Motorcycle fairing mirrors represent an intersection of form and function, offering bikers a blend of aesthetic appeal and improved riding safety. As business owners in the motorcycle industry, understanding these specialized mirrors not only enhances product offerings but also aligns with consumer preferences for sleek design. This article delves into the design and aesthetics, functional benefits, current market trends, installation nuances, and recent innovations in materials and technology related to motorcycle fairing mirrors, equipping you with valuable insights for your business strategy.

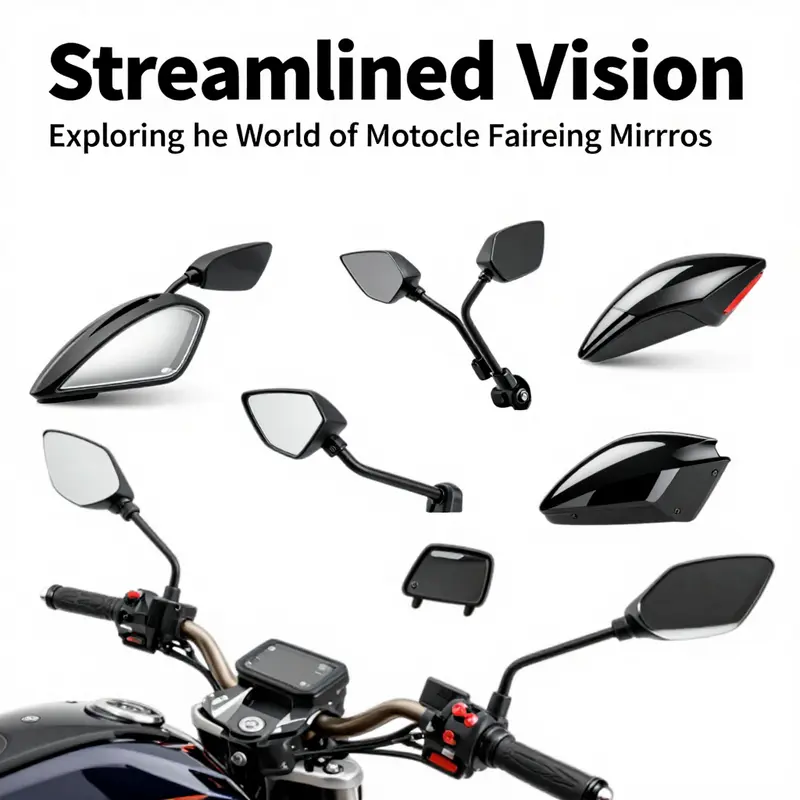

Shaping Presence: The Design and Aesthetics of Fairing-Mounted Mirrors

Shaping Presence: The Design and Aesthetics of Fairing-Mounted Mirrors

Motorcycle fairing mirrors do more than reflect what is behind. They define silhouette, suggest speed, and finish a bike’s visual story. When designers integrate mirrors into the fairing, they treat them as extensions of the bodywork. The result is a unified surface where mirrors follow the same lines and materials as the panels that surround them. That unity transforms a practical item into a statement of intent.

The aesthetic power of fairing-mounted mirrors begins with proportion. Mirror size is balanced against the fairing’s curves to preserve flow. A too-large mirror interrupts lines and looks bolted-on. A too-small mirror risks being invisible at speed and failing its safety role. Designers choose shapes that echo headlight contours, tank angles, and side panel sweeps. Teardrops, sharp trapezoids, and elongated rectangles are all selected to harmonize with a specific bike’s character. Each form communicates something: aggression, elegance, or aerodynamic efficiency.

Material choice further refines the message. Matte finishes create a modern, understated look. Gloss finishes give depth and weight. Chrome or polished metal adds a vintage or premium tone, catching light and drawing the eye. Carbon fiber inserts or textured plastics signal performance. When the mirror housing matches the fairing material, the bike reads as a single crafted object. When it contrasts, it creates deliberate accents that emphasize lines and surfaces.

Color and finish are not purely decorative. They change perceived volume and motion. Matte black tends to recede visually, making fairings look sleeker. A bright or polished mirror becomes a focal point, useful on touring bikes where visibility and presence matter. Subtle color matches soften transitions between parts, while deliberate contrasts highlight engineering details and surface junctions.

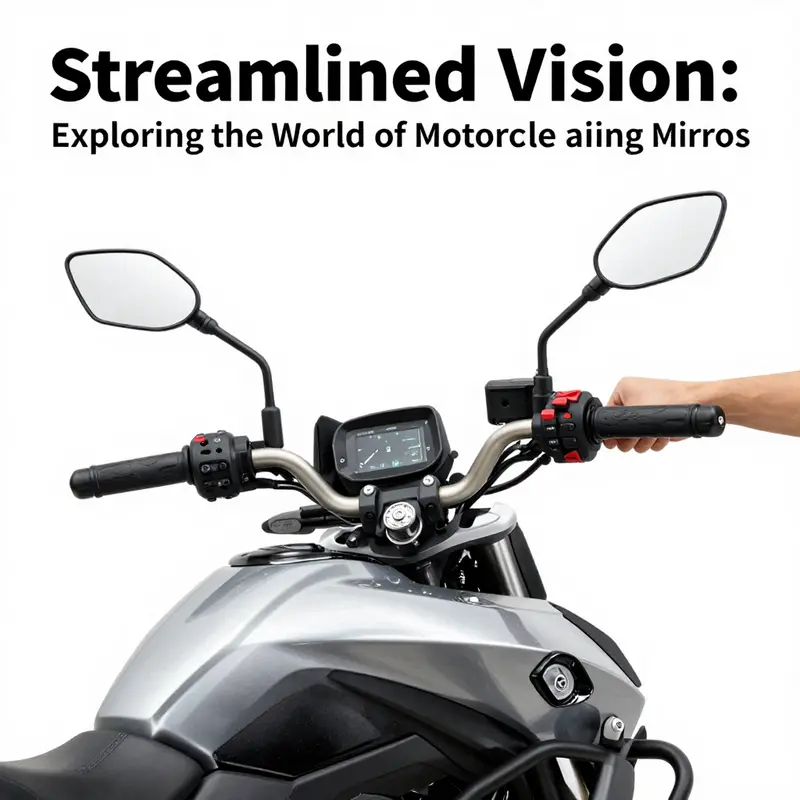

Integration extends beyond surface treatment to attachment and placement. Fairing-mounted mirrors are often molded into or bolted through panels. This integration reduces protrusions that catch wind. It also allows designers to place mirrors in positions that handlebars cannot reach. That freedom supports cleaner cockpit layouts and a more refined rider interface. A mirror set mounted near headlight surrounds or along inner fairing walls can feel almost hidden. Yet it performs without commanding attention.

A seamless appearance demands attention to the small things. Edge treatments, gap tolerances, and bezel profiles matter. Smooth transitions where mirror housing meets fairing reduce aerodynamic drag. Tight seams add a premium feel. Visible screws can be blacked-out or finished to match surrounding surfaces so they do not interrupt the visual flow. Even the curvature of the mirror glass is considered against the fairing curvature to maintain optical and aesthetic consistency.

Sleek, minimalist designs have grown popular. These approaches strip mirrors down to essential lines. The housing becomes a thin wing or a low-profile blade. Minimalism pairs well with sport and naked machine aesthetics. It reinforces the impression of purposeful engineering. Yet minimalism must still respect safety. Designers often use subtle bulges or flared edges to ensure adequate rearward visibility. The balance between minimal form and functional field of view is a careful negotiation.

Conversely, touring and cruiser bikes often favor larger, more pronounced mirror forms. There, mirrors contribute to a presence on the road. Larger housings allow for wider glass and multiple reflective surfaces. They also permit built-in features, such as vibration damping structures. On these bikes, mirrors become part of the rider’s comfort system. They support a relaxed, commanding riding posture and complement heavier, sculpted fairings.

Aerodynamics is a silent partner to style. A mirror that slices through air with minimal turbulence improves stability and reduces noise. Fairing integration makes it possible to channel airflow along the bodywork. Designers engineer internal pockets and mounting rails that guide air around and past the mirror. The result is not only better fuel efficiency at speed, but also a quieter, more predictable ride. For performance-oriented models especially, these small gains compound into meaningful handling improvements.

Durability and vibration control are functional details that shape aesthetic decisions. Mirrors mounted solidly to the fairing transmit less vibration than handlebar-mounted units. This supports thinner glass and more slender housings without compromising clarity. Robust internal mounts also allow for more aggressive finishes that withstand the elements. A well-engineered mirror will keep its alignment and finish longer, preserving the bike’s intended look over years of use.

Safety requirements remain a guiding constraint. Designers cannot sacrifice sightlines for style. Effective fairing mirrors must provide clear views for lane changes, merging, and situational awareness. This need guides mirror placement and curvature. Convex glass is sometimes used to widen the field of view without increasing housing size. Designers use subtle angles in placement to maximize visibility for typical rider postures. The goal is an unobtrusive component that still offers complete rearward awareness.

The cultural dimension of mirror design is significant. Mirrors carry heritage cues that riders recognize. Polished housings recall classic touring machines. Carbon fiber hints at racetrack pedigree. Each finish and shape taps into a language of riding identities. For custom builds, mirrors can anchor a transformation, signaling the direction of the modification. On production bikes, they contribute to brand recognition by echoing consistent design motifs.

Customization possibilities add another layer to aesthetics. Riders choose mirror styles to tune their bike’s personality. Some prefer matched finishes for a factory-cohesive look. Others pick contrasting mirrors to create visual punctuation. The variety of available shapes and finishes supports both subtle and dramatic changes. Because fairing-mounted mirrors often use model-specific mounting points, aftermarket options can maintain the original integration while altering the visual tone.

Practical details influence perceived quality. The tactile feel of adjustment mechanisms and the precision of finish edges affect how riders judge the component. A mirror that adjusts smoothly and stays put gives confidence both functionally and visually. Weather sealing around mounting points and corrosion-resistant coatings maintain visual integrity over time. These engineering choices keep the aesthetic promise intact across seasons.

Fairing mirror design also responds to lighting and the urban environment. Polished surfaces can produce glare at certain angles. Designers compensate with anti-reflective coatings and careful curvature choices. Matte finishes reduce stray reflections but can show wear differently. The mirror’s role in nighttime visibility is another consideration, as housing contours influence how headlamp beams interact with the bike’s front end.

Ultimately, the aesthetic success of fairing-mounted mirrors depends on coherent design thinking. When form follows multiple functions—visibility, aerodynamics, durability, and brand language—the mirror becomes a natural element of the motorcycle’s identity. Riders then experience a machine that looks composed and purposeful. The visual payoff is a bike that reads as complete and intentional, where every line and surface contributes to the whole.

For riders and builders seeking compatible bodywork and fairing options, exploring model-specific fairing resources can help match mirror styles to appropriate panels. A focused selection of fairings for YZF models offers useful references when considering aesthetic pairings and integration strategies: https://ultimatemotorx.net/product-category/yamaha-fairings/fairings-for-yzf/

Designers and riders will continue to refine the balance between image and function. Fairing-mounted mirrors have evolved past mere necessity. They now anchor style language while upholding the safety and performance standards riders expect. As materials and mounting techniques advance, mirrors will keep shaping how motorcycles look and how they feel on the road.

From Profile to Protection: Functional Benefits of Motorcycle Fairing Mirrors in Riding Safety

Mirrors mounted on the fairing do more than contribute to a bike’s silhouette; they shape how a rider perceives the road, responds to distant cues, and positions the instrument cluster and headlight within a single, cohesive visual field. When new designs place rearward vision inside the inner fairing, near the headlight or along the side panels, the mirror housing becomes part of a larger sculpture that speaks to aerodynamics as much as it does to aesthetics. The deliberate inside-the-fairing placement is not only about a cleaner line; it is also about creating a stable, predictable reflection that remains consistent in a range of riding conditions. In touring and cruiser configurations, where long hours in the saddle demand a calm cockpit, this integration matters as much for safety as for style. The visual continuity reduces the number of protrusions that can catch wind, and that reduction in wind pressure can translate into steadier mirror views over the miles. The functional benefits of fairing-mounted mirrors hinge on how they interact with the bike’s aerodynamics, vibration, and sightlines. When mirrors sit flush with the fairing, their exposure to turbulent gusts and engine heat can be minimized compared with handlebars-mounted options that contend with more direct wind forces. The streamlined profile minimizes both wind noise and the micro-shudder that can blur a reflected scene at high speed. Riders report that a stable image–where the horizon does not jitter or blur as throttle, bumps, or passing lanes shift the frame–helps with sustained cross-checks of traffic in the mirror. In a sense, the mirror becomes less a separate instrument and more an extension of the rider’s peripheral awareness. The lines of the fairing and the mirror housing work together to minimize the separation between what the rider sees in front of the bike and what is happening behind it, strengthening the continuity of attention that is essential to safe riding. A key design choice in fairing-mounted mirrors is the lens configuration. The option for either a flat or a convex mirror mirrors a balance between accuracy and breadth of view. A flat mirror offers a true representation of distance, which can be comforting for riders who rely on precise depth cues when merging or changing lanes. A convex lens, by enlarging the field of view, reduces the need for frequent head turning and helps spot vehicles that sit on the edge of perception. For highway speeds and busy urban traffic alike, the convex option can extend situational awareness into blind-spot territory, though riders must recalibrate their sense of distance to objects in reflection. The decision often comes down to rider preference and riding context, but the larger safety implication is clear: a thoughtfully chosen mirror helps maintain line-of-sight confidence with minimal distraction. The inner-fairing location further enhances this, because the mirrors stay in a stable, predictable orientation even as the rider adjusts posture on long rides or shifts weight through curves. Beyond the glass, the mirror housing itself plays a protective and ergonomic role. A durable molded plastic enclosure that matches the fairing’s contour is more than an aesthetic match; it shields the reflective surface from road grit, spray, and heat. The choice of finish–polished chrome, matte black, or a color that blends with the bike’s tone–affects not only the visual cohesion but also the ease with which a rider can interpret reflections at a glance. A well-finished housing reduces visual noise, allowing the rider to focus on the crucial task of assessing traffic rather than assessing the mirror’s condition. In practical terms, this means fewer moments spent adjusting the bike’s stance to improve the mirror angle and more time spent watching for changing traffic dynamics. Compatibility and fitment are practical safety considerations in their own right. Several manufacturers offer fairing-mount mirrors designed to fit specific models, ensuring the mirror aligns with the fairing’s geometry and does not intrude upon headlight performance or instrument visibility. The result is a pair of mirrors that feel like they belong to the bike rather than an afterthought added later. For riders, the immediate safety implication is a reduced risk of misalignment after long highway stints or after installation adjustments. Proper installation–checking mirror height, tilt, and left-right symmetry–helps maintain a consistent field of view across a range of speeds and riding styles. When mirrors are installed with care, the rider’s head remains naturally oriented toward the street, rather than shifting focus between an out-of-picture reflection and the road ahead. In the broader context of riding safety, fairing-mounted mirrors contribute to a cleaner cognitive load. A rider’s attention can be divided between road hazards and the instrument cluster; a mirror that sits within the fairing often reduces the cognitive steps required to locate the reflected image. This is especially valuable on long rides, where fatigue can blunt reaction times. The mirrors’ integration into the fairing can also lower the risk of accidental contact with branches, parking barriers, or other riders’ mirrors that occasionally occurs with protruding handlebar-mounted units. The more a rider can maintain a calm, continuous awareness of rear traffic without feeling a tug of war between multiple sightlines, the more bandwidth remains for interpreting lane changes, signaling intentions, and scanning for hidden hazards such as weaving vehicles or accelerating cross-traffic. The evaluative lens here is not merely aesthetics; it is a question of how the rider translates perception into quick, appropriate action. Fairing-mounted mirrors support a streamlined profile that diminishes drag and, in turn, reduces wind-induced instability that can ripple through the rider’s posture and line of sight. A stable rear view helps prevent over-corrective steering in response to a glancing vehicle, a common source of risk in fast traffic. While the existing knowledge base on the specific safety benefits of fairing mirrors is limited, the logic of integrated design is clear: when mirrors are a seamless part of the bodywork, they are easier to keep aligned, easier to see through, and easier to interpret without shifting focus away from the road. That seamlessness fosters confidence, and confidence in rearward visibility is a meaningful contributor to riding safety. As manufacturers continue to refine materials, finishes, and mounting systems, the emphasis remains on durability, reliability, and ease of installation across different motorcycle models. The durability of a mirror housing, resistance to vibration, and the integrity of the reflective surface all factor into long-term safety outcomes. Maintenance becomes a straightforward part of routine care: a quick wipe to remove grime, a quick check that the mirror still mirrors true distance, and a quick realignment after a pedal or wind-induced shock. In the end, the safest ride is one in which the rider’s attention is not compromised by incongruent visibility or by distracting reflections. The fairing mirror, when well designed and properly fitted, becomes a quiet enabler of safer riding rather than a flashy accessory that demands extra cognitive work. For readers who want to see how fairing components fit into broader customization and upgrade strategies, consider exploring the broader landscape of fairings and their integration into modern bikes. This broader context helps situate the fairing mirror as part of a system designed to optimize both appearance and function. For example, you can explore the fairings category to understand how fairing geometry influences overall aerodynamics and visibility. Within that context, the mirror becomes a component that respects the integrity of the fairing’s lines while delivering reliable rearward vision. Honda fairings category offers a sense of how components are designed to integrate with surrounding panels, even as it remains clear that the same principles apply across various makes and models. The result is a cohesive, integrated cockpit where every piece serves the rider’s safety and the machine’s character. In considering safety, one should not treat the mirror as a standalone device but as a collaborator in the rider’s sense-making process. The decision to opt for fairing-mounted mirrors should be guided by how the mirror’s placement supports consistent perception, reduces wind-induced instability, and minimizes the cognitive demand required to monitor traffic. The best solutions balance field of view with image clarity, ensure durable construction, and preserve a clean, aerodynamic silhouette that keeps the rider focused on the road ahead. As the rearview mirrors of today continue to evolve, their role in riding safety remains intimately tied to how well they integrate with the bike’s design philosophy–creating a safe, confident, and enjoyable riding experience. External resource: For a broader view on motorcycle safety and visibility, you can consult established safety guidelines and research at https://www.nhtsa.gov/road-safety/motorcycle-safety.

Seamless Vision: The Evolution, Value, and Craft of Fairing-Mounted Motorcycle Mirrors

The pursuit of a flawless, integrated look on motorcycles has driven a quiet revolution in how riders perceive and are perceived on the road. Fairing-mounted mirrors have shifted from simple convenience to a design language that speaks to aerodynamics, aesthetics, and rider confidence all at once. Rather than clinging to the handlebars, these mirrors nest within the contours of the fairing, often tucked toward the inner edge of the paneling or perched near the headlamp where they become part of the bike’s silhouette. The result is a cleaner line that reduces visual clutter and, for many riders, a more cohesive sculpture on wheels. This evolution isn’t just about looks; it embodies a shift in how engineers marry form and function. By aligning the mirrors with the fairing geometry, manufacturers can optimize airflow around the front of the bike while preserving or even enhancing rearward visibility. The effect is a subtle yet meaningful upgrade in both performance and perception, especially for touring and sport-touring machines where every marginal gain in aerodynamics translates into real-world comfort on long journeys and steady highway cruises.

The placement inside the inner fairing—close to the headlight or along the side panels—redefines the rider’s line of sight without demanding extra reach from the hands. In practice, the mirrors become almost invisible from a certain vantage, contributing to that factory-finish aesthetic that enthusiasts crave. The batwing-style housings that frequently accompany this design further this impression, delivering a characteristic sweep that harmonizes with the fairing’s curves. Finishes range from the bold glare of polished chrome to subdued satin blacks, giving riders a palette that can echo vintage vibes or contemporary minimalism. The choice of finish is more than stylistic; it interacts with the bike’s overall color scheme and material palette, creating a unity that can elevate even a modest upgrade into a statement piece. While some riders prize chrome for its retro appeal, others lean toward non-reflective surfaces to curb glare in bright sun or to coordinate with other blacked-out accents on a touring build. The challenge is achieving that balance where reflection aids visibility without becoming a distraction at speed.

Material choice matters as much as the design. The common approach uses durable molded plastics for the housing, a combination that offers impact resistance, weather resilience, and ease of shaping to match the fairing’s profile. The lens itself—whether flat for a true representation or convex for a wider field of view—must contend with rider safety, glare, and the potential for distortion. Convex lenses expand the visible sector behind the bike, which is a safety boon in dense traffic or on twisty roads, yet some riders prefer flat lenses for less distortion and a more accurate depiction of approaching vehicles. The mounting geometry, too, plays a pivotal role. A well-engineered fairing-mount system secures the mirrors against vibration, wind pressure, and road shocks, preserving alignment so that correction after a rough patch isn’t a constant ritual. The goal is a stable, reliable vista that remains consistent as speed increases and wind forces intensify.

From a design perspective, the mirrors’ integration into the fairing supports a broader conversation about ergonomics and rider confidence. When mirrors are visually integrated, they reduce the perceived clutter around the handlebars, allowing the rider to focus more on the road ahead. In practice, this means fewer adjustments while riding, less time spent fiddling with mirrors in traffic, and a greater sense of steadiness during long sessions of highway cruising. The engineering challenge behind this seamless look is to ensure that the mirrors deliver broad sightlines without enlarging the fairing’s frontal area in a way that negates the aerodynamic advantage. Brands and builders pursue this balance with an eye for both manufacturing efficiency and rider satisfaction. The result is a family of mirror solutions that can be adapted across a spectrum of models, from streamlined sport bikes to substantial touring machines, without compromising the airfoil profile that defines each bicycle’s character.

As the market matures, the spectrum of configurations widens. Riders can choose flat or convex glass, a decision that hinges on riding contexts and personal preference. Flat mirrors offer a straightforward, life-like view of adjacent traffic, which some riders find easier to interpret at a glance. Convex mirrors broaden the rearward field, an attribute highly valued in urban environments where traffic density and changing lanes demand a wider awareness. The hinge mechanism—whether fixed, adjustable, or capable of micro-angle tuning—further tailors the experience. A sturdy, precisely engineered adjustment ensures that the mirror’s vantage point remains aligned with the rider’s seating position and height, a factor that changes with different fairing shapes and rider physiques. The installation process, therefore, becomes a measure of readiness. Proper torque, alignment, and seal integrity are essential not only for visual clarity but also for maintaining the enclosure’s weatherproof performance over time.

Market dynamics mirror these design and engineering choices. Market researchers have noted a steady appetite for integrated, one-piece aesthetics that deliver both elegance and aerodynamic benefit. The trend toward customization is another key driver. Owners increasingly seek high-end, statement-making finishes—edge-cut tapered edges, distinctive silhouettes, and color options that echo the bike’s theme or the owner’s personal style. These bespoke touches transform a functional accessory into a visible axis of personal expression. At the same time, there is a shift in how riders source these parts. Beyond traditional dealerships, e-commerce platforms have broadened access, offering a broader array of fitments and finishes, sometimes with transparent pricing and customer feedback that informs purchasing choices. This diversification benefits riders who want to experiment with a look or test fitment on a first build before investing in a complete upgrade.

The pricing landscape for fairing-mounted mirrors reflects the market’s bifurcation between value-oriented and premium offerings. Base, universal kits can be surprisingly affordable, sometimes listed at around ten dollars and change, making them an appealing entry point for budget-conscious riders or those who use these mirrors primarily as cosmetic enhancements. More common, mid-range options cluster around the hundred-dollar mark, offering reliable performance, simple installation, and a wide range of finishes to match the fairing. The premium tier—aimed at riders who demand distinctive aesthetics and optimized performance—can reach beyond two hundred dollars, driven by specialized design features, materials, and meticulous craftsmanship. This price structure illustrates a broader dynamic in the aftermarket: organizations compete on a spectrum where low-cost, core functionality sits alongside high-end, design-forward solutions that emphasize durability and refinement. For riders, this means a straightforward path from a budget upgrade to a high-end statement piece, with many convergence points along the way.

In this environment, decision-making becomes a blend of practicality and aesthetics. The most important questions often revolve around fitment compatibility, visibility, and maintenance. A fairing-mounted mirror must align with the fairing’s curvature and the rider’s seating position; otherwise, the effort invested in choosing a stylish option evaporates in the form of a distorted image, cramped field of view, or increased wind noise. Riders also weigh the long-term value: how the mirrors tolerate sun exposure, temperature swings, and road spray, and whether their finish will resist pitting, chipping, or fading. The perceived value of a mirror presents itself not only in the clarity of the glass but in the harmony of its housing with the bike’s overall design language. A mirror that mirrors the bike’s lines can elevate the entire silhouette, whereas a misfit piece can look out of place and undermine the investment.

For those who are curious about how to explore compatible options, many riders begin with broader categories of fairing components. They seek pieces that “fit within the fairing profile” and offer a range of finishes that complement the line work of the bike. A practical approach is to consider how the mirror’s housing merges with the fairing’s edge and whether the mounting points align with existing hardware. The result should feel like a natural extension of the bike rather than an add-on. In this context, it’s common to encounter a spectrum of finishes—from classic chrome to matte black—that allow a rider to either echo chrome accents elsewhere on the bike or to suppress shine for a more cohesive look. The aesthetics, of course, dovetail with performance: the lower wind resistance and the more streamlined shape can contribute to a smoother ride at highway speeds while preserving visibility.

To help readers connect with real-world choices while maintaining a broad perspective, consider how some riders navigate the model landscape when seeking fitment. Riders often browse model-specific fitments that address the nuances of particular fairing shapes and mounting locations. This ongoing dialogue between design language and rider preference underscores how fairing-mounted mirrors have matured from a simple afterthought to a sophisticated element of a motorcycle’s architectural fabric. For those who want to dive deeper into model-specific options, a practical starting point is exploring the broader category that aligns with the bike’s year and fairing style. As a next step, riders can examine newer releases and updated fairing lines for 2023 and beyond to gauge how manufacturers optimize mounting geometry for both aesthetics and function. A glance at evolving fairing profiles shows a clear trajectory: every new release tends to come with refined mirror housings, improved lens geometry, and more reliable mounting systems that tolerate the rigors of daily riding and long-distance adventures. In short, the fairing-mounted mirror has evolved from a niche accessory into a thoughtfully engineered component that blends artistry with engineering.

Those intrigued by the ongoing convergence of style and safety might explore new fairing options in general categories as part of a broader perusal of updates and innovations. For instance, readers can peruse the latest catalog of fairings labeled as “new for 2023” to see how contemporary fairing profiles influence mirror integration. This exploration highlights how the mirror’s role extends beyond rearward visibility to affect the bike’s overall aerodynamic performance, its visual language, and the rider’s confidence at speed. As with any meaningful upgrade, the most satisfying outcomes come from a careful pairing of fitment, finish, and function, all tuned to the rider’s posture, line of sight, and riding environment. When done thoughtfully, fairing-mounted mirrors do more than reflect what’s behind; they complete a design equation that celebrates cohesion, clarity, and controlled elegance. The result is a riding experience that feels both precise and effortless.

To connect these ideas with practical pathways, riders often seek out model-agnostic resources that help map fitment and finish to their specific bike. A useful touchstone is a catalog that highlights alignment with fairing profiles and offers a spectrum of finishes for easy comparison. For readers who want a direct route to exploring related options without turning the page of a catalog for every potential model, a concise entry point is the Honda fairings category, where you can browse a broad range of compatible panels and see how a mirror solution can harmonize with the overall fairing aesthetic. This approach emphasizes how the fairing and mirror combo can feel like one engineered system rather than two separate add-ons. For readers who prefer a more visual guide, the design language of a fairing-mounted mirror is often best understood by looking at the integration of lines, reflections, and curvature in tandem with the fairing’s silhouette. In the end, the strongest choices are those that respect both the rider’s practical needs and the bike’s stylistic intent, delivering a coherent, confident presence on the road.

As riding communities continue to evolve, the fairing-mounted mirror stands as a prime example of how motorcycle accessories can deepen the connection between rider and machine. It is a small piece of hardware that carries significant weight—literally and figuratively—by shaping visibility, weather resilience, and the bike’s personality. The journey from a basic reflective surface to a purpose-built, integrated component mirrors a broader shift in how riders approach customization: not merely to stand out, but to harmonize function, form, and freedom of movement on every mile of the road. The mirror’s quiet revolution is a reminder that sometimes, the most impactful innovations are those that disappear into the design, letting both rider and machine look and travel as one.

The Fitting Frontier: Installation Nuances and Compatibility of Fairing-Mounted Motorcycle Mirrors

Fairing-mounted mirrors do more than reflect the road behind you. They sit as a quiet hinge between the bike’s bodywork and the rider’s situational awareness. In a design language that prizes clean lines and aerodynamic efficiency, the mirrors must both disappear into the fairing and deliver a reliable, glare-free view in a variety of angles. The installation and compatibility story isn’t glamorous at first glance, but it governs every ride’s safety, the ease of maintenance, and the long-term value of the investment.

Before you go shopping for new mirrors, the most important step is to measure and verify. Not every fairing hole pattern is the same, even within the same model family. The mounting points may differ in hole spacing, the angle of the fairing around the headlight, or the structure that anchors the inner panels. A mirror sold as a universal replacement may promise broad compatibility, yet the actual bolt pattern and the physical geometry often require custom alignment or a specific adapter. In practice, this means you should gather the exact model year, fairing type, and any aftermarket add-ons that affect mounting depth. The manufacturer will often publish a specification sheet listing thread size, mount type, and required torque for fasteners. In many cases, universal units assume a certain fairing thickness and interior clearance that a universal unit cannot predict. Because the mirror sits inside the aerodynamic cavity rather than on a simple handlebar stalk, a misfit can create contact with the inner fairing, rub the paint, or alter the mirror’s clearance with the rider’s forearm.

From a safety standpoint, the focus is twofold: visibility and stability. The image you see in the glass is a function of both the mirror’s glass type and the housing’s alignment relative to your line of sight. When the mounting is off by even a few millimeters, the rearward view can be obstructed or yield a blind spot that grows with speed. The inner fairing often houses other components, and the space for mirror stalks is not unlimited. Therefore, the two most critical checks after installation are to confirm a clear, unobstructed view and to verify that the mirror stays in position under vibration and wind pressure. Riders report that a properly aligned mirror yields a clean field of view with minimal distortion, while a loose mirror or one with a misaligned angle can create glare or distortion that makes lane positioning more stressful rather than safer.

The choice between integrated and non-integrated fairing mirrors matters for both performance and aesthetics. Integrated mirrors, embedded into the fairing or windscreen assembly, deliver an aerodynamic advantage by reducing protrusions that disrupt the laminar airflow around the bike. They also protect the glass from minor impacts and from the pinch points of cleaning and maintenance. However, because these units are part of the fairing’s anatomical design, any accident or panel service can require more extensive replacement and re-tuning to restore proper alignment. On the other hand, modular or bolt-on fairing mirrors offer flexibility for riders who like to change the look or adjust the field of view to suit different riding styles. The faster, easier maintenance of bolt-on units appeals to touring riders who log thousands of miles and want predictable replacement parts. In either case, you still need to confirm that the chosen mirror matches the fairing’s contour and headlight geometry so it does not clash with the light housing or interfere with the glove-friendly reach to the control switches.

Beyond the fit itself, the physical structure of the mounting point is essential. Standard practice involves two core parameters: thread size and the ability of the mounting location to accommodate the mirror’s stem or backing plate. In many cases, the most common thread options for after-market fairing mirrors are M6 or M8, but some fairings use metric equivalents that differ slightly in pitch. Even when a mirror claims universal compatibility, the actual mounting depth, the shape of the backing plate, and the clearance behind the fairing can limit whether you can install the unit without grinding, trimming, or fabricating a spacer. The intuitive expectation—that a universal option should snap in with no drama—brands a setup that can quickly become a source of repeated adjustments at the first sign of wind noise. Compatibility is rarely about a single feature; it’s the sum of hole locations, thread engagement, overall thickness of the fairing skin, and the internal geometry around the headlight and the turn signals. A mismatch can cause the mirror to sit at an awkward angle, strike the fairing during full suspension travel, or even compromise the integrity of surrounding fasteners.

Manufacturers, including those who design fairing-mounted mirrors for touring or sport-touring platforms, often acknowledge this landscape by noting that their products are tested for certain model-year ranges rather than an exhaustive catalog of every possible combination. The reality is clear: you should treat compatibility as a combination of precise measurements and controlled testing. Before you commit, perform a mock fit with the exact mirror you intend to install. If possible, test the view through your chosen mirror at multiple steering inputs and body positions. The goal is to reproduce the intended field of view in the space available, ensuring you won’t discover a blind spot when you lean into a bend or tuck behind a roadside barrier. Not every installation will be perfect on the first attempt, but a deliberate approach—checking fit, re-checking alignment, and verifying clearance against the headlight, wiring harnesses, and any fairing-mounted gaskets—prevents a failure that could be both costly and dangerous.

In this narrative, the principle of compatibility extends beyond mere bolt patterns. It involves the very fabric of the fairing’s design, including the curvature of the inner panels, the positioning of mounting bosses, and the relationship between the mirror’s housing and the fairing’s edge. Some riders find that a slightly different mirror shape, which preserves a wider field of view while reducing corner distortion, harmonizes with the bike’s silhouette and the rider’s seating position. Others prefer a compact housing that hugs the contour around the headlight, preserving a factory-finished appearance. The design language is a reminder that function and form are not opposing forces; they converge in the engineering ethic that governs how a bike communicates with its rider through sight, balance, and wind.

Even the installation sequence deserves a moment of attention. While an experienced technician may perform the task with minimal downtime, it is worth noting that the level of care invested in aligning and tightening fasteners affects long-term stability. When mounting to an inner fairing, you will often encounter clips, gaskets, or shims that preserve the seal around the headlight and the windshield. The mirrors need to be attached to bosses that resist flex under high-speed buffeting. It’s wise to begin with a dry fit, then apply a light thread-locking compound if the manufacturer approves, and only then torque the fasteners to the specified rating. After securing the hardware, you should verify that the mirror can be moved through its range of adjustment without binding, and you should confirm that there is no interference with the windshield wipers, the headlight beam pattern, or the ambient air intakes that keep the engine cool. This approach minimizes post-installation surprises and helps ensure the rider sees a clean, accurate reflection regardless of weather or road surface.

For riders who want to broaden their understanding of fairing aesthetics and mounting geometry, a broader exploration of fairing categories can provide context for why fairing-mounted mirrors look and perform the way they do. In particular, the Honda fairings category can offer a window into how different manufacturers approach mounting points, reinforcements, and the interplay between glass, housing, and fairing curvature. This context is not only about style; it’s about understanding how a given fairing’s geometry informs mirror choice and installation strategy. Honda fairings category.

The practical takeaway is simple. If you are contemplating upgrading to fairing-mounted mirrors, treat the decision as a system choice rather than a quick swap. Seek model- and year-specific solutions when possible, verify compatibility with your fairing’s mounting pattern and depth, and plan for a careful alignment that preserves visibility and safety. The conversation shouldn’t end with a glossy finish and a new chrome housing; it should continue with a functional mirror that can be adjusted to maintain a clear rearward view in every riding scenario. And because the fairing environment is a living thing—exposed to vibration, temperature changes, and the occasional brush with branches—the installation must be considered part of the bike’s ongoing maintenance routine.

When you step back to consider the broader landscape, fairing-mounted mirrors sit at an intersection of aerodynamics, ergonomics, and modular customization. Their increasing popularity in touring and adventure-oriented builds reflects a collective desire for cleaner lines and predictable performance. Yet this popularity also raises the bar for accuracy in fitment, the faith you place in the mounting hardware, and the discipline of verifying the mirror’s field of view after any maintenance that touches the fairing. The narratives of riders who have wrestled with fitment issues, then resolved them through careful measurement and the right combination of components, illuminate a practical truth: the right mirror is not simply a cosmetic upgrade but a carefully calibrated extension of the rider’s perception. In that sense, the installation and compatibility factors are little more than the practical grammar through which the craft of motorcycle aesthetics, safety, and engineering speak with one another.

External resource: https://www.h-d.com/warranty

Seeing Through Skill and Science: Material Innovations and Technological Advances in Fairing-Mounted Motorcycle Mirrors

Seeing through the glass is only part of what modern fairing mounted mirrors offer. The real story sits in the layers below the surface, where engineers and designers fuse aerodynamics, materials science, and safety into a single, integrated unit. These mirrors no longer hover on the edge of the fairing as afterthoughts; they become an essential element of the bike’s silhouette and its behavioral predictability in traffic. To understand why, one must trace how materials choices and mechanical design choices interact to shape not just what a rider sees, but how the bike behaves when the road is rough, wind is gusty, and limbs are moving at highway speed. The trend toward fairing mounted solutions reflects a broader shift in motorcycle design: form and function converge, not compete, and the mirror becomes a clear embodiment of that convergence.

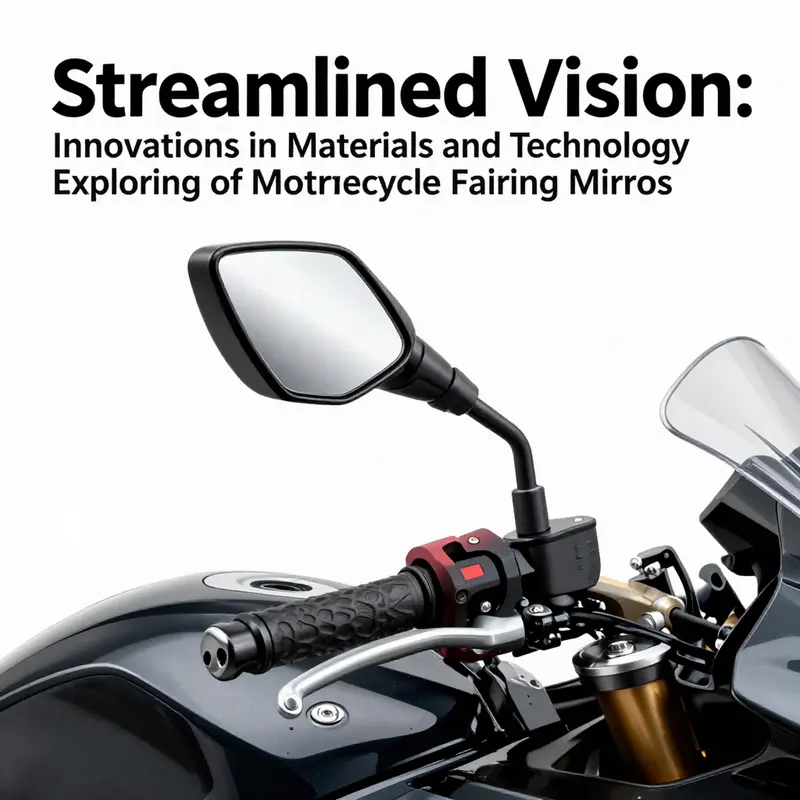

At the core of contemporary fairing mirrors is a move toward lighter, stiffer, and more durable materials. Real matte carbon fiber laminates appear as a premium option in higher end assemblies, where the goal is not merely to shave weight but also to improve rigidity around the mirror blade and housing. Carbon fiber’s strength-to-weight ratio translates to less flex in the reflection plane and reduced vibration as the bike barrels along uneven pavement. When the glass is steadier, the rider gains a more stable horizon line in the mirror, which translates to faster, more confident judgments in lane changes and corner exits. Yet carbon fiber alone is not the entire story. The most effective mirror assemblies blend carbon with high quality aluminum in a carefully engineered hybrid structure. Aluminum provides a resilient backbone that can better tolerate heat, fatigue, and impact without the blade or housing warping. The result is a composite sculpture that balances stiffness, weight, and cost considerations, offering a premium feel without compromising durability over the life of the bike.

Another decisive material advance centers on the housing itself. Impact resistant polycarbonate has emerged as a leading choice for mirror housings, delivering superior durability and energy absorption compared with traditional plastics or metals. Polycarbonate resists cracking when the bike is bumped by a car door, drops onto a concrete surface during parking maneuvers, or is knocked by tangle of branches on a forest road. Its lightness also contributes to a small but meaningful reduction in unsprung mass, a factor that subtly aids steering response and wheel rebound behavior. In folding mirror designs, where the hinge must endure repeated stress during hard use or a low-speed tumble, polycarbonate housings can tolerate repeated flex cycles with far less fatigue than many alternative materials. The hinge itself is often engineered with precision micro tolerances and protective coatings to keep the action smooth even after countless cycles of folding and unfolding.

The way a mirror attaches to the fairing has also evolved. Early approaches relied on clamps or external brackets that could create drag, disrupt smooth lines, or introduce flutter at high speed. Modern configurations embrace integrated mounting strategies that align with the fairing’s contours and airflow pathways. The result is a seamless silhouette that preserves the fairing’s aerodynamics while still delivering a wide, well distributed viewing angle. In practical terms, that means less wind noise, lower buffeting, and a more coherent ride feel at 80 mph and beyond. The risk of misalignment is reduced because many factory-grade solutions are designed to work within the same tolerances that OEM components follow. This alignment is not purely aesthetic; it directly affects how evenly the rider perceives the space behind and to the sides during fast lane changes.

Beyond the raw materials, the technology inside these mirrors is becoming increasingly sophisticated. The choice between a flat blade and a convex blade continues to be a personal preference, but the ability to tailor curvature to riding style is now more accessible. Convex blades offer a wider field of view, an asset in heavy traffic, while flat blades can provide a more accurate edge perspective important when scanning long highway gaps for changing conditions. Some premium assemblies incorporate subtle anti glare treatments or coatings that reduce harsh reflections under bright sun, a feature that helps the rider keep a clear sense of depth and distance as the vehicle pulls away from the rider’s line of sight. The optics are designed to be stable across a broad temperature range, so the mirror does not bow or distort as oil heat rises in the engine bay or as the sun bakes down on a summer afternoon.

Manufacturing precision remains a cornerstone of performance and longevity. The process starts with molds that reproduce the fairing’s lines so perfectly that the mirror housing looks like a natural extension of the bike. Then comes the careful finishing—polished chrome accents, matte black edges, or a satin clear coat—that both protects the surface and enhances the visual integration with the fairing. Surface finishes are not cosmetic tricks; they help resist microabrasions from sand, salt, and road debris. The coatings also contribute to a maintenance story that riders appreciate: less frequent polishing and a longer-lasting factory sheen. For riders who obsess over a factory-grade look, these surfaces create that sense of a bike that feels complete, a design where every inch has been calibrated to support both visibility and style simultaneously.

From a safety and ergonomics standpoint, the fairing mounted mirror must not only look integrated but perform with an unobstructed, balanced view. This involves thoughtful placement that considers the rider’s seated posture, helmet width, and the bike’s overall geometry. Inside the fairing, the mirror’s position near key aero features like the headlamp or side panels is chosen to minimize wind that could push the mirror out of alignment while still ensuring visibility in the critical rear side zones. This internal architecture supports a more stable image even in gusty conditions. The ability to tune the mirror’s angle with simple, deliberate adjustments also helps riders dial in their preferred balance between rear and side views. In this context, the mirror becomes a safety device as well as a design element, contributing to safer lane positioning and smoother overtaking maneuvers without forcing the rider to shift their grip or posture.

Rider experience shapes the ongoing evolution of fairing mirrors. Some riders value the mirror’s visual weight as a cue that the bike is engineered for high performance; others prioritize a minimal, almost invisible presence that makes the fairing seem like a single, unitary sculpture. Designers respond to both sensibilities by offering finishes ranging from neutral matte to high-gloss chrome accents, all engineered to stand up to weather and UV exposure. The result is a spectrum of options that lets riders custom-tailor the look of their fairing while preserving the internal advantages—weight savings, greater stiffness, improved impact resistance, and a more coherent aerodynamic profile. The modern fairing mirror thus sits at the intersection of aesthetics and engineering, a rare case where beauty and function reinforce one another rather than competing for attention.

The broader ecosystem around fairing mounted mirrors also matters. OEM style configurations are designed to match the bike’s original aesthetics while meeting stringent visibility standards. This alignment with factory expectations makes aftermarket upgrades feel like a natural extension of the bike, rather than a jarring aftermarket modification. It is a subtle but meaningful trend: riders do not want to compromise their bike’s identity when they upgrade. They seek products that maintain the same lines, finishes, and proportions, while delivering measurable gains in weight and resilience. In this context, the conversation shifts from simply choosing a mirror to selecting a complete, harmonized system that respects both the bike’s form and its function. The materials, the hinge mechanics, the mounting approach, and the optical choices all work in concert to maintain the integrity of the riding experience instead of diminishing it.

For readers curious about the latest developments in fairing related products, a gateway to current options exists in the broader catalogue of fairings and their accessories. This pathway highlights how the market segments are evolving and how mirror assemblies are becoming part of the fairing family rather than separate add-ons. As the dialogue between form and function continues, more riders will discover that a well-designed fairing mirror can be a quiet but powerful contributor to safety, handling, and overall riding satisfaction. The emphasis is on cohesive design that integrates the mirror with the fairing so that every ride feels more predictable, more comfortable, and more enjoyable in a way that only a true engineering-driven solution can deliver.

Riders exploring the broader landscape of fairing innovations can explore the 2023 new products category for options related to fairings and their accessories. See the dedicated section here: 2023 new products. This link serves as a practical starting point for those who want to connect the dots between material choices, manufacturing processes, and the evolving aesthetics of fairing mounted mirrors.

For more technical depth on the material standards and performance characteristics of modern motorcycle mirrors, consult an external resource that surveys the current landscape of materials, specifications, and testing insights. This resource offers a detailed lens on how real matte carbon fiber, polycarbonate housings, and integrated safety design come together in production mirrors. External resource: https://www.motorcycle-mirror-market.com/side-mirror-overview-material-standards-technical-specifications-performance-insights

Final thoughts

Motorcycle fairing mirrors not only contribute to the aesthetics of a bike but also play a critical role in rider safety and comfort. As trends evolve, understanding the design, installation, and technological advancements of these mirrors ensures your motorcycle business stays competitive. By embracing the latest innovations and aligning offerings with consumer preferences, you can foster business growth and enhance customer satisfaction.