Motorcycle fairing accessories are vital for optimizing both the appearance and performance of motorcycles. With an increasing number of consumers seeking to customize their rides, understanding these components can provide business owners with valuable insights into market demand. This article will explore the role of carbon fiber, the importance of high-performance fasteners, and how aerodynamic enhancements through fairing accessories can elevate riding experiences, ultimately guiding businesses to better serve their customers’ needs.

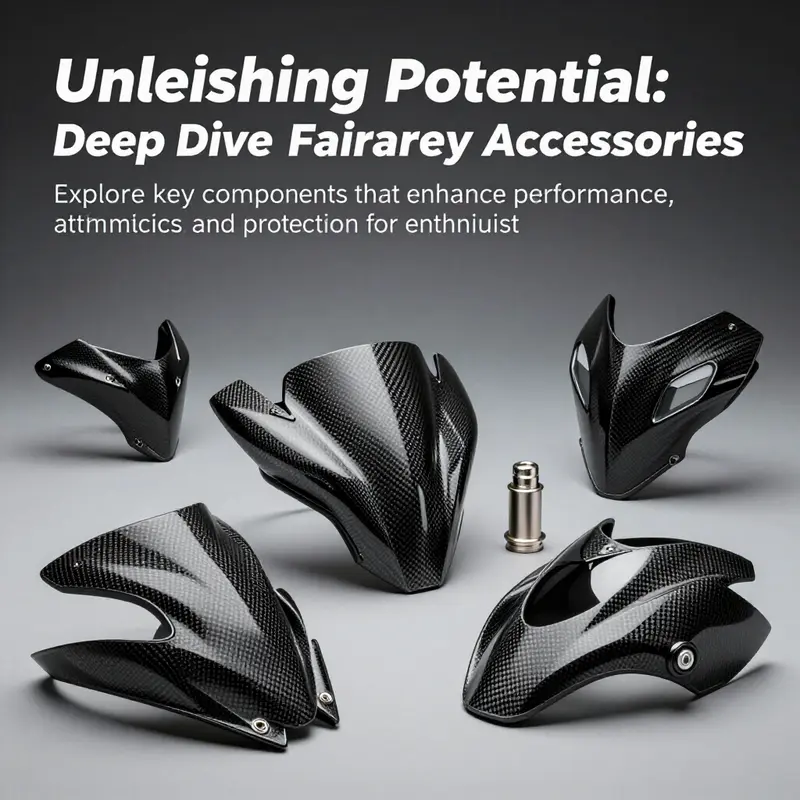

Weaving Lightness, Strength, and Style: Carbon Fiber’s Quiet Revolution in Motorcycle Fairing Accessories

Carbon fiber has moved from a luxury badge to a practical foundation for modern motorcycle fairings. In the realm of fairing accessories, carbon fiber is not simply a surface choice; it is a careful marriage of engineering and identity. The material’s appeal rests on its ability to reduce weight while increasing stiffness, and on a distinct visual language created by the familiar weave. This combination matters across the entire fairing system, from side air deflectors that shape airflow to full covers that establish the vehicle’s silhouette. The result is a set of accessories that can alter a bike’s feel as much as its look, redefining expectations for both riders and observers. The broader trend is not about chasing novelty; it is about integrating form and function so that every contour serves a purpose, whether that purpose is slicing through air with minimal drag, protecting fragile components, or signaling a commitment to precision engineering.

Weight is the most immediate benefit. Carbon fiber density is far lower than steel, weighing roughly a quarter or less of equivalent steel mass. When used in fairing components, this translates into tangible weight savings for the motorcycle as a whole. The effect may seem subtle, but it compounds across the machine: lighter panels reduce unsprung weight, which improves suspension response and steering authority. In practice, a fairing system built from carbon fiber can help a rider feel more immediate feedback from the handlebars, quicker turn-in at the apex, and a more composed ride in crosswinds. Because fairings are large surface structures, even modest weight reductions here have a noticeable impact on how the machine carries itself, how quickly it recovers from gusts, and how it negotiates mid-corner trim adjustments at speed. These advantages often translate into improved fuel efficiency as the engine works less to overcome inertia, and into better braking stability as the load transfer is more predictable under rapid deceleration.

But weight is only part of the story. Carbon fiber’s tensile strength is exceptionally high—roughly seven times that of steel on a comparable volume—meaning a given thickness can offer robust resistance to bending and impact. In the context of fairings, that strength directly translates into better protection for the engine, radiators, and other vital components behind the shell. It also allows designers to fine-tune stiffness in critical areas, which helps preserve panel shape under load and reduces flutter at high speeds. When a rider leans into a sweeping bend or when the bike encounters a sharp gust, a carbon fiber panel maintains its geometry, contributing to consistent airflow and predictable handling. This structural integrity is especially valuable for two-piece or modular fairing systems, where individual panels must mate precisely at fit lines while still absorbing vibration and heat over long riding sessions.

Durability and safety go hand in hand. Aftermarket carbon fiber fairings can absorb energy more effectively than their fiberglass or plastic counterparts, reducing the likelihood of catastrophic deformation in minor impacts. The mix of a stiff skin and a carefully chosen core or laminate helps distribute impact forces more evenly, which can lower the risk of cracks propagating through essential mounting points. For riders who ride aggressively on diverse road surfaces, this resilience translates into lower maintenance downtime and faster re-entry to the riding experience after a close encounter with road debris. The improved impact resistance also reduces the risk of sharp fragments, contributing to rider safety and easing the replacement process after a mishap.

Aesthetics offer another strong argument. The carbon fiber weave, whether finished in a high-gloss sheen or a restrained satin, reads as a premium signal that the bike is designed with intent. The look is not static; it communicates a message about engineering craft and attention to detail. When designers leverage carbon fiber across multiple contact surfaces—front fairing, side panels, and rear silhouettes—the overall shape appears more cohesive, with lighter lines and crisper transitions that emphasize aerodynamic potential. The visual language of carbon fiber often becomes a part of the motorcycle’s identity, signaling performance orientation even before the rider powers the engine. This is particularly meaningful in a market where aesthetics and performance are inseparable rather than competing priorities.

Beyond appearance, carbon fiber is a facilitator of advanced aerodynamics. The ability to mold complex curves with precision enables air to flow in ways that reduce drag and manage lift at speed. In a modern fairing system, carbon fiber parts can be engineered to support venting channels, cooling air intakes, and mounting points for sensors or auxiliary equipment. Even if a rider is not chasing top speed, the stability gained from optimized airflow improves ride confidence in windy conditions and at open-road speeds. The same material can be tuned to create subtle changes in surface curvature that delay boundary layer separation, thereby maintaining more attached flow along the fairing surfaces. Such nuances often translate into steadier throttle response and less buffeting at highway velocities, contributing to overall riding comfort over long distances.

The cutting edge of application is where carbon fiber meets evolving sensor and propulsion technologies. Some premium platforms explore embedding sensors, radar, or other electronics within the fairing assembly without breaking the aerodynamic envelope. In practice, this means that functional elements near the nose or lower fork area can carry sophisticated systems while remaining lightweight and streamlined. Such innovations illustrate a broader trend: carbon fiber is not simply a skin over the frame but a structural partner in the motorcycle’s sensory and dynamic ecosystem. When distributed thoughtfully, these embedded elements can reduce the need for clunky external housings and enable more aerodynamic integration of critical components such as cooling ducts or light-weight sensor housings. The net effect is a smoother silhouette and a more coherent package that blends performance, safety, and aesthetics into a single engineering statement.

Manufacturing choices matter as much as material choice. Traditional carbon fiber fabrication often relies on prepregs and autoclave curing, delivering a stiff, precise product with near-perfect surface finish. The surface quality—whether a glassy high-gloss sheen or a restrained satin—does not only affect aesthetics; it influences how air interacts with the surface, which in turn affects boundary layer behavior and drag. The laminate layup—how many plies, where they are oriented, and how they weave into each other—determines stiffness, impact resistance, and even vibration dampening. Advances in curing technology, including vacuum-assisted resin transfer molding and improved resin systems, allow designers to tailor the balance between rigidity and flexibility across a panel. The use of bio-based resins in combination with carbon fiber is expanding, driven by sustainability concerns without sacrificing the mechanical properties that riders demand in the top tier of performance machines. These resin systems, while still able to deliver the same structural integrity, reduce the environmental footprint of production and create a narrative of responsible engineering that resonates with a growing segment of riders who care about materials science as a facet of performance and stewardship.

Repair and customization underscore another practical dimension of carbon fiber. For enthusiasts looking to restore a classic or upgrade a damaged panel, carbon fiber provides a robust option for patchwork or full replacements. Rather than relying on conventional plastics that may warp or crack, carbon fiber skins offer a durable, repairable solution that can be shaped to match the original geometry. In community projects, riders share how they reproduce a damaged rear or side panel using carbon fiber laminates and precise mold work, underscoring carbon fiber’s versatility from repair to personalization. The ability to reproduce a component with near-mirror accuracy means a rider can retain the bike’s original lines and structural behavior, which is especially valuable for models with highly tuned aerodynamics where even small deviations in panel shape can alter performance.

The integration story is not about a single part but about a system. Two-piece carbon fiber side air deflectors, when combined with lighter covers and reinforced fasteners, can dramatically alter how a bike breathes at speed. The air deflectors guide the boundary layer so that it joins the fairing with minimal separation, reducing buffeting and improving high-speed stability. At the same time, the fairing covers contribute to a clean, continuous silhouette, helping to maintain laminar-like flow over more of the surface. This is where the synergy of materials and hardware matters: lightweight panels, matched with high-strength titanium fasteners, keep the structure tight yet forgiving under vibration and heat. The result is a cohesive ensemble where each element complements the others, rather than a collection of individual parts. The careful alignment of fibers, resin, and bonding agents matters as much as the mounting hardware because small misalignments can reveal themselves as vibration, creak, or minor fit gaps that undermine perceived quality and aerodynamic performance.

Hardware choices become part of the performance equation. Titanium fasteners, with their strength-to-weight advantage and excellent corrosion resistance, complement carbon fiber’s elegance by ensuring the assembly remains secure under racing or off-road conditions. The combination lowers overall weight, reduces maintenance intervals, and supports a more aerodynamic surface by avoiding protruding metal-fastener shapes that would disrupt flow. In this broader view, carbon fiber does not stand alone; it integrates with hardware, finishing, and protection layers to create a coherent, high-performance fairing ecosystem. The fastener selection also influences serviceability—engineers design mounting points that are not only strong but accessible, enabling quicker maintenance during track days or long tours. The result is a fairing system that remains simpler to service without compromising the structural or aesthetic intent of the original design.

The broader cultural and design implications are important too. Carbon fiber fairings carry a narrative about precision and purpose. Riders who choose them are signaling a commitment to meticulous engineering and a shielded aesthetic that does not shout but whispers superiority. The weave pattern itself invites attention, and the precision of fit matters—the 100% adhesion and alignment that professional fabrication aims for is not merely cosmetic; it reduces micro-movements that could eventually degrade seals or vents. In that sense, carbon fiber is both a technical decision and a stylistic one, because it affects how people feel when they ride: a sense of lightness, directness, and control. This emotional resonance matters in a market where the rider’s sense of ownership and pride can be as important as measured performance gains. A well-designed carbon fiber fairing communicates that the rider values not just speed, but also the craft behind each contour.

As manufacturing methods evolve, the availability of carbon fiber fairing components expands beyond the realm of premium, purpose-built machines. The same principles apply to a broader set of motorcycles and ambitions, from track-ready machines to capable street riders. The weight savings and improved stiffness integrate with other lightweight upgrades, creating a virtuous circle where every gram saved in the fairing complements the entire drivetrain and chassis. The result is a more responsive, confident, and efficient riding experience, one that allows riders to push the envelope with fewer compromises on handling, braking, or aerodynamics. The carbon fiber pathway thus becomes accessible to a wider community of riders who value both performance and visual appeal, encouraging a culture of iteration and refinement rather than a one-off transformation.

For readers seeking concrete paths to explore carbon fiber fairing accessories within their own builds, a practical approach begins with clarity about goals. If the priority is performance and handling, designers will favor panels and deflectors engineered for minimal weight and maximal stiffness, along with compatible mounting hardware. If the goal is aesthetics and a premium appearance, the finish and weave make a difference, and careful selection of gloss or matte surfaces becomes part of the design decision. The beauty of carbon fiber is that it supports a spectrum of intentions without forcing a single path. It invites experimentation, while preserving reliability and structural integrity. With this mindset, riders can craft a fairing system that not only sheds weight but also communicates a philosophy of engineering discipline and craft.

In sum, carbon fiber’s role in motorcycle fairing accessories is not a single trend but a durable capability that underpins modern design. It enables lighter, stronger, more integrated components that can shape air, influence dynamics, and elevate the rider’s experience. The ongoing evolution—from bio-based resins to sensor-laden integration—suggests that the fairing will continue to morph into a more intelligent, adaptive shell. The chapter on this material’s influence is not just about the look or the weight; it is about a foundational approach to how motorcycles encounter wind, posture, and speed with precision and poise. For riders and builders who seek to harmonize performance with style, carbon fiber offers a language that is as technical as it is poetic, allowing the machine to speak with a lighter, clearer voice.

As you consider your next upgrade, remember that carbon fiber is not a single, isolated upgrade but a pathway to a more integrated philosophy of riding. It invites a holistic view where each panel, each fastener, and each line on the fairing contributes to a shared objective: to move with greater ease, to endure more faithfully, and to look unmistakably engineered in the process. The journey through carbon fiber is a journey through material science meeting rider aspiration, a fusion that has quietly reshaped how modern motorcycles meet the wind. If you are curious about how these concepts translate into real-world platforms, you can explore the Yamaha fairings category to understand how a brand-agnostic approach to fairing aesthetics and performance comes together in a cohesive product family. Yamaha fairings.

External resource for further reading on materials innovation in motorcycles: Bosch Automotive offers a detailed overview of how advanced materials are shaping two-wheeled design and performance. Bosch Automotive article.

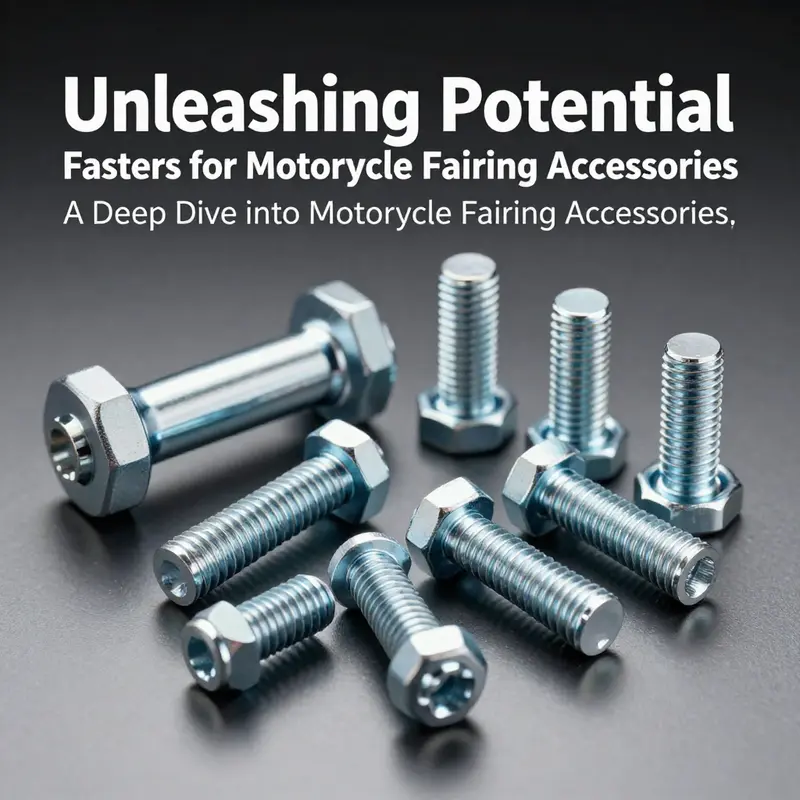

Secure, Light, and Aerodynamic: The Hidden Power of High-Performance Fasteners in Motorcycle Fairing Accessories

Fasteners are the quiet backbone of every motorcycle fairing system. They do more than hold panels in place; they shape how the entire structure interacts with wind, vibration, and the rider’s daily experiences. In the world of aftermarket and OEM fairing accessories, the choice of fasteners can determine whether a carefully sculpted carbon fiber panel stays true at warp speed, or whether a lightweight shell begins to flex, rattle, and create unwanted drag. The chapter on high-performance fasteners for motorcycle fairing accessories is therefore not a mere footnote to materials and looks. It is an examination of how small, precise engineering decisions translate into meaningful gains in handling, aerodynamics, and even rider confidence during long rides or demanding track days. When we talk about fairings—whether they envelop a sport bike’s intake paths, shield the radiator, or lend a head-turning silhouette—fasteners are the hinge on which performance and personality pivot. High-performance fasteners are designed to withstand the constant pressure of vibration, the corrosive creep of road salt and spray, and the mechanical demands of rapid assembly and disassembly. They also preserve the clean, uninterrupted lines that define an aerodynamic fairing. A clumsy, mismatched fastener can introduce micro-mobility: a tiny gap here that creates a path for turbulent flow, a head of a bolt that protrudes and spoils the surface finish, or a threaded insert that pulls away under torque. The aesthetic impact is matched by a practical one: a fairing that cannot be secured reliably is not just a visual defect but a potential safety issue when the rider needs to inspect the engine, adjust a mounting point, or replace a damaged panel after a track day. The narrative around these fasteners begins with material choices, especially when the goal is to reduce weight without compromising strength. Titanium, particularly Grade 5 titanium, is a frequent favorite in high-performance circles because it offers a remarkable combination: substantial weight savings and high tensile strength. In practical terms, titanium bolts and nuts can shave significant grams from a fairing assembly compared with traditional stainless steel hardware, and that weight reduction contributes to a lower unsprung mass. The benefits accumulate across a complete fairing kit. Lighter hardware reduces the inertia of large panels during acceleration, deceleration, and cornering, which in turn makes the bike feel more responsive to rider input. It also matters in terms of thermal management and fuel efficiency, albeit on a smaller scale; the reduced mass affects the dynamics of how the fairing interacts with wind and the rider’s torso, subtly influencing stability at speed. The corrosion resistance of titanium is another practical advantage. In racing and off-road environments, where salt spray, mud, and chemical exposures can accelerate deterioration, titanium bolts and nuts resist such abuse far better than lower-grade metals. The result is not only prolonged life for the mounting hardware but a more reliable, consistent seal around fastened joints. That reliability is critical when fairings must seal out water and wind to preserve interior mechanisms and instruments, or when torques must be sustained during sudden accelerations without loosening. The design features that accompany high-performance fasteners further illustrate the discipline behind modern fairing engineering. Hexagonal heads, for instance, are more than a stylistic choice. They provide excellent tool access, allowing mechanics to reach tightly spaced mounting points with minimal strain and reduced risk of stripping. This feature becomes crucial during maintenance sessions, when riders remove and reinstall panels for cleaning, inspection, or additional upgrades. The geometry of the thread itself matters. A broad spectrum of thread sizes finds use in fairing applications, commonly ranging from M4 to M10, with overall lengths from approximately 16 millimeters to 30 millimeters. This range supports diverse configurations—from compact, lightweight upper fairings to larger, multi-piece side panels that demand longer engagement in structural inserts. The compatibility question is not trivial. The fastener system must integrate seamlessly with automotive-grade standards to withstand the cyclic loading that fairings experience in racing and endurance riding. That means consistent torque resistance, predictable clamp force, and a steadfast hold under vibration. It also means clean, secure finishes that resist galling and seizing, particularly when carbon fiber or composite materials are involved. Titanium’s relationship with carbon fiber, in particular, requires respectful handling. The risk of galling is lower than with certain other metals, but it is not zero. Proper torque values and, where appropriate, anti-seize compounds or compatible coatings help ensure that a fastener can be installed, removed, and reinstalled without degrading either the bolt or the panel. Beyond material and geometry, fastening systems for fairings increasingly embrace modularity and speed. Fairing quick-release fasteners represent a growing innovation that prioritizes rapid access without sacrificing structural integrity. For riders who frequently switch between street setup and track-ready configurations, quick-release mechanisms can dramatically shorten maintenance cycles. They simplify disassembly for cleaning, radiator checks, or airflow testing, and they speed up tire or chain service intervals that might require removing panels for better access. This modular approach complements the broader ecosystem of fairing hardware, where specialty spacers, bushings, and locking mechanisms ensure that each panel sits flush against its neighboring surfaces, forming a continuous, uninterrupted silhouette. The interplay between hardware and aerodynamic performance is subtle but meaningful. When fasteners are too long, misaligned panels can introduce gaps that disrupt smooth airflow and create edge vortices that increase drag and wind noise. When fasteners are too short or poorly chosen for the molding, the clamp force can be compromised, causing micro-movements that generate creaks, chatter, or fatigue over time. The goal, then, is to engineer fastener systems that achieve consistent clamping loads across a spectrum of temperatures and speeds, while maintaining clean surface finishes. In practice, engineers and riders alike consider several guiding principles. First, compatibility and standardization matter. A coherent fastener system minimizes the risk of cross-threading and misalignment. It simplifies maintenance and reduces the chance that a panel will be left unsecured mid-ride. Second, durability under vibration must be baked into the design. This includes selecting materials that handle cyclic loading well and using thread lockers or mechanical locking features that resist loosening without requiring frequent re-tightening. Third, corrosion resistance and environmental durability must be accounted for. Road debris, grime, and salt exposure demand a solution that can withstand harsh riding conditions for years, not just months. Fourth, the installation experience should be straightforward. Engineer-friendly head shapes, accessible torque ranges, and consistent thread engagement lengths help technicians achieve precise, repeatable results without requiring specialized tools or excessive force. And finally, the aesthetic finish must align with the rest of the fairing’s look. A bolt head that catches the eye or a nut that contrasts with the panel can undermine the visual unity of a high-performance build. The ideal fastener therefore respects both form and function, delivering strength without creating visual distraction or aerodynamic inefficiency. In addition to these principles, several practical considerations shape the selection and use of high-performance fasteners. For instance, the total fastener count on a given fairing is rarely random. It is informed by the distribution of load paths across the panel geometry, the locations of mounting points that experience higher shear forces, and the intended service life of the bike. On a track-oriented build, the rider may favor slightly stiffer engagement in certain joints to preserve panel alignment under high acceleration and cornering loads. On a street setup, ease of maintenance and corrosion resistance can take precedence, particularly in climates with heavy moisture or salt exposure. The torque protocol is another critical determinant of performance. Using a calibrated torque value for each bolt size ensures that the clamp force is within a safe and effective range. Under-tightening can lead to panel flutter, while over-tightening risks stripping threads or damaging composites. In the case of titanium fasteners, technicians must also recognize that titanium behaves differently from steel under heat and friction. Though strong, titanium’s surface can be more sensitive to galling if not paired with compatible nuts or coatings. This reinforces the importance of selecting a cohesive fastening system rather than mixing disparate materials without engineering judgment. The broader ecosystem around fasteners for fairing accessories also includes removable, quick-release options that appeal to performance enthusiasts. Quick-release hardware is designed to accelerate panel removal for inspections or upgrades, while preserving the panel’s alignment when reinstalled. The design philosophy behind these systems emphasizes repeatable, precise engagement and robust retention under normal riding conditions. Even in this specialized niche, the economics of material choice matter. Titanium is more expensive than stainless steel, and its procurement may influence the overall cost of a fairing upgrade. For many riders, the performance payoff—reduced weight, improved corrosion resistance, and a cleaner, more integrated look—justifies the investment, particularly on builds that see track use or long-term exposure to harsh environments. Yet the cost must be weighed against the maintenance plan. High-end fasteners often require careful handling, appropriate tools, and clean workshop practices to prevent cross-threading or contamination of threads. Clean, dry storage and proper lubrication practices extend the life of the fasteners and preserve their performance characteristics over a multi-year horizon. When discussing the integration of fasteners within a broader fairing system, it helps to view the entire assembly as a network of joints, each with its own role in the whole. The mount points that attach the fairing to the frame must transmit aerodynamic loads without yielding. The attachment to the subframe and engine guard panels must resist impact forces and vibrations that occur on rough roads or during aggressive cornering. The joinery between adjacent panels should be designed to maintain a seamless look, preventing light gaps that would reveal the underlying structure and disrupt the wind flow. In this sense, the fastener choice becomes a balancing act between lightweight engineering and rugged reliability. It is a balancing act that benefits from a disciplined approach to design that borrows from automotive engineering practices. The discipline emphasizes predictable, quantifiable performance over guesswork, with careful consideration given to material compatibility, surface finishes, and the coordination of all mounting elements. The resulting effect is a fairing system that remains visually cohesive, performs consistently under pressure, and resists the cumulative wear that comes with spirited riding. For readers who want a practical touchpoint while exploring these ideas, consider how a rider might approach choosing a fastener kit for a particular build. Start with the heaviest load-bearing panels and work outward to the smaller, more decorative pieces. Prioritize titanium or other high-strength, corrosion-resistant options for critical joints while using more economical materials for less stressed connections. Pay attention to the head design and tool access, ensuring that the chosen hardware can be tightened and inspected without requiring specialty tools in a crowded pit lane. Align the mechanical decisions with the rider’s goals—track tempo, daily commuting, or weekend canyon carving—and you’ll establish a fastening strategy that complements the entire fairing system rather than fighting against it. It is worth noting that the broader community of fairing enthusiasts often shares practical insights about maintaining their hardware. Regular inspections after hard riding sessions can reveal loosened fasteners or signs of corrosion, prompting timely replacement before a panel shifts or loosens during a ride. A calm maintenance ritual—checking torque on critical joints, cleaning residues from threads, and applying compatible lubricants where appropriate—helps ensure the entire system remains taut, quiet, and aerodynamically efficient. The conversation around high-performance fasteners also benefits from the awareness that not all fairings are created equal. A sportbike’s fairing may rely more on precise panel gaps to manage airflow and rider comfort, while a touring model might prioritize long-term durability and corrosion resistance in exposed mounting points. Recognizing these distinctions guides riders and technicians toward a fastening strategy that aligns with the bike’s intended role, climate, and riding style. The end result of thoughtful fastener selection is a fairing system that stays true to its intended form, resists the indignities of vibration and weather, and continues to deliver feedback-rich handling that riders crave. For riders who are building or upgrading a fairing system, a nuanced understanding of fasteners is invaluable. The hardware does not simply hold plastic, carbon, or composite panels in place; it enables the airfoil to do its job, maintains a smooth silhouette, and preserves the rider’s confidence when pushing through a set of twisties or chasing a lap time. To connect this discussion to the broader ecosystem of fairing accessories, consider how fasteners intersect with other components such as side air deflectors, fairing covers, and mounting hardware. Each element relies on a robust attachment strategy to realize its aerodynamic and protective potential. When fasteners perform well, the overall system experiences fewer maintenance interruptions, less wind noise, and a cleaner, more purposeful visual impression. Conversely, a seemingly minor mismatch in fastener sizing or material choice can ripple through the setup, undermining the benefits of more advanced carbon fiber or alloy components. The takeaway is a simple, robust one: high-performance fasteners are not a mere afterthought but an essential design decision that influences aerodynamics, durability, and rider experience across a spectrum of riding conditions. They deserve careful consideration in any fairing upgrade, from the choice of material and head style to the attention paid to torque, engagement depth, and environmental durability. As riders and builders continue to push the envelope of what a fairing can do, the fasteners that hold those panels in place will remain a critical frontier—quiet, precise, and profoundly consequential for those who demand the most from their machines. For readers seeking a brand-relevant orientation within the broader fairing ecosystem, a reference to brand-aligned fairing categories can be useful; see the Honda fairings collection for related options and compatibility considerations. Honda fairings. External reference for further technical depth on high-performance fastening materials can be found here: https://www.alibaba.com/product-detail/Custom-Motor-Parts-Titanium-Gr5-Bolts_1600748293118.html

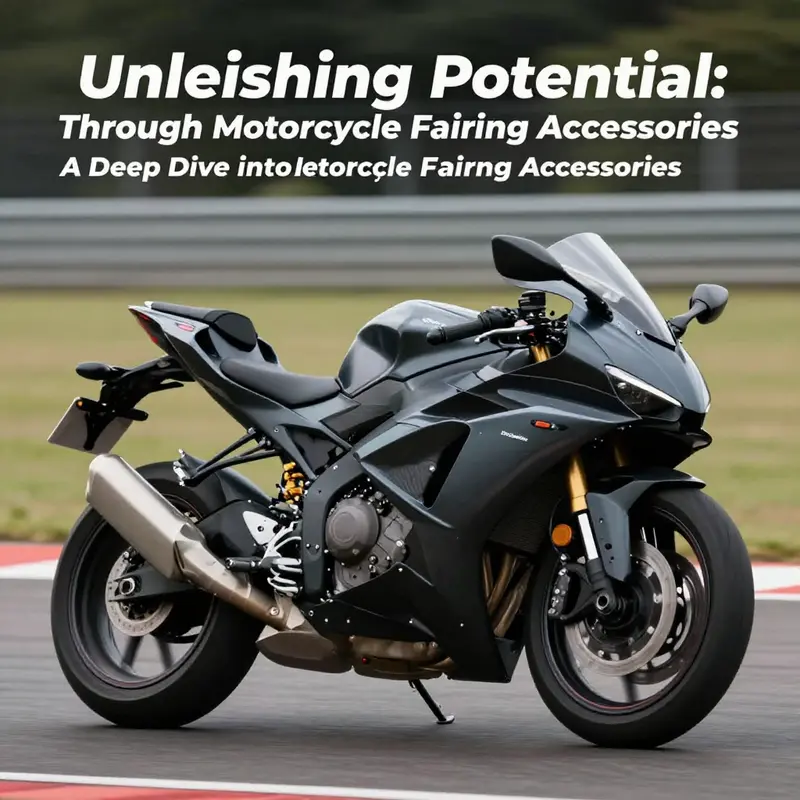

Wind Craft in the Saddle: Aerodynamic Mastery Through Motorcycle Fairing Accessories

Air is a stubborn yet generous partner for riders who chase speed and control. Every twist of the throttle, every lean into a corner, and every gust that meets a cloaked machine are conversations with the air itself. Motorcycle fairing accessories are the craft tools that turn that conversation into a dialogue of efficiency, stability, and personality. They are not merely surface adornments; they are engineered elements that guide airflow around the bike and smooth the rider’s experience at speed.

Towards the front, winglets and spoilers are designed to manage the first lines of force. They create subtle vortices and redirect currents to reduce separation behind the forks, yielding a calmer air stream and a more stable steering feel as speeds climb. When the bike leans, the air inside and outside the fairing behaves differently; careful shaping helps balance those effects and keeps the front wheel planted while reducing rider buffeting.

On the sides, carbon fiber deflectors guide airflow along the body to minimize crosswinds and smooth pressure around the engine and exhaust. The material choice matters; carbon offers high strength to weight and stiffness that stays true under heat and vibration, contributing to a faster looking and faster feeling machine with lower wind noise.

A full fairing kit shapes the entire air path around the bike. Modern kits combine ABS or other plastics with well tuned curves to reduce form drag while directing air toward useful escape routes, protecting components and helping keep the engine cooler in demanding riding conditions. The modular nature lets riders mix and match sections for customization without breaking aerodynamic intent.

Beyond the skin, lightweight fasteners and brackets matter. Titanium fasteners reduce weight and improve corrosion resistance, while easier service and lower unsprung mass subtly enhance feel and control. The design favors reliable mounting and straightforward maintenance so riders spend less time with tools and more on the road.

Materials and standards anchor the practice. Many fairings use composites and prepregs to hold precise fit and surface finish, with attention to gaps, edges, and integration with electronics. Certification marks and compliance signals remind riders that performance upgrades consider safety, durability, and reliability in equal measure.

For owners who pursue model specific upgrades, catalogs show how a family of components can share mounting points and tolerances, allowing gradual upgrades without a complete redesign. This consistency supports maintenance and upgrades while preserving aerodynamic intent.

Finally, the rider remains central. A consistent riding line, deliberate body position, and measured inputs amplify the benefits of a well matched fairing system. The aerodynamic package becomes a living part of riding craft, rewarding patience and thoughtful experimentation.

Final thoughts

Motorcycle fairing accessories play a crucial role in enhancing both form and function for riders. By leveraging the benefits of advanced materials like carbon fiber and high-performance fasteners, businesses can meet the evolving demands of motorcycle enthusiasts. Additionally, the focus on aerodynamics through innovative designs not only boosts performance but also appeals to the aesthetic preferences of modern riders. Understanding these elements enables business owners to better cater to the market, ensuring they provide top-quality products that enhance the riding experience and foster customer loyalty.