Lower fairings play a pivotal role in motorcycle design, combining functionality with style. These components not only streamline airflow to enhance performance but also contribute to the comfort of riders by reducing wind exposure. Business owners in the motorcycle industry must understand the importance of lower fairings, especially as they offer customization opportunities for audio systems and aesthetics. Additionally, aftermarket options can provide riders with diverse choices and features that suit their specific needs. This article delves into the design and composition of lower fairing components, their functionality in aerodynamics and wind deflection, the benefits of aftermarket options, and current market trends driving accessory and upgrade demands.

Streamlining the Ride: The Lower Fairing as Aerodynamic Armor and Identity in Modern Motorcycles

The lower fairing beneath a motorcycle’s primary bodywork embodies a quiet revolution in how riders experience speed, wind, and comfort. It is more than a mere panel; it is a carefully crafted interface between machine and rider, shaping airflow, shielding the rider’s legs, and signaling the bike’s character from first glance. In touring visions and sport-leaning cruisers alike, the lower fairing sits at the intersection of function and form. Its role begins with the obvious task of directing air away from the engine and chassis, but the story extends far deeper into comfort on long stretches, handling under varying weather, and the visual language that defines a motorcycle’s stance on the road. Advances in design have turned lowers from simple protective shells into complex, integrated systems that enhance performance and identity without sacrificing ease of use or reliability.

Airflow and comfort are the core reasons for the lower fairing’s existence. Encasing the lower engine and frame, lowers interact with the boundary layer of air that flows toward the rider’s legs. When aerodynamics are neglected, wind gusts and turbulence can produce fatigue, particularly on long rides where speed, posture, and weather conditions compound the effect. Computational fluid dynamics (CFD) has become a standard tool in shaping these panels. By simulating how air travels around the lower body of the bike, engineers can predict where eddies would form, where buffeting might reach the rider, and where surface seams could trigger noise or drag. The goal is a clean, laminar flow over the rider’s legs and a reduction in wake behind the bike, which in turn contributes to smoother handling and reduced rider fatigue. This is not vanity physics; it is a practical, measurable improvement in daily riding experience.

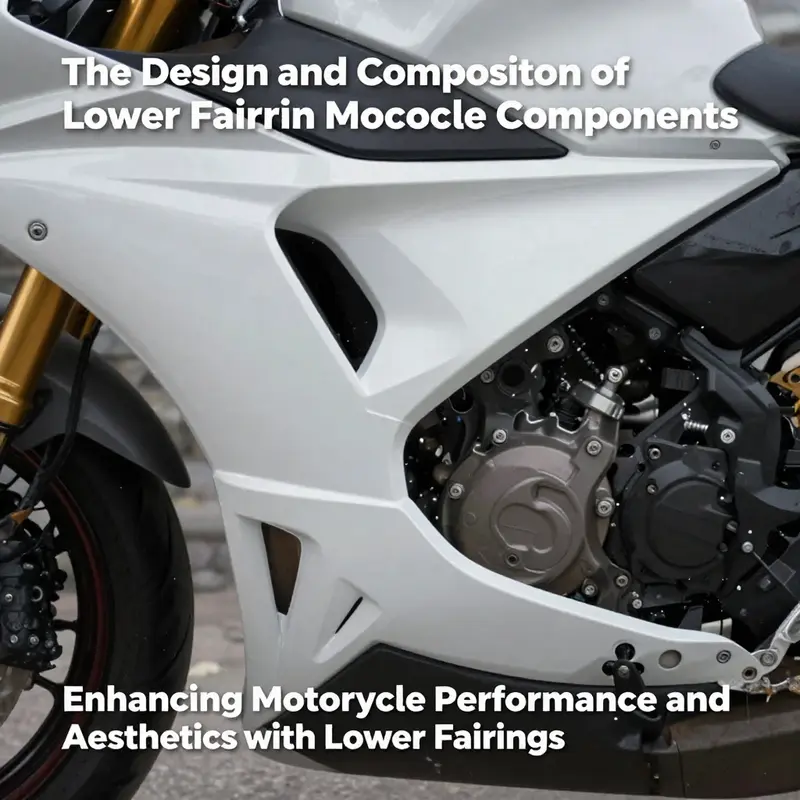

Materials selection underpins how effective a lower fairing can be and how readily it can be repaired or customized. ABS plastic remains the most common choice, favored for its balance of impact resistance, stiffness, moldability, and cost. ABS allows designers to create complex contours that blend with the main fairing and provide integrated features such as air ducts, cavities for wiring, and mounting points. Its ductility means that a panel can be both rigid in operation and forgiving in the event of minor impacts. Fiberglass, with its higher strength-to-weight ratio and greater customization potential, is a frequent option for bespoke or high-performance builds where riders want more aggressive geometry or unique surface textures. Carbon fiber sits at the premium end, delivering exceptional stiffness and a striking aesthetic while dramatically reducing weight. The trade-offs—price, repairability, and manufacturability—mean each rider’s goals will tilt toward a different material path. The material choice reverberates through durability, repair workflows, and how paint and finish respond to UV exposure and weathering, all of which ultimately influence maintenance planning.

Functionally, lowers do more than just streamline air. They can provide practical utility through integrated storage solutions in some designs, especially on adventure and touring machines where extra pockets or recessed compartments become handy on long trips. The idea is to fold utility into form without inviting a cluttered silhouette or added weight. A well-designed lower blends into the bike’s visual identity, offering a clean, continuous line that reinforces the rider’s sense of speed and purpose. In that sense, the lower fairing becomes a key element of the machine’s personality, echoing the bike’s overall styling cues, even when the primary fairing is visually dominant. The choice of curves, the angle of the side panels, and how the edges meet the engine cover all contribute to a cohesive aesthetic that communicates both efficiency and character.

From a manufacturing stance, precise fitment is essential. Even small misalignments can disrupt aerodynamics, allowing gaps that generate drag or create buffeting zones. The mounting points, tolerances, and the way a lower fairing nests against surrounding panels demand tight control during production and careful verification during aftermarket installation. This is why OEM lowers tend to emphasize a factory-perfect fit, while aftermarket options, though offering broader styling and price ranges, require attention to compatibility with the year, model family, and sometimes regional configurations. For riders who opt for this path, the aftermarket ecosystem has grown robust, with many lines designed to align with the factory geometry while providing new materials, finishes, or integrated features such as audio enclosures or LED indicators. This balance between fidelity and customization is at the heart of the modern lower fairing market.

The functional versatility of lower fairings continues with their potential to house or accommodate add-ons that enhance the riding experience. Venting lowers, for example, incorporate integrated air intakes to improve engine cooling and ventilation. In air-cooled or semi-vented configurations, these ducts become a practical route for maintaining optimal operating temperatures, especially during sustained highway cruising or hot-weather riding. Other lowers are designed to carry audio systems, with speaker pods built into the panel or mounted behind grills. The concept is to create a seamless integration where the sound system feels like a natural extension of the bike’s personality rather than an afterthought. The gains here are not only auditory. The added weatherproofing and enclosures can also influence the overall insulation and aerodynamics of the lower, contributing to a quieter, more controlled riding environment at speed.

The decision to adopt vented or non-vented lowers, or to pursue audio-integrated designs, hinges on a rider’s priorities. A vented lower can aid cooling and potentially improve air distribution to certain engine components, which philosophers of performance describe as reducing thermal load and preserving long-term efficiency. If the rider’s focus is purely on wind protection and comfort, a non-vented lower with a smooth exterior can deliver a calmer, shielded feel for the legs and hips. For riders who crave audio, the integration of speaker pods and weather-sealed wiring channels becomes a practical certainty. The result is a capability that complements the motorcycle’s touring or cruising identity, allowing riders to pace their journey with less fatigue and more enjoyment. The engineering philosophy behind these designs emphasizes modularity: a common core lower that can accommodate a range of features and a variety of finishes and mounting options, all while preserving the essential aerodynamic function.

To those who experiment with customization, lower fairings offer a canvas for personal expression without compromising performance. The aesthetic narrative can be extended through paint finishes, textures, and sculpted details that echo or contrast with the primary fairing. The right finish can emphasize speed even when the bike is stationary, while a carefully chosen contour can visually broaden or sharpen the stance of the machine. The balance is to maintain a cohesive look with the rest of the bodywork, ensuring the lower contributes to a unified silhouette rather than appearing as a separate accessory. In this sense, the lower fairing anchors the bike’s visual identity, just as it anchors the rider’s physical comfort in the saddle.

The aftermarket ecosystem has grown to reflect this multi-faceted role. Riders seeking to upgrade often explore compatible lowers that claim to fit a range of touring or cruiser platforms. The goal is a hassle-free upgrade path with reliable fitment, preserving or enhancing the bike’s aerodynamics and balance. Compatibility considerations usually revolve around bodywork shape, mounting points, and the interaction with the main fairing or radiator covers. While compatibility is easier to achieve when sticking with OEM parts, aftermarket lowers offer more choices in materials, finishing options, and the possibility to pair with specialized features like speaker enclosures or extra lighting. The trade-offs can include longer installation times, additional wiring work for electronic add-ons, and the need to confirm warranty implications. Still, many riders find the payoff worth the extra planning, particularly when the result is a more comfortable ride, a more expressive appearance, and a more integrated audio or lighting setup that feels native to the bike rather than tacked on.

In exploring the broader landscape of lower fairings, it’s helpful to consider how different brands and model families approach compatibility and styling. A practical lesson emerges: the most successful lowers maintain a design language that respects the bike’s original geometry while inviting customization. They use consistent mounting philosophies, materials with predictable thermal and impact behavior, and finishes that can be matched to a range of paint schemes. For riders who want to see a sense of how a given category of fairings might be implemented across brands, a look into the BMW fairings catalog provides a sense of how different lines approach form and function within a shared framework. The catalog demonstrates how a single structural concept can yield many aesthetic expressions while preserving fitment integrity and aerodynamic performance. This balance of universality and customization underscores why the lower fairing has emerged as a staple in modern motorcycle design.

From a practical standpoint, riders should approach lowers with a clear understanding of their riding goals, maintenance expectations, and the realities of installation. If a panel is intended to provide wind protection and reduce fatigue on long trips, the emphasis should be on a clean seal with the main fairing, a smooth transition at the edges, and a frame that resists warping in heat and cold. If audio or lighting is a priority, the design must factor in weatherproof enclosures, reliable waterproofing for seals, and robust routing paths for wires that avoid heat sources and moving parts. Storage-oriented lowers require careful planning of space, access points, and weight distribution to ensure no interference with exhaust routing or heat shields. Maintenance considerations emerge as well: damaged plastic can often be repaired with heat and resin, while fiberglass or carbon fiber may require more specialized repair techniques. Paint and clear coats must be chosen for UV resistance and compatibility with the underlying material to ensure long-term durability.

The narrative of the lower fairing is thus a story of careful engineering meeting personal preference. It is about the patient shaping of air as it flows around the machine, the quiet confidence of a panel that deflects wind with little fuss, and the way a rider can tailor the experience through thoughtful material choices, strategic venting, and purposeful add-ons. It is also about the pragmatics of upgrading: ensuring that a desired combination of aerodynamics, cooling, storage, audio, lighting, and aesthetics can be achieved without sacrificing safety or reliability. For riders who want a tactile sense of control—that their bike is not only fast but also well-behaved at highway speeds—the lower fairing offers tangible, measurable benefits. And for those who see their bike as a canvas for expression, lowers provide a stage where form and function perform in concert, reinforcing the narrative of speed and adventure with a cohesive, personally meaningful look.

For readers seeking concrete, brand-agnostic guidance on selection and integration, the core advice remains consistent: prioritize fitment accuracy and alignment, choose materials that match riding conditions and budget, and consider how any added features will affect aerodynamics and maintenance. If you plan to install venting, enclosures, or lighting, prepare for a thoughtful routing plan and weatherproofing strategy. As with any significant cosmetic or functional upgrade, verify compatibility across model years and configurations to avoid misfit issues that can erode the very advantages you seek. In this way, the lower fairing becomes not just a protective shell but a nuanced interface between rider, machine, and environment—a compact yet powerful contributor to comfort, performance, and personality on two wheels.

Internal linking note: explore the BMW fairings catalog to see how lower panels are integrated with broader bodywork while maintaining a consistent design language across a family of bikes. This example illustrates how a single concept—lowers as aerodynamic and aesthetic enhancers—can adapt to diverse platforms while preserving fit, function, and identity. BMW fairings catalog.

External reference for deeper technical guidance: comprehensive, up-to-date treatment of lower fairing design, CFD considerations, and industry applications can be found in the Technical Guide to Lower Fairings (2026) at Motorcycle Engineering’s resource center. https://www.motorcycleengineering.org/technical-guide-lower-fairings-2026

Underneath the Streamline: How Lower Fairings Shape Aerodynamics and Protect the Bike

How the lower fairing sculpts airflow and protects what matters

A motorcycle’s lower fairing is a small but powerful piece of engineering. Nestled along the lower sides of the engine and beneath the frame, it quietly manages airflow, deflects unwanted wind, and shields the undercarriage from damage. Though less visible than a full front fairing, the lower fairing influences ride stability, fuel consumption, and component longevity in ways riders feel every mile. This chapter examines how that influence is achieved, the design decisions behind it, and why choosing the right lower fairing matters for both performance and everyday use.

At its core, the lower fairing is an aerodynamic tool. Air hitting the motorcycle encounters many abrupt transitions: the wheel wells, the engine’s complex shapes, exhaust headers, and a rider’s legs. Left unmanaged, these features generate turbulence beneath the chassis. Turbulent flow increases drag, destabilizes the bike at speed, and redirects buffeting toward the rider. A well-shaped lower fairing smooths that chaotic region. It creates continuous surfaces that guide air from the leading edges to the rear, reducing vortices and lowering the pressure differentials that cause drag. The result is measurable: improved highway fuel economy, reduced frontal buffeting effects, and a steadier machine at speed.

Wind deflection is not limited to overall drag. The lower fairing shapes how air moves around the rider’s lower torso and legs. This matters on long rides and at high speeds. Even when a full fairing screens the upper body, airflow under the seat and around the thighs can create lift or unpredictable lateral forces. By channeling air cleanly past these areas, a lower fairing reduces pressure fluctuations that lead to rider fatigue. Comfort gains are subtle but cumulative: less constant correction of steering inputs, reduced lower-body vibration, and diminished direct wind pressure on the hips and knees. For touring and long-distance riding, those incremental improvements translate into longer, less tiring days in the saddle.

Protection is the lower fairing’s other major role. The undercarriage houses vital parts—oil filters, engine casings, exhaust components, and lower wiring—that are exposed to road debris and water spray. A robust lower fairing acts as a shield, diverting stones, salt, and road grit away from these elements. It also limits direct water flow during wet rides, helping maintain consistent cooling and reducing the likelihood of corrosion. In this defensive role, material selection matters. Durable plastics like ABS absorb minor impacts and resist cracking. Composite options such as fiberglass or carbon fiber can offer greater stiffness and a premium finish, although they differ in weight, price, and repairability. The optimal choice balances resilience with the desired weight characteristics and aesthetic goals.

Thermal management and airflow control often sit behind the fairing’s visible curves. Engineers integrate vents, ducts, and outlet paths to ensure critical components receive the cooling air they need. Vented lower fairings incorporate targeted inlets that draw fresh air toward oil coolers or radiator flanks, while channeling hot air away from the rider’s legs and under-seat cavities. Properly designed vents reduce hotspot formation and maintain stable operating temperatures. This careful channeling also minimizes the need for flow-disturbing elements later in the system, like additional ducting or fans, which can add weight and complexity.

A point frequently overlooked is how lower fairings interact with other bodywork. When paired with complementary front or full fairings, the lower section completes a cohesive aerodynamic package. The seams and gaps between components must be managed to avoid creating new turbulence. Designers often taper edges, align panel surfaces, and use overlapping joints to preserve smooth streamlines. Where alignment is imperfect or aftermarket pieces are mismatched, those seams become turbulence sources, negating much of the fairing’s benefit. Ensuring precise fitment, whether from factory-supplied parts or carefully engineered replacements, is essential for the intended aerodynamic gains to materialize.

Aftermarket lower fairings present an opportunity to optimize both style and function. Many riders choose replacements that add features such as integrated speaker pods, additional vents, or reinforced impact areas. These modifications can enhance comfort and usability, but they must respect the underlying airflow logic. Adding a speaker enclosure, for example, alters the local volume and surface shape, which can change pressure distributions near the rider’s legs. If the new geometry disrupts airflow unnecessarily, the rider may experience increased buffeting or altered steering feel. Quality aftermarket options aim to replicate the original aerodynamic intent while enabling customization, but lower-cost alternatives sometimes sacrifice fit or flow performance.

Material and construction choices further influence behavior during real-world use. ABS plastic offers a well-rounded profile: it is tough, flexible under impact, and straightforward to mold into complex curves that support smooth airflow. Fiberglass allows precise shaping and is repairable after impact, but it can be heavier and more brittle. Carbon fiber delivers superior stiffness and a premium weight-to-strength ratio, yet it is more expensive and can shatter under certain impacts. Beyond strength, surface finish affects aerodynamic performance. A smooth, consistent finish reduces micro-turbulence; rough textures or uneven paint layers increase friction and slightly raise drag. Maintenance—keeping the lower fairing clean from tar, oil, and road grime—preserves both its protective function and its aerodynamic efficiency.

Integration with other systems is a practical consideration. Lower fairings often house lighting or turn signal elements, audio enclosures, and wiring harnesses. Their interior cavities require thoughtful routing to protect components from heat and road spray. Access panels or removable sections enable maintenance without full disassembly. When planning upgrades or replacements, riders should verify how easily serviceable components remain. Hard-to-reach filters or oil drains hidden behind a fixed lower fairing add service time and complexity during routine maintenance.

The trade-offs between stability, cooling, and weight define many design decisions. A larger, more enclosed lower fairing may reduce drag and improve protection but can trap heat if not properly vented. Conversely, highly perforated or open designs enhance cooling but increase turbulent flow beneath the bike. Smart designs balance these by using directional ducts that channel air where needed while maintaining smooth external surfaces. Computational fluid dynamics (CFD) and wind-tunnel testing guide these compromises, enabling designers to predict how small changes in curvature or vent placement influence performance across different speeds.

Fitment accuracy is a final, practical note that ties many of these themes together. Precision in mounting points, panel gaps, and fastener integrity preserves the aerodynamic plan. Even a small misalignment can create a pocket where air separates from the surface, forming a drag-increasing wake. For owners considering replacements, choosing a part designed for their model year and configuration reduces the likelihood of such issues. Proper installation, including torqueing fasteners to specification and ensuring panels sit flush, often delivers most of the promised benefits.

For riders seeking targeted improvements—whether reducing fuel consumption on long trips, smoothing the feel of crosswinds, or protecting critical components from debris—the lower fairing offers a concentrated set of advantages. Its role is not flashy, but it is foundational: it shapes the air the bike meets, guards the parts that keep the machine running, and refines the riding experience in subtle, cumulative ways. Thoughtful selection, careful installation, and attention to venting and material choices turn a simple panel into a highly effective performance and protection component.

For examples of model-specific lower fairings and replacement options, explore a curated selection of compatible panels and designs for sport and touring machines at this collection of fairings. For deeper technical insight into the aerodynamic principles behind fairing design, refer to a detailed analysis available from an industry technical resource: https://www.motorcycle.com/technical-insights/aerodynamics-and-fairing-design-in-modern-motorcycles

Under the Skin of the Ride: Aerodynamics, Comfort, and Customization through Aftermarket Lower Fairings

A motorcycle lower fairing is more than a cosmetic shield tucked beneath the engine. It is a carefully engineered element that shapes how a bike cuts through air, how the rider experiences wind, and how the machine carries its own character from chassis to spectacle. When riders seek to tune the balance between performance and personality, the lower fairing becomes a practical and aesthetic fulcrum. The choice to go aftermarket is often not just about fitting a piece to a frame; it is a statement about what the rider values most in long-distance comfort, daily usability, and the way a bike presents itself on the road. In the chain of components that cradle the rider’s confidence, the lower fairing plays a silent but persistent role, smoothing turbulence, shielding vital parts from road spray and debris, and offering a canvas for color, texture, and the subtle language of lines that tells a story about a bike’s purpose.

From a wind engineering perspective, the lower fairing sits at a strategic crossroads where every gust has a way of curling around the bike’s belly and interacting with the rider’s legs, hips, and lower torso. The design aims to redirect flow in a way that reduces wake behind the engine and frame, which in turn lowers parasitic drag and minimizes buffeting—especially at highway speeds where a rider’s posture and the bike’s geometry amplify or dampen wind forces. The result is not mere speed; it is steadiness and comfort. When the wind is channeled away from sensitive areas, the rider’s upper body can remain relaxed, gas and brake inputs come with less torso strain, and the long hours of travel begin to feel more like a glide than a grind. The lower fairing also contributes to stability by managing the airflow under the chassis. A well-integrated undercarriage shield can help maintain a predictable airflow pattern around the engine, oil cooler, and exhaust, which translates into steadier steering feel and fewer surprises during fast changes in direction or when the bike is leaned into corners. It is a quiet optimization, often invisible to casual riders but deeply felt by those who spend hours in the saddle.

Material choice is the most tangible lever for these outcomes. ABS plastic remains the workhorse of aftermarket lower fairings because it balances strength, impact resistance, and cost. Its relative lightness makes it easy to mold into intricate shapes that cradle air intakes, vents, or subtle sculpting lines. Fiberglass offers a stiffer alternative with the potential for milder weight penalties and sharper edges; it appeals to riders chasing aggressive aesthetics or a particular curvature that stock components do not provide. Carbon fiber, while more brittle in direct impact and typically pricier, represents a pinnacle of stiffness-to-weight ratio and visual drama, giving a premium glimpse of how lightness and structural integrity can unite. Each material choice carries trade-offs in durability, repairability, and surface finish, but what remains constant is the broadened scope for customization. The aftermarket scene thrives on this flexibility, inviting riders to tailor thickness, contour, and finish to suit a model’s geometry and a rider’s taste.

The aesthetic dimension of lower fairings often reflects a broader trend toward personalization without sacrificing functionality. The lower portion of a bike’s bodywork contributes to the overall silhouette in a way that is immediately perceptible to onlookers and riders alike. A vented lower fairing can introduce a more aggressive, performance-forward look while providing practical benefits like improved engine cooling and ventilation. On tours and long rides, integrated features come into play as well. Some aftermarket offerings integrate lighting, little storage compartments, or channels for routing cables cleanly to audio systems or auxiliary sensors. Even when a rider prioritizes a clean, minimalist appearance, the choice of finish—matte versus glossy, solid color versus graphic motif—can shift how the bike reads in motion. The craft of shaping, bonding, and finishing is a reminder that the lower fairing is a union of engineering and artistry.

A significant portion of the aftermarket value lies in the potential for enhanced comfort and enjoyment through audio and environmental integration. Speaker pods housed within the lower fairing are a recurring feature that has moved beyond novelty into practical daily use for riders who value an immersive experience without compromising the bike’s native lines. The concept is straightforward: embed small speaker enclosures in a way that harmonizes with the fairing’s geometry, shield the units from impact and weather, and route power and signal through a tidy harness. When executed well, these pods deliver a balanced listening experience with minimal vibration transfer and a reduced need for aftermarket external housings that would otherwise mar the bike’s sides. The integration challenge is real, though. It requires attention to heat dissipation, weather sealing, and the fairing’s structural integrity so that added weight and ports do not disrupt the intended airflow pattern. Yet, for riders who prize a richer audio environment on open highways or while cruising scenic byways, an aftermarket lower fairing with speaker capability becomes a practical expression of modern touring culture.

Beyond materials and acoustics, fitment is the decisive practical hinge for any aftermarket lower fairing. OEM parts guarantee a perfect match to a given model year and configuration, but the aftermarket ecosystem has grown robust enough to offer broad compatibility across related generations and chassis families. The reality is that perfect fitment depends on a precise alignment with the bike’s frame lines, engine casing, coolant and air intakes, and the routes chosen for wiring and hoses. A lower fairing that sits flush against the engine cases and the frame reduces rattles and vibration, helps maintain consistent gaps with adjacent body panels, and minimizes the chance of snagging on road debris or during a parking-lot maneuver. For riders who aim to install an aftermarket lower fairing themselves, the key is not just the cosmetic agreement but the mechanical one: will the fairing line up with mounting points, will the inner contours clear exhaust heat shields, and will the wiring harness for any integrated systems reach its destination without forcing modification? The answers vary by model and generation, which is why fitment compatibility and the specificity of the cataloged mounting points matter as much as the visual appeal.

In the realm of customization, the spectrum extends beyond color and texture into functional configuration. A lower fairing can be crafted to accommodate different lighting schemes, air intakes, vents, or cooling ducts that complement a given engine’s thermal envelope. For riders seeking to preserve a timeless look while adding practical upgrades, a vented or partially vented design can offer a compromise between shielding and breathability. Audio enthusiasts might specify speaker configurations, grill patterns, and grille materials that align with the fairing’s surface treatment, ensuring that the visual rhythm remains harmonious even as the soundscape deepens. Storage options, though modest in most touring configurations, become more feasible when the fairing’s interior volume is accounted for during design. In all cases, the end goal is not merely to reclaim a few inches of wattage or a few decibels of bass but to weave a cohesive package where aerodynamics, heat management, and human factors converge.

The decision to pursue aftermarket lower fairings is often a balancing act among wind protection, heat management, and the rider’s comfort over long distances. Wind protection is closely linked to the rider’s height, posture, and the bike’s overall geometry. A lower fairing designed for a mid-height rider might do a superior job at channeling airflow around the thighs and hips for one person and deliver less benefit to a taller rider. Heat management similarly benefits from a thoughtful design that avoids funneling hot engine air directly toward the rider at stop-and-go speeds while still allowing adequate cooling air to reach the motor under load. These considerations matter most on road-driven adventures where every hour adds up and the temperature can rise with traffic and altitude. In addition, the wiring harness and integration points for audio or lighting require careful routing, secure fasteners, and weatherproof seals so that the installation remains reliable across seasons. When these threads are joined with a craftsmanlike finish, the result is a fairing that feels true to the bike’s original intent while extending its capabilities.

A final consideration concerns the broader ecosystem around aftermarket options. The marketplace has grown to accommodate riders seeking both value and variety. While some may treat the lower fairing as a straightforward shell to alter the bike’s profile, others see it as a platform for a broader customization project, one that could include new paintwork, revised wiring, and an updated instrument cluster alignment. The cost of admission varies with materials, thickness, and features like integrated lighting or audio. Yet even with a wider price range, the payoff can be measured in reduced fatigue, improved ride quality on imperfect pavement, and a refreshed sense of identity for a machine that often travels thousands of miles each year. It is a reminder that customization is not only about appearance; it is about how a bike behaves when the road becomes the primary teacher of endurance and rhythm.

For readers who want to explore a catalog of compatible options and gauge how the fit and finish line up with their goals, a catalog of fairings can provide a helpful map of possibilities. For example, a dedicated catalog of fairings from popular categories can offer context on fitment, material options, and styling cues. See the catalog here: Honda fairings. This link is a practical guide to the language of fitment, illustrating how the fairing’s contour, mounting pattern, and visual treatment interact with a bike’s existing geometry. It also helps riders understand how a given product could harmonize with a model year’s body lines and with the rider’s own design preferences, whether those preferences lean toward retro, modern, or something that sits between.

In the end, the decision to adopt an aftermarket lower fairing rests on a blend of engineering reasoning and personal taste. The best outcomes emerge when riders approach the project with a holistic mindset: assess wind protection and heat management, select a material that suits the expected use and budget, ensure fitment with the model’s mounting points and wiring, and embrace a finish that reflects the bike’s character. The lower fairing, once installed, becomes a quiet partner in the ride: a component that reduces fatigue, preserves precious engine and electrical integrity, and communicates through lines and shade the rider’s confidence in speed, weather, and road texture. The transformation is not only external. It is a recalibration of the relationship between rider, machine, and environment, a reimagining of what a bike can carry beneath its skin as it meets the world. A well-chosen lower fairing speaks in a language that blends comfort with purpose, style with function, and the immediacy of wind with the patience of miles.

For readers seeking practical guidance on what to look for and who should consider a lower fairing upgrade, there is a comprehensive guide that outlines fitment considerations, material trade-offs, and how to evaluate a fairing’s integration with an existing setup. This external resource offers a thoughtful framework for deciding whether aftermarket lower fairings align with a rider’s ambitions and riding conditions: https://www.motorcyclecruiser.com/harley-lower-fairing-guide-what-to-look-for-and-who-should/

Finally, as with any significant modification, anticipate a process that rewards careful planning, precise measuring, and a willingness to adjust. The world of aftermarket lower fairings is a spectrum rather than a single destination. The right choice balances wind, heat, and noise levels with a design language that feels inevitable when the bike is in motion. It invites riders to imagine the next chapter of their journey not as a series of compromises but as a sequence of refined compromises—where each improvement in airflow, protection, and audio comes together to create a ride that is more than the sum of its parts. The lower fairing does more than shield the engine; it shapes the story the machine tells on the road, a story that resonates every time the throttle opens and the wind redraws the horizon across the rider’s field of view.

Sound, Speed, and Shield: Market Currents Shaping Lower Fairing Upgrades for Modern Riders

The lower fairing on a motorcycle has evolved beyond its original role as a wind-cutting shield and debris deflector. Today, it sits at the intersection of form, function, and sound, orchestrating a rider experience that blends comfort, performance, and personal expression. Market signals point to a vibrant future for lower fairings and their associated upgrades, where the same panel that tames wind also carries speakers, cooling ducts, and carefully shaped aerodynamics. Recent market analysis places the global motorcycle fairing market at about $15.3 billion in 2025, and it projects a compound annual growth rate of roughly 10.12% from 2026 to 2033. Those numbers are not merely academic; they translate into a steady stream of options for riders who want more control over airflow, more resonance from their music, and more statement in their bike’s silhouette. This growth narrative hinges on a handful of core drivers that keep converging on every model—from touring cruisers to sport-touring machines—and it helps explain why lower fairings are now a central platform for aftermarket innovation and OEM refinement alike.

One of the most visible trends is the integration of advanced audio systems into the lower fairing. Riders no longer settle for chargers and small speakers perched on handlebars; they expect audio that leverages the large, shielded space of the fairing to deliver robust, well-balanced sound for long rides. In this market, the lower fairing becomes a dedicated enclosure and a sonic chamber, optimized to minimize dampening and maximize clarity. The design challenge is intricate: the enclosure must accommodate midrange and treble performance while also handling dynamic road noise, wind turbulences, and vibrations from the engine, all without overburdening the bike’s electrical system. The result is a multi-function module that merges weatherproofing, acoustic engineering, and electrical integration into a single, cohesive unit. This trend toward integrated audio redefines what riders expect from a fairing—no longer merely protective skin, but a personal concert hall carved into the bike’s bodywork. A side effect is the rise of customizable audio configurations, from factory-supported stages to aftermarket options, enabling riders to tailor sound quality to highway speeds or city streets without swapping out the entire fairing assembly.

Alongside audio, aerodynamic efficiency and rider comfort continue to shape lower fairing design. Foremost, manufacturers and aftermarket builders are refining the underbody and lower-panel geometry to improve airflow toward the engine and cooling ducts, while also directing a smoother wind path around the rider’s legs and lower torso. Even when the wind cannot be eliminated entirely, smart shaping can reduce fatigue, maintain cabin temperature, and minimize wear on gear shifters and accessories exposed to constant airflow. In practical terms, this translates to lower fairings that look more integrated with the bike’s front-end architecture. The surface lines, air intakes, and shield contours work together to create a seamless profile that protects as effectively as it breathes, without compromising accessibility to critical components or serviceability for maintenance.

The material choices for lower fairings reflect a balancing act between strength, weight, cost, and durability. ABS plastic remains the workhorse for mass-market models because of its resistance to impact, ease of molding, and cost-effectiveness. For riders chasing lighter weight and higher stiffness, fiberglass and carbon fiber composites offer tangible benefits, though at a higher price point and with different manufacturing tolerances. The material mix often follows the intended use case: touring and cruiser configurations may lean toward cost-effective ABS with added reinforcement for long-term durability, while sport-touring and premium custom builds might incorporate carbon fiber accents or full panels where weight savings and stiffness translate into better handling at speed. This material ecosystem supports a broader ecosystem of accessories and add-ons, including vented lower fairings with integrated air channels, heat-exchanger ducts, and, of course, speaker pods that can be integrated without compromising the panel’s protective role.

A notable shift in the market is the demand for universal-fit and OEM-standard quality options. Dealers and wholesalers increasingly stock lower fairings designed for broad compatibility, allowing buyers to source reliable components at scalable prices. That trend aligns with a broader appetite for customization that doesn’t require a full OEM parts catalog to achieve a refreshed look or improved performance. Universal-fit panels often come paired with adaptable mounting systems, weatherproof seals, and plug-and-play electrical harnesses, reducing installation time and the risk of misalignment. Yet, this is not a one-size-fits-all story. The emphasis on OEM-standard fitment remains strong for riders who crave exacting tolerances and warranty-backed reliability. In such cases, even well-made aftermarket options are designed to align with specific frame geometries and fairing attachment points, minimizing the need for drilling or extensive rewiring. The result is a spectrum of choices that can be navigated by riders with varying budgets, technical comfort, and aesthetic goals.

With the market expanding and consumer expectations rising, the upgrade path for lower fairings increasingly embraces a holistic view of the riding experience. Accessories like adjustable windshields, integrated LED indicators, and even crash-bar integrations are frequently paired with lower fairings to create a more complete, protective, and visually coherent package. The trend signals a broader move toward “upgrade ecosystems” where a rider can source a compatible set of components that complement each other in function and style, rather than piecemeal add-ons that solve a single issue but complicate installation or maintenance. This broader ecosystem approach elevates the lower fairing from a simple bodywork piece to a central platform for rider comfort, safety, and enjoyment.

In this landscape, the aftermarket sector continues to grow as a robust alternative to OEM-only pathways. Buyers are increasingly comfortable with in-depth evaluation of fitment accuracy, material quality, and long-term performance. The price-to-performance ratio has become a more important decision factor, especially for riders who want meaningful upgrades without paying a premium for factory-backed options. The availability of bulk-order and wholesale options further accelerates market penetration, enabling riding clubs, fleets, and individual enthusiasts to outfit multiple bikes with consistent styling and performance. The result is a flourishing marketplace where a single lower fairing can be specified to accommodate built-in speakers, climate-control channels, or even active aerodynamics, depending on the rider’s needs and ambitions. In this environment, designers and engineers must balance elegance with practicality, ensuring each new variant maintains a coherent silhouette and predictable serviceability.

The conversation about lower fairings would be incomplete without acknowledging the practicalities of installation, compatibility, and future maintenance. While OEM parts guarantee a precise fit and a straightforward warranty path, they often come with longer lead times and higher costs. Aftermarket options deliver compelling value, as long as buyers verify the model year compatibility and the presence of compatible mounting points. Prospective buyers should assess not only the panel’s external appearance but also internal mounting geometry, harness routing, and the potential for interference with other accessories such as exhaust heat shields, crash bars, or frame sliders. For riders expanding into audio, the wiring diagram becomes a critical document, and the possibility of needing a dedicated power source or fuse control should be anticipated. The market responds to these needs with kits and documentation that aim to simplify the process, but due diligence remains essential to avoid misfitment or the inconvenience of post-purchase modifications.

Designers are increasingly mindful of the rider’s evolving preferences for personalization. The lower fairing is a canvas for a rider’s style, enabling choices in color, texture, and geometry that harmonize with the bike’s overall language. This trend dovetails with broader personalization in the motorcycle community, where riders want their machines to reflect not only performance specs but also personality and heritage. The rise of customized paint finishes, matte versus gloss textures, and precise line work on lower fairings speaks to a broader consumer demand: that performance hardware and aesthetic statements belong in concert, not in competition. In many cases, this has encouraged manufacturers to offer modular styling elements—interchangeable panels, trim pieces, and accent inserts—that allow riders to swap looks without reconstructing the entire fairing system.

For readers seeking practical examples of how these trends manifest in real-world choices, consider how a rider might approach the decision to upgrade a touring bike’s lower fairing. The choices begin with primary goals: reduce wind fatigue and improve cooling on long highway sections, or enhance audio immersion and navigation readability during weekend rides. The next step considers materials and weight: is a light, stiff panel with a carbon fiber accent the right choice, or does a budget-friendly ABS option deliver the needed protection with decades of proven performance? Then comes the integration plan: will one install a vented lower fairing with an integrated speaker pod, or will they opt for a simpler, shield-focused panel plus an aftermarket audio enclosure mounted in a dedicated pod? Each path has trade-offs in weight, heat management, wiring complexity, and warranty implications, but all share a common thread—lower fairings have become a strategic platform for shaping a motorcycling experience, not merely a cosmetic or defensive piece.

Riders who want to explore options across brands can start by examining cataloged fairings that emphasize compatibility and modularity. The landscape is increasingly diverse, with suppliers offering in-stock lower fairings designed for quick replacement and easy upgrades. This accessibility supports both new riders seeking a refreshed look and seasoned enthusiasts pursuing more complex configurations, such as integrated lighting or weather-sealed audio channels within the lower shell. The presence of universal-fit options does not erode the value of model-specific, OEM-standard designs; rather, it expands the possibilities for each rider to tailor fitment, finish, and function to their particular bike and climate.

For those who want a direct pointer into a broad catalog while still appreciating model-specific nuance, a curated example can be found in the Honda fairings category, which demonstrates how aftermarket and OEM styling cues converge to offer a cohesive, model-conscious selection. See more here: Honda fairings on Ultimate MotorX.

As the market expands, there is no single path to success or satisfaction. The most enduring value comes from a thoughtful blend of aerodynamic design, structural reliability, and user-focused features like audio integration and intuitive mounting. The evolving lower fairing ecosystem invites riders to reimagine what a single piece of bodywork can do. It is a living interface between the rider, the machine, and the road—the kind of interface that makes a long ride feel shorter, a windy day feel manageable, and a highway lull feel almost like a private concert hall. This is the essence of the current market: a momentum that promises more comfort, more control, and more expression, all harmonized within the same piece of engineering that first caught the wind.

Externally, the market’s health and trajectory are reinforced by a broader appreciation for how accessory ecosystems support safer and more enjoyable riding. When lower fairings incorporate features like integrated wind deflection, venting for engine cooling, and discreet, weather-ready speaker enclosures, they contribute to rider wellness by reducing fatigue and by delivering essential information, navigation prompts, and entertainment at appropriate volumes and distances. The synergy between comfort, safety, and performance is the backbone of the current market, and it explains why more riders are comfortable venturing into upgrades that are both technically sophisticated and visually coherent with the bike’s lines. In this sense, the lower fairing becomes a modular stage for the modern riding experience—one that is capable of evolving with technology, changing tastes, and shifting climate realities.

For readers who want to keep a finger on the pulse of OEM and aftermarket dynamics, it is worth noting that the market’s growth is not a monolith. Different regions pursue different emphases, with some markets prioritizing durability and modularity for fleet or rental bikes, while others push for premium, bespoke builds that blur the line between accessory and integrated design. Across the board, however, the trend toward combined functionality—sound, airflow management, weather protection—remains a unifying thread. As more riders demand scalable and compatible options, manufacturers and suppliers respond with flexible mounting schemes, lighter materials, and better weatherproofing. The result is a continuously improving interplay between the rider’s needs and the engineer’s response, a dance in which the lower fairing remains both the stage and the performer.

External resource for deeper context on OEM accessory ecosystems and industry perspectives can be consulted here: https://www.harley-davidson.com/en_us/accessories/parts.html

Final thoughts

Lower fairings serve as a key component in enhancing the performance and aesthetic appeal of motorcycles. By understanding their design and functionality, motorcycle business owners can better cater to the needs of riders seeking both comfort and style. The potential for customization through aftermarket options further expands the market reach, allowing for innovative designs that align with emerging trends in the industry. As the demand for unique motorcycle experiences grows, so too will the importance of integrating quality lower fairing solutions in both new and existing bikes. Thus, investing in advancements in lower fairing technology and design will not only satisfy customer desires but also position businesses at the forefront of a dynamic market.