Japanese motorcycle fairings represent a critical aspect of modern motorcycling culture, playing a vital role in performance, safety, and aesthetics. These components are engineered with precision, utilizing advanced materials and methods that ensure they enhance aerodynamics while providing robust protection for riders. With contributions from leading manufacturers like Kawasaki, Yamaha, and Honda, the technology and design behind these fairings reflect Japan’s dedication to motorcycle innovation. This article will take a deep dive into several key areas: the materials and construction techniques used, the performance enhancements offered, the safety standards that govern them, the aesthetic innovations that make them visually appealing, and the aftermarket customizations available to enthusiasts. Each chapter will build upon the last, providing a comprehensive understanding of the significance of motorcycle fairings in the Japanese market.

Aerodynamic Armor: Materials, Craft, and Craftsmanship in Japanese Motorcycle Fairings

Fairings are often read as the outward face of a motorcycle, but in the realm of high-performance riding they function as an integrated system that blends physics, material science, and manufacturing discipline. In the context of Japanese engineering culture, these shells are not decorative armor but a carefully engineered constraint on air, heat, and vibration. They shield the rider, guide the flow of air around the machine, and contribute to the bike’s precise handling by preserving a stable center of pressure and a consistent silhouette at speed. That precision is evident in the way fairings hold their shape under the duress of wind gusts, how they resist warping during rapid accelerations, and how the finish remains resilient against UV exposure and weathering over many seasons. The result is a seamless synthesis of form and function, where every line and joint encodes a performance decision and every junction is a small triumph of manufacturing control. In this light, fairings emerge as a microcosm of the broader discipline that defines modern Japanese motorcycle manufacturing: meticulous design, rigorous testing, and a relentless pursuit of reliability under demanding conditions.

The material choices behind these shells reveal a calculated balance between rigidity, weight, and durability. Fiberglass composites, polycarbonate, and ABS plastic each occupy distinct roles in the fairing ecosystem. Fiberglass composites, created by embedding glass fibers in a resin matrix, deliver superior stiffness and excellent aerodynamic shaping capabilities. They can be hand-laid into complex, sculptural forms with tight tolerances, allowing for aggressive lines and tight radii that are difficult to achieve with other materials. Gel coats or protective paints finish fiberglass parts, guarding against moisture ingress and imparting a resilient surface that can be polished to reduce drag and maintain a smooth boundary layer. This approach is favored for track-oriented builds and high-performance variants where every gram of weight and every millimeter of curvature matters. Polycarbonate, a high-strength thermoplastic, mirrors fiberglass in its impact resistance while introducing advantages in weight and optical clarity when used for light panels or elements requiring visibility through the shell. It handles sharp impacts more gracefully than many other plastics, yet it can be susceptible to scratching and may not hold ultra-compact forms as easily as laminated composites. ABS plastic represents the workhorse of mass production. Its molding behavior, impact resistance, and cost efficiency make it a practical choice for standard or commuter models where the aim is consistent supply and broad compatibility. The compromise with ABS is typically in stiffness and long-term deformation under extreme performance loads, but when engineered with proper ribbing, laminate layups, and optimized wall thickness, ABS parts can still meet demanding safety and durability expectations for everyday riding.

The manufacturing techniques that transform these materials into finished fairings are as telling as the materials themselves. Hand laying remains a critical method for high-performance shells. This process is not merely artisanal; it is a strategic choice that allows engineers to tailor fiber orientations and resin systems to the exact load paths seen in real-world riding. Hand-laid fairings can achieve superior structural integrity, with improved impact resistance and more predictable thermal expansion characteristics. The layering sequence, veil placement, and resin cure profiles are adjusted to match each model’s dynamic needs, providing stiffness where the rider notices it most—around the steering head and along the lower knee. Conversely, injection molding dominates in large-scale production. It delivers repeatable geometry, tight tolerances, and consistent surface finishes at a lower unit cost, making it essential for stock replacements and lower-cost variants. The trade-off is a degree of uniformity that may require additional post-molding work to achieve the same level of aero-smoothness seen in hand-laid parts.

Surface treatment completes the transformation from raw material to functional shell. A robust surface finish protects against micro-cracking, UV degradation, and environmental exposure while enabling a gloss that reduces friction with the air. Gel coats, clear coats, and paint systems are tuned for weather resistance, color fastness, and environmental durability. The bonding between panels—whether joined with mechanical fasteners, adhesives, or a combination—must withstand vibration, temperature cycling, and the repeated stresses of high-speed riding. The overall architecture must also accommodate the bike’s cooling and electrical systems, ensuring that vents, ducts, and internal channels stay aligned as heat builds and winds intensify. In this light, fairings become an engineering canvas where material science and surface engineering converge to sustain performance across a long service life.

Beyond materials and methods, the design philosophy behind fairings centers on how air behaves around a moving body. Aero shaping in a racing-influenced environment demands attention to a long list of interacting phenomena: boundary layer management, flow separation at high angles of attack, and the subtle shaping of lines to minimize form drag while preserving downforce where needed for stability. Integrated air intakes and venting systems illustrate this balance. They extract heat from radiators and engine compartments without creating unnecessary drag or buffeting. The shape must also accommodate the rider’s body position, which shifts the center of pressure as posture changes through cornering and braking. In practice, that means a fairing is designed to maintain clean, attached flow over a wide envelope of yaw angles and forward speeds, a nontrivial ambition that requires sophisticated computational insight and iterative wind tunnel or wind tunnel-like testing in development programs.

Quality assurance in this context is not a single test but a suite of evaluations that simulate the bike’s life in the field. Impact resistance tests anticipate impacts from road debris or a mishap in a corner, while UV exposure trials confirm that color and gloss endure long sessions in bright sunlight. Thermal stability checks ensure that materials do not creep or warp under heat generated by the engine and the sun. These assessments are more than verification exercises; they feed into design refinements, tightening tolerances, and guiding choosing among materials for specific model lines. The result is a family of shells that look cohesive when viewed in a showroom and behave predictably when the bike is at speed, racing down a straight, or darting through a windy mountain pass. The aesthetic is intentional, yet always subordinate to the physics of airflow, load paths, and thermal management. The fidelity of this balance is what marks a true performance fairing and signals the heritage of a manufacturing ecosystem that prizes repeatability, precision, and reliability.

In this ecosystem, the story is not only about what is inside the shell but also about how the shell relates to the rest of the machine. The inner structure often features ribbing and insert technologies that buttress joints and control vibration transmission to the outer surface. The interface between the fairing and the frame, the subframe, and the engine is crucial; misalignment here can produce rattles, unwanted noise, or degraded aerodynamics. The best examples demonstrate a calm, integrated silhouette where the transitions between panels are seamless, the fasteners are concealed or deliberately visible for serviceability, and the overall geometry supports quick and repeatable maintenance along the bike’s lifecycle. This level of integration is a testament to the engineering ethos that guides Japanese manufacturing: a fairing must be more than a cover; it must be a functional part of the bike’s structural and thermal system, working in concert with the chassis to deliver performance with durability.

Within the broader ecosystem of brand-specific parts, the Kawasaki fairings category offers a clear window into how OEMs translate engineering notes into detailed, shapely shells that withstand race-grade demands while still serving daily riders. The link between design intent and production capability is visible in the attention given to joint lines, surface refinements, and the way fairings communicate with the bike’s electronics and cooling architecture. This approach mirrors the philosophy found across Japanese brands, where precision is applied at every stage—from initial sculpting to the final fit on a production line. The continuity across models, and even across generations, reveals a discipline not just in style but in the physics of airflow, stress, and temperature management. For readers who want a deeper technical grounding, official resources and guides highlight the material properties and performance criteria that shape fairing design. A comprehensive overview can be found in industry technical literature that outlines how glass fibers, resins, and polymer blends respond to load, impact, and environmental exposure, a framework that helps explain why a seemingly simple shell can be a crucial performance factor. For a deeper dive into official guidelines, see Suzuki’s fairing guide. (https://www.suzukimotorcycles.com/technical-resources/fairing-guide)

How Japanese Fairings Boost Speed, Stability, and Rider Endurance

Japanese motorcycle fairings are more than cosmetic shells. They are precision-engineered components that shape how a bike moves through air, manages heat, and protects its rider. In performance-oriented machines, fairings perform a carefully balanced set of functions: they reduce drag, tame turbulence, lower weight, channel cooling air, and create predictable handling at speed. The result is measurable gains in acceleration, top speed, cornering stability, and long-distance comfort.

At the heart of their performance contribution is aerodynamic refinement. Japanese designers use wind-tunnel testing, computational fluid dynamics, and iterative prototyping to sculpt bodywork that guides airflow cleanly around the motorcycle profile. A well-shaped fairing reduces the frontal area exposed to airflow and smooths pressure gradients across the bike. This lowers aerodynamic drag and cuts the energy needed to maintain a given speed. Lower drag translates to higher top speed with the same power output. It also improves fuel efficiency, because the engine expends less effort against air resistance on sustained runs.

Beyond a raw drag coefficient, fairings manage the quality of airflow. Sharp edges, ill-placed seams, and awkward panels create turbulence. That turbulence becomes buffeting at the rider’s chest and head, and it shakes the bike at precise frequencies. Japanese fairings often incorporate subtle features such as curved lips, vortex-generating contours, and tapered tails to control the wake. These elements reduce buffeting and stabilize the pressure field behind the windshield. The result is steadier handling during lane changes or gusty crosswinds, and reduced rider fatigue on long rides.

Weight is another critical factor in performance. Using high-strength, low-weight materials allows fairings to protect and shape the motorcycle without needlessly increasing mass. Japanese engineering balances toughness and lightness. Thermoplastics with high impact resistance perform well in street use. For more demanding applications, composite layups—fiber-reinforced plastics with careful resin selection—offer superior stiffness-to-weight ratios. Lower mass improves acceleration and braking response. It also helps the bike change direction more readily, enhancing agility in corners and reducing the effort required from the suspension to control motion.

Fairings take on a structural and thermal role as well. Many modern designs integrate ducts and channels that direct cooling air toward the radiator, oil cooler, and engine casings. By controlling where air goes, fairings preserve engine temperatures under heavy load. This supports consistent power delivery and prevents heat-related performance degradation. Targeted venting also pulls hot air away from the rider, improving comfort and concentration. On track-focused shapes, internal shrouds and duct geometries are tuned to feed cooling air at specific speeds, balancing aerodynamic efficiency and thermal management.

Lighting and visibility integration are practical performance considerations often overlooked. Streamlined housings formed into the fairing lower parasitic drag compared to bulky separate lamp units. Integrated lighting also supports better optics alignment, which improves the rider’s ability to see and to be seen. When headlamps, turn indicators, and daytime running lights are designed into the bodywork, they contribute to both aerodynamic cleanliness and active safety.

The layout and coverage of fairings influence rider posture and ergonomics. Full fairings offer extensive wind protection that keeps high-pressure zones off the torso and shoulders. This reduces wind force on the rider and creates a more aero-efficient combined profile. Reduced fatigue follows, and that lowers reaction delays and improves concentration on long rides or during multi-lap sessions. Conversely, minimal fairings leave the rider exposed, increasing energy expenditure against wind and limiting sustained high-speed performance.

Predictable handling is essential in performance contexts. Fairings change the distribution of aerodynamic loads across the motorcycle. At speed, lift or downforce can shift the effective weight on the front or rear wheel, affecting steering feel and traction. Japanese fairing designs aim to keep these loads stable through a wide speed range. Tucked aerodynamic elements, small spoilers, or integrated chin pieces help maintain front-end grip without inducing abrupt changes when speed varies. The result is a motorcycle that remains neutral and planted when accelerating, braking, or transitioning through corners.

Maintenance and serviceability also affect real-world performance. Well-engineered fairings provide access points and modular panels that simplify routine checks and repairs. Faster service times ensure the bike spends less time in the shop and more time tuned and available for performance riding. Durable finishes resist stone chips and UV damage, keeping aerodynamic profiles true over many seasons. A panel that holds its shape keeps airflows predictable. Deformed or cracked fairings can introduce unexpected turbulence and compromise stability.

For riders seeking the greatest gains, full fairing packages calibrated to the chassis and suspension offer the highest return. When designers consider the complete vehicle system, the shapes of the fairing, the rake and trail, and the suspension settings can be harmonized. This systems approach produces cohesive behavior under load. Small aerodynamic tweaks tuned to the frame geometry can unlock smoother high-speed steering and more consistent lap times.

Aftermarket options exist for enthusiasts who demand race-focused setups or track-only modifications. These options often push materials and forms further toward reduced weight and higher stiffness. However, any modification must respect regulatory and safety requirements. Track-focused pieces may require different mounting points or reinforcement, and they sometimes change cooling efficiency. Riders and teams must ensure that any altered airflow or shifted weight does not unintentionally destabilize the chassis or compromise component cooling.

Finally, fairings are part of the motorcycle’s communication with the rider. Well-executed design delivers cues about aerodynamic balance and expected behavior. A streamlined nose and a tapered tail communicate high-speed intent. A broad belly pan and ducted cheeks imply serious cooling and longer sustained output. These cues shape rider confidence. Confidence impacts how aggressively a motorcycle is ridden, which ultimately affects lap times and real-world performance.

For riders who own bikes within specific families, dedicated fairing packages are available that match the model’s geometry and intended use. For example, tailored fairings for sport models help preserve factory handling and ensure proper fit. To explore a selection of dedicated fairing options for a popular sport series, see this collection of Kawasaki Ninja fairings.

For further reading on materials, testing procedures, and aftermarket considerations, an in-depth guide covers impact resistance, UV testing, and thermal stability for modern fairings: https://www.carinterior.com/aftermarket-motorcycle-fairings-guide-2024

Guardians of the Glide: How Safety Standards Shape Japanese Motorcycle Fairings

Fairings are often the first thing a rider notices on a sport bike. Beyond the racing-inspired lines and glossy finishes, these shells function as the bike’s shield against wind, weather, and rough pavement. Yet in a country whose engineers push mechanical limits with every model, fairings operate under a strict set of performance and safety expectations that ensure fast riding does not come at the expense of rider security. In Japanese practice, safety standards are woven into the fairing’s material choices, its attachment system, and even the mere clearance around headlights and indicators. The result is a product that wears its safety as visibly as its style, a quality that helps explain why Japanese fairings are often cited as benchmarks in a global market.

The framework governing these components is anchored in domestic vehicle safety regulations that the nation’s Ministry of Land, Infrastructure, Transport, and Tourism administers. There is currently no universal international regulatory regime that covers every aspect of a fairing; instead, Japan relies on a comprehensive national standard that covers the entire lifecycle of the component, from design and material selection to production and post-market use. This approach keeps safety tightly aligned with evolving vehicle performance while still allowing room for design innovation. In practice, manufacturers must demonstrate that their fairings, even after years of exposure to sun, heat, and vibration, retain their shape, their mounting reliability, and their critical functions. This is not merely about surviving a crash, but about preventing a crash in the first place by reducing unpredictable movement of a damaged shell and preserving the rider’s control.

A central pillar of the safety regime is structural integrity. Fairings must stay securely attached at speed, with fasteners and mounting points designed to resist detachment under crash loads or the jostling encountered on a long, high-speed straightaway. Designers consider the entire energy path during an impact, ensuring the shell remains a controlled part of the rider’s protective system rather than becoming a hazard to the rider or to others on the road. The expected behavior of the fairing in a collision is as important as how it looks when the bike is parked in a showroom. In practical terms, this means choosing attachment hardware that can endure repeated postures and temperatures, as well as a shell that sheds energy without fracturing into sharp shards. The test regimes simulate scenarios where a fairing might be kissed by a curb or grazed by another vehicle, and the results feed back into the next generation of mounting strategies and finish engineering.

Material standards play a similarly decisive role. The modern fairing is a balance between resilience and weight. Designers often work with high-impact resistant thermoplastics such as ABS and, in performance-oriented builds, composites like carbon fiber. Each material must pass exacting criteria for strength, impact resistance, and elongation before it can be approved for production use. ABS offers a forgiving balance of toughness and formability, helping fairings hold tight radii and complex curves without cracking under stress. Carbon fiber, while lighter and stiffer, demands careful handling and protective coatings to resist UV degradation and thermal fatigue as the bike dives through wind at speed. The choice of material is a statement of intent: a commitment to performance by design that does not sacrifice rider safety when the road presents its harsher side.

Impact resistance testing is another non-negotiable element in the lifecycle of a fairing. The aim is not to build a shell that never cracks, but to ensure that, when energy is transmitted to the body of the bike in a crash, the fairing behaves predictably. It should absorb some energy, deform in a controlled fashion, and not shatter or detach in a way that could injure the rider or nearby road users. This facet of testing ties directly to the rider’s protection, as a brittle or fractured panel can signal deeper mechanical issues that compromise integrity or aerodynamics. Materials are typically evaluated for resilience to impact from various angles and at a range of temperatures, ensuring performance across diverse riding conditions—from cool mornings to sun-scorched afternoons.

Rider visibility and lighting compliance are equally vital. A fairing must not obscure the rider’s line of sight, and it must preserve the functionality of essential lighting systems. Headlights, taillights, and turn signals must remain clearly visible, and the fairing must not shelter them from airflow in a way that could reduce effectiveness. The integration of venting and intake systems presents a further design challenge: the intake must serve the engine’s cooling needs while not introducing blind spots or sharp edges that could injure the rider in a crash. Achieving this balance requires a disciplined design process that respects both aerodynamics and safety, a hallmark of the meticulous engineering culture that governs this sector in Japan.

Compliance and regulations extend beyond straightforward product tests. Modifications made to fairings for track use or racing—whether for improved aerodynamics, weight reduction, or cooling optimization—must still satisfy the relevant safety standards. The line between performance enhancement and regulatory compliance is carefully policed, because changes that compromise the original geometry or structural features can render a motorcycle non-compliant or unfit for road use. This is not a sterile caution; it reflects a practical recognition that the bike’s safety ecosystem depends on predictable, tested interactions among the shell, the frame, and the rider. In this sense, the safety framework shapes not only what the fairing is, but what the bike is allowed to become under the track lights and in the wind tunnel.

The harmony between form and function is not incidental. Japanese fairings often embody a philosophy that sees aerodynamic efficiency as inseparable from safety. Subtle design features—the curvature of a panel, the contour of a vent, the placement of a mounting bracket—are chosen with an eye to how wind energy translates into stability at high speeds and how small misalignments can affect rider control. Integrated air intakes and venting systems illustrate this philosophy well: they guide cooling air to the engine and brake systems while preserving the shell’s protective role. The aesthetic language is not an afterthought but a byproduct of this careful engineering, where beauty is realized through geometry that respects safety, weight, and rigidity. As new iterations roll out within the 2023new category, safety remains inseparable from style, and the dialogue between designers and regulators continues to define what a modern fairing can be.

For riders and builders, the practical implications are immediate. Proper installation of a fairing is not a cosmetic concern; it is a safety-critical procedure. The fit must be precise, with gaskets and fasteners arranged to prevent loosening or flutter at speed. Routine checks of the mounting hardware, along with attention to wiring and the sealing around openings, help prevent problems that could escalate into safety risks. The quality of the finish matter—warpage, delamination, or UV-induced discoloration can signal deeper mechanical issues that compromise integrity or aerodynamics. A fairing that maintains its aerodynamic contour over thousands of miles helps preserve stability, reduce drag, and ensure predictable behavior during cornering, braking, or any sudden gust of wind that might otherwise push a bike off its intended path.

From a broader perspective, the safety standards embedded in Japanese fairings reflect a mature manufacturing system that values rigorous testing, disciplined materials science, and a deep respect for rider protection. They reveal how a single component can anchor multiple design goals: keeping the rider shielded from the wind and elements, guiding air to the engine with minimal drag, and maintaining structural coherence through a dynamic, high-energy life on the road. In this sense, the fairing becomes a living interface between human riders and the machine, a boundary that enforces safety without sacrificing speed. The result is a family of shells that endure the test of time and the temptations of wind, showcasing how a country renowned for precision engineering translates theoretical safety standards into tangible riding confidence.

For readers seeking a direct path to related parts and community resources in this space, the ongoing cataloging of fairings across various categories illustrates how safety considerations are embedded into product ecosystems. The 2023 new category, in particular, highlights how changes in geometry and materials respond to evolving standards while still inviting riders to customize their machines within safe limits. This linkage offers a practical glimpse into how policy and design meet the road, demonstrating that safety is not an obstacle to expression but a framework that enables it. See the 2023new category for more context on how new designs approach fairing safety in tandem with performance demands. 2023new

For those who want to explore the regulatory backbone in more depth, official guidelines and safety standards can be found through the national transportation authority’s resources. In particular, MLIT’s vehicle safety regulations outline the expectations for structural integrity, materials, impact absorption, and lighting compliance that shape every stage of fairing development. These standards ensure that as bodies of plastic and reinforced resin grow more capable of withstanding energy and protecting riders, they also stay aligned with the broader safety ecosystem that governs all road-going vehicles. Access to these guidelines reinforces the idea that safety is an active practice—built into the design process, verified through testing, and sustained through continual oversight. For a direct overview, refer to the MLIT official source. MLIT Official Website

Sculpted Speed: How Japanese Fairings Redefined Motorcycle Aesthetics and Performance

Sculpted Speed: The New Visual Language of Japanese Motorcycle Fairings

Japanese motorcycle fairings have evolved into more than protective shells; they now define a machine’s personality while serving precise aerodynamic functions. Over decades, designers and engineers in Japan blended form and function so tightly that a bike’s silhouette often announces its intent before the engine is heard. The driving aesthetic is clear: reduce drag, manage airflow, and communicate performance through surfaces, lines, and finishes that feel engineered rather than ornamental.

At the center of this transformation is a move from static, one-piece clamshells toward layered, directional surfaces that interact with airflow. Designers sculpt concave and convex planes to guide air across the bike and around the rider. Where once a fairing simply enclosed components, modern shapes incorporate splitters, venting channels, and subtle wing-like protrusions that adjust pressure and direct cooling air. These elements are conceived not as add-ons but as integral parts of the visual composition. The fairing’s curves, cutouts, and seams tell a consistent aerodynamic story: the bike slices, the rider tucks, and turbulence is controlled.

Active aerodynamic features have become a hallmark of this era without dominating the visual language. Mechanisms that deploy or adjust surface geometry do so with restraint. Movable blades and small actuated surfaces remain compact and articulate, contributing to a high-tech aesthetic while preserving a coherent profile. The visual cue of motion is suggested even at rest, with panels and vents arranged to imply forward thrust. This approach creates a perception of capability that matches on-road behavior. Riders perceive increased stability and agility; designers achieve the same by shaping the fairing to manage lift and crosswinds.

Materials play a decisive role in the modern look and feel. The transition from heavy fiberglass to engineered plastics and composites changed what designers could do. Acrylonitrile butadiene styrene (ABS) remains popular for its balance of impact resistance and formability, but composites like carbon fiber and thermoplastic polymers offer slimmer cross-sections and sharper, more complex geometries. These materials allow for thinner leading edges, tighter radii, and integrated structural reinforcements without excessive weight penalties. The surface finish also evolved: multi-layer paints, pearlescent coatings, and nano-scale clearcoats produce depths and reflections once possible only on exotic cars. Light behavior across a fairing—specular highlights, soft gradations, and abrupt contrasts—becomes part of the design vocabulary.

Color and texture are applied strategically to emphasize form. Designers use contrasting finishes—matte versus gloss, opaque versus translucent inserts—to articulate vents, ram air scoops, and split lines. Subtle micro-textures on lower panels reduce glare from road debris and add a tactile quality to close-up viewing. In some cases, layered pigments create a chameleon effect, shifting hue depending on the viewing angle and light intensity. This color-shifting treatment makes the bike read as more dynamic in motion and more intricate when parked, enhancing perceived craftsmanship.

Lighting integration has shifted from mere visibility to an aesthetic system that complements fairing geometry. Headlight clusters and daytime running lights are embedded as sculptural elements, following the fairing’s contours rather than sitting as separate modules. Thin LED arrays allow designers to carve narrow light signatures that act as both identity markers and aerodynamic passages. When positioned within choke points or splitters, lighting can highlight airflow paths or the alignment of vents, reinforcing the sense that every cosmetic choice serves a technical purpose.

Under this visual evolution, the interplay between ergonomics and aesthetics has tightened. Fairings no longer force riders into uncomfortable positions for the sake of a sleek profile; instead, designers optimize rider posture and legroom while shaping fairing lines that still reduce frontal area. Seat cowl transitions, tank knee indents, and shoulder cutaways are integrated so the human form reads as part of the machine. The result is a cohesive silhouette where rider and bike appear as a single aerodynamic unit.

The influence of precision manufacturing cannot be overstated. Tighter tolerances in molding and assembly yield cleaner gaps and more deliberate seam lines. Panel joins become visual accents rather than functional necessities. Fasteners are hidden or expressed as design features, and mounting points are engineered to preserve surface continuity under load. This technical cleanliness enhances the premium perception of a motorcycle and contributes to longevity; well-fitted fairings resist vibration and retain finish longer under harsh conditions.

Aftermarket and limited-run variations have also pushed aesthetic boundaries. Custom paint, laser-cut vents, and carbon-fiber overlays allow owners to personalize machines while maintaining aerodynamic integrity. The aftermarket ecosystem in Japan supports high-quality replacements and stylistic upgrades that mimic factory precision. This culture of refinement encourages iterative improvements: successful custom ideas often inspire manufacturer updates in subsequent models, creating a feedback loop between riders, tuners, and original designers.

Sustainability and finish durability are increasingly part of the aesthetic conversation. UV-resistant coatings, scratch-masking clear layers, and impact-absorbing undercoats extend the life and appearance of fairings. These treatments maintain color integrity and gloss, ensuring that a bike’s presence does not diminish after repeated exposure to sunlight, rain, or stone chips. From a design standpoint, longevity becomes an aesthetic value: surfaces are meant to age gracefully while retaining the original visual intent.

Regulatory and functional constraints have shaped aesthetic choices without diluting creativity. Vent sizes, reflector placement, and lighting brightness are negotiated early in the design process to preserve clean lines. Track-oriented variants and homologated parts undergo specific tuning to balance appearance with compliance. The result is a pragmatic elegance: fairings look purposeful because they must satisfy both regulatory requirements and high-speed performance demands.

One practical implication of these innovations is the way riders experience motorcycles visually and kinesthetically. A well-designed fairing reduces rider fatigue by managing wind and buffeting. It also communicates confidence: a bike that appears stable and planted influences rider behavior and perceived safety. Design cues like wide front shoulders, low nose profiles, and integrated splitters not only perform but also set expectations for handling characteristics.

The contemporary aesthetic of Japanese motorcycle fairings reflects a broader design philosophy: every visual decision serves an operational role. Surfaces are not ornamented for their own sake; they are sculpted to channel air, to cool vital systems, to shelter the rider, and to express speed. This discipline produces machines that feel coherent—machines whose looks and behavior align.

For riders and enthusiasts interested in exploring current aftermarket and fresh releases that embody these design trends, see the collection of recent fairing designs in the 2023 lineup: 2023 new fairings collection.

For a deeper technical analysis and broader industry perspective, the detailed research resource linked below provides further reading on recent innovations and the engineering behind them:

External resource: https://www.motorcycle-technology.com/japanese-motorcycle-fairing-innovations-2024

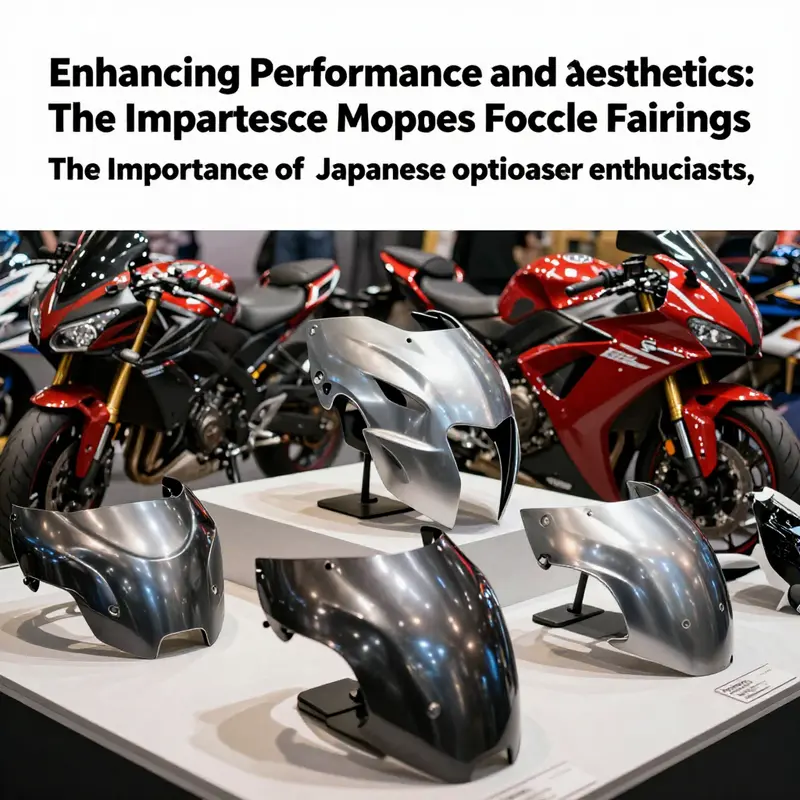

Winged Identity: The Subtle Craft of Aftermarket Fairings on Japanese Motorcycles

The arc of air across a sport bike is more than physics; it is a statement. In the world of Japanese motorcycles, aftermarket fairings are where engineering meets personal narrative. They are not just shells to cover a frame; they are expressive tools that sculpt how a rider feels the wind, how a bike breathes at speed, and how the machine sits visually in a crowd. The choice to swap or augment factory bodywork is rarely about mere aesthetics. It is a careful negotiation between form, function, and the rider’s evolving relationship with cornering friction, drag, and visibility. In this landscape, the fairing becomes a canvas where precision manufacturing, aerodynamics, and individual taste converge, revealing how Japanese makers and their communities push the envelope of what a bike can be when pared down to its most essential, wind-influenced elements.

At the core of aftermarket fairings is a triad of purpose. First is protection: fairings shield the rider from direct wind pressure, weather, and debris at speed, turning a long ride into a more controlled experience. Second is aerodynamics: shaping the bodywork to guide flow along the bike’s surface reduces drag and can deepen stability at high velocity. Third is identity. The lines, textures, and color narratives of a rider’s fairing speak about involvement, seriousness, and pride in craft. This triad is especially potent in Japan, where a culture of meticulous engineering blends with a vibrant aftermarket scene. Enthusiasts assess not only whether a piece looks right but whether it preserves, or even enhances, the bike’s handling envelope. The result is a continuous dialogue between the machine’s factory geometry and the rider’s bespoke adjustments, a dialogue that mirrors the careful tuning seen in track-ready setups and showroom replicas alike.

Materials matter as much as shapes. The most serious aftermarket options lean toward high-strength, light-weight composites. Carbon fiber, with its characteristic weave and stiffness, is a common sight on performance-oriented builds, delivering visual drama along with measurable gains in rigidity and weight reduction. Yet carbon’s appeal is balanced by cost, repairability, and the realities of street use. Many riders blend carbon with high-grade ABS or polycarbonate sections to strike a balance between resilience, cost, and color stability under sun exposure. The emphasis on UV resistance and thermal stability speaks to a longer game: the fairing must resist chalking, fading, and warping after season after season of use. These considerations echo testing regimes in Japan, where weather, road salt, and heat cycles are realities that demand durable finishes and predictable aging.

The shapes themselves tell a nuanced story. Full fairings remain the classic choice for riders seeking maximal aerodynamic continuity and a cohesive silhouette that hides mechanical clutter. Half-fairings and three-quarter configurations offer a different philosophy: less weight, more open air for the rider’s legs and the bike’s internals, and a modular approach to airflow management. Integrated air intakes and venting systems are not decorative add-ons; they are functional elements designed to balance cooling needs with the goal of reducing aerodynamic lift at speed. The design logic often ties directly into the bike’s original lines, meaning a well-made aftermarket piece can look like it belongs, while a hurriedly thrown-on panel may disrupt both airflow and symmetry. The best designs read the bike’s geometry and extend it, rather than clash with it, so the rider experiences a seamless transition from stock feel to modified poise.

With form comes meticulous attention to fitment. Compatibility matters more than brand-name bragging in the context of performance riding. A fairing must align with mounting points, frame geometry, and the bike’s electrical architecture. It must accommodate headlights, indicators, and any sensors without creating grounding conflicts or harness routing headaches. This is why professional fitment guides, precise instruction sheets, and sometimes specialized hardware become essential parts of the aftermarket ecosystem. The process of installation can be a careful blend of measured precision and patient trial. Riders invest time in preparing the mounting surfaces, rechecking alignment after initial mock-ups, and sealing joints so that water intrusion or rattling does not undercut the ride’s quality. The result is a bodywork package that behaves as much as it looks, a difference that becomes especially meaningful on a long road or a high-speed track.

Aesthetics in this space are rarely superficial. Graphic design, color matching, and the strategic use of textures transform a panel into a window onto a rider’s identity. Graphic design on fairings—whether bold color blocks, subdued racing motifs, or bespoke artwork—demands careful coordination with the bike’s existing lines. The layup and painting process must consider curvature, edge sharpness, and adhesion on curved surfaces. Clear coats must resist yellowing and cracking, while decals should age evenly with the surrounding panel. When executed with care, the result is a cohesive visual language that makes the rider feel at home in the bike’s presence, whether the machine is parked curbside or slicing through a tunnel at half a second per lap.

In Japan, this culture of customization sits atop a framework of safety, legality, and track-ready discipline. Aftermarket options are often vetted for safety and regulatory compliance, particularly when modifications extend to windshields, lighting, and venting that could affect visibility or signaling. Riders who push their machines onto the track frequently adopt stricter standards, ensuring that any modification does not invalidate safety equipment or crash protection features. This disciplined approach helps explain why a well-chosen aftermarket fairing can improve confidence at speed, reducing rider fatigue through better wind management and a more stable seating position. The trade-off is a continual balancing act between performance gains and the potential for added weight, complexity, or maintenance burden. In this light, a careful, well-documented upgrade can feel as principled as it is thrilling.

For those who want to explore broader options without sacrificing compatibility, catalogs and community guides can be invaluable. A rider might browse a dedicated catalog for a specific Japanese-brand fairing line, assess fitment guides tailored to their model year, and weigh the benefits of carbon texture against painted finish and durability. When venturing beyond stock, it is common to check fitment guides that specify mounting points, wiring harness routes, and boundary conditions for the fairing’s movement during operation. As a practical matter, some riders seek a balance between the speed-oriented benefits of a lighter choice and the durability required for daily riding. The best setups keep the rider comfortable, shielded from wind, and visually aligned with the bike’s established identity while offering a personal signature that remains unmistakably theirs.

The social and technical ecosystem surrounding aftermarket fairings is as important as the parts themselves. Workshops, forums, and retailers contribute to a shared knowledge base about what works on Japanese motorcycles. Enthusiasts exchange tips about preserving finish quality, maintaining tight seals against weather ingress, and selecting hardware that won’t loosen after a few aggressive corner entries. In this environment, even small decisions—like whether to overpaint a join line, or to use a micro-seal around the edge of a fairing panel—can influence long-term durability and ride feel. The result is a community that treats wind as a collaborator rather than an adversary, shaping hundreds of subtle choices into a practical, rideable philosophy of customization. For riders who want to see options in a concrete, browsable form, the Yamaha fairings catalog offers a window into what the broader ecosystem has to offer in terms of fit, finish, and compatibility. Yamaha fairings catalog.

The economics of customization also matter. A fairing swap is a composite decision: the rider weighs material cost, labor time, and potential resale value against the hoped-for improvements in aerodynamics and aesthetics. A well-chosen upgrade can preserve resale value by keeping the bike visually coherent and functionally reliable, whereas a poorly matched component can degrade performance and lead to higher maintenance costs. This reality helps explain why many riders prefer the balance of aftermarket pieces that are designed with a particular model in mind, rather than universal panels that may require significant trimming or adaptation. As with any add-on of consequence, the best outcomes arise when the rider engages in an iterative process—test fit, assess, refine, and ride again—treating the bodywork as a living part of the motorcycle rather than a fixed accessory. In this light, aftermarket fairings become a form of ongoing engineering dialogue between rider, machine, and road.

The broader implication is clear. Japanese motorcycles have always tethered performance to precision, design to durability, and speed to story. Aftermarket fairings carry that heritage forward, translating a factory’s disciplined geometry into personal expression without surrendering the ride’s stability or safety. They invite riders to refine their relationship with wind, to rethink how a machine breathes at speed, and to reimagine how a motorcycle presents itself on the street and the track. The result is not merely a new look. It is a renewed conversation about what speed feels like, how visibility affects confidence, and how a rider’s taste can be mechanically embodied in the sculpture of wind. For those who practice this craft, the fairing is both shield and signature—an engineered shell that lets the rider speak through the language of air.

As the scene evolves, riders continue to test, tweak, and trade ideas, moving the needle on how aerodynamics, materials, and aesthetics converge. The ongoing dialogue underscores a simple truth: when done with care, aftermarket fairings do more than alter a bike’s appearance. They enhance the rider’s sense of control, reduce fatigue on long or demanding runs, and deepen the bond between machine and operator. In the end, the winged silhouette is less about chasing speed and more about shaping the journey—an intimate, technical, and distinctly Japanese conversation between wind and rider. For those drawn to the blend of craftsmanship and performance, the market remains a fertile ground where imagination and engineering meet, and where every new panel tells a story of speed, resilience, and personal style. To explore practical options and fitment details within a brand context, consult the Yamaha fairings catalog linked above. And for broader parts and sourcing guidance, see external resources that compile practical catalogs and part availability in the motorcycle aftermarket world: https://www.performancebike.com.

Final thoughts

The intricate world of Japanese motorcycle fairings bridges the gap between performance, safety, and artistry. With a foundation built on advanced technology and careful craftsmanship, these fairings are not just protective elements; they are integral components that enhance the overall riding experience. As we explored the various aspects, from the materials and construction techniques to safety standards and aesthetic innovations, it’s clear that these designs reflect the dedication of Japanese manufacturers to excellence. Business owners and enthusiasts alike can appreciate how aftermarket customizations allow for personalization while adhering to standards. Understanding the multifaceted role of motorcycle fairings not only highlights their importance but also emphasizes the continuous evolution of motorcycle technology in Japan.