harsh, riding environments.

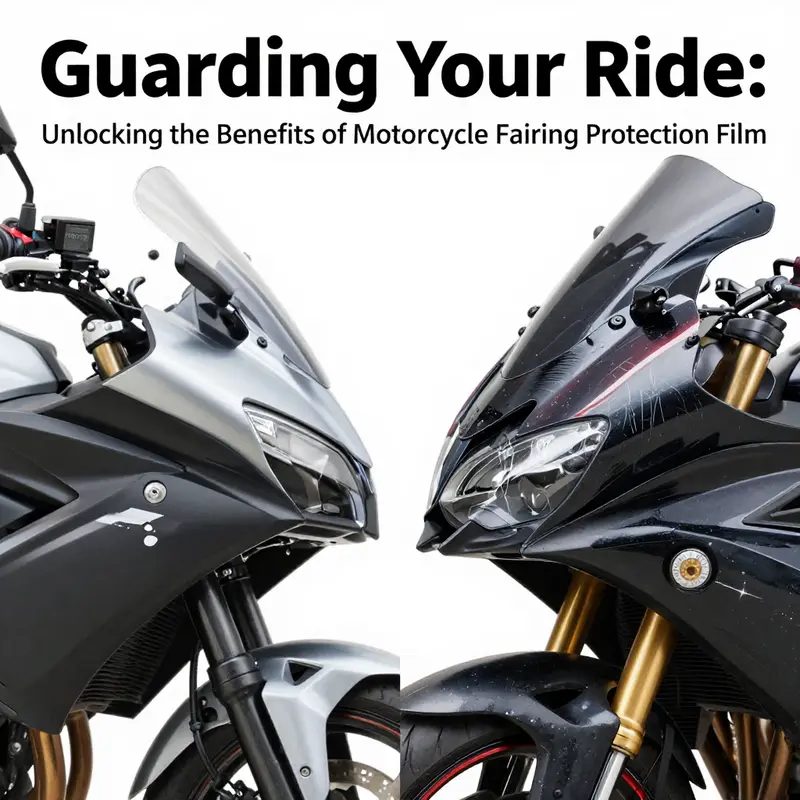

The most critical property of any protective film is its ability to resist the everyday marks that accompany speed and exposure. Gravel, small stones kicked up by nearby cars, branches brushing past the fairing in a narrow canyon or urban corridor, and even the occasional encounter with a bug swarm can leave chips and fine scratches that dull gloss and invite moisture and staining. A top-tier film uses a hard-coated surface that stands up to such contact. On the pencil hardness test, a 2H or higher rating is a commonly cited threshold that signals a robust surface capable of withstanding minor abrasions without admitting visible scars. This is not about making the finish invincible, but about giving the finish a fighting chance to retain clarity when confronted with the ordinary hazards of riding. The film’s surface hardness helps to ensure that when a stone or twig brushes by at highway speed, the impact leaves little more than a whisper of evidence, and often nothing at all after a quick wipe or a brief heat exposure.

Beyond the initial scrape resistance, the story of a modern protection film is defined by self-healing capabilities. A layer that can repair itself after minor swirls or light scratches quietly returns the surface to its original gleam when exposed to heat—sunlight, warm water, or a gentle breeze of engine heat on a hot day can trigger the healing process. This self-healing property is not a novelty; it is a practical response to the reality that riding involves friction, pressure, and micro-abrasions that accumulate over time. When a film can mask those faint lines and restore gloss, the fairing preserves its depth of color and reflective quality, maintaining a showroom appearance far longer than would otherwise be possible. It is a feature that may go unnoticed by casual observers, yet it quietly extends the life of the protective layer and, by extension, the bike’s perceived value.

Durability is not only about resisting scratches but also about withstanding the sun’s relentless attention. UV resistance is a prerequisite for any film intended to live outdoors. Prolonged sun exposure can fade colors, alter tones, and gradually introduce yellowing or embrittlement if the film lacks modern UV inhibitors and a stable polymer base. High-quality films are formulated to resist yellowing and cracking even after years of sun, rain, and temperature swings. They maintain clarity, which means the fairing continues to look as if it were freshly polished, even as the clock winds forward. Durability also encompasses resistance to the kinds of chemicals a rider might encounter during routine cleaning, fuel splashes, or roadside grime. A film that degrades in the face of common automotive cleaners or fuel residues undermines the protection it provides and invites the very maintenance issues the film was meant to avert.

Among the practical advantages of choosing a well-made film is the promise of a precise, effortless installation. A generous, generic sheet can be tempting, but real value comes from a film packaged with a precision-cut template or digital design file tailored to a rider’s exact model. The fit matters—edges must adhere tightly, contours should wrap snugly around curves, and gaps must be minimized to avoid peel-back or lifting at corners. A properly fitted kit reduces the risk of air bubbles and misalignment, two common issues that can compromise both appearance and protection. In this regard, the most reliable offerings are paired with a model-specific approach that respects the unique geometry of each bike’s fairing. An illustrative illustration of this alignment is the way a kit can follow the sculpted lines of a sport bike yet still lay flat across a faceted surface, achieving a seamless, invisible edge. When the installation mindset centers on fit, maintenance naturally follows: the film remains in place, and the underlying finish remains untouched by friction or exposure.

Another vital trait is chemical resistance. Roads are a cocktail of elements—oil, fuel vapors, road grime, and cleaning agents—that can interact with materials in surprising ways. A robust film resists these chemical challenges, preserving its integrity and clarity while remaining easy to clean. This resistance reduces the risk that cleaning rituals themselves will cause micro-scratching or hazing of the protective layer. The best films are engineered to resist degradation from everyday exposures and to maintain their protective function without requiring aggressive solvents or specialized cleaners. The result is a simpler, more reliable maintenance routine—one that keeps the bike looking sharp with minimal effort.

The narrative of protection film quality is not about chasing a single benefit in isolation. It is about a holistic approach that harmonizes scratch resistance, self-healing behavior, UV stability, precise fit, and chemical resilience into a single, transparent shield. The rider benefits in several ways: enhanced aesthetic longevity, preserved resale value, and reduced downtime for cosmetic repairs or repainting. Because the film is designed to be nearly invisible, it does not compete with the bike’s original color or finish. Instead, it works behind the scenes, allowing the rider to enjoy a stable, consistent appearance—even after long highway routes or weekend trips through rougher country lanes. When taken together, these features form a practical philosophy: protect the finish where you ride, in a way that respects the bike’s design and your time.

In this light, installation becomes less about the act of applying a sheet and more about stewardship. The preparation is straightforward: clean, dry surfaces, remove any residue, and ensure temperature is within the recommended range for application. The result is not merely a layer of film, but a proactive insurance policy for the bike’s bodywork. It is a careful balance between safeguarding the look you prize and maintaining the ease of care you expect from modern material science. A well-chosen film also respects the rider’s desire for model fidelity. For those who value brand-agnostic performance yet still want to honor the distinctive curves of their motorcycle, the precision of a model-specific kit offers the best of both worlds.

For riders who are exploring options for their own machine, there are practical avenues to consider beyond the generic glances at gloss and clarity. A reputable approach emphasizes the interplay between performance and aesthetics: how a film adheres, flexes, and recovers on complex fairing geometries; how well it resists yellowing in long-term sun exposure; how self-healing reduces the need for frequent polishing or reapplication; and how simple it is to maintain without specialized products. The decision should rest on the expectation that the protective layer will perform consistently in real-world riding conditions, not just in laboratory tests. And while the discussion can feel technical, the value is tangible: fewer chips, preserved color depth, and a fairing that looks as new as the day it was unboxed, after hundreds or thousands of miles.

For engineers, glossies, riders, and shop technicians alike, the guiding principle remains straightforward: choose a film that combines a robust surface, a responsive self-healing mechanism, solid UV stability, and a fit that respects the fairing’s natural lines while staying easy to install and maintain. A film that delivers on these dimensions helps ensure that the bike remains a source of pride, rather than a canvas of wear marks. It makes sense to consult model-specific resources and catalogs to understand how a particular kit will interact with the bike’s geometry and color. In practice, the difference is not merely cosmetic; it is functional. A well-chosen film helps protect the finish from the relentless strike of road debris, environmental hazards, and the everyday care that a rider gives to his or her machine. When you ask what makes a protection film truly worthwhile, the answer rests not in a single feature but in the deliberate alignment of all these qualities—the kind of alignment that keeps a motorcycle’s form as resilient and as beautiful as the day it was built.

For a deeper dive into how materials and protection standards shape these choices, explore broader industry guidelines and standards that frame best practices for fairing protection. See the Motorcycle Industry Council’s authoritative overview on fairing materials and protection standards for context and guidance. External resource: Motorcycle Industry Council—Fairing Materials and Protection Standards.

Internal link note: model-specific fit and installation considerations can be aided by examining model-oriented offerings such as the BMW fairings category, which showcases how precision-cut templates translate complex curves into a clean, edge-to-edge application. This reference illustrates how the dance between protection and aesthetics plays out in real-world motorcycle bodies, reinforcing the idea that the right film is as much about design compatibility as it is about material science.

Guarding the Shine: How Modern Motorcycle Fairing Protection Films Preserve Finish and Value

The fairing is more than a stylistic shell; it is the bike’s first line of defense against road grit, heat, and the occasional careless curb encounter. In snapshots captured at highway speeds or in crowded urban traffic, the gloss on those curves tells a story about ownership, pride, and care. A high-quality protection film acts as a transparent shield, absorbing the sting of stones, gravel, and insect impacts while preserving the original paint and the crisp definition of the bike’s lines. As with any long-term investment, the payoff is measurable: less cosmetic damage, fewer touch-ups, and a higher resale value when the time comes to part with the machine. The technology behind modern films has evolved beyond a simple sticker that smooths over a scratch. Today’s urethane-based coatings offer self-healing properties, anti-yellowing technology, precision fit, and a balance of durability and flexibility that lets the film hug complex contours without cracking. Together, these features make protective film not just an accessory, but a strategic component of a bike’s maintenance plan.

Selecting a film for motorcycle fairings means weighing several core attributes. Self-healing capability matters because minor scratches and swirl marks from ordinary riding will inevitably accumulate. When exposed to heat from sun or warm water, the film’s surface can flow slightly, erasing those micro-scratches and restoring a seamless look. Anti-yellowing technology is equally crucial; UV exposure can gradually create a hazy cast that erodes the film’s near-invisibility. A high-quality finish should remain virtually invisible, preserving the bike’s original color depth and clarity. But invisibility is not the sole criterion. A protective film must offer a precise fit for your model, conforming to curves, ridges, and abrupt transitions without gaps that invite moisture or dirt. That is where model-specific patterns or pre-cut kits become a decisive advantage, ensuring full coverage with clean edges that respect the bike’s geometry. Durability and flexibility complete the triad: the film must resist impact from small debris while still bending smoothly around fairing corners, vents, and headlight bezels. In practice, this combination translates to a shield that protects aesthetic value and reduces maintenance effort, especially for riders who rack up mileage on rough or debris-prone roads.

From the perspective of real-world choices, three film families frequently surface in discussions among riders and technicians. First, there is JDM high-performance clear protective film. This option emphasizes a high-gloss finish that enhances the original appearance without altering its look. The clear, non-tinted presentation makes it an attractive choice for riders who want protection without any stylistic change. Importantly, it is designed to be easy to apply and remove, which makes it appealing for temporary protection during a season or when a rider plans to swap appearances in the future. The second option, SUNTECH automotive protective film, is celebrated for durability and its capacity to shield fairings from minor impacts, road debris, and environmental elements. Its self-healing properties are particularly valuable for riders who ride on highways or gravel backroads, where micro-scratches accumulate. The third option, 3M Scotchgard protective film, carries the weight of a brand trusted across automotive applications. It combines chemical resistance, abrasion resistance, and UV protection to deliver long-term safeguarding of paintwork. Each of these films shares the core advantages of modern protection film: clear visibility, a forgiving surface for maintenance, and the potential to preserve the aesthetic and resale value of the motorcycle without permanent modifications to its appearance.

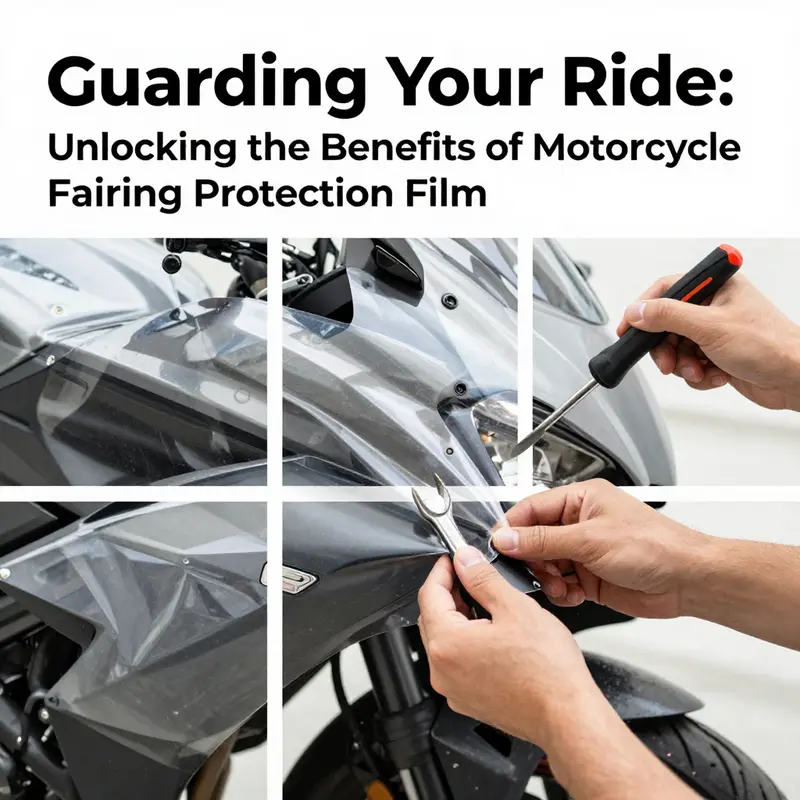

Practically speaking, installation and maintenance are key to realizing the promised benefits. While professional installation is ideal for achieving a flawless, bubble-free finish and precise contouring, DIY kits are accessible to experienced riders who enjoy a hands-on approach. Preparation is essential: the fairing must be thoroughly cleaned, free of wax or polishing residues, and completely dry before application. A clean surface ensures adhesion and reduces the chance of micro-bubbles forming under the film. During application, a careful sequence of squeegee passes and heat softening helps the film conform to rivets, vents, and tight radii. Excess film around edges can be trimmed with a sharp blade, and the final result should be a seamless edge that mirrors the curvature rather than fighting to lay flat. As with any film, maintenance is straightforward. Gentle washing with mild soap and water keeps the surface clear, while avoiding abrasive cleaners or high-pressure washing concentrated on the film itself. Over time, a quick inspection can reveal any lifting at edges, which is often addressed with a brief reheat and reapplication along the margin. The simplicity of routine care is a selling point for many riders who want to keep their machine looking fresh with minimal downtime.

Beyond the pragmatic considerations of shine and scratch protection, there is a broader economic argument. A well-applied protection film protects the underlying paint from UV fade and micro-damage that can otherwise necessitate repainting or color-supply repairs. From a resale standpoint, a nearly pristine fairing surface signals careful ownership and can translate into a higher asking price. The film’s ability to resist yellowing and its self-healing properties help maintain the bike’s original aesthetic across years of sun exposure, weather cycles, and daily commuting. In practice, a rider who invests in a high-quality film often finds that the initial cost is offset by reduced touch-ups and maintenance, along with the perception of a bike that has aged with grace rather than wear and tear showing through.

As riders consider model-specific options, the fit and compatibility of a film with the fairing’s geometry become a practical concern. Many modern kits are designed around specific models or families of models, enabling a precise fit that minimizes gaps near shoulder lines, windscreen junctures, and radiator covers. For riders who prefer a more traditional look while still seeking protection, the option to apply a film with minimal visible change is appealing. For those who take pride in customizing the appearance, clear films allow the paint to show through while safeguarding it, though some riders may also explore films with a slightly tinted edge that remains subtle and nearly imperceptible once mounted. When evaluating options, it can be helpful to reference the Honda fairings category as a practical index of model-specific coverage and patterns. Honda fairings provides a sense of how kits are matched to popular shapes and line work for a broad spectrum of bikes.

In the broader landscape of protection films, there is also a cue from reputable retailers and manufacturers about where to start shopping. Reading product comparisons and reviews can illuminate differences in edge stability, clarity, and long-term performance. An external resource can provide additional context about film chemistry and industry standards. For riders seeking additional background information, a widely recognized consumer source outlines how self-healing polyurethane films function, how UV resistance is tested, and how edge adhesion is evaluated under varying climate conditions. This deeper dive into the science behind the protection film can help a buyer separate marketing claims from verifiable performance. External readers may consult general automotive protection resources to understand how multi-layer urethane films are engineered to balance transparency, resilience, and ease of serviceability over time. For those who want to explore a broad marketplace, a popular retail portal offers a gateway to multiple brands and patterns, allowing comparisons across fitment, finish quality, and price.

From a practical standpoint, the decision often comes down to how a rider plans to use the bike, the level of exposure to debris, and how important a near-invisible appearance is to them. If your riding involves frequent gravel sections or urban roads with loose particles, a clear film with robust self-healing and UV resilience can be a wise investment. For riders who lean toward easy removal and potential future appearance changes, a film that is designed for straightforward application and removal might be preferable. Either way, the installation is not merely a one-off moment; it is part of a maintenance philosophy that recognizes film as a living, protective layer. The key is to treat the film as an ongoing companion—inspect it periodically, keep the edges clean, and reapply any marginal sections if wear begins to show.

For readers who want to dive deeper into model-specific choices, the internal link above points to a curated collection that reflects common fairing shapes and configurations. This contextualizes how a given film pattern translates into a smooth, uninterrupted surface rather than a patchwork fit. It also serves as a reminder that optimal protection isn’t just about raw material performance; it’s about how the film integrates with the bike’s design language and your own riding routine. As brands and formulations evolve, the core idea remains: a high-quality protection film preserves gloss, resists abrasion, and makes maintenance a simpler, more predictable part of bike ownership. To broaden your understanding of the market, you can also explore upcoming models and new releases in related product categories across reputable retailer platforms. External resources can offer broader perspectives on film chemistry and performance testing, enriching the practical choices riders make when extending the life and beauty of their motorcycles. For those who want to reference additional product information directly, this external resource provides a useful starting point: https://www.jd.com.

Invisible Armor: Installing and Maintaining Motorcycle Fairing Protection Film for Lasting Shine and Value

A motorcycle’s fairing is both a canvas and a shield. When you ride at speed, the road offers a relentless onslaught of stones, gravel, insects, and environmental grime. A high-quality protection film acts as an invisible armor, preserving the original finish while offering resilience against chips, micro-scratches, and UV fade. The result is a fairing that retains its luster and value even after years of exposure. But the benefits are not just cosmetic. By preventing wear on the surface, the film helps maintain the integrity of the coating beneath, reducing the likelihood of costly touch-ups or repainting later. The key lies in meticulous preparation, careful application, and disciplined maintenance. When done right, the film remains practically invisible, allowing the bike’s design language to shine through while the protection does the work of a silent guardian.

Preparation is the foundation. Before any adhesive meets the paint, the surface must be pristine. Start with a motorcycle-specific cleaner that cuts through oil and wax without leaving residues. A lint-free microfiber cloth wipes away every trace of dirt, grease, and polishing agents from all fairing panels, including the edges and seams where dirt can accumulate. It is not uncommon for dust to cling to curves or for micro residues to hide in corners. The cleaner should be followed by a thorough rinse with clean water and a complete dry to prevent any moisture from compromising adhesion. The work environment matters just as much as the surface. Choose a clean, dust-free indoor space with a controlled temperature, ideally between 10°C and 30°C (50°F–86°F). Direct sunlight, high humidity, and wind can cause the film to develop air pockets or cure unevenly, so a calm setting with stable conditions is essential.

Gathering the right tools is a quiet confidence booster. You will need a professional-grade squeegee or a soft plastic card, a sharp utility knife or a precision trimmer, a heat source such as a heat gun or a hair dryer, a measuring tape, and a soft, non-abrasive cloth for final buffing. The film itself should be designed specifically for motorcycles; automotive wraps may not offer the same flexibility for complex curves or the same adhesive performance on motorcycle substrates. When selecting the film, look for self-healing properties, anti-yellowing technology, and the ability to conform to tight radii and tight radii around fuel caps, fairing corners, and pillion sections. The modern premium options blend clear protection with durability, maintaining clarity under UV exposure and heat.

The installation process is a dance between precision and patience. Start by measuring the area you intend to cover. For a clean, custom fit, pre-cut the film slightly larger than the target surface. This margin is your friend for adjustments and trimming. Begin the application at the center of the panel and work outward. Peel back a small section of the backing, align the film, and then use the squeegee to press it down firmly while gradually revealing more of the backing. The goal is to push air bubbles toward the edges, where they can escape or be smoothed out during the final pass. When working on curved or intricate areas—such as the fuel tank contours, winglets, or wheel arches—apply heat gently. A low‑setting heat gun or hair dryer makes the film more pliable, allowing it to wrap around seams without wrinkling or lifting. Move the heat source continuously and in small bursts to avoid overheating any single spot, which could soften the adhesive beyond control. As you move, periodically check for tension and alignment. If a bubble persists, a tiny pinprick with a sterile blade and a quick re-squeegee usually seals the issue without compromising the finish. Edges deserve special care. After the surface is covered, push residual air from the center outward, then trim any excess film with a sharp blade for a clean, flush edge. A final light pass of heat around the perimeter can help the edge tuck into curves and recesses, reducing the risk of future lifting.

Attention to detail during the cut and lay process pays dividends in longevity. It is often said that a good install is a well-bonded install. This is why leaving a small margin around target areas is prudent; it allows the film to breathe and settle into the contour under its adhesive. It also minimizes the risk of visible gaps at corners where heat and UV stress can cause shrinkage or curling. When dealing with larger panels, consider applying the film in sections rather than a single piece. This approach reduces the chance of misalignment and makes it easier to correct minor misfits before the adhesive sets. If you work with a pre-cut kit designed for your model, you may find the panels align almost instinctively. For model-specific guidance, riders with Honda CBR machines can refer to Honda fairings for CBR for a sense of how fitment is approached on a sportier chassis. The kit concept translates well into a smoother, more predictable installation, especially on complex geometry.

After the film clings to the fairing, the first hours become a test of adhesion in real-world conditions. The protective layer must set, so patience is essential. Most manufacturers recommend waiting 24 to 72 hours before washing the bike, exposing it to rain, or subjecting it to high-speed runs. During this curing window, avoid harsh detergents, degreasers, or pressure washers near the edges, as these can weaken the bond or lift the film at the seams. If your climate or usage necessitates cleaning during curing, use a gentle regimen with mild soap and water and a soft cloth, sparingly, while avoiding vigorous scrubbing that could disturb the adhesive. Once cured, routine maintenance becomes a simple, satisfying ritual. Clean with mild soap and water, using a soft sponge or cloth, and dry with a microfiber towel. Refrain from abrasive pads or brushes that could mar the film’s surface. Regular inspections of edges and seams help catch lifting, bubbling, or micro-scratches early, allowing a quick re-softening and re-smoothing with a touch of heat and a fresh squeegee pass.

The advantages of modern protection films extend beyond scratch resistance. Many premium formulations feature self-healing capabilities, so light scratches and swirl marks dissipate when exposed to heat—sunlight, or a warm water rinse can enable this comforting restoration effect. UV resistance is another critical attribute; films with anti-yellowing technology maintain clarity and transparency even after prolonged sun exposure. Hydrophobic coatings on some films shed water and resist mineral spots, simplifying maintenance and keeping the finish looking pristine after rides in wet conditions. These features translate into less time spent on cosmetic care and more time enjoying the ride while preserving resale value. Aesthetic discretion remains a core appeal: the film is designed to be transparent, so the paint’s color and the fairing’s lines remain the visual focus, not the protective layer itself. It is this almost invisible barrier that makes it possible to protect the surface without altering the bike’s original intent.

Choosing the right film for a motorcycle is not merely about toughness. It is about compatibility with the bike’s curves, materials, and environments. Motorcycle films are engineered to flex and cling to complex shapes without cracking or peeling, a vital consideration for fairings that are not flat panels. Even with a top-tier product, the installation outcome hinges on surface preparation, accurate measuring, and controlled application. For riders who prefer to leave the work to a professional, the payoff is a flawless finish where the film follows every contour with seamless adherence. In practice, a professional installation ensures that the film’s protective properties are optimized for long-term durability and that any edge treatment is executed to prevent lift and micro-peels over time. The combination of proper material selection and skilled technique is what delivers the quiet, almost invisible defense that protects both appearance and value over the life of the bike.

Maintenance after installation is not a set-and-forget routine. It is a discipline that respects the film’s adhesive chemistry and the bike’s weathering. During the curing window, avoid washing or applying cleaners near the edges; after curing, use only mild cleaners and soft tools. If you notice any edge lifting, a gentle reheat and a re-squeegee pass can re-anchor the film. For broader longevity, consider periodic inspections at service intervals and following the film manufacturer’s guidance on re-application windows. Though many riders enjoy a DIY approach, there is no substitute for experience when working with curved radii and tight corners. A misstep here can lead to small bubbles or lift that become more noticeable with time. The reward, however, is substantial: a fairing that retains its original tone, a surface that resists micro-scratches, and a finish that remains vibrant after years of exposure.

In the broader arc of motorcycle care, a protection film is a strategic investment. It is not merely a cosmetic layer; it is a maintenance ally that shields the fairing from the most common and most stubborn forms of wear. The coverage, when done with care, is comprehensive enough to handle daily rides and long tours alike, while the maintenance routine stays refreshingly simple. The film’s presence is felt in the reduced need for touch-ups and resprays, the ease of cleaning, and the confidence to ride hard without worrying about small, cumulative damage eroding the surface. When the aim is to protect the bike’s aesthetic and value, invisible armor provides a practical, enduring advantage that aligns with the rider’s passion for performance and appearance alike.

External resource: For a practical, model-agnostic walkthrough of installation, this AutoBlog guide offers a clear, professional-oriented overview that complements the insights here: https://www.autoblog.com/motorcycle-protection-film-installation-guide

The Invisible Shield: How Motorcycle Fairing Protection Film Elevates Resale Value

Protecting a motorcycle’s fairing is more than a cosmetic choice; it is a strategic move that affects long-term value. The fairing, often crafted from plastic or composite materials, bears the brunt of road debris, gravel, insects, and the occasional impact during spirited riding. Over time, those encounters can leave chips, scratches, and, with UV exposure, a dull or discolored finish. A high-quality protection film acts as an invisible guardian, a transparent shield that absorbs the first blows and shields the paint and plastic beneath from environmental wear. In the marketplace, such a shield translates into a more pristine appearance and a heightened sense of care, two signals that buyers value when evaluating a used bike. A well-preserved fairing speaks volumes about maintenance discipline and risk management, and those signals can meaningfully influence resale outcomes even when the mechanical condition remains strong.\n\nThe value proposition of protection film rests on its ability to preserve the original finish. Factory finishes or pristine-looking fairings command attention because they imply the bike has seen fewer repairs, less refinishing, and less color fading due to sun. When a buyer encounters a fairing free from chips and swirl marks, the impression is not merely cosmetic; it is a perception of condition. This perception matters because the resale process is as much about psychology as it is about hardware. A final sale tends to tilt in favor of models that look well cared for, and a sacrificial layer of film makes that care tangible without altering the bike’s lines or color. The film’s presence becomes a cue that the owner treated the bike as a valuable asset, not just as a ride. In this sense, protection film becomes an economic signal—one that translates into a premium in the eyes of buyers who equate flawless appearance with fewer headaches for the next owner.\n\nThe economic impact grows stronger for bikes where the fairing constitutes a central element of the bike’s identity and value, such as sport-touring and fully faired configurations. In these cases, the fairing is not just a surface; it is a signature of aerodynamic design, engineering intent, and visual appeal. When the film preserves the gloss and clarity of the original color without visible alteration, it preserves the bike’s overall charisma. Buyers often view the protected surface as a warranty of ongoing maintenance. The film acts as a front-line defender against the environmental micro-aggressions that would otherwise accumulate into a costly repaint or panel replacement over the years. In a market where condition is a primary driver of price, the preserved finish translates into a higher perceived value and, correspondingly, a resale premium relative to similar models with unprotected fairings. This premium is not a guaranteed sticker price; it is a function of the buyer’s confidence in the bike’s condition, the film’s application quality, and the duration of the finish’s preserved appearance.\n\nFrom a materials perspective, the right protection film brings several features that reinforce resale value. Self-healing properties help repair minor scratches and micro-swirls when exposed to heat, restoring a surface that looks new to the casual observer. Anti-yellowing technology ensures long-term clarity, so the original color and gloss remain faithful to the factory look across the bike’s life. A precise fit is essential because gaps, wrinkles, or lifting edges can ruin the visual appeal and create maintenance headaches for the next owner. The ability to conform to complex curves without cracking or peeling is crucial for high-end fairings that feature intricate contours. Durability and flexibility must balance to absorb road impacts while wrapping around the bike’s shapes with a seamless finish. When these features come together, the film does more than defend against dings; it preserves the very perception of the bike’s condition, which is what buyers often anchor their willingness to pay on.\n\nThe installation quality cannot be overlooked, because the economic argument hinges on how well the film is applied. A professional installation that achieves full coverage with clean edges and no trapped air yields a nearly invisible layer. Even a perfectly formulated film can lose value if misapplied, creating a blemished finish that undermines buyer confidence. For the hands-on rider who considers DIY, the guideline remains consistent: surface preparation is critical, and careful handling is essential to avoid contamination or misalignment. The maintenance routine aligns with the investment in the film. Gentle washing with mild soap and water keeps the surface clear and free of abrasive particles that could scratch the film. Avoiding harsh solvents and direct high-pressure washing on the film helps ensure its longevity. These maintenance practices reinforce the resale value by keeping the finish pristine for longer, thereby extending the window in which the bike presents as nearly new to prospective buyers.\n\nIn the market, the signal of care does not exist in isolation. Buyers often assess the broader history of the bike—service records, upgrades, and the overall aesthetic integrity of the exterior panels. A well-applied protection film serves as part of a narrative: the owner prioritized preservation and invested in an upgrade that protects the bike’s appearance without altering its visible character. This narrative can influence buyers who are balancing price against risk. The result is a potential premium in the resale value, particularly for bikes whose fairings are prominent design features or where the finish contributes to the bike’s iconic look. The message is simple: a protective film that remains clear and intact communicates ongoing maintenance discipline and care, both appealing to value-conscious buyers and those who aim to minimize the risk of post-purchase repairs.\n\nFor readers exploring model-specific options, the concept of fit is especially important. A kit designed to match the bike’s fairing geometry can deliver a cleaner, more seamless look than a generic sheet. The market often rewards those who invest in precision-fit protection because it reduces the risk of edge lifting, air pockets, or visible seams as the bike ages. A neat, uninterrupted surface helps preserve the original silhouette and paint depth, both of which matter when buyers assess the bike’s future appeal. Practically, this means selecting a film designed for the exact model or a high-quality universal option that can be trimmed to maintain the integrity of curves and edges without compromising coverage. The difference between a snug fit and a loose application can be the decisive factor in how buyers perceive the bike’s condition and, consequently, its value.\n\nAs riders weigh the economics of protection, it helps to consider real-world scenarios. A bike with factory-finished or pristine fairings that has been protected by a high-quality film is less likely to require costly repairs for common road hazards. The absence of chips and paint deterioration reduces the need for repainting, panel replacement, or re-finishing—a chain of events that can erode resale value and complicate negotiations. Conversely, a bike whose fairings show clear signs of wear may require price concessions or additional investment to restore the finish. In this light, the film acts as a shield against depreciation caused by surface damage, preserving both the aesthetic and the financial value.\n\nFor deeper context on how protective films influence long-term vehicle value, consider industry insights that frame this as more than a cosmetic upgrade. The combination of a clear, self-healing, UV-resistant film with a precise fit creates a durable, nearly invisible layer that signals proactive ownership and responsible maintenance. It is not a guarantee of peak resale price but a credible contributor to higher buyer confidence and stronger asking standards. The relationship between appearance and value is nuanced, yet widely recognized in marketplaces where condition and presentation drive the premium a buyer is willing to pay. In this sense, the investment in protection film is a strategic step toward safeguarding resale value over the life of the motorcycle.\n\nInternal resource for readers pursuing practical fitment considerations can be found by exploring model-specific fairing options in the motorcycle parts catalog, which offers curated choices for different brands and model generations. For example, a look at the BMW fairings section provides insight into how tailored kits address unique curves and junctions, highlighting the value of an exact fit to preserve the bike’s silhouette and glaze. BMW fairings offers a concrete reference point for understanding fitment quality and visual outcomes without relying on generic overlays.\n\nExternal reference that complements the discussion on long-term protective value is available in a detailed exploration of motorcycle paint protection and its role in dealer and owner strategies. This resource frames the protective film as a long-term investment in value retention, illustrating how careful maintenance decisions translate into tangible resale benefits. External resource: Motorcycle Paint Protection – Devenir concessionnaire Musée, published October 27, 2025. https://www.devenirconcessionnaire-musee.fr/motorcycle-paint-protection/ (External reference).

Final thoughts

Investing in motorcycle fairing protection film is a strategic choice for business owners focused on preserving their fleet’s condition and enhancing value. By understanding its critical role, recognizing key features that ensure quality, knowing top product recommendations, and applying straightforward maintenance, owners can expect not only the aesthetic longevity of their motorcycles but also a much-improved resale value. Protecting your investment today guarantees lasting satisfaction tomorrow.