Motorcycle fairing lights play a critical role in rider safety and style, blending functionality with aesthetics. As a business owner in the motorcycle industry, understanding the nuances of these lighting components is essential for meeting consumer needs. From the advantages of LED technology to various applications, design compatibility, and safety regulations, this article explores the multifaceted aspects of motorcycle fairing lights that can influence customer choices and enhance their riding experience. Each chapter will provide insights pertinent to various businesses in the motorcycle sector, allowing you to make informed decisions in product offerings and customer engagement.

null

null

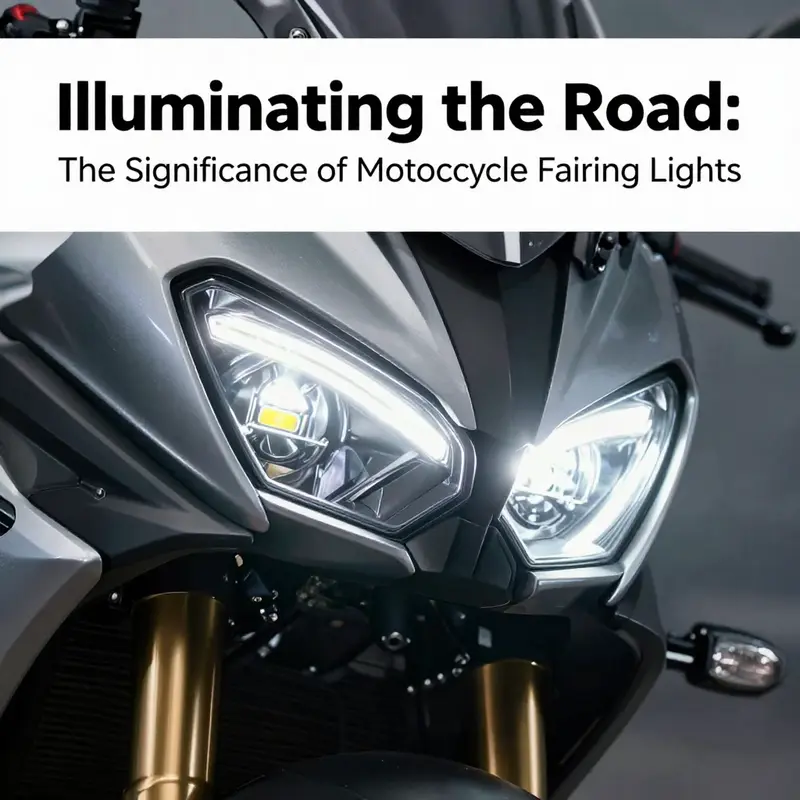

Conspicuity in Motion: Elevating Safety and Visibility Through Motorcycle Fairing Lights

Lights mounted in the fairing are more than decorative accents; they are a core component of how a motorcycle communicates with the road. In mixed traffic, where visibility is often compromised by glare, weather, or the speed of nearby vehicles, the fairing lighting system acts as a constant cue station. It signals presence, intent, and trajectory to drivers who might not spot a rider until the last moment. When designed with careful attention to distribution, color temperature, and integration with the bike’s aerodynamics, these lights help transform a fast-moving silhouette into a clear, legible object. The goal is not merely to be seen, but to be understood. In this sense, fairing lights become part of a rider’s ongoing language with other road users, a kind of nonverbal communication that supports safer, more predictable riding. LEDs have become central to this language, delivering brightness with minimal energy draw and a reliability that matches the demands of daily use and long rides alike.

At the heart of modern fairing lighting is LED technology. LEDs deliver high luminosity with a fraction of the energy required by older lighting schemes, which means less strain on the electrical system and more reliable operation on cold starts, wet mornings, or extended commutes. Their instant-on capability is also a safety boon: there is no warm-up period, no delayed response when a rider taps the brakes or signals a lane change. This immediacy matters in fast-moving traffic where milliseconds can influence another driver’s reaction. LEDs also tend to offer better color consistency and longer lifespans, reducing the frequency of replacement and maintenance. In practical terms, the rider can rely on fairing lights to perform when it matters most, without the worry of dimming or failure during a ride.

The spectrum of applications embedded in fairing lights extends far beyond a simple headlamp substitute. Running lights provide continuous illumination during daylight and dusk, heightening conspicuity so a motorcycle remains visible from several angles even when the bike is leaned into a corner or navigating through traffic. Turn signals housed within the fairing are often tucked into panels or the fender’s contours, so their light pattern reads clearly from the front and sides. Position lights, placed at the front and rear, help convey the bike’s dimensions and posture, giving following motorists a sense of the motorcycle’s size, speed, and intended actions. Some riders opt for strobe-like features or quick-flash options in specific configurations to catch attention in particularly heavy-traffic conditions or low-light environments. While this kind of feature can be striking, it must be implemented with careful attention to local regulations and rider safety to avoid confusion for other road users.

From a design standpoint, fairing lights must harmonize with the vehicle’s lines, materials, and weather exposure. Many lights are engineered for a universal fit, intended to adapt to a wide range of models with minor modifications. Yet almost every model also benefits from some level of model-specific integration, where the light’s mounting points, lens shape, and heat management are tailored to preserve the fairing’s aerodynamic performance and the bike’s overall aesthetics. The materials chosen for the lights—durable polycarbonate or robust ABS plastics—are selected for weather sealing and impact resistance. The outer lenses are often treated to withstand UV exposure and resist aggressive road debris, while internal optics are designed to maximize brightness where needed and to minimize stray glare for oncoming traffic. The aim is a seamless blend: a light that reads as part of the bike’s body rather than an afterthought glued to its surface.

Even as the hardware evolves, the regulatory landscape remains a factor riders must consider. There is no single global standard that governs every facet of motorcycle fairing lighting, but responsible manufacturers align their products with broadly recognized safety and quality certifications. These certifications help assure buyers of reliable brightness levels, predictable color temperatures, and durable construction under weather and vibration. The result is a set of products that riders can trust to meet minimum safety expectations while offering room for innovation. The emphasis on quality—beyond mere compliance—helps ensure that a light system endures through adventures, city commutes, and long-distance tours alike. The combination of robust materials, precise optics, and dependable electronics creates a lighting system that can be relied upon even when the weather turns foul and visibility becomes intermittent.

Innovation in fairing lighting now often centers on how light is distributed and reflected. A notable direction in tail-light design involves multi-surface reflection that amplifies brightness and reach. Imagine a tail-light structure that uses dual reflective surfaces, with an arc-like convex element positioned to bounce and spread light outward and upward. This arrangement improves the likelihood that a braking light or rear signal is visible from a wider range of angles, particularly when a rider is decelerating or maneuvering through traffic. The practical effect is clearer signaling for drivers behind and to the sides, which translates into quicker, more accurate responses. While the specifics of any single patent may remain behind corporate walls, the overarching principle is evident: more efficient use of emitted light through refined geometry can yield meaningful gains in conspicuity without increasing power consumption.

Beyond optics, intelligent and connected lighting is moving from novelty to necessity. Modern fairing light systems increasingly interface with the motorcycle’s onboard computer, the rider’s phone, and, in some cases, cloud-connected services. Such connectivity enables adaptive lighting strategies that respond to riding conditions, speed, or traffic patterns. For example, ambient light sensors can adjust brightness for daylight versus night riding, while smart algorithms can modulate the intensity of running lights during city riding to minimize glare for other road users. In more elaborate configurations, the lighting system can sync with braking events and turn signals to ensure consistent behavior across the front and rear, reducing confusion for motorists who observe from multiple angles. The human factors benefit is straightforward: a rider can maintain situational awareness with fewer manual adjustments, while other drivers benefit from predictable, legible signals.

While efficiency and intelligence define the current wave of innovation, environmental stewardship remains a meaningful driver of development. LED-based fairing lights embody energy-conscious design, consuming far less power than older technologies and extending the life of both the bulbs and the electrical charging system. This longer life translates into fewer replacements and less waste over time, which matters for riders who encounter harsh weather, rough roads, or extended trips far from service centers. In addition, manufacturers increasingly explore eco-friendly materials and sustainable manufacturing practices as part of the product life cycle. The result is a lighting system that aligns with broader goals of responsible riding without compromising on brightness, reliability, or durability. The combined emphasis on efficiency, longevity, and responsible materials contributes to a more sustainable approach to motorcycling upgrades and customization.

From an empirical standpoint, the literature on motorcycle visibility supports the intuitive benefits of advanced lighting. When lights are bright, well-distributed, and clearly aligned with the motorcycle’s geometry, other road users perceive the bike earlier and gauge its speed more accurately. This enhanced conspicuity correlates with safer lane positioning, more predictable braking, and fewer near-miss incidents in challenging conditions. Riders who invest in integrated lighting systems often report greater confidence in their ability to assert presence in traffic without resorting to aggressive riding. In a sense, fairing lights function as a persistent, low-effort safety feature that complements rider behavior and protective gear. The broader takeaway is that when lighting design combines brightness, distribution, durability, and smart capabilities, it contributes to safer road sharing for motorcyclists and surrounding drivers alike.

The practical realities of choosing and installing fairing lights underscore the balance between capability, compatibility, and cost. For most riders, the decision begins with the intended riding context: urban commuting, highway cruising, or spirited back-road performance. Running lights can be prioritized for high daytime visibility, while turn signals may be integrated into the fairing’s contour to keep the signals highly legible from the front and the sides. For those who spend significant time on secondary roads or in poor weather, a brighter tail-light arrangement and well-designed brake signaling become more important. In all cases, it is essential to verify mounting compatibility with the bike’s fairing geometry, electrical load capacity, and the intended use of any additional features such as strobing or smart controls. Even when choosing a seemingly universal kit, some minor modifications or professional installation may be required to preserve aerodynamics, weather sealing, and the intended visual balance of the fairing.

To help readers connect with real-world options without drifting into product-specific territory, it can be helpful to explore how fairing-light integration sits alongside broader customization ecosystems. The fairing, as a canvas, invites a spectrum of lighting personalities—from clean, understated lines that emphasize the bike’s silhouette to bold, high-contrast configurations that announce presence with confidence. The designer must consider how the light interacts with the surface texture, color, and curvature, especially at critical junctions where wind resistance and rider position affect illumination. A well-integrated system respects the fairing’s lines, preserves the rider’s perceptions of cornering geometry, and still communicates clearly with other road users. Ultimately, the value of a thoughtfully designed lighting package lies in its ability to stay in the background while contributing to a rider’s safety and the bike’s distinctive visual language.

For readers seeking broader context, internal resources that illustrate how fairing design and lighting converge can be helpful. For example, the BMW fairings category offers a window into how fairing components are designed to accommodate lighting elements while preserving form and function. BMW fairings provides a sense of how aftermarket and OEM pieces balance aesthetics with practical integration. This balance—between form and function—remains central to the ongoing evolution of fairing lights, underscoring that lighting decisions are never isolated from the bike’s overall design philosophy. The trend toward smarter, more luminous, and more durable fairing lights reflects a broader move within the motorcycle industry to fuse performance, safety, and style into a cohesive riding experience.

Looking ahead, the trajectory of fairing-light technology hints at even more sophisticated, context-aware capabilities. The next generation may feature enhanced auto-adjustment of brightness and color temperature based on speed, weather, and traffic density. More nuanced optical designs could guide light patterns so signals remain legible from extreme angles, while advanced heat management preserves performance in strenuous riding conditions. As connectivity expands, riders could customize lighting scenes tied to riding modes, environmental sensing, and even sharing data with a broader safety ecosystem on the road. Yet the core principles will endure: lights must be bright enough to convey intent, distributed to reach multiple perspectives, and integrated so they complement the bike’s character rather than compete with it. For riders and enthusiasts alike, the result is a more confident, safer, and visually compelling riding experience that respects both technology and artistry. External research and industry reports continue to reinforce the role of enhanced lighting in reducing accident risk and shaping a safer, more connected riding culture. External resource: https://www.financialnews.com.cn/

Seamless Light, Seamless Ride: Designing and Aligning Motorcycle Fairing Lights for Fit, Function, and Flair

The lines of a motorcycle’s fairing are more than an enclosure for a headlight and its hardware; they form a dialogue between wind, rider posture, and the perception of speed. When lights are integrated into that sculpted surface, they do more than illuminate the road; they complete a visual equation. The goal is not a clever feature at the edge of the bike but a coherent system where form follows function and function, in turn, reflects a deliberate style. In this chapter, we explore design and compatibility as a single, continuous thread. We consider how materials, geometry, and electrical integration work together so that a lighting module does not look tacked on but feels like a natural extension of the machine. Only then can riders enjoy improved visibility without sacrificing the aerodynamics that shape ride quality, fuel efficiency, and comfort at highway speeds for hours on end.

LED technology dominates this space for good reason. LEDs offer exceptionally low power draw, long life, and instant-on brightness, all of which are critical when every watt and millisecond matters. In a fairing context, the advantage is twofold: fewer draws on the electrical system reduce the potential for heat buildup and flicker in a cramped cockpit, while instant brightness improves conspicuity in daylight and night alike. This combination supports both safety and reliability—two pillars that underpin any design considered suitable for long-term ownership. Yet LEDs are not a universal cure. The very attributes that make them appealing—small size, high efficiency, and high brightness—also demand careful attention to how the light source is cast, how it is shielded from the elements, and how it will age when exposed to sun, rain, and road debris. The most durable fairing lights rely on robust housings—typically polycarbonate or ABS—that resist impact and resist weathering. The lens material must be resilient, with anti-scratch coatings and UV stabilization to prevent yellowing over time. The result is a unit that remains clear and effective from the moment it’s installed until the bike’s next major service interval.

Beyond the LED core, design considerations begin with fitment. The ideal light sits where the rider expects to see it and where the bike’s own lines suggest it should be seen. Fitment accuracy is not merely about tightening bolts; it is about aligning the light’s optical axis with the rider’s line of sight and the bike’s frontal silhouette. An upper front headlight fairing, for example, is not a generic insert but an element that must align precisely with the shield, be trimmed to the contour of the bike’s upper lip, and integrate with the existing wiring harness without forcing any changes that could upset the harness routing or weather seals. When fitment is right, the light looks like part of the fairing, not an aftermarket add-on.

Material choice also guides how a light performs over time. A well-engineered unit uses a housing that balances rigidity with a degree of resilience to vibration. The fairing itself is a body that must endure wind pressure, rain intrusion, and the occasional impact with road spray or a loose rock. A robust housing prevents micro-cracks in the lens, which can propagate into fogging or reduced light transmission. In the context of high-speed riding, where air is a critical factor, the corners and edges of the light must be shaped to minimize drag, while the lens itself should avoid glare that could blind or distract other road users. The design should also consider road debris and heavy rain: the seal between the lens and the housing must be dependable, and the rear of the unit should be protected enough to keep water and grit from migrating into the electrical connectors.

Compatibility is the other half of the equation. The market provides a spectrum—from exact-fit components designed to clip into a specific fairing model to more flexible, universal assemblies that claim compatibility across a broad range of models with minor modification. The difference matters in concrete terms. Exact-fit components deliver precise alignment, ensuring the light sits exactly where the fairing transitions into the fuel tank or rider’s field of view. They also simplify electrical integration by matching connector types, wiring color codes, and mounting points. When a rider chooses a model-specific option, the risk of misalignment or wiring incompatibility drops dramatically, translating into less installation time and a lower chance of post-install electrical gremlins. On the other hand, universal options offer flexibility and can be a practical choice for riders who mix and match bikes, or who want to experiment with different aesthetics.

In practice, compatibility hinges on a few practical checks. The first is mounting geometry: do the mounting holes or clips line up with the fairing’s internal structure, or will you have to drill, modify, or improvise brackets? The second is electrical compatibility: do the connectors match the bike’s harness, and is the color code consistent with the bike’s existing lighting system if the unit is intended to run as a running light or an integrated turn signal? Third is weather sealing: does the assembly maintain a continuous seal with the fairing when mounted, and does it preserve the fairing’s overall aerodynamic profile? A mismatch in any one of these areas can introduce turbulence, increase cabin noise, or create heat pockets that shorten the unit’s life.

The interplay between design and compatibility is most evident when a rider considers the fairing’s overall silhouette—the way the light follows the bike’s lines rather than interrupting them. A clean lighting solution tends to be one that shares a common denominator with the fairing’s geometry: a gentle curvature that echoes the fairing’s surface, a color temperature that reads as an extension of the bike’s lamps, and a form that avoids sharp corners which can cast unwanted shadows or reflect light back into the rider’s eyes. In this sense, the lighting system becomes a design cue rather than a separate ornament. Some riders prefer a minimalist approach, with slim, low-profile units that tuck into the curve of the fairing with as little disruption as possible. Others gravitate toward a more aggressive, angular look that projects a stronger pose in front of the machine. Both approaches can work, provided the choice is anchored in the same principles: precise fit, respectful airflow, and a visual mass that harmonizes with the bike’s proportions.

A critical, often overlooked aspect of design and compatibility is the way a lighting module communicates with the rider’s sense of the bike’s presence. Running lights must be bright enough to be seen in broad daylight, yet not so overpowering as to wash out other vehicle signals. Turn signals integrated into the fairing must offer clear, rapid response without creating a strobe-like effect that could confuse other drivers. Position lights, placed at the front and rear, should be visible at the proper angles to convey the machine’s dimensions to surrounding traffic without producing blind spots for the rider. Strobe or high-intensity options may intrigue some riders for added conspicuity, especially in low-light or urban environments, but the safest, most deliberate choice preserves legibility and reduces distraction for others on the road.

In terms of the design language, the style choices should reflect the rider’s intended riding conditions. A sport-oriented rider might favor tight, edge-driven geometry that emphasizes a fierce profile and integrates more seamlessly with race-inspired fairings. A commuter or sport-touring rider may prioritize softer edges and a more forgiving light distribution that minimizes glare to oncoming traffic while still guaranteeing early and persistent visibility. The objective, again, is coherence: the light should be a natural extension of the fairing’s lines, not a counterpoint that competes for attention. The rider’s personal taste matters, but it should be guided by practical considerations—how the light performs at different speeds, how robust the seals are in heavy rain, and how easily the kit can be serviced or upgraded as technology evolves.

To ensure that design and compatibility remain aligned across the lifetime of a motorcycle, many riders consult a curated collection of compatible fairing options that reflect a spectrum of fitment realities. For instance, a category that gathers upper front headlight fairings alongside compatible lighting modules can be a practical reference point. This approach reduces guesswork and helps ensure that the selected components will align with the bike’s contours, leaving little to chance in the assembly. In this spirit, riders can explore a catalog of exact-fit options that correspond to their bike’s fairing geometry, while still keeping an eye on universal solutions for future customization. The important outcome is a clean integration that respects the bike’s original design language and does not disrupt the rider’s awareness of the machine’s lines.

The conversation surrounding design and compatibility also invites a larger look at maintenance and longevity. A well-considered fairing light must remain accessible for service without requiring a full disassembly of the fairing. Designers often channel the wiring behind the panels, use quick-release fasteners, and provide gaskets and mounting hardware that resist corrosion from road salt and moisture. The end result is a system that not only looks right but also lasts through years of riding and exposure to the elements. That longevity is what transforms a good-looking accessory into a trusted component—one that the rider will rely on in rain, in dawn light, and in the shifting shadows of a late-afternoon ride.

As riders weigh the balance between form and function, the practical steps are straightforward. Start with a clear set of priorities: Is the aim to maximize conspicuity in daylight, to improve cornering visibility with turn signals, or to maintain a minimalist stance that preserves the fairing’s sculptural identity? Next, evaluate fitment by checking mounting points, connector compatibility, and seal integrity. Then consider how the light’s shape and color interact with the fairing’s lines and the rider’s field of view during different riding conditions. Finally, review the maintenance path: how easily can the unit be replaced or upgraded as lighting technology advances? Answers to these questions foster a design-centric approach to selecting lighting that is not merely functional but truly integrative.

In practice, a rider may also look to practical references that illustrate how others have balanced these demands. While the catalog of options is not a substitute for hands-on measurement, it can provide a useful map of what is possible when a fairing’s geometry is known and respected. Within a well-curated catalog, exact-fit options will align with the fairing’s contour lines, while universal options will offer adapters and mounting strategies that preserve the bike’s aerodynamic integrity. The upshot is a smoother, more confident installation that makes the bike feel complete rather than patched together. This mindset—design-led compatibility—serves as a foundation not only for the initial fit but for future upgrades and refinements as lighting technology evolves.

To connect these ideas to practical exploration, riders can reference dedicated fairing communities and catalogs that assemble both the geometry and the electrical considerations behind different lighting options. For those who want to see how a given collection handles the balance of line, fit, and light, a representative resource chain can guide choices without forcing a single, rigid aesthetic. The goal remains to allow the bike’s fairing to carry the light’s intent in a way that looks inevitable, not improvised. And when the rider finally steps back to assess the bike after installation, the result should feel like a single, coherent statement: a machine whose lighting is a natural continuation of its shape, its speed, and its rider’s intent.

For readers seeking a concrete avenue to examine compatible options, a practical entry point is the dedicated fairings catalog that curates models designed to fit a wide range of bikes. This resource helps align the visual language of the fairing with the lighting system, ensuring that the light does not break the fairing’s rhythm but rather enhances it. By focusing on precise alignment, durable construction, and thoughtful integration, the rider achieves a lighting solution that supports safety and elevates the bike’s presence on the road. In the end, the best choice is one that performs reliably, ages gracefully, and makes the entire vehicle feel as if it grew its lighting from within the fairing itself.

Internal link for reference on compatible fairing categories: BMW fairings category.

External resource for further reading: https://www.carinterior.com/motorcycle-headlight-fairing-guide-how-to-choose-right/

Raising Sight and Respect on the Road: The Regulatory Fabric Guiding Motorcycle Fairing Lights

Two things shape how a motorcycle speaks to the road before the rider even twists the throttle: the way its lights illuminate the path ahead and how those lights are governed by rules that aim to keep everyone safer. Motorcycle fairing lights are not mere accessories. They are integrated systems that must align with the bike’s aerodynamics, with electrical systems in the frame, and with the social contract of road use. In practice, this means a blend of engineering discipline and legal compliance. The lights on the fairing must respond to real-world needs—visibility in broad daylight, signaling to other drivers, marking the machine’s dimensions in all weather—while staying within the quiet boundaries of what regulators consider safe, predictable, and non distracting. The resulting standard landscape is a mosaic of color requirements, beam patterns, testing protocols, and installation criteria that differ around the world, yet share a common aim: to reduce uncertainty on the road and to prevent glare or misinterpretation that could lead to a crash.

LED technology dominates these components for good reasons. LEDs deliver bright, instant-on light with remarkable efficiency. They sip electricity, a critical advantage on a motorcycle where the charging system and battery capacity are tuned to a tight balance. LEDs also offer design flexibility; they can be tucked into the curves of a fairing, hidden behind clear lenses, or incorporated into subtle daytime running lights that enhance visibility without shouting for attention. Yet efficiency alone does not determine acceptance. The light output must be photometrically specified, the color must be within accepted ranges, and the beam must be shaped so it does not dazzle oncoming or preceding road users. This is where standards become the invisible referee of design, shaping what is permissible in public view and what remains a private aesthetic experiment.

In a practical sense, the front of a motorcycle fairing is most often required to emit white or amber light in the forward position. The rear, by contrast, uses red for taillights and brake indicators. The rules around flashing or strobe effects are nuanced: rapid flashing is generally restricted for standard headlamps and taillights, though certain high-visibility applications may permit strobe use in limited contexts. Light color, brightness, and aiming are not only matters of safety but of legality. A light that is too intense or poorly aimed can turn a safety feature into a nuisance, creating glare that harms other drivers more than it helps the rider. Hence the ongoing tension between bright, modern LEDs and the restraint demanded by safety codes.

Across regions, the enforcement architecture resembles a three-layered fabric: color and performance standards, certification and conformity markings, and installation or fitment requirements. In Europe, for example, the E-mark system signals conformity with European regulations, with front lights generally restricted to white or amber and rear lights to red. The presence of an E mark—an indicator of compliance with ECE regulations such as ECE R48 for lighting—becomes a passport of sorts for legal road use. Flashing states are restricted for standard luminaires, reinforcing the idea that reliability and predictability are prized. In the United States, the federal framework under the Department of Transportation emphasizes brightness, color, and proper aiming. While there may be no universal mandate to install LED upgrades, any lighting must be certified and correctly aimed to prevent glare. The concrete implication for fairing lights is that an accessory or aftermarket addition must not only perform well but also align with the vehicle’s overall compliance profile.

China introduces the next layer of a harmonized approach with a notable shift on the horizon. The Motor vehicle lighting and signaling device installation regulations in the GB 18100 series are undergoing a consolidation and modernization, culminating in a new standard that is set to take effect on January 1, 2026. This revamped framework aims to unify and update the rules governing the installation and performance of headlights, turn signals, brake lights, and associated devices integrated into the motorcycle bodywork, including fairing lights. It is not a revision to be taken lightly; it represents a concerted effort to align optical performance with precise positional criteria, so that installations do not blind others yet still provide adequate illumination for riders. In practice, the new standard tightens the requirements for optical geometry, mounting position, and durability under environmental conditions. The groundwork being laid by the National Technical Committee on Automotive Standardization, together with testing and certification bodies, signals a global trend toward more predictable, testable lighting systems on motorcycles. This has ripple effects for designers and manufacturers who must plan fairing light solutions that can be certified across markets or, at minimum, adapted to meet the most stringent of national expectations. For fairing lights, the implication is clear: the alignment between optics, mounting geometry, and vehicle integration will be scrutinized with greater care, and the days of ad hoc installations that barely meet basic visibility targets are ending.

The standards conversation is not merely about compliance for compliance’s sake. It informs the very way designers approach fairing integration. The aesthetic language of a motorcycle—its lines, its stance, its aggression or elegance—must harmonize with optics that are purposeful and safe. To accomplish this, engineers choreograph a sequence of decisions: selecting an LED array that offers sufficient luminance and color balance, choosing lenses and diffusers that shape the beam in a predictable pattern, and designing housings that resist water intrusion, vibration, and the thermal cycling that accompanies city riding and high-speed travel. Materials such as polycarbonate or ABS plastics are commonly chosen for their toughness and transparency, with seals and gaskets that prevent moisture ingress while allowing easy maintenance. A fairing light assembly is thus a carefully engineered module, not a loose bundle of LEDs stuffed into the fairing cavity. The reliability story matters as much as the brightness story. When a rider is cruising through a rainstorm or a long highway stretch, the lights must perform, not degrade into flickering dimness or intermittent failures.

To this end, photometric performance testing becomes a core milestone. The beam pattern must meet specified distributions to avoid glare while delivering adequate illumination along the rider’s line of travel. Vibration resistance tests simulate the harsh environment of engine vibration, wind, and rough pavement. Environmental tests push the assembly through temperature extremes and moisture conditions that mimic real-world usage. The upshot is that a well-designed fairing light system will not only make the rider more visible but will also retain its optical integrity and physical integrity over the product life. This is why legitimate manufacturers emphasize quality management standards and certifications, such as ISO 9002 or equivalent, which signal the company’s commitment to a robust, repeatable process for designing, producing, and verifying lighting components suitable for motorcycles.

In terms of design philosophy, two strands shape most fairing light offerings: universal fit and model-specific adaptation. A globally marketed light may advertise itself as universal, suggesting it can be adapted to various models with minor modifications. In practice, universal fit often requires adjustments to mounting points, cable routing, and perhaps the angle of projection to align with a particular fairing’s geometry. Model-specific units, by contrast, are tailored to the exact contours of a given motorcycle line, ensuring the cleanest integration and the most predictable optical performance. Designers must also contemplate the fairing’s air flow and heat dissipation. The aerodynamic goal is to avoid adding drag or generating unnecessary turbulence while still delivering a visually cohesive appearance. This balance between form and function is not a mere design preference but a requirement for performance and safety on the road.

The aesthetic dimension should not be dismissed. Fairing lights contribute to the bike’s silhouette and can deliver a distinctive look that signals a rider’s presence in traffic. A tasteful application of LEDs along the lower fairing, a slim strip that traces the edge of the windscreen, or a crisp turn signal integrated into the side panel—these touches can elevate a bike’s appearance without compromising safety. Yet the allure of style must always defer to the host of regulatory constraints that govern placement, color, brightness, and signaling behavior. A well-executed fairing lighting system is one that communicates clearly to other road users while preserving the design integrity of the machine. It is the art of engineering harmony: lights that enhance visibility but never become a distraction, a design language that respects the road as much as it celebrates the rider’s individuality.

As riders and builders continue to push for clever integrations—running lights that offer daytime visibility, turn signals that blend into the fairing geometry, and even strobe or high-visibility accents for challenging weather—standards bodies keep pace by refining what counts as measurable safety. The conversation moves from a simple question of brightness to a more nuanced inquiry: how does the beam interact with other vehicles, how does the color temperature affect perception at dusk and dawn, and how does the entire system perform after thousands of miles of exposure to sun, rain, and road grit? The answers are not only about brighter LEDs but about responsible engineering that respects the entire ecosystem of road users. In this sense, the fairing light becomes a microcosm of a broader movement toward safer, smarter, and more standardized motorcycle lighting systems that can adapt to diverse riding styles while preserving universal safety benefits.

For readers who want to see how lighting and fairing design can intersect with model lines, consider exploring a catalog that brings together a range of fairing configurations. A curated selection of fairing categories demonstrates how designers weave lighting elements into various bikes, balancing the need for compatibility with the desire for distinctive styling. This approach illustrates a core principle: lights are not simply add-ons; they are integral parts of the vehicle’s narrative and its safety posture. When a rider approaches a curve at road speed, the forward light interacts with the rider’s perception and with the oncoming traffic. When negotiating a lane change, the integrated turn signal communicates intent with clarity and predictability. And when cruising in daylight, the running light warms the bike’s visibility profile, helping other drivers perceive the motorcycle earlier and more reliably.

In this evolving landscape, one practical takeaway is the importance of aligning your fairing light choices with the broader regulatory context. If you are selecting a kit or commissioning a design for a new fairing, consider not only the brightness and color but also the installation topology, the mounting hardware, and the weather sealing standards. A thoughtfully chosen system will be easier to install, more durable in adverse conditions, and more likely to meet certification requirements across different regions. The result is a ride that is safer, more stylish, and less prone to regulatory friction when justifying its presence on the road. And for riders who want to connect with communities or retailers that specialize in fairings, a practical touchstone can be a resource that showcases how different fairing catalogs approach light integration, including model specific considerations and universal fit strategies. As a point of reference, you can explore a representative fairings catalog such as the BMW fairings category, which offers insight into how lighting is harmonized with specific model architectures while still accommodating a range of aftermarket lighting solutions. BMW fairings catalog.

The regulatory arc that governs motorcycle fairing lights is not a dry ledger of requirements. It is a living framework that reflects how technology improves visibility, how riders demand safer road sharing, and how manufacturers translate safety objectives into practical, reliable products. The push toward unified or harmonized standards across regions signals a future where lighting solutions can move more freely across markets without compromising safety or performance. At the same time, it encourages designers to embrace robust testing, durable construction, and thoughtful integration that respects the machine’s architecture. This is the essence of responsible innovation: creating lights that help riders see and be seen, while ensuring that those same lights contribute to a calm, predictable, and courteous driving environment for everyone on the road. External considerations remain important, and continuing dialogue among regulators, manufacturers, riders, and researchers will shape how fairing lights evolve in the years ahead. For readers seeking a detailed regulatory reference, the formal standardization trajectory in China, the EU E-mark framework, and US DOT guidelines collectively frame a global expectation for performance and safety that will influence every fairing lighting choice.

External resource and further reading: the Chinese Standard Administration document detailing the upcoming GB 18100 revisions provides a comprehensive view of the technical and procedural changes anticipated in 2026. It is a useful anchor for understanding how national standards translate into practical design and installation criteria for fairing lights and other signal devices. https://www.sac.gov.cn/zwgk/ghbg/202511/t20251104_40795.html

Final thoughts

Incorporating motorcycle fairing lights is not just a matter of aesthetics but a crucial component for safety on the road. As a business owner, understanding the full scope of LED technology, applications, design compatibility, and safety standards allows you to better serve your customers. By aligning your offerings with consumer needs and regulatory compliance, you can enhance safety, visibility, and style for riders. Keeping abreast of these elements will not only improve customer satisfaction but potentially elevate your standing in the competitive motorcycle market.