Motorcycle fairing foam plays an integral role in the motorcycle industry, serving as a vital component in ensuring both performance and protection for riders. As a business owner, understanding the nuances of motorcycle fairing foam can enhance product offerings and improve customer satisfaction. This article delves into four key aspects: the composition and types of fairing foam, its role in vibration and impact absorption, a comparative analysis of OEM and universal options, and the importance of maintenance and replacement. Each chapter equips you with essential knowledge to better position your business in this competitive marketplace.

null

null

Foam as Quiet Armor: The Hidden Role of Motorcycle Fairing Foam in Damping Vibration and Absorbing Impacts

The visible silhouette of a motorcycle—shaped panels, sculpted lines, and the gleam of paint—belies a subtler, crucial layer of engineering. Between the rigid shell of the fairing and the bike’s metal or composite frame lies a cushion of foam that does more than fill space. It acts as a quiet, tireless mediator, shaping how vibrations from the engine and road travel through the bodywork and, by extension, how the rider experiences the ride. In the simplest terms, motorcycle fairing foam is a buffer, but its function is far from simple. It dampens, aligns, shields, and preserves the integrity of the fairing itself, turning what could be a jangling assembly into a cohesive system that feels solid, refined, and predictable on every kilometer of tarmac.

The role of foam begins at the most basic level: vibration control. An engine, especially a high-revving one, is a source of periodic energy that travels through the bike’s chassis and into the fairing. The fairing, being a relatively thin shell attached to the frame, can amplify or transmit those energy pulses if it comes into direct contact with rigid supports or with fasteners that transmit motion. Foam serves as a compliant interface, absorbing a portion of the energy before it can excite the shell. The result is a reduction in the perceived vibrations by the rider, which translates not only into reduced fatigue during long rides but also into a more stable cockpit where gauges, mirrors, and switches remain steadier under dynamic conditions. The difference may be subtle, but it is measurable in rider comfort, steadier windscreen positioning, and fewer rattles that can creep in after mile upon mile of road texture changes.

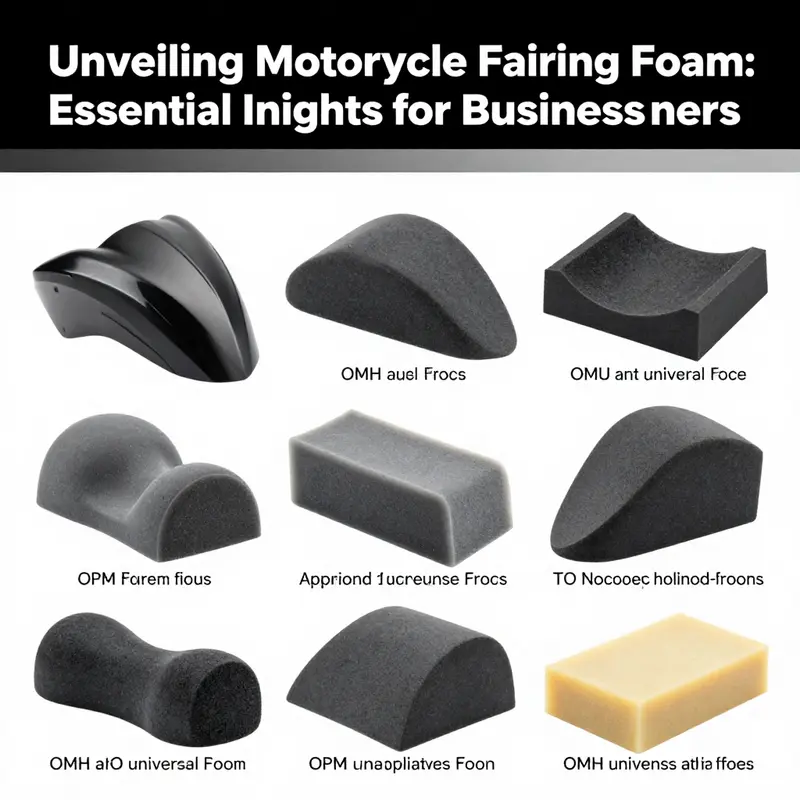

This damping action is influenced by the foam’s physical properties—its thickness, density, cell structure, and resilience. Across the industry, you’ll encounter a spectrum: thinner pads that offer modest dampening with minimal added weight, and thicker, denser fills that deliver more substantial energy absorption at the expense of weight and space. It is common to see foams with thicknesses in the 12mm to 20mm range, chosen to match the particular model’s aerodynamics, fairing geometry, and the level of insulation desired. Universal foam pads, such as compact 33×33 cm sheets, provide a general-purpose solution that can be trimmed and fitted across a range of bikes, while OEM-specific foams are designed to meet exact contours and gaps with precision. The latter ensures a snug, gap-free interface that not only dampens better but also helps maintain the fairing’s intended profile and alignment with the frame, preserving both fit and aero performance.

A key advantage of these foams lies in how they support alignment and ride quality. When a fairing is poorly aligned, gaps can form, allowing air to escape or turbulence to develop in a way that worsens noise, buffet, and even aerodynamic drag. The foam acts as a pressure-activated shaper, filling irregularities and guiding the fairing’s edge to sit where it should with respect to the frame. This is particularly important for modern full or split fairings that enclose large portions of the thermal and structural layout. In these systems, even a small deviation can create vibration pathways or channel wind noise in the rider’s helmet. Foam, therefore, contributes to a smoother airflow path by maintaining a consistent fairing outline and by reducing micro-movements that would otherwise translate into audible or tactile feedback during a ride.

The protective dimension of fairing foam should not be overlooked. In the event of a tip-in, crash, or stray road debris impact, the foam softens and distributes a portion of the kinetic energy that would otherwise be concentrated at a single contact point. This energy dispersion can shield the fairing from cracking and can lessen the likelihood of sharp edges becoming dangerous projectiles. The result is a more resilient bodywork system that can absorb, rather than transmit, the shock. Foam’s role as an energy absorber is complemented by the surrounding materials and fasteners, but it remains a critical, low-cost line of defense that can determine whether a fairing sustains cosmetic damage or suffers structural deformation after a mishap.

Moisture management is another practical consideration that affects performance over time. In wet climates or when washing the bike, residual moisture can creep into crevices behind the fairing. If the foam is not moisture-resistant, repeated exposure can lead to swelling, softening, or a gradual loss of structural integrity. In short order, that degradation can undermine both vibration damping and energy absorption. Durable foams are engineered to resist water uptake and to maintain their shape under moisture exposure. They also pair with compatible adhesives and sealants that help prevent water from migrating into the adhesive interface, where it could weaken bonds or promote corrosion along metal components. In the long run, a moisture-stable foam helps ensure that damping performance remains consistent across seasons, rather than drifting as the bike experiences humidity cycles and temperature swings.

Heat management is another axis where foam quality matters. Engine bays and exhaust zones radiate heat that can travel through the fairing structure. In high-performance or touring configurations, the fairing foam may include properties that resist heat transfer or incorporate backing layers that serve as thermal insulation. Proper foam selection thus contributes not only to rider comfort but also to the longevity of the fairing’s substrates. By limiting heat buildup near junctions, bolts, and mounting points, the foam can help prevent material fatigue, cracking, or paint degradation that would otherwise accelerate wear. When combined with heat shielding strategies and reputable mounting hardware, foam becomes an essential piece of a broader thermal management approach that keeps the front bodywork looking and performing well across miles and seasons.

Selecting the right foam involves balancing several trade-offs. Thicker, denser foams offer stronger damping and greater mechanical protection but add weight and may require careful trimming to avoid interfering with panel alignment. Lighter, thinner foams preserve weight and can be easier to install, yet may not deliver the same level of energy absorption or gap control. OEM-specific foams are tailored to a particular model’s geometry, ensuring exact fit and predictable performance, while universal pads offer a flexible, cost-effective option for riders who operate a mix of bikes or undertake restorations where exact OEM shapes are not readily available. In either case, the goal is to achieve a snug interface that damps energy, preserves alignment, and remains stable across weather and wear.

From an installation perspective, the work is about more than slapping a pad in place. It begins with a careful assessment of where the foam will sit and how it will interact with fasteners, brackets, and the inner surfaces of the fairing. It may involve trimming to match curves, engineering a path for wiring or breather tubes, and ensuring that the foam’s edges do not create new vibration paths by binding against hard points. Effective installation also relies on compatible adhesives and sealants that maintain a reliable bond without being so aggressive that they damage the fairing’s finish when removal becomes necessary. A well-fitted foam pad becomes an invisible ally: it holds the fairing in proper contact with the frame, minimizes rattles, and preserves the intended ride feel without demanding attention from the rider.

The broader context of material science informs these choices. Foam used in fairings is typically selected for a light-to-moderate density, good compressive resilience, and stable performance across temperature swings. Open-cell foams can offer excellent energy absorption characteristics and flexibility, while closed-cell foams can deliver superior moisture resistance and less permeation of fluids. The best selections often combine a layered approach: a core damping layer that handles energy absorption, backed by a moisture- and heat-resistant skin or backing that protects against the environment and maintains dimensional stability. The ending effect is a fairing that not only dampens vibrations and absorbs impacts but also remains true to the bike’s aero form and paint finish over years of exposure to sun, rain, and road grime.

Maintenance and lifecycle considerations also shape the conversation. Foam pads can wear or compress after years of use, especially in bikes that routinely jump between city streets and rural backroads where bumps and potholes are common. In such cases, replacement becomes practical, restoring damping performance and preserving fairing alignment. Replacement can range from simple, affordable universal pads to more exacting OEM replacements that match the original geometry with exacting precision. NOS—new-old-stock—options may exist for classic builds, offering original-style foams that fit as intended while preserving the bike’s authentic look and feel. For riders who prize originality, these options provide a bridge between restoration and modern performance, ensuring that the foam still functions as the designer intended when the bike rolled from the showroom floor.

The foam’s contribution to ride quality also intersects with the broader goals of performance tuning. While a rider may focus on engine output, suspension feel, or tire grip, the fairing’s interaction with the air stream and the rider’s body is partly governed by that small cushion of material tucked behind the shell. A well-chosen foam pad helps stabilize the fairing under load, reducing flutter and mass-impulse effects that could otherwise influence steering feel at high speed or during aggressive cornering. In this way, foam plays a supporting role in the bike’s overall balance, aiding precision and confidence when the rider pushes the machine toward its limits. The effect may be subtle, but it compounds across hours of riding, contributing to a sense of connectedness between rider, machine, and road.

For readers seeking practical pathways, it helps to reference a broad, model-agnostic guide to selecting fairing materials for challenging environments. A thorough, external resource delves into the considerations for wet climates and how to identify materials that maintain performance when rain, humidity, and road spray are factors. This broader perspective complements the micro-level decisions about foam density and thickness by situating them within environmental resilience and long-term durability. By integrating insights from both internal testing and external guidance, riders and technicians can craft a fairing system that remains dependable across seasons and routes.

For readers exploring related components and options, a practical touchpoint is the Honda fairings category, which provides a wide range of panels and matching infrastructure that often necessitates compatible foam cushions for proper fit. It serves as a starting reference for understanding how foam interacts with different fairing geometries and mounting schemes across a spectrum of builds. Honda fairings demonstrates how diverse fairing shapes and attachment methods influence cushion selection and assembly, underscoring the importance of choosing foam that aligns with the intended geometry and mounting strategy. This alignment is essential not only for ride comfort but also for achieving consistent aerodynamic performance and maintaining the bike’s aesthetic integrity over time.

In sum, the fairing foam is not a cosmetic afterthought. It is a functional, adaptive element that mediates energy, controls noise, and preserves the structural and aesthetic integrity of the fairing system. By choosing appropriate thickness and density, ensuring moisture resistance, accounting for heat, and executing precise installation, riders can realize meaningful gains in comfort, protection, and long-term durability. The foam’s contribution, though quiet, is foundational to the overall experience of riding a motorcycle with well-integrated, well-cushioned bodywork. In a sense, it operates as a form of quiet armor—one that accepts the rhythm of the road so that the rider can focus on the journey ahead, undistracted by vibration, rattles, or heat creeping through the panels.

External research and continuing study of fairing materials remind us that environmental conditions will always shape our choices. Wet climates demand resilience against moisture, while hot climates challenge thermal stability and adhesive integrity. Balancing damping, weight, and fit in a coherent system is a confluence of material science, practical experience, and thoughtful design. For riders who want a deeper schematic of how to approach these decisions, a broader external resource offers well-rounded guidance on surviving and thriving in wet climates, illuminating how material choices—foam included—affect ride quality and fairing durability. External resource on wet climates provides a useful perspective on environmental considerations that complement the specific focus on foam.

null

null

Preserving Precision: Maintenance, Replacement, and the Quiet Physics of Motorcycle Fairing Foam

The fairing on a motorcycle is a delicate blend of form and function. It shields the rider from wind, channels air for cooling, and contributes to the bike’s overall silhouette. Inside that sleek shell lies a humble, often overlooked material: the foam that cushions, insulates, and secures the fairing to the frame. When well chosen and properly installed, fairing foam dampens vibrations, reduces unwanted rattles, and helps maintain a snug, aero-stable fit. When neglected or inadequately specified, the foam can become a source of noise, misalignment, and even heat-related inefficiencies that ripple through the bike’s performance. The story of maintenance and replacement is not merely about keeping parts in place. It is about preserving the integrity of the rider’s experience—quiet operation, precise fit, and reliable protection against the road’s surprises—while ensuring that the fairing continues to behave as the designer intended during high-speed runs, windy highway stretches, or tight cold starts where the seal against the frame matters as much as the shell’s appearance. Over time, foam degrades through a combination of exposure and stress. UV light relentlessly attacks the surface, stiffening and cracking the material. Temperature fluctuations—the hot engine bay during a long ride, the cool air at highway speed, the shifts between sunlit and shaded segments of a mountain pass—induce micro-cracks and loss of resilience. Road vibrations compound the problem, especially in full or semi-enclosed fairings where the foam not only cushions but also acts as a spacer to hold panels in precise alignment. The cumulative effect of these factors is more than cosmetic wear. It is a decline in energy absorption, a greater likelihood of rattles, and a shift in how well the fairing withstands minor impacts from gravel, debris, or a careless parking lot encounter. In that sense, foam maintenance is a practical convergence of materials science and riding ergonomics: the foam must remain a predictable cushion, a stable damper, and a consistent anchor. The path to reliable performance begins with understanding the role of material quality. The foam used in fairings comes in a variety of densities and thicknesses because different motorcycles demand different stances. A thinner, denser pad may be ideal for a sport bike where stiffness translates into crisp panel alignment, while a slightly softer, thicker layer can better absorb the rev-howl of a touring engine and mitigate heat transfer within a larger, more enclosed fairing. The industry often measures thickness in millimeters and pad sizes in centimeters to match the geometry of the paneling. Classic universal foam pads—such as square or rectangular blocks designed to sit between the fairing and frame—highlight a pragmatic approach: easy-to-cut shapes, simple adhesion, and a functional range of densities that can be adapted to many bikes. Yet the universal approach trades some precision for convenience. By contrast, OEM-specific foams are cut to exact contours and thicknesses to fit particular models, ensuring not just a snug look but a reliable seal against vibration and a predictable interface with the engine bay’s heat profile. In practice, riders weighing the value of OEM fit against aftermarket flexibility must weigh the consequences of misfit, compromised anchorage, or inconsistent density along wrap angles and edges. One of the most practical distinctions in this landscape is the choice between OEM foam and aftermarket substitutes. OEM foam is designed to be a faithful replica of the original material, ensuring the same density distribution, compressive behavior, and attachment profile that left the factory after the first assembly. The upside is straightforward: optimal alignment, predictable performance, and compatibility with factory adhesives or mounting points. The downside is often the higher price tag and limited availability, especially for aging models. Aftermarket options, meanwhile, offer affordability and broader availability, which can be appealing to riders maintaining older bikes or those who do not require exact replication of the original foam’s microstructure. The caveat is meaningful: not all aftermarket foams mimic the original’s resilience, surface finish, or adhesive compatibility. In many cases, a cheaper foam pad may compress more under load, exhibit less consistent resilience after heat cycling, or fail to maintain the same gap profile between panels. These discrepancies can translate into rattles, misalignment at corner radii, or even interference with the closing action of a fairing door or panel. The decision framework, therefore, centers on evaluation of density, thickness, contour fidelity, and how each option behaves under the dynamic load of riding conditions. When contemplating replacement, the practical steps begin with a careful inspection of the existing foam. Cracking, signs of surface splitting, and visible compression are obvious indicators that the material is no longer performing as intended. Detachment is another critical clue; if the foam has loosened from its mounting points or lost its integral bond to the panel or frame, its job as a spacer and damper is compromised. A thorough inspection also considers edge integrity where the foam meets fasteners, clips, or adhesive seals. If a rider perceives an increase in panel vibration or hears new metallic rattles during acceleration or over pavement irregularities, it is often a sign that the foam’s damping properties have diminished and replacement should be considered. Beyond visual checks, a tactile assessment can confirm whether the foam still cushions effectively. Pressing a few representative points can reveal uneven compressibility or localized hardening, which would signal that the foam has aged unevenly and won’t distribute loads consistently across the fairing interface. In selecting replacement foam, the guiding principle is fidelity to the original’s functional role. The density, thickness, and contour must align with the fairing’s interface geometry and the rider’s objective—whether that objective is maximum vibration damping for a long-distance ride, or a more rigid fit for high-speed handling and edge stability. For some bikes, a combination approach works well: a slightly denser pad at high-wace contact areas paired with a softer cushion in less critical zones to maintain both stiffness and comfort. Installation matters as much as material choice. Adhesive selection, surface preparation, and clean mounting surfaces are essential to ensure the foam remains firmly in place under vibration and temperature swings. A clean, dry substrate is often the best ally for the foam, with adhesives chosen to withstand heat and the occasional exposure to weather. Inadequate preparation or incompatible adhesives can lead to premature detachment, creating a cascade of misalignment issues that erode aero performance and increase the risk of rattles. For riders seeking replacement materials, the market presents a spectrum of options. OEM foams deliver a high probability of fit and performance, but the premium price and occasional scarcity push many toward aftermarket solutions. When evaluating these options, a careful reading of density and thickness specifications becomes crucial. A foam pad described as the correct thickness but with a noticeably lower density will compress more under typical riding loads, potentially altering gap tolerances or the alignment of fairing seams. An overly dense pad may underperform by resisting necessary minor micro-movements, which can actually translate into frustration in the form of creaks or rubbing between panels. The evaluation process should also consider the foam’s heat-shielding capabilities, which can be particularly important in high-performance or touring configurations where engine heat is trapped in the fairing. In such cases, a foam with better thermal resistance can mitigate heat buildup around sensitive mounting points and help preserve the integrity of nearby plastics or painted surfaces. The replacement decision also intersects with the broader ecosystem of bike maintenance resources. For riders who want an informed, practical guide before committing to purchase, trusted repair resources offer a balanced view of the tradeoffs between OEM and aftermarket options, including labor costs, fitment challenges, and the risks of a lower-grade material. A reliable resource in this space emphasizes the importance of understanding how pricing moves with density, thickness, and contour precision, and how these factors influence the long-term performance of the fairing. For readers seeking a straightforward path to informed choices, a concise reference point can be the OEM-vs-aftermarket guidance that synthesizes material science with hands-on repair experience. This guidance highlights not only the material properties but also the operational realities of installing foam in a working motorcycle fairing. Beyond the immediate decision of what foam to install lies the question of how to maintain the installed foam over time. Routine inspections should be incorporated into periodic maintenance checks, especially after long rides, accidental impacts, or changes in environmental conditions. A quick post-ride inspection can reveal early signs of detachment or compression inconsistencies, offering a window to address issues before they worsen. Regular cleaning is also important. Dirt, road grime, and oil residues can degrade adhesive bonds and create uneven contact surfaces, undermining the foam’s dampening function. With this in mind, a careful wipe-down using appropriate cleaners ensures the mounting surfaces stay clean and that the foam adheres properly during reassembly. This approach to maintenance—proactive inspection, careful cleaning, and timely replacement—helps sustain the foam’s protective and aerodynamic performance across the bike’s lifetime. In the broader context of motorcycle maintenance, the foam’s role is a bridge between the shell and the frame. It ensures that the fairing remains a unified system rather than a loose assembly of parts. Its influence on aerodynamics is subtle but meaningful: an accurately foamed interface eradicates minor gaps, minimizes turbulence, and ensures the fairing can do its job at speed with minimal energy loss. The consequence of neglect can be audible as well as functional. Rattles become louder, the rider’s body becomes more sensitive to panel resonance, and the perceived quality of the ride declines. These are not merely comfort concerns; they reflect the fairness of the engineering behind the bike. Foam that maintains rigid yet compliant contact with the frame supports the intended airflow patterns, which in turn influences cooling efficiency and engine bay thermal management. When the foam holds its shape, the fairing aligns with the frame, seals against the wind, and preserves the intended aerodynamic profile, all of which contribute to a cohesive riding experience. For readers who want to explore practical specifics without diving into model-by-model minutiae, the guiding principle remains consistent: match the foam to the job the fairing needs to perform. Whether this means selecting a high-density, contoured pad to sustain a demanding sport-riding regime or choosing a slightly more forgiving, heat-resistant foam for long-distance touring, the aim is to preserve the fairing’s structural role while keeping noise, vibration, and misalignment at bay. In practice, that means careful measurement before purchase, consideration of the bike’s typical operating environment, and adherence to installation recommendations from manufacturers or trusted repair guides. It also means acknowledging that the foam is a consumable part—one that benefits from timely replacement to protect the surrounding shell and, most importantly, the rider’s comfort and safety. For readers seeking deeper, practical decision-making guidance on fairing foam maintenance and replacement, one can consult established repair guides that consolidate practical experience, materials science, and cost considerations. These resources illuminate how the investment in quality foam translates into a longer service life for the fairing, fewer nuisance repairs, and more consistent performance across seasons. In the end, the foam’s value lies not in its visibility but in its quiet, dependable service: a small, resilient layer that keeps the shell tight, the air moving cleanly around the bike, and the rider perched in comfort with confidence. As a final note, when moving from repair planning to actual procurement, remember that detailed product information, compatibility, and installation guidance are essential. A well-chosen foam pad, thoughtfully installed, can preserve the fairing’s integrity for years of riding, while a rushed, misaligned replacement can set off a chain reaction of fitment and performance issues. For a compact overview of the OEM versus aftermarket landscape and to access a detailed, practical decision guide, consider consulting a consolidated repair resource that emphasizes the real-world implications of density, thickness, and fit. This approach aligns with the broader objective of keeping motorcycle fairings performing as designed—quiet, aligned, and protective at speed. For a practical, model-agnostic reference that centers the user experience and the mechanics of replacement, you can explore an OEM NOS foam pad listing here: OEM NOS foam pad listing. This link provides a concrete example of how OEM-grade components are presented, even as riders weigh their replacement decisions in the context of their own bike’s geometry and riding needs. For readers seeking a broader, external perspective on fairing maintenance and replacement, the CarInterior guide offers a comprehensive, end-to-end resource that complements the practical considerations discussed here: https://www.carinterior.com/motorcycle-fairing-replacement-guide/. Together, these references underscore the central message: maintenance and thoughtful replacement of fairing foam are small steps with large payoffs in ride quality, durability, and aerodynamics.

Final thoughts

Understanding motorcycle fairing foam is paramount for business owners in the motorcycle industry. From its composition and role in performance to the pros and cons of OEM versus universal options, every aspect influences product quality and rider satisfaction. Additionally, emphasizing the importance of regular maintenance and timely replacement can significantly enhance a motorcycle’s longevity and overall riding experience. By integrating this knowledge into your business strategies, you can cater to customer needs more effectively and position your offerings for success in a competitive market.