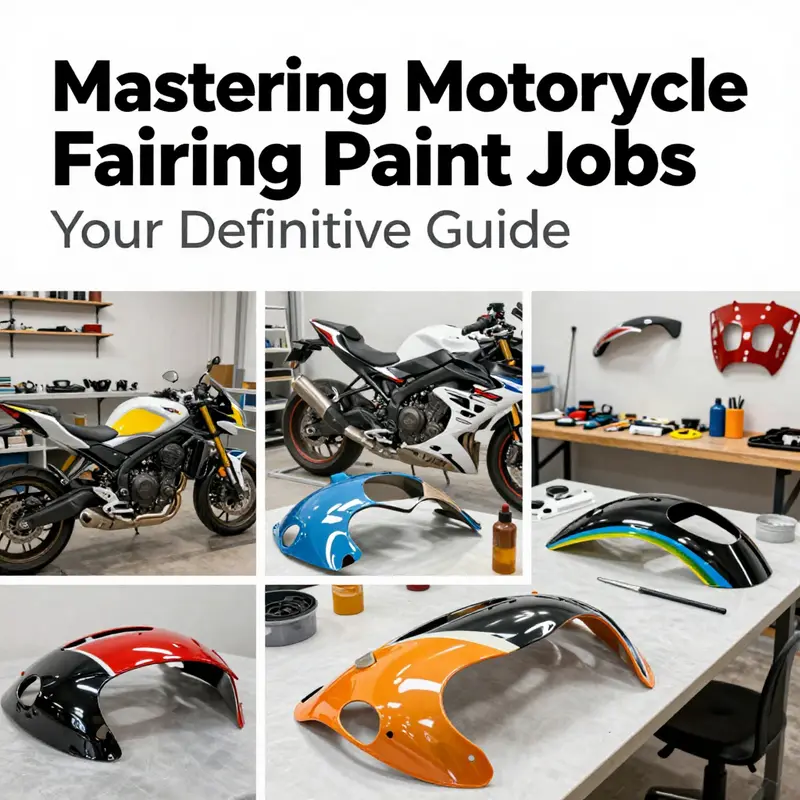

As motorcycle enthusiasts and business owners, understanding the nuances of painting motorcycle fairings is essential for delivering high-quality services that bolster customer satisfaction and retention. This comprehensive guide delves into the multifaceted aspects of achieving a professional fairing paint job. You will learn about the detailed steps required, from preparation techniques to finishing touches, ensuring that your work is not only visually appealing but also durable. Each chapter builds upon the last, equipping you with the knowledge needed to excel in this specialized area of your business.

From Bare Plastic to Showroom Shine: A Cohesive Journey Through a Professional Motorcycle Fairing Paint Job

A motorcycle fairing is more than a shell that cuts wind. It is a canvas that blends form, function, and identity. The paint job on fairings is where countless decisions converge: the choice of materials, the sequence of steps, the environmental conditions, and the craft of applying color so that it endures the ride as long as the bike itself. The process begins long before the first atom of color hits the surface. It begins with accessibility and restraint: removing the fairings so nothing you don’t intend to paint is exposed to overspray, drips, or dust, and so the painter can work with neutral access to the curves, corners, and edges. This removal is not a sign of rough handling but of respect for the finish. Every edge, every seam, every transition line should receive care, because the final result will reveal itself in how clean those boundaries look after the last coat is cured. Once the fairings are off, the work shifts to preparation, a phase that is less glamorous but absolutely decisive. The surface must be both clean and properly textured to accept the paint. Dirt, grease, and wax residues act like barriers; they push the coating away, causing uneven adhesion, micro-peels, and dull spots that deny depth to the color. A degreaser or a dedicated plastic cleaner clears away these films. Then comes the light touch of sanding. Sanding is not about stripping away the surface; it is about creating a key—a network of micro-abrasions that provide tooth for the paint and primer to grip. The recommended range for fairings is gentle and conservative: fine-grit sanding, typically in the 800–1200 range, to leave a texture that is soft and uniform. The goal is not to remove material but to prepare it so the future layers can nestle into the surface with even bite. After sanding, a tack cloth is run over every contour, picking up dust and the last invisible traces of debris. It is in this moment that the body of the bike seems to become a blank, ready for the language of color to speak clearly and truthfully. Masking follows as a companion discipline to prep. The same precision that marks the sanding must accompany masking. Surrounding areas such as lights, mirrors, handlebars, and exposed fasteners need protection from overspray and from the potential attack of adhesion-robbers like solvents and waterborne dust. High-quality painter’s tape and plastic sheeting become tools of discipline, ensuring that clean lines occur where they should and that the rest of the bike remains pristine. The mask is not merely a barrier; it is a guide that helps the painter anticipate the geometry of the finished piece. With the surface prepped and masked, priming becomes the next decisive act. A primer formulated for plastic or composite materials does more than just seal the surface. It builds a receptive ground for the base color, improving adhesion, flex resistance, and overall durability. Plastic surfaces are notoriously slippery when clean, so the primer’s role is twofold: it bridges the texture to the paint and it cushions the coating against micro-movements that occur with vibration and temperature changes during riding. The primer must dry completely according to manufacturer instructions before painting proceeds. Then the paint arrives as the main language of the fairing’s appearance. The guidance here leans toward 2K urethane paints, a robust option that yields strong adhesion, UV resistance, and a hard, resilient finish capable of withstanding fuel exposure and the environmental challenges of outdoor riding. Two-component systems require careful mixing with a chosen hardener, following exact ratios to ensure the cure is predictable and the gloss level remains stable over time. The application demands thin, even coats rather than a single heavy pass. Thin coats reduce runs, minimize sag, and create a smoother surface bed for the next layer. The distance to the surface, the spray pattern, and reciprocating passes must be consistent across each session, and every coat should be allowed to flash briefly—typically ten to fifteen minutes—so the solvents can evaporate and the surface can set enough to bond to the next layer. This stage is where the eye learns the rhythm of the job: uniform distance, steady speed, and deliberate overlap to avoid gaps. In the best work, the color begins to reveal its character through the layers, not through a single, abrupt flood of pigment. After the base color has achieved a satisfactory build and the surface has passed the visual test for evenness and depth, the next step introduces a clear coat. The clear coat adds a multi-dimensional depth that catches light and life in the environment around the bike. It locks in the color, offers additional UV protection, and provides a shield against minor abrasions and chemical exposure. A high-gloss 2K clear coat, applied in several transparent passes, gives the finish a showroom level of depth while preserving the integrity of the color beneath. The clear coat is not a finishing flourish alone; it can enhance the perceived hue and give the surface a glassy, wet look that many riders value for its drama and clarity. Then comes the crucial phase of curing and finishing. Curing is when the paint system hardens completely and becomes resilient to the stresses of heat, humidity, and daily use. This process often requires a controlled environment—a dedicated paint booth or a similarly regulated space—where temperature and humidity are monitored to optimize solvent evaporation and film formation. Rushing curing can trap solvent, cause micro-cracking, or lead to hazy finish. A typical full cure can take 72 hours or more, depending on ambient conditions. During this time, washing is off-limits to minimize disturbance to the forming layers. Once curing is complete, a gentle polish can refine minor imperfections, dust nibs, or small areas where the surface caught a speck of grit during its final stages. A fine polishing compound can bring back a nearly flawless gloss without thinning the clear or chasing color through the paint. The goal is to achieve a surface that reads as continuous and mirror-like, with the color appearing to breathe as it catches the light. The path to a truly professional result is sometimes judged by how gracefully the process handles deviations. Imperfections are not the end; they are signposts. Dust in the first clear coat, a slight orange peel, or a minor color inconsistency can be corrected with careful sanding, additional light coats, or small patches of touch-up, always followed by proper cure and polish. The most effective practitioners anticipate these eventualities and plan for them by allowing for ample dry and cure time within their schedule, maintaining clean lines, and using controlled, repeatable technique with every pass. The sequence above is not merely a checklist; it is a philosophy of craft. It recognizes the plastic nature of fairings and the demands of the road, and it respects the need for control over every variable that can influence the final look. The painter learns to read the surface as a living canvas—one that responds to temperature, humidity, materials, and technique as if the fairing itself is part of a wider ecosystem in which performance and aesthetics exist in a delicate balance. In practical terms, this philosophy translates into a disciplined routine: remove the fairings, clean thoroughly, sand lightly, mask with care, prime for adhesion, apply base color in thin, measured coats with proper flash times, seal with a durable clear coat, and finally cure in a controlled environment before any polishing. It is a sequence that rewards patience and precision more than speed. For riders who want to tailor a colorway to a specific model or to achieve a particular visual signature, the paint system can be adapted with subtle adjustments. The base color can be tinted within safe limits to achieve unique hues, or a design can be introduced through masking and multiple base coats to create crisp lines and layered effects. The clear coat remains the final guardian, preserving the undertones of the color while sealing the surface from the daily onslaught of weather, fuel, and road debris. When considering model compatibility and customization options for fairings, it is important to think about how the paint job will interact with aftermarket kits and modifications. The choice of primer, base color, and clear coat can influence how well a panel compiles with replacement parts or kit components. If the project involves Honda fairings or other model-specific panels, you may encounter variations in surface texture or attachment points that require adjustments in masking coverage or primer adhesion. For enthusiasts considering this kind of upgrade or repair, a practical approach is to reference the relevant fairings category to understand the range of compatible components and the potential fitment considerations. For parts sourcing and compatibility, explore the Honda fairings section as a starting point for panels that align with your build. This internal link guides you toward the available options and helps streamline the planning stage of the paint project: Honda fairings. In the end, the outcome of a professional paint job rests on more than the color or the finish. It rests on respecting the surface’s history, applying the right materials in the right order, and allowing each layer to work with the next. The beauty of a well-executed finish is that it invites light to dance across the curves, accentuating the fairing’s lines and the bike’s silhouette. It is a dialogue between the rider’s personality and the machine’s architecture, expressed through depth, gloss, and resilience. A polished fairing is not merely a cosmetic upgrade; it is a commitment to maintenance, care, and the ride itself. The chapter you’ve followed reflects a balance between technique and patience, with an eye toward longevity and aesthetics. For those seeking more guided insights, many reputable sources offer step-by-step walkthroughs and visual references that can complement this foundation. A thorough, picture-driven guide can demystify the subtleties of surface preparation and layering, helping both newcomers and seasoned painters refine their approach while maintaining the integrity of the bike’s design. For a detailed, visual guide, you can consult resources that walk through the painting process in depth, such as the in-depth tutorial from Motorcycle Cruiser: Motorcycle Cruiser – How to Repaint a Motorcycle Fairing for a Professional Finish. The chain of steps—from meticulous prep to careful curing—remains the same, but the nuance comes from practice, the specific materials you choose, and the environment you control. Embracing that nuance will help you create a finish that not only looks formidable but also holds up to the realities of riding. As you embark on your own fairing repaint, remember that the finish is the last line of defense that communicates both care and capability. It is the visible promise that the investment of time, patience, and precision has paid off in a surface that gleams under sun and streetlight alike. And with the right approach, your motorcycle can carry a color that feels as alive as the machine itself, a color that tells your story every time you roll out onto the pavement.

Surface Mastery: Preparation Techniques That Make a Motorcycle Fairing Paint Job Last

A motorcycle fairing is more than a shell that sharpens airflow; it is a canvas that carries color, depth, and personality. Yet the final look only lasts as long as the surface underneath it will allow. The paint job begins long before the first drop of color hits the plastic. It starts with meticulous preparation that respects the material, honors the lines of the fairing, and anticipates the life it will lead on the road. When you approach preparation as a deliberate sequence rather than a hurried set of tasks, you unlock a durability and gloss that survive sun, rain, and the inevitable chips that come with riding. The path from bare plastic to a head-turning finish is a quiet craft, built on clean surfaces, thoughtful adhesion, and controlled environments. In this chapter, we follow a practical, cohesive thread through the essential steps, weaving together how each move strengthens the next and how attention to detail in preparation pays off in the sheen and longevity of the final result.

The journey begins with access. Removing the fairings from the bike is not merely a matter of convenience; it is a strategic move to prevent overspray and to reach every corner with equal care. When you detach the panels, you can work on both sides, the seams, and the inner curves without fighting against obstacles. This openness makes it easier to inspect for surface defects that could otherwise hide under paint. Once the pieces are free, lay them in a clean, sheltered space where dust is minimal and air can circulate. The goal is to create a cockpit of preparation, not a crowded workshop where grit and fibers drift into freshly treated areas. A clean, dust-free stage is not a luxury but a prerequisite. Even small particles can show up as specks in the final coat, breaking the smooth, even feel that a high quality paint job demands.

The first substantive move after removal is thorough cleaning. Plastic fairings are porous to oils and waxes left from storage or road use, and those residues sabotage adhesion at the root. A dedicated plastic cleaner or a plastic-compatible degreaser does the job without attacking the surface. Use a lint-free cloth and work in small sections, wiping away grime, brake dust, and hand oils. It is tempting to cut corners here, especially after a long day of work, but the consequence of neglect becomes visible as the primer lifts or the color refuses to bond in some spots. The aim is a surface that feels clean to the touch and looks uniform when you wipe it with a fresh cloth. After cleaning, inspect for remaining gloss, residues, or micro scratches. Any lingering slick surface can be a barrier to proper adhesion, so you may repeat the cleaning step or detail with a second pass in stubborn areas.

Next comes a careful abrasion that establishes a true key for subsequent coatings. Sanding is not about removing the plastic or forcefully scuffing it into submission; it is about creating a microtexture that offers mechanical bite for primer and paint. Start with a moderate grit that scuffs gloss without carving deep scratches. A common approach is to begin around 400–600 grit to lightly dull the surface and remove any glossy or worn layers. From there, you move to a finer stage, typically around 800–1500 grit, to smooth the texture while preserving the essential roughness that helps adhesion. Some riders favor even finer work, moving into 1200–2000 grit territory, especially when a smoother base is desired for highly reflective finishes. The key is to keep the scratches shallow and uniform, avoiding cross-hatch patterns that become visible after paint. It helps to wipe the surface clean between grits to monitor progress and ensure no stray particles or deeper gouges remain. The sanding step is the hinge that connects cleaning to priming; neglect it and even the best primer struggles to do its job.

After the surface has its texture, the next move is priming. For plastic fairings, a dedicated plastic primer or adhesion promoter is essential. These products bridge the gap between the slick plastic and the solvent-rich paints that will follow. They fill micro-porosities, seal the surface, and enhance the longevity of the color by improving bond strength. Apply the primer in thin, even coats rather than a single heavy layer. Allow adequate drying time between passes, and inspect for uniform coverage. A well-applied primer dries with a dull, even tone and a slight tack that feels ready for color without being sticky. If you notice pinholes, fisheyes, or blotchy patches, address them before the base coat goes on. This may involve light sanding and another spritz of primer, always ensuring a clean, dust-free environment between steps. Skipping this stage or rushing it creates a ripple effect—peeling edges, cracking, or micro delamination that undermines the entire paint job later.

Masking and protection follow primers as a discipline in precision. The goal is to sculpt clean boundaries while preserving the rest of the bike from overspray and unintended color transfer. Use high-quality painter’s tape and masking film to cover edges, seams, and any areas that touch metal components or hardware. Pay attention to the lines around the fairing, the wheel wells, the inner edges, and the attachment points where the panels meet. A well-executed mask yields crisp lines and predictable results in the base color. When you pull the tape after the paint has cured on those edges, you want to encounter a neat separation rather than a ragged outline. The masking step is a psychological moment too: it requires steady hands, a patient pace, and a willingness to invest time to protect the work already done.

Environmental control becomes part of the craft at this stage. The right conditions support consistent drying and help prevent dust from settling on fresh layers. Ideal room temperature is in the range of roughly 20–25 C (68–77 F), with relative humidity around 40–60 percent. Direct sun and gusty winds can accelerate or unevenly dry coatings, causing texture or solvent evaporation issues. The goal is a calm, clean burn-off where solvents can escape evenly and the film can form a stable, durable layer. In the absence of a dedicated paint booth, a clean garage with adroit airflow and a simple filtration approach can be sufficient. The idea is to minimize dust and temperature swings during the entire painting sequence.

With the surface prepped and the environment controlled, you are ready for the base color. The base coat is where the character of the final finish begins to emerge, but it remains subordinate to the work you did in the preparation stages. Color matching can be a careful business, especially if you are aiming for a custom shade or a perfect touch-up of an existing color. Mix base coats carefully, and strain the paint to remove any particulates before spraying. Use light, even coats rather than a single heavy application to avoid runs, sags, or blushing. The target is uniform color depth across the entire fairing and consistent opacity, even in hard-to-reach curves. Allow sufficient drying time between coats, checking for uniform gloss and color evenness after each pass. If you notice color inconsistencies, evaluate lighting and the possibility that additional coats or even a refined sanding step between coats might be needed to create a seamless finish. This phase rewards patience and a willingness to build in multiple layers to achieve an even, saturated hue.

Many riders elect to finish with a clear coat to heighten depth, seal the color, and provide UV protection. A clear coat is not merely an aesthetic flourish; it contributes to longevity and an overall sense of polish. Apply clear in several light coats, followed by a final, slightly heavier layer to build a protective film that resists yellowing, hazing, and embrittlement over time. The clear coat also assists in leveling minor surface irregularities and helps to preserve the crispness of lines around edges and decals, should you choose to reintroduce them later. Like the base color, the clear coat benefits from careful, incremental application and a controlled environment. After the final layer cures, you can evaluate the depth and smoothness of the finish under consistent lighting, looking for uniform reflections and a consistent microlayer appearance across all fairing panels.

Curing is the quiet stage that completes the chapter. A controlled cure, protected from dust and temperature fluctuations, helps the film reach its full hardness and adhesion. Temperature, humidity, and exposure time all influence cure rate and the ultimate gloss of the finish. In a best-case scenario, you would wrap the painted pieces in a gentle, dust-free environment as they finish their cure, or move them into a paint booth with proper ventilation and a stable climate. Once cured, the fairings can be reassembled with care. It is wise to inspect the edges where panels meet and ensure there is no residual tack or slight misalignment that would cause chafing or uneven wear. This is the moment when the preparation work truly shows its payoff—the finish looks smooth, the color depth is rich, and the panel seams sit flush with a professional alignment. The resulting surface is durable, resistant to minor impact damage, and more forgiving of weather exposure than a hastily prepared job.

The chain of practice described above is not merely a sequence of mechanical acts. It is a philosophy about respect for the material and the rider’s expectations. When you approach a motorcycle fairing paint job with an emphasis on preparation, you stage a performance that many riders never witness—the patience and precision that translate into long-term beauty. The work is not about a single dramatic spray but about the cumulative effect of clean, dry surfaces, proper adhesion, and layered protection. Each stage supports the next: cleaning ensures the bond; sanding creates a mechanical grip; primer seals and primes; masking defines the boundaries; environmental control stabilizes the coating; base color builds depth; clear coat preserves the color. When one link in this chain falters, the entire finish bears the consequence. When all links align, the result is a finish that remains vibrant through years of exposure and riding, retaining its gloss, resisting chipping, and showing a depth that reflects the care invested in preparation as much as in color choice.

For those who want a practical touchpoint on related topics, consider exploring broader fairing catalogs for future projects. For newer listings and options that may align with your plan, explore the 2023new category. 2023new. If you are seeking additional external guidance to supplement this preparation framework, a comprehensive practical guide on repainting motorcycle fairings offers further context and checklists, including cleaning, sanding, and priming nuances that can help you compare approaches and confirm best practices. External resource: https://www.carinterior.com/how-to-repaint-motorcycle-fairings-a-practical-guide/

The Alchemy of Color: Materials and Tools Behind a Flawless Motorcycle Fairing Paint Job

The finish on a motorcycle fairing is more than just color. It is the quiet conversation between material science, technique, and patience that yields a surface both beautiful and durable. This chapter threads together the essential materials and tools that turn a set of bare plastics into a shield of glossy color. The aim is not merely to apply paint but to create a bond that lasts as long as the ride itself, resisting UV exposure, heat, and road grime. To begin, picture the fairing as a blank canvas shaped by the rider’s intent. The choice of plastic or composite matters because it governs how the surface will accept primers, base coats, and clear coats. A primer designed specifically for plastic or composite materials becomes the first ally in the process. It acts as a bridge, sealing micro porosities in the substrate and ensuring the color that follows adheres securely. Cleanliness and preparation are the unsung heroes here. Oil residues, wax films, and dirt can sabotage adhesion in ways small in appearance but big in consequence. A dedicated cleaner, such as a plastic-safe degreaser, is applied with care to remove every trace of grease. The aim is not just a clean look but a surface that behaves predictably under subsequent steps. In the same spirit, masking decisions should be deliberate. Precision tape and masking paper are not mere accessories; they are the guardians of transitions. They prevent overspray on lights, hardware, and the adjacent metal parts, preserving the lines that give each fairing its character. A good masking plan reduces improvisation later, which can lead to unsightly bleed lines and compromised edges. The preparation is not glamorous, but it is the foundation that keeps the color honest and the final finish free from regret. As the surface dries after cleaning, the conversation shifts to texture. A light sanding with fine grit—typical ranges around 1200 to 2000 grit—creates a micro-etched surface that invites the next layer to grip without creating deep scratches that telegraph through the color. The goal of this sanding is not to erase the previous finish but to feather the edges so that the transition between old and new paint reads as a single plane rather than a visible seam. For those who begin with a stubborn old layer, an initial coarser pass—using grains in the 80 to 240 range—can remove rough spots, while careful progressive refinement with higher grits produces a smooth, uniform bed for adhesion. The feathered edge is more than technique; it is an optical trick that helps the eye read the color as continuous, even across complex curves and corners. Once the surface is evenly prepared, a primer tailored for plastic or composite materials goes on. The primer’s job is twofold: it seals the surface from moisture and air that might break down the paint and it creates a uniform base that the base color can sit upon without showing through. When choosing primers, the rule is simple: match the material, not the color. Plastic primers adhere better to ABS, polycarbonate, or fiberglass composites, reducing the chance of issues such as pinholes or cracking later in life. After the primer dries, some shops opt for a light sanding to remove any imperfections and to ensure the base coat has a flawless stage on which to perform. The base coat—the color layer—follows. This is where the artistry of the paint job meets the science of adhesion. A high-quality automotive spray paint is preferred, though many projects benefit from a custom-mixed color prepared by a professional supplier. The color must be consistent, stable, and free from streaking when sprayed in multiple passes. The general consensus favors applying multiple thin coats rather than a single heavy layer. Thin coats dry more evenly, reduce the risk of runs, and allow the painter to correct minor flaws between passes. The drying time between coats becomes a matter of discipline rather than guesswork. Rushing this step invites dust entrapment, solvent pop, or unhappy color depth. Humidity and temperature matter here as well. A controlled environment helps prevent moisture from seeping into the finish, which would otherwise manifest as haziness or color drift. A proper color base is not finished after the first coat; it is built through patience and precision. Each pass should be assessed for coverage, consistency, and edge control. When the color looks even, a deliberate pause to examine under different lighting can reveal subtle issues that only surface in certain angles. At this stage, the option to add a clear coat becomes compelling. A clear top coat provides depth, enhances gloss, and, crucially, protects the base color from UV damage, abrasion, and chemical exposure. The gloss depth is a function not only of the clear itself but of the number of base coats beneath it, the evenness of those coats, and the curing environment. Several light layers of clear are typically better than a single heavy pour; this approach minimizes drip risk and helps the finish maintain a uniform thickness. The curing process is the final test in many shops. A controlled environment—think of a dedicated paint booth or a similarly ventilated, climate-stable space—ensures the solvents fully evaporate and the film cross-links properly. Temperature, humidity, and air flow are not afterthoughts; they are determinants of a tough, long-lasting finish. Temperature too low can slow curing and invite solvent entrapment; too high, and solvents can flash too quickly, leaving surface tension that becomes a soft point under abrasion. Ideal conditions strike a balance that supports both cure rate and surface quality. In the hands of a practiced painter, the combination of materials and environmental control yields a result that feels almost inevitable: a smooth, glassy plane that respects every curve of the fairing and holds color with confidence through miles of road and sun-drenched days. The choice of tools underpins this outcome as surely as the choice of materials. A spray gun is the central instrument, and the debate between gravity-feed, siphon-feed, HVLP, and airless systems centers on control, material usage, and finish quality. The common thread across successful jobs is the steady, even atomization of paint. The operator’s goal is to avoid heavy “orange peel” texture while preserving a crisp edge that reads as continuous rather than segmented. An air compressor with adequate CFM rating keeps the spray pattern consistent and helps prevent pressure drop during extended sessions. The qualitative difference between a good finish and a great one often traces back to the setup: clean hoses, properly sized fittings, and a well-tuned gun that delivers a fine, controllable spray rather than a jet of droplets. Sanding tools complement the gun’s performance. An electric orbit or dual-action sander speeds up the heavy lifting of removing old paint and shaping the surface. Dry sanding blocks and a careful hand finalize the process, especially along the feathered transitions formed by the underlying color or by masking edges. These tools are not merely mechanical aids; they embody the discipline required for a showroom-like result. The preparation of surfaces extends beyond the obvious blocks of time spent with sandpaper. Filling minor imperfections—small dents, digs, or divots—in the fairing can prevent those blemishes from telegraphing through the final color. A putty or filler layer, followed by gentle sanding, fills in the micro-pores of the plastic and smooths the fairing’s surface so that the base coat can lie flat and true. A clean, corrosion-free environment also depends on the right solvents for thinning paints and cleaning tools. Thinners, reducers, and cleaners are chosen in reference to the paint system and the primer being used. Using the wrong solvent can cause premature curing, solvent pop, or poor adhesion. The modern painter’s toolkit also includes protective gear: a respirator with organic vapor cartridges, safety goggles, chemical-resistant gloves, and a full-face shield when working in a spray booth. This is more than safety; it is a guarantee against fumes that, while invisible, can dull the painter’s focus and compromise the finish. Even with the right gear, adequate ventilation remains essential. Dust collection and cleanroom-like filtration help maintain a surface free of micro-particles that would otherwise settle into the finish on the final cure. The array of supplementary materials—putty, sanding blocks, grinding wheels for edge work, and even common household aids like tack cloths for removing dust—supports a single, coherent objective: the absence of fault lines, the integrity of color, and a finish that remains pristine over time. The importance of masking cannot be overstated. A fully masked surface reduces the risk of accidental color crossing and preserves the crisp edge lines that define the motorcycle’s silhouette. The painter’s eye is trained to anticipate where color bleed could occur, and masking is the primary defense. Masking paper protects larger areas, while pre-cut tapes delineate radii and transitions with a precision that would be impossible to achieve with later corrections. The result is a fairing that, once the tape is lifted, reveals boundaries that look intentional, almost engineered rather than improvised. In practice, this means aligning the masking with the fairing’s natural seams and joints, working slowly around curves, and inspecting the edge life after each removal. The materials and tools described here are the backbone of a chapter-long craft, but the true measure of success is the finished surface: a uniform, glossy field that seems to glow with depth when the light strikes it at the right angle. The motorcyclist who sees this work recognizes more than color; they sense resilience—the knowledge that the finish will endure the hazards of daily riding and the occasional track session. While the path to that finish is paved with science and steady hands, it remains accessible to anyone who respects the sequence: prepare and prime, color and layer, seal and cure, then step back and let the light reveal the truth of the work. If you are exploring compatibility and parts as you plan, you may find it useful to consider a dedicated category that reflects how different manufacturers approach fairings and color. For instance, a catalog such as the Honda fairings collection offers practical context on how shape, curvature, and mounting points influence surface preparation and edge handling. This helps frame the painting process not as a single action but as an integrated sequence that respects the fairing’s geometry and the rider’s design goals. To keep the discussion grounded in practicalities, the following note serves as a reminder: the materials and tools described above are not interchangeable with any one brand or model. They are guidelines, adaptable to various fairing shapes and plastic families. The essence is that adhesion, even color, and clarity of finish rely on a thoughtful pairing of substrate, primer, base color, and clear coat, all executed under proper conditions with the right tools. A successful paint job, then, is a disciplined blend of method and artistry, a translation of the rider’s vision into a durable, mirror-like surface. As you prepare to move from the shop bench to the outdoor ride, keep in mind that the chapter on design and customization that follows will hinge on the groundwork laid by these materials and tools. The paint deserves respect, and the process deserves patience; with those, the motorcycle fairing becomes more than a shell. It becomes a statement forged in rhythm with the bike’s performance and the rider’s personality. External resource: https://ultimatemotorx.net/product-category/honda-fairings/

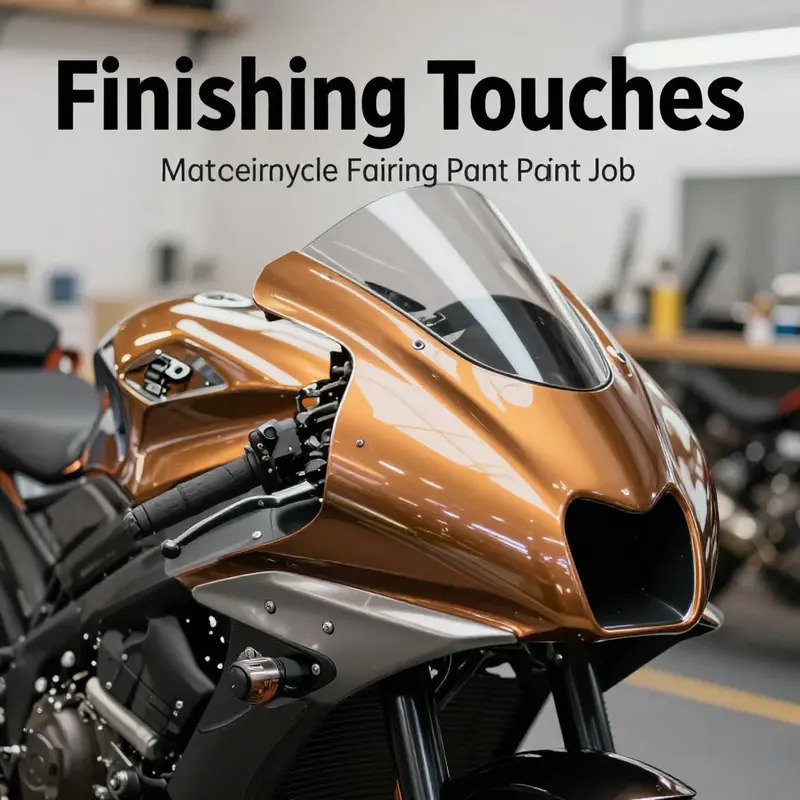

The Final Reveal: Mastering Finishing Touches for a Deep-Gloss Motorcycle Fairing Paint Job

The finishing touches in a motorcycle fairing paint job are not an afterthought. They are the part of the process where intention, technique, and time converge to deliver a surface that looks far sharper than it did when the color first met the plastic. A fairing’s finish has to endure the realities of wind, sun, rain, and road debris, yet still shine with a depth that makes the color sing. When the base and the clear are laid down correctly, the work moves from painting to polishing, from protection to perfection. This is where many riders and hobbyists realize the difference between a good result and a studio-grade finish. The narrative of finishing touches is a quiet one, built on patience, meticulousness, and respect for the material. Plastic fairings respond best when their surface is prepared, cured, and treated with care, because adhesion hinges on that careful foundation and because any small imperfection, once locked under a final layer of clear, becomes a permanent feature of the finish.

Drying time remains a critical measure of progress even after the final coat is applied. Once the last layer of paint is down, it is essential to allow the coating to cure thoroughly before moving to any refining steps. The commonly recommended guideline is to wait at least three hours per coat before handling or moving to the next stage, but the exact timing can vary with temperature, humidity, and the paint system in use. Patience here pays off later when the surface accepts additional work without showing newly created defects. Jumping ahead too quickly invites runs, sagging, or soft spots that compromise the entire job. A controlled environment—ideally a dust-free space with stable temperature and moderate humidity—helps ensure the drying phase yields a uniform, robust film. In a workshop setting, this environment often means a dedicated paint booth or a similarly contained area where airflow is managed and dust is minimized.

Even with careful drying, the surface may harbor microscopic imperfections after the coats have cured. This is where fine sanding becomes a crucial ally in the finishing process. Lightly abrading the top layer with very fine-grit paper, typically in the range of 2000 to 3000 grit, helps to remove the last traces of orange peel and any minor dust nibs that escaped the initial cleaning and sanding stages. The aim is not to remove the color, but to flatten the surface so that the subsequent clear coat can lay down evenly and uniformly. When performed correctly, this step reveals a surface that looks near-mirror smooth under bright, raking light. The key is to keep the sanding action gentle and to check frequently by wiping the surface clean with a tack cloth and inspecting with natural daylight. Any excessive sanding into the pigment can cause haze or a dull spot, so a light touch guided by careful inspection is essential.

After the surface has been refined through gentle sanding, the application of a clear coat takes center stage. The clear layer is more than a glossy overlay; it is a protective shell that enhances color depth, provides UV resistance, and locks in the finish against environmental assault. The practical approach is to apply the clear coat in multiple light passes rather than attempting a single thick layer. This minimizes runs and sagging and helps build an even, glassy finish. The precise number of passes exceeds one, but the overarching rule is to follow the manufacturer’s guidelines for flash time—typically a window of about 15 to 30 minutes between coats. Flash time allows solvents to evaporate enough so that each new layer adheres properly without lifting the one beneath it. Patience here translates into long-term durability: the benefits appear as color retention, scratch resistance, and a surface that remains resilient under weather exposure.

Once the final clear layer has been applied and the surface has cured, which often means a full 24 to 48 hours in the right environment, the project shifts toward bringing out the ultimate sheen. Polishing is the step that converts a good finish into a mirror-like surface. Using a dual-action polisher—an orbital tool that reduces heat buildup and minimizes the risk of burning the paint—paired with appropriate polishing compounds, lifts the last vestiges of haze and micro-scratches. The process usually begins with a medium or fine-cut compound to remove minor imperfections, followed by a finishing compound that enhances gloss. A careful hand on the polisher, with consistent speed and even pressure, ensures you do not create new swirl marks or smudges. The goal is a uniform, high-gloss finish that catches the light and enhances the color depth without looking bruised by overzealous polishing.

The final inspection, ideally conducted under natural light, is the moment of truth. A careful walk around the motorcycle, looking for dust nibs, missed spots, or subtle blemishes, makes or breaks the perceived quality of the paint job. Even the most diligent painter can overlook something in a dimly lit workshop, only to discover it when the sun shines on the panel. The inspection is followed by minor touch-ups where needed: a tiny dab of clear to seal a speck of dust or a quick re-buff of a small area after it has fully cured. This stage is quiet yet essential. It ensures that the finish is not merely consistent across panels but flawless at the edges and seams where two pieces meet. The dialogue between inspection and touch-up is a careful one, balancing the risk of overworking the surface with the necessity of perfecting every minor detail.

From a practical perspective, the finishing phase is where equipment choice and technique can noticeably shift the outcome. A spray gun with a 1.3 millimeter nozzle facilitates good control when working with plastic primer and base coats. The nozzle size matters because it influences atomization, fan pattern, and the level of control you have over the amount of material being deposited on the surface. Plastic primers, designed to adhere to flexible plastics, create a better anchor for the subsequent color and clear coats. The overall goal is to achieve an even, atomized spray that wets the surface without creating scarce spots or heavy builds that lead to texture irregularities. Choosing the right equipment and using it with steady technique reduces the likelihood of the dreaded orange peel effect and helps the final finish achieve that sought-after depth and clarity.

Environmental discipline remains a cornerstone of the finishing touches. A clean, dust-free environment is not merely a nicety; it is a necessity. Dust particles in the air can land on a wet surface and become embedded in the final finish, requiring re-sanding and re-polishing that can erase the gains of weeks of work. Personal protective equipment—gloves, a respirator, and eye protection—becomes part of the routine as soon as the painting begins, not as an afterthought when the day is done. Temperature and humidity influence how fast solvents evaporate and how the film forms. Keeping conditions stable avoids shifts that could lead to a cloudy appearance or a mismatch between panels. These realities remind us that finishing touches are as much about environment and discipline as they are about technique.

A well-executed finish is not simply about looks. It is a lasting investment in the resilience of the paint job, preserving color integrity, shine, and resistance to UV light and environmental wear. The deeper the gloss and the richer the color under natural light, the more the fairing communicates a sense of care and craftsmanship. The finish’s longevity is a practical reward for the time spent dialing in every step—every minute of drying, every careful sanding pass, every lightly sprayed clear coat, every hour of curing, and every careful polish. In the broader arc of a motorbike’s aesthetics, the finishing touches determine how long the new look will endure before the next refresh is due.

For readers seeking a broader context around the craft, consideration of model compatibility and accessory options can help frame the finishing work within ongoing customization projects. If you are mapping a broader refresh or exploring fairing options for a specific model, a catalog of fitment options can be a useful companion reference. You might, for instance, browse options aligned with a particular brand’s fairings to understand how panel shapes and materials affect finish behavior. This approach helps you anticipate potential challenges with texture, adhesion, or polishing across different plastics and composite materials. For readers focusing on, say, Honda fairings, exploring dedicated catalog pages can provide a sense of accepted practices and common surface characteristics that inform the finishing process. Honda fairings can be a practical touchstone for planning refinishing work and understanding how different fairing geometries influence sanding and polishing techniques. Honda fairings catalog offers a snapshot of what to expect in terms of profile and material, helping to align expectations with the realities of finishing work on those shells.

Beyond the hands-on sequence, the mindset of finishing touches centers on consistency, patience, and a disciplined workflow. It demands an eye trained to catch subtle discrepancies in light, a steady hand during sprayouts, and a willingness to pause when the surface demands it. The final appearance is not an accident; it is the result of a deliberate, iterative process in which each stage informs the next. The difference between a fairing that looks good in photos and one that holds up to the rigors of riding is the willingness to slow down at the end and to invest in the high-precision steps that protect the finish from weather, abrasion, and time.

For practitioners who are building their method, the finishing stage can be treated as a culmination of the entire refinishing plan: surface preparation, color integrity, protective layering, controlled curing, and a deliberate polish that reveals the full spectrum of the color. The experience of completing these steps yields not only a professional appearance but a tangible sense of accomplishment. When the fairing gleams in daylight and remains resistant to micro-scratches after hundreds of miles, the finishing work has proven its value. The narrative of finishing touches, then, is a practical and artistic practice that transforms prepared surface into a durable, striking finish capable of withstanding the ongoing rhythms of riding life.

For readers who would like to explore further practical guidance or align their approach with broader resources, an external guide to pro-level painting techniques offers a comprehensive roadmap. This resource expands on the subtleties of drying times, multiple lightweight coats, essential curing environments, and the polishing sequence that yields a showroom-like gloss. It complements the in-depth steps outlined here and can help you refine technique across different projects and model families. Accessing this external reference provides a broader frame for the finishing phase, reinforcing the discipline required to achieve a flawless, lasting finish. External pro-painting techniques guide to deepen understanding of the final polish and protective strategies.

In closing, the finishing touches are where the craft translates into surface reality. They are the bridge between color selection and the durable, glossy finish that endures through miles of wind and weather. The steps—from patient drying and ultra-fine sanding to the precise layering of clear coats and the final, careful polish—combine to deliver a result that commands attention in the best way. When done thoughtfully, the final reveal is more than aesthetic satisfaction; it is peace of mind that the paint job will remain vibrant, resilient, and true to your intentions long after the last wrench has been put away and the bike has rolled out into the light.

Final thoughts

Painting motorcycle fairings professionally is not just about aesthetics; it is vital for durability and customer satisfaction. As a business owner, mastering the comprehensive steps from preparation to executing the finishing touches will enhance the quality of your work and ultimately, your business reputation. By investing time into understanding the detailed processes and using the right materials, you can offer a service that stands out in the competitive automotive industry. Remember that every motorcycle you paint represents your brand, and excellence is the goal.