Grommets in motorcycle fairings may be small, but they play a crucial role in the performance and durability of a bike’s bodywork. They secure and protect the fairings, absorb vibrations, and reduce noise while ensuring a snug fit against the frame. As a business owner in the motorcycle industry, understanding these grommets helps you meet customer needs. This article covers grommet types and materials, their role in vibration and noise reduction, and best practices for replacement. By the end, you’ll be positioned to make informed decisions that enhance the customer experience.

Dampening the Pulse: The Subtle Science of Motorcycle Fairing Grommets

The fairing of a motorcycle is more than cosmetic armor. It is a carefully engineered shield that governs aerodynamics, rider comfort, and the endurance of the bodywork itself. When a rider imagines the forces at play—the engine’s vibrations, the cadence of the road beneath, the wind’s every gust—the fairing becomes a living boundary between metal, plastic, and muscle. In that boundary a small, often overlooked component does a heavy lifting: the grommet. These rubber or TPU cushions sit around bolts and screws that anchor the fairing to the frame, but their role extends far beyond simply filling a hole. They are the quiet guardians of the ride, the dampers of vibration, the buffers that prevent chafing, and the shield that protects costly bodywork from fatigue over tens of thousands of miles. The story of a healthy fairing begins with selecting the right grommets, installing them correctly, and understanding how different materials perform under the stress of real-world riding. In practice, the grommet’s purpose is straightforward, even in a world where engineering often grows more complex with every new model: to isolate the rigid fasteners from the delicate skin of the fairing, to absorb energy that would otherwise crack or deform, and to reduce the audio and tactile resonance that makes a bike feel harsh at speed or over rough pavement.

To grasp why grommets matter so much, one must first imagine the path of a bolt as the heartbeat of the mounting point. The fairing’s plastic or composite panel is naturally more compliant than the thread and head of a steel bolt. Without a buffer, the continuous micro-movements generated by engine operation and wheel travel translate into stress concentrations where the bolt exits the hole. Over time these vibrations produce microcracks, chafing around the hole, and the eventual loosening of fasteners. A single cracked fairing can spoil the visual line of the design, invite moisture intrusion, and force a more expensive repair or replacement. The grommet’s job is to keep the two worlds—rigid metal and flexible panel—apart just enough to allow relative motion without damage. It also provides a modicum of shock absorption, so the bolt does not hammer the panel during high-frequency vibrations. The grommet thus contributes to ride quality, perceived quality, and long-term durability, often with a surprisingly modest price of entry.

Material choice is central to the grommet’s performance. Rubber compounds have dominated motorcycle grommets for decades because of their elasticity, resilience, and ability to return to shape after compression. Among these, EPDM stands out for its robust resistance to ultraviolet light, ozone, and temperature extremes. This makes EPDM particularly well-suited to performance and touring bikes that spend long hours in sunlit, heat-drenched environments. The EPDM composition maintains flexibility across a broad temperature range, so the grommet does not harden and lose elasticity after a hot day or a cold morning. Some designs blend natural rubber with EPDM or employ blends to balance costs with performance, but the guiding principle remains consistent: the material should maintain its seal, its shape, and its damping characteristics under dynamic loads and environmental exposure.

In certain high-stress applications, a steel core or insert can be embedded within the grommet. This reinforcement ensures that the grommet can anchor the bolt with a degree of stability that resists compression set and pullout, essential for mounting points that endure repeated high-load cycles. The combination of a flexible rubber exterior and a rigid core offers a pragmatic compromise: the exterior responds to vibrations and temperature changes, while the core supplies the stiffness needed to hold the hardware securely in place. This is especially important on sport bikes and touring machines that experience aggressive torque delivery and long highway slogs, where the fairing must remain anchored without allowing metal-on-metal contact. The steel core also helps maintain the correct hole-to-bolt alignment, ensuring that the fastener doesn’t tilt or rib against the material as vibrations accumulate.

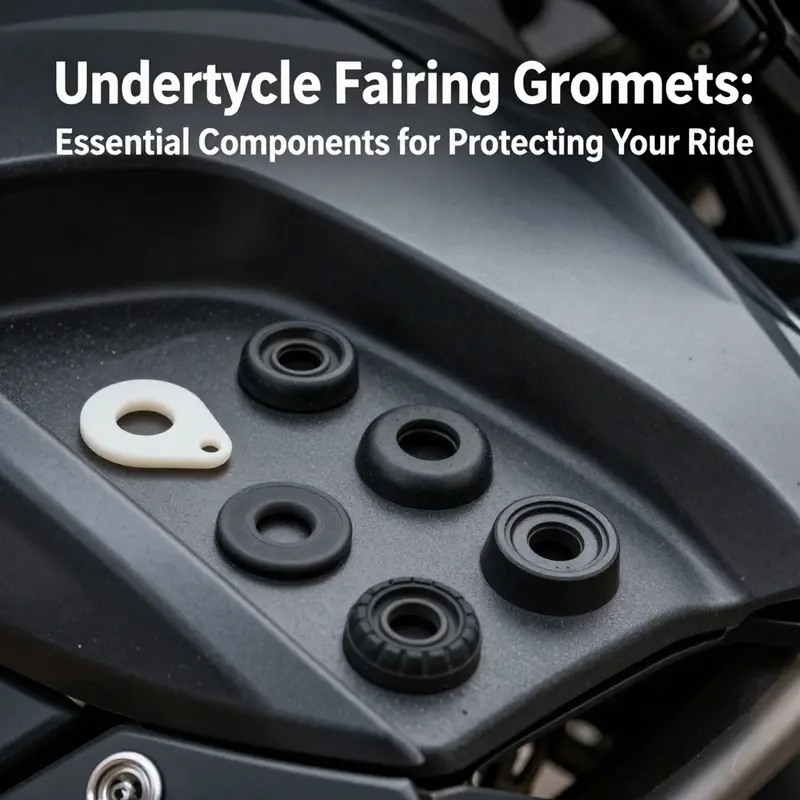

Not all grommets are created equal, and the design spectrum is broad. Grommets come in a range of sizes and shapes to suit specific mounting points—whether the fairing bolts into a subframe, attaches to a stay, or threads through a bracket that links the panel to the bike’s spine. Universal grommets offer value and flexibility, often sold in sets that cover a variety of common mounting points across multiple models. In contrast, custom-fit grommets are molded or selected to fit particular bike models with precise dimensions. The latter provide a more predictable seal and a cleaner appearance, which can matter to riders who care about the aesthetic integrity of the bodywork. The right choice depends on how the fairing is designed, how the mounting points align, and how the rider uses the bike. A sport bike with tight tolerances may benefit from precise, model-specific grommets, while a touring machine that sees a wide range of road conditions might benefit from a slightly more forgiving universal option that still delivers damping and protection.

As with almost every component that touches the rider’s experience, the environmental realities dictate material selection. UV exposure is not merely a cosmetic concern; it can alter the elasticity of rubber, encouraging cracking and micro-fissures that compromise the seal and damping over time. Ozone, another relentless environmental factor, can oxidize rubber and reduce its ability to rebound after compression. Temperature swings—from chilly dawns to scorching noons—test the grommets’ resilience, particularly when the bike has been parked in direct sun or is subjected to engine heat that radiates into the mounting area. A grommet that can endure these conditions without losing its cushion will maintain not only the fairing’s appearance but its functional integrity as well. In addition to UV and temperature considerations, the grommet must stand up to oil, fuel vapors, and cleaning agents that may seep into the mounting region during maintenance. EPDM’s resistance to oils and aging makes it a durable default, while TPU offers a harder-wearing alternative with excellent abrasion resistance and a different compression profile. When the design calls for a softer touch to insulate delicate plastics or composites, a natural rubber blend with carefully tuned hardness can provide the necessary damping without compromising the fit.

The interplay between material selection and design becomes most apparent when considering how a grommet supports the fairing’s structural integrity. The outer diameter must align with the mounting hole, the inner diameter with the bolt, and the wall thickness must withstand both compression and shearing forces. If a grommet is too soft, it may deform under load and fail to center the bolt, allowing the panel to drift and rub against the bolt head. If it is too stiff, it may transmit more vibration than it dampens, defeating the purpose of isolation. The ideal grommet behaves like a careful moderator: it cushions the bolt against the panel, maintains a stable seating, and absorbs the energy generated by the engine’s vibrations as they travel through the frame. It also creates a forgiving interface that prevents chafing on the fairing’s holes, which can otherwise scuff the finish and reduce the panel’s lifespan. In this sense, the grommet is a tiny engineer, quietly balancing forces that, if left unmanaged, would accumulate into visible cracks, loose fasteners, or rattling noise that undermines the rider’s confidence in the bike.

There is also a subtle but important relationship between grommets and the overall ride experience. A well-chosen grommet can reduce the transmission of noise into the cockpit. Even when the engine and exhaust contribute their own sounds, a damper at the mounting point helps keep the passenger and rider from perceiving every vibration as a mechanical bracelet around the frame’s joints. This is not merely about comfort; it is about preserving the fairing’s structural cohesion. When a grommet remains effective, the fairing maintains its aesthetic lines, and the panel avoids micro-movements that could lead to loose fasteners or cracking. The rider benefits from a smoother feel—less harshness over rough pavement and reduced wind buffeting, as the fairing’s alignment remains more precise. In many respects, the grommet’s influence extends beyond the panel it cushions, contributing to a calmer, more precise ride sensation across a broad spectrum of riding styles.

To speak plainly about the practicalities of selection and maintenance, consider three core steps that a conscientious rider or mechanic can follow. First, identify the mounting points where the fairing joins the frame or brackets, noting whether the hole is a through-hole or a blind hole, whether a retainer or a hollow spacer sits adjacent, and whether there is any preexisting evidence of wear. Second, match the grommet’s inner diameter to the bolt shank, its outer diameter to the hole’s circumference, and its height to the depth of the pocket it occupies. If in doubt, measure carefully and consult the bike’s service manual or a model-specific grommet kit, recognizing that a precise fit translates into predictable damping and a longer life for the panel. Third, inspect the grommets during routine maintenance. Look for signs of compression set, cracking, swelling, or hardening. Replace any grommets that show visible degradation, as continued use of aged grommets undermines the entire mounting system. When replacement is necessary, choosing EPDM-based grommets with or without a steel core should be guided by the mounting point’s load and the ambient conditions. In a climate with intense sun and heat, a reinforced EPDM or a TPU version might be advantageous where the extra stiffness is balanced by improved longevity. In cooler environments, a slightly softer compound could offer better initial damping without compromising the panel’s ability to stay centered on the bolt.

A nuanced part of maintenance is recognizing when the grommets do not merely wear but alter their function. A grommet that has compressed over time becomes a poor cushion and can cause the bolt head to bear directly on the fairing material, increasing the risk of material fatigue and direct abrasion. In such cases the rider might notice a subtle or even pronounced shift in the fairing’s alignment, a new creak when the bike encounters bumps, or a faint rattle over rough roads. The fix is straightforward: replace the worn grommets with fresh ones that match the model’s mounting geometry. It is tempting to improvise with a slightly different size or material to save a few minutes or dollars, but the integrity of the mounting and the fairing’s appearance depend on a precise fit. The discipline of correct sizing and material choice pays dividends in ride quality and the long-term health of the panel. For riders who prefer a turnkey approach, there are aftermarket kits designed as universal replacements, which can be a practical solution for owners who perform routine swaps across multiple bikes or plan a repair run during a vacation or a service window.

The ecosystem of aftermarket options reflects two realities of modern motorcycling: variety and compatibility. Many universal grommets are designed to accommodate a spectrum of models across multiple manufacturers, while others are tailored to specific bikes or fairing families. The decision often comes down to the expected ride regime and the mechanical complexity of the bike in question. A fairing that endures aggressive cornering, high-speed wind loads, and uneven road surfaces benefits from grommets whose materials and geometry can manage elevated shear and puncture risks. Conversely, a bike ridden mostly on smooth pavement with moderate highway use can benefit from simpler, cost-effective grommets that still deliver adequate damping and protection. In both cases, the grommet is a small but essential component in the chain that preserves the fairing’s integrity and appearance. The careful rider recognizes that the initial cost of quality grommets is an investment in the bike’s overall value, preserving not only its exterior lines but its resale potential, aesthetic appeal, and mechanical reliability over the years.

For readers who want to connect this chapter to concrete parts categories and to the broader ecosystem of fairing maintenance, a practical path is to explore model-specific or compatible grommet options within a broader fairing ecosystem. A model-focused perspective helps maintainers align the grommet choice with the exact mounting geometry and the anticipated service life. As the riding seasons cycle and the bike’s miles accumulate, the grommets continue to do the delicate work of maintaining the fairing’s position, while allowing the panel to breathe with the rest of the chassis. In this sense, the grommet is not merely a spacer; it is a performance component that interacts with the material properties of the fairing and with the dynamic stresses imparted by the motorcycle’s powertrain and road interface. The result is a smoother, more controlled ride that preserves the protective and aesthetic functions of the fairing without becoming a maintenance headache.

In practice, the process of selecting and replacing grommets can be integrated into routine service intervals. When a rider performs basic fairing removal for inspection, it is an opportune moment to check the grommets. The inspection should go beyond the visible surface and consider whether the grommets still provide proper damping and seating. A quick test is to press on the fairing near the mounting points and observe whether movement is damped and centered rather than sloppy or offset. If the grommets feel soft, brittle, or uneven, replacement is warranted. For riders who want to ensure ongoing compatibility with a wide range of fairing components, it may be wise to stock a few common sizes in a kit, including versions with a steel insert and those without, so that they can address both older and newer mounting configurations.

Finally, while this chapter has centered on the core function, materials, and maintenance of grommets, the broader truth remains: small parts can have outsized effects on the rider’s experience. The choice of grommets, their material properties, and the care taken during installation contribute to a fairing’s longevity, its resistance to weather and road hazards, and the quiet, confident feeling a rider experiences as they roll down a highway or navigate twisty back roads. When a rider appreciates how such a modest component influences the larger system, the importance of thoughtful maintenance becomes clear. In the end, the grommet’s duty is simple in its aim yet profound in its impact: to ensure that the fairing remains a faithful partner to the bike’s frame, delivering both protection and performance while keeping the aesthetic elegance of the bodywork intact across miles and seasons. For those exploring specific model fits, a practical path is to examine the fairing categories associated with particular brands, as those pages often index the appropriate mounting hardware and grommet configurations alongside the panels themselves. For model-specific considerations, you can explore the Honda fairings category to discover compatible mounting solutions that keep the line clean and the ride smooth while maintaining the precision of the original design. Honda fairings.

External resource: Types and materials of motorcycle fairing grommets. https://www.motorcyclefairinggrommets.com/types-and-materials-of-motorcycle-fairing-grommets/

Small Cushions, Big Impact: The Quiet, Smooth Role of Motorcycle Fairing Grommets

Across the sleek surface of a motorcycle fairing, a quiet, almost invisible world works to shape the ride. Tiny rubber or TPU cushions sit between the rigid panels and the steel or aluminum frame, absorbing impact, damping vibration, and breathing life into the texture of sound that travels through the bike. These grommets are not flashy components; they are the unsung connectors that translate engine torque, wheel reverberations, and road irregularities into a more comfortable, more durable, and more predictable riding experience. In an overall topic as broad as motorcycle fairing grommets, the discussion often circles around fit, material composition, and installation as discrete tasks. Yet the truth is that these small devices influence adhesion between components, limit micro-movements that would otherwise accumulate into cracks, and control how noise travels from mechanical sources to the cockpit. Understanding their function requires looking at how the components interact when the machine is in motion, why certain materials perform better under heat and UV exposure, and how proper maintenance can extend the life of both fairings and the riders who depend on them for comfort and confidence on the road.

The grommet’s role begins with vibration isolation. A motorcycle is a cascade of vibrating bodies. The engine itself is a source of substantial rhythmic energy, but the vibration is not confined to the engine block. The drive chain, the wheel hubs, the suspension linkage, and even the cockpit—where the rider sits—contribute to a symphony of oscillations. Without a deliberate buffering layer, those oscillations move through the frame and into the fairings. The result can be a range of audible symptoms: rattles that seem to emanate from the dash of the bike, buzzing tones in mid-frequency bands, a metallic clack whenever the throttle is opened, and low-frequency thumps that align with the cadence of the engine. The grommets interrupt the path of these vibrations by converting some of the mechanical energy into heat and elastic deformation. In effect, they decouple the fairing from the frame enough so that the energy transmitted to the plastic or composite panels is damped rather than amplified. The consequence is a quieter ride and a fairing that remains visually and structurally stable, even after many miles in varied conditions.

Vibration isolation is closely tied to acoustic insulation, another crucial function of these small components. Sound is not merely a loudness phenomenon; it is a spectrum of frequencies, some of which travel more efficiently through solids than others. The fairing grommets help interrupt the transmission of mid-to-high frequency noise that originates from fasteners, engine mounts, and mounting hardware. When a rider experiences fatigue after long stretches on the road, it is often not simply the engine’s roar but a complex mixture of buzzes and rattles that infiltrate the cabin. By reducing the path for sound transmission, grommets contribute to a calmer cockpit, which translates into improved focus and less rider fatigue. This effect is especially meaningful on touring-oriented bikes or sport-tourers where comfort over extended periods is a critical selling point for the design, not merely a luxury.

But the grommet’s contribution goes beyond comfort. They play a protective role for both the fairing and the frame. The fairing is an outer shield for fragile infotainment components, mirrors, and control housings. If a grommet is worn or missing, the fairing can experience micro-movements that result in contact with metal surfaces. Over time, this contact can wear away paint, abrade edges, or create micro-cracks in the laminate of the panel. A cracked fairing not only looks unsightly but can allow moisture ingress or additional stress concentrations that propagate more serious damage during high-speed runs or bouncing over rough pavement. Grommets, by maintaining a controlled gap and a cushionable interface, safeguard the structural integrity of the fairing and its mounting points.

From a materials perspective, these components must stand up to a demanding environment. Natural rubber and thermoplastic polyurethane are common choices, each with its own balance of elasticity, durability, and resistance to the elements. Natural rubber offers excellent damping characteristics and resilience across a broad temperature spectrum, but it can be more vulnerable to UV degradation and ozone exposure if not properly stabilized. TPU, meanwhile, provides superior wear resistance and a more uniform performance under heat cycling, though it can be stiffer than natural rubber. The choice between these materials hinges on the riding environment, the expected mileage, and how the rider prioritizes quiet operation versus a slightly firmer ride feel at the mounting points. In both cases, a well-made grommet maintains its compressive properties over time, preserving the thickness and resilience that are essential for effective damping.

The size and shape of a grommet are not decorative choices; they are carefully matched to bolt diameters, hole clearances, and the geometry of the fairing attachment. A tiny mismatch can create a stiffness anomaly that undermines vibration isolation. If a grommet is too thick at the contact surface, for instance, it can translate to higher peak forces transmitted to the fairing during takeoff and landing chevrons or over road irregularities. If it is too soft or too flexible, it may extrude or not seat properly, allowing unwanted movement and reducing long-term reliability. For this reason, many manufacturers and aftermarket providers categorize grommets by model-specific dimensions. For riders performing repairs or replacements, it is crucial to match the original size and shape or to adopt a universal kit that explicitly lists compatibility with the model range. The practical upshot is that a precise fit delivers predictable damping characteristics, preserves panel alignment, and minimizes the risk of rattles returning after a maintenance event.

Installation is a deceptively straightforward task, yet it rewards careful attention. The process begins with a visual and tactile inspection: check every mount point for signs of wear, check the grommet bore for cracks, and ensure that the surrounding panel edges are free of sharp burrs that could cut into the grommet. When replacing worn grommets, the rider or technician should remove the old piece completely and clean the bore with a soft brush to remove any debris, dust, or old adhesive. A light coating of compatible sealant or lubricant may sometimes be used to help the grommet settle into place, but excess grease can attract dirt and defeat the purpose of the cushioning. The goal is to seat the grommet evenly around the mounting bolt so that the fairing remains in its intended position without bending or warping under load. A properly seated grommet reduces the likelihood of slippage, which can compromise both the look and the functionality of the fairing.

The practical implications of these choices ripple through the rider’s day-to-day experience. A well-maintained grommet bed helps the fairing resist warping and cracking, preserves the alignment of lights and indicators, and maintains seals around edges that might otherwise suffer from flexing. It also contributes to a more confident ride. When a rider approaches highway speeds, the wind loads and the micro-movements of panels become more pronounced. The grommets’ damping effect on these micro-movements keeps the fairing stable, reducing flutter and the dynamic noise that can accompany high-speed operation. In addition, because the grommet interface is designed to tolerate temperature fluctuations, it helps the fairing endure sun exposure and heat without hardening, cracking, or losing elasticity. The effect is a longer-lived fairing system with consistent performance across a wider range of environmental conditions.

As with many repair components, maintenance is not a one-time act but an ongoing practice. Regular visual inspections are essential, especially after long trips or rough roads. Riders should look for visible cracking, hardening, or deformation, as well as signs that the grommet has shifted or is no longer seated properly. If any of these symptoms appear, replacement is recommended to prevent a cascade of issues, from audible rattles to structural stress on the mounting points. Monitoring the condition of grommets is a cost-effective way to protect the fairing and the rider’s comfort. In addition, replacing old grommets can pair well with attention to the mounting hardware itself. Corrosion or looseness in bolts can transfer load that the grommets were meant to absorb, defeating their purpose and potentially accelerating wear. The practical approach is to treat grommet maintenance as part of a broader fairing health check—a habit that many riders adopt to ensure longevity and consistent aesthetics.

For those who prefer to examine real-world examples of fit and function, the concept of compatibility with a wide model range matters. Aftermarket kits often promote universal compatibility, enabling riders to outfit multiple bikes or to replace worn components across a family of models. The value of universal kits lies in the ease of sourcing and the potential cost savings, but the trade-off can be a need for careful selection to ensure a proper fit. The most reliable results still come from matching the grommet to the bolt diameter, base panel thickness, and mounting hole geometry. In the realm of maintenance and upgrades, the grommet becomes a reference point for the entire mounting system: when the grommet behaves as intended, the rest of the assembly feels and sounds as designed. The fairing remains a stable, protective shell rather than a loose set of panels that move independently, a change that makes all subsequent work, from panel removal to component alignment, simpler and more predictable.

This discussion cannot ignore the broader ecosystem in which these components live. Availability, ease of replacement, and the perceived value of keeping a bike in pristine condition all intersect with the functional role of grommets. Riders often weigh the time saved by opting for universal replacement kits against the certainty of OEM- or model-specific parts. The reality is that most riders benefit from a balanced approach: use precise, model-specific grommets when possible for critical mounts, and keep a small selection of universal grommets for non-critical locations where a marginally different fit will not compromise performance. The net effect is a smoother, quieter ride that also preserves the fairing’s structural integrity and cosmetic longevity.

In the broader context of engineering practice, fairing grommets illustrate a key principle: small, well-chosen components can have outsized effects on performance, comfort, and durability. Their role in damping, isolation, and sealing demonstrates how careful material selection, precise geometry, and mindful installation translate into real-world benefits for riders. The practical takeaway for enthusiasts is straightforward. If you want to protect your fairing, extend its life, and enjoy a quieter ride, start with a grommet review. Inspect the mounting points, check for wear, and replace worn pieces with correctly sized, quality materials. The payoff is not merely a quieter cabin; it is a more dependable, comfortable platform that performs at its best mile after mile.

For readers seeking a more technical lens on the engineering principles behind these rubber components, a comprehensive guide on the topic covers how materials buffer vibrations and insulate acoustics in high-rotation contexts. While the resource is in Chinese, it provides valuable insights into the durability and behavior of rubber-based cushioning in automotive settings, with practical implications that cross over to motorcycles: Sina Finance has published a detailed treatment on the subject. For a deeper dive, you can explore the resource at the following reference: https://finance.sina.com.cn/roll/20260201/184397851.shtml.

In summary, motorcycle fairing grommets may be small, but their impact is outsized. They quiet the cockpit, protect the fairing from the stresses of daily riding, and help maintain the visual integrity and structural soundness of the entire bodywork. By choosing the right materials, ensuring accurate fit, and committing to regular inspection, riders can enjoy a ride that is not only more comfortable but also more reliable as the miles accumulate. And for those who crave a concrete picture of how a well-chosen grommet set integrates with a specific brand’s fairings, an example of a model-aligned option can be found in dedicated fairing categories that curate parts by bike family, such as the Honda fairings collection.

Internal reference: For model-specific integration and a sense of how grommets align with particular fairing assemblies, you can explore related content in the Honda fairings category. This provides practical alignment considerations and supports the idea that the right grommets are a foundational element of a well-fitting, durable fairing system. See: Honda fairings.

Ultimately, the quiet, smooth ride rests on a chain of small decisions, among them the choice to protect and preserve the simplest interface between frame and body. When maintenance becomes a habit, the grommets reward riders with fewer rattles, longer-lived panels, and a more satisfying sense of control—an intangible but very real measure of quality on every journey.

External resource note: For a broader, in-depth look at the engineering principles that underlie vibration buffering and acoustic insulation in rubber components, consult the Sina Finance article linked above. It offers a technical perspective that resonates with the practical maintenance concerns discussed here and situates grommets within a larger framework of vehicle component durability.

Sealing the Ride: The Quiet, Protective Power of Replacing Motorcycle Fairing Grommets

Grommets in motorcycle fairings are more than decorative; they protect wires, seal joints, and damp vibrations. When worn or cracked, they can let moisture in, create rattles, and accelerate wear on panels.

Key considerations: fit, material, geometry. Use exact-fit grommets sized to the model; materials like rubber or TPU have UV/temperature considerations. Poorly sized grommets pinch wires or fail to seal.

Installation tips: remove panel, clean bore, test fit, use light lubricant only on outer surface, ensure wires sit flat, torque bolts to spec.

Maintenance approach: inspect during service, replace in packs for convenience, check surrounding hardware, align panels.

In the end, replacing grommets maintains quietness, durability, and ride quality.

Final thoughts

In summary, motorcycle fairing grommets serve as vital components that significantly affect the riding experience. By understanding their types and materials, acknowledging their role in reducing vibration and noise, and knowing the best practices for replacement, business owners can enhance their services and improve customer satisfaction. Advocating for quality replacements not only benefits the motorcycle’s longevity but also contributes to safer and more enjoyable rides. Investing time in understanding these components will keep your customers coming back, ensuring their motorcycles remain in top condition.