Injection molded motorcycle fairings play a pivotal role in the design and performance of modern motorcycles, blending durability, precision, and aesthetic appeal. As the motorcycle industry continues to evolve, understanding the innovations in manufacturing processes, the economic impact and supply chain dynamics, technological advances, quality control measures, and market trends related to these components becomes essential for business owners. Each chapter will delve deeper into how injection molded fairings not only enhance motorcycle functionality but also support global commerce and cater to customer preferences in a highly competitive market.

From Molten Resin to Track-Ready Skin: Materials and Manufacturing of Injection Molded Motorcycle Fairings

Injection molded motorcycle fairings begin life as design intent and engineering constraints, and their journey from concept to completed panel is a tightly choreographed blend of materials science, precision tooling, and controlled manufacturing. At the heart of that transformation is injection molding, a process that converts thermoplastic resin into complex, dimensionally stable bodywork that must meet aerodynamic, cosmetic, and durability requirements all at once. This chapter traces the critical decisions and process steps—material selection, mold engineering, machine settings, surface finishing, and quality control—that together determine whether a fairing will be a seamless OEM-style part or a brittle, ill-fitting aftermarket piece.

Material choice drives nearly every subsequent manufacturing decision. High-grade ABS stands out as the workhorse for injection molded fairings because it balances impact resistance, heat tolerance, and paintability. ABS can flex under localized loads without cracking, which matters when a fairing takes an unexpected knock. Modified or reinforced ABS blends are common where stress concentrations are expected—around mounting tabs, fastener bosses, or complex intersections of panels—because those variants reduce the risk of hairline fractures while maintaining surface quality. Polycarbonate blends are used selectively when higher stiffness or clarity is required, but they demand tighter process control and often higher mold temperatures. Designers sometimes consider alternative substrates such as fiberglass or carbon fiber composites for low-volume or performance-focused builds, but those materials do not suit high-volume injection molding due to longer cycle times and much higher tooling costs.

Mold design establishes the geometric and cosmetic potential of the finished fairing. High-precision molds are machined from hardened steel for longevity in large runs, while aluminum tooling may be used in pilot runs or low-volume production to cut lead time and cost. Mold cavities and cores reproduce the motorcycle’s contours and incorporate features such as compound curves, undercuts, and fine surface textures. To produce consistent panels, molds must control wall thickness, incorporate carefully placed cooling channels, and include robust ejection systems. Gate location and runner design influence both the appearance of the part and the internal stress distribution. A well-engineered mold minimizes weld lines and flow marks, prevents sink spots, and allows uniform cooling to keep warpage below acceptable tolerances.

Process parameters—temperature, injection pressure, and cooling rate—are the levers operators pull to make the resin behave predictably within the mold. Temperature control ensures the polymer reaches a homogenous melt; too cool and it won’t fill complex features, too hot and it degrades. Pressure settings determine packing and compensation for shrinkage during cooling; pressure must be high enough to fill thin sections but moderated to avoid flash or excessive stress. Cooling is where cycle time and part quality meet: faster cooling shortens production time but risks uneven solidification and warpage, while slower cooling enhances dimensional stability at the expense of throughput. Modern injection molding lines pair closed-loop sensors with programmable logic controllers to keep these variables within tight bands, and add-ons such as conformal cooling in the mold itself further improve uniformity.

Automation and integrated production scale enable cost-effective, consistent output. Robotic part removal, in-line trimming stations, and automated inspection reduce manual handling and the variability it brings. For manufacturers supplying ready-to-fit painted kits, automated paint booths and UV-cure systems deliver repeatable finishes and reduce lead times. The choice to automate is particularly impactful in regions with dense supply chains where manufacturers produce high volumes for multiple international markets; automation allows them to satisfy order variability while keeping per-unit costs competitive.

Surface finishing and paint processes convert a raw molded blank into a panel that matches a bike’s factory aesthetics. Because ABS accepts paint well, professional paint shops can achieve OEM-level gloss and color matching. Many suppliers use proprietary paint mixes developed by experienced technicians to match model-specific palettes rather than relying on generic color codes. This approach improves finish consistency and durability and helps minimize color shift between panels produced in different batches. Prior to painting, parts undergo precise preparation: trimming of flash and gate marks, sanding of any inconsistencies, and the application of base coats, clear coats, and UV-resistant sealing layers. For parts intended for outdoor use, coatings include UV stabilizers to prevent long-term fading, and corrosion-resistant primers for any embedded hardware.

Quality assurance begins at material receipt and continues through final inspection. Incoming resin is tested for melt flow index, moisture content, and contamination. During molding, in-process checks monitor cycle time, part weight, and dimensional tolerances to detect drift early. Finished pieces undergo visual inspection for surface defects, color consistency checks under controlled lighting, and fit trials on reference frames or jigs to verify mounting hole positions and edge alignment. For critical tolerance features, manufacturers use coordinate measuring machines or laser scanning to compare parts against the CAD master. These checks ensure that aftermarket or replacement fairings will mate correctly with existing motorcycle components, preserving handling characteristics and aerodynamic performance.

In mass-market production hubs, an integrated ecosystem shortens lead times and improves coordination across tooling, molding, painting, and logistics. Proximity to specialized mold shops and coating houses reduces the need to ship delicate tooling and parts over long distances, helping suppliers deliver finished fairings faster and with fewer quality handoffs. Such integration benefits buyers through faster turnarounds and simplified terms like Delivered Duty Paid (DDP) where the supplier manages shipping and customs. For brands or shops seeking tailored solutions, this ecosystem supports OEM and ODM services—full kit supply with model-specific fitments and factory-style paint finishes, including panels compatible with popular sport and commuter models.

Practical design-for-manufacture considerations help balance aesthetics and strength. Wall thicknesses are kept uniform where possible to avoid thick sections that can shrink and sink. Radiused edges reduce stress concentrations, and ribs or gussets reinforce mounting bosses while adding minimal visual bulk. Designers plan for attachment points and cable clearances to avoid late-stage modifications that undermine the molded part’s integrity. When motorcycle styling demands razor-thin edges or translucent elements, careful selection of resin grade and mold polishing techniques can preserve the visual intent without sacrificing durability.

The finished fairing is more than appearance; it contributes to rider safety and machine performance. A correctly molded and mounted bodywork reduces aerodynamic drag, stabilizes airflow around the chassis at speed, and shields mechanical components from debris and weather. Durable materials and robust molding practices ensure panels resist the regular stresses of vibration, thermal cycling, and minor impacts. For buyers and specifiers, understanding the interplay between material selection, mold engineering, process control, and finishing is essential when evaluating suppliers or specifying parts.

For further reading on core injection molding principles, material behavior, and process controls that underpin the manufacturing techniques described here, the resource below provides a technical overview and practical guidance.

External reference: https://www.injectionmolding.com/injection-molding-process

For examples of model-specific fairing kits and the kinds of finished products that result from these manufacturing practices, see Kawasaki fairings available from an established supplier: https://ultimatemotorx.net/product-category/kawasaki-fairings/.

From Molds to Global Highways: The Economic Pulse of Injection-Molded Motorcycle Fairings

Injection molded motorcycle fairings sit at the intersection of performance, aesthetics, and global commerce. They are not merely cosmetic shells; they are aerodynamic tools forged in a highly automated chain of design, material science, and precision manufacturing. The core material is ABS, a tough thermoplastic that blends rigidity with impact resistance and weather stability, enabling shapes with tight tolerances and smooth surfaces that stay consistent across thousands of units. The molding process uses high-pressure injection into steel molds, creating intricate geometries and integrated features such as air channels, mounting bosses, and edge treatments in a single shot. The result is a component that can mimic factory finishes at a fraction of the cost of traditional composites while offering better impact endurance and easier recycling. For buyers, this translates into reliable OEM-like replacements and performance-oriented aftermarket kits that fit with little fuss and perform under sun, rain, and gravel. Behind the scenes, the supply chain for these parts rests on a dense regional ecosystem in southern China’s Guangdong Province, where cities such as Guangzhou and Foshan host thousands of factories dedicated to mold making, automated coating, and final assembly. This scale enables rapid ramp-ups and a level of consistency that would be difficult to achieve with dispersed suppliers. Lead times shrink when production lines are integrated, and some operations report feasibility of delivering ready-to-ship kits roughly thirty-to-forty-five percent faster than looser networks. The logistics layer is equally important; many suppliers offer Delivered Duty Paid shipping through major regional ports, eliminating a layer of customs complexity for buyers across North America, Europe, and Australia. The concentration of capability in this region has translated into a dominant share of global output, with a sizable majority of fairing production sourced from these hubs. The result is an environment where both OEM-style replacements and niche aftermarket products can be offered with consistent fit, predictable color, and dependable post-paint durability. From the design room to the shop floor, the market features extensive OEM/ODM services that provide fully painted fairing kits tailored to a wide range of models, using proprietary paint blends rather than generic color codes. This approach yields a more durable, uniform finish that holds gloss and hue under UV exposure and temperature swings. In practice, this translates to a bike that retains its factory-like appearance after years of riding through sun and rain, with a finish that resists chalking and microcracking. The underlying chemistry and process control—precise resin blends, controlled drying, and automated quality checks—are what translate a digital CAD concept into a reliable, mass-produced panel. For readers curious about the breadth of aftermarket options, the 2023 new fairings category offers a clear window into how numerous shapes and finishes can be aligned with specific chassis. 2023 new fairings category. Economically, the impact of this production model extends beyond material savings. The scalability of injection molding drives rapid production cycles, enabling suppliers to respond quickly to evolving market demands and model-year introductions. With volume comes repeatability, and repeatability reduces variance in wall thickness, surface gloss, and fit, which in turn lowers warranty and returns costs. In a global context, on-time delivery rates in leading supply networks often exceed 97 percent, a benchmark that signals disciplined scheduling, proactive maintenance, and robust logistics coordination. The ability to respond to urgent changes within six to eight hours—whether due to a design tweak, a spec update, or a sudden surge in demand—further underpins a resilient supply chain. Such responsiveness matters as product lifecycles compress and new styling cues demand faster introduction cycles, while still maintaining consistent quality across tens of thousands of components in a single model year. In other words, the factory line is not merely producing parts; it is maintaining a smooth cadence that keeps assembly plants and aftermarket distributors moving in step with retailers and riders. Viewed through the lens of global manufacturing, China has emerged as the dominant hub for injection-molded fairings, driven by a confluence of advanced tooling, access to high-volume resin suppliers, and an integrated transport network. The breadth of available mold configurations—from compact shell sections to larger, multi-piece assemblies—supports a spectrum of applications, from protection and weight management to styling and branding. The use of half fairings helps strike a practical balance between rider visibility, wind protection, and weight, making the technology accessible to a broader segment of riders and teams who aim to optimize handling without adding excessive weight. Yet the same concentration that fuels scale also introduces exposure to regional disruptions, policy shifts, or supply shocks. The challenge, then, is to couple that scale with risk management—diversified supplier networks, dual-sourcing of critical resins, and stringent quality systems that keep the line stable even when external conditions change. The long-run economics—low unit costs, high repeatability, and broad capacity—continue to attract both established manufacturers seeking consistency and ambitious startups chasing performance gains, creating a feedback loop that sustains demand and spurs further innovation in mold design and coating science. From a technical standpoint, the success of these parts hinges on durable, purpose-built molds crafted from robust tool steels and maintained with precision. The molds must withstand thousands of cycles while preserving surface texture and dimensional fidelity; they are the heart of consistent part quality, enabling the replication of complex geometries with minimal variation. That fidelity, in turn, reduces the need for manual finishing and ensures that paint masks and seal lines align across units. The production ecosystem therefore links to education and knowledge sharing: mold design standards, machine specifications, and inspection protocols become as important as the resin itself. The broader narrative is one of advanced manufacturing where digital design feeds into physical tooling, which then ties into automated painting, curing, and packaging. In this continuum, the goal is not merely to produce a single fairing but to create a reliable, scalable system that can deliver consistent aerodynamics and aesthetics across tens of thousands of units in a single model year. As the industry evolves, attention shifts toward sustainability and continued improvement in both materials and processes. ABS offers recyclability advantages over some composites, and ongoing work on regrind content and smart molding cycles promises to reduce waste and energy use without sacrificing performance. At the same time, the promise of integrated data from mold sensors, process analytics, and finished-part inspection hints at a future where quality is predicted and controlled in real time, reducing scrap and accelerating corrective actions. The result is a picture of injection-molded fairings not only as a cost-effective, scalable solution but also as a platform for continuous improvement that aligns with broader goals of efficiency and environmental stewardship. In practice, the industry’s vitality stems from the synergy of material science, mechanical design, and global logistics, all sustained by a workforce that understands both the artistry of surface appearance and the rigor of repeatable manufacturing. External reference: CarInterior’s Motorcycle Fairings Guide provides practical insight into materials, finishes, and what buyers should watch for in quality and durability. See the guide for a concise rundown of properties that underpin the numbers behind these chapters.

Shaping Performance: How Injection Molding Advances Motorcycle Fairing Design and Production

Materials, machines, and methods come together in injection molded motorcycle fairings to shape both form and function.

The evolution of fairings has moved well beyond cosmetic shells; modern fairings are engineered components that manage airflow, protect mechanical systems, and contribute to rider safety. Injection molding sits at the center of this transformation because it can repeatedly produce complex geometries with tight tolerances, stable mechanical properties, and consistent surface quality. The technological innovations now influencing fairing design and production span materials science, mold engineering, digital design tools, quality systems, and factory-level integration. Each advancement shortens development cycles, lowers per-unit cost, and raises the baseline of performance buyers expect.

High-impact thermoplastics remain the backbone of injection molded fairings. Materials such as advanced polycarbonates and engineering-grade ABS blends offer an established balance of impact resistance, stiffness, and surface finish. Composite blends—where thermoplastics are modified with reinforcing fibers or elastomeric modifiers—allow manufacturers to tune flex, fatigue resistance, and weight. The choice of polymer affects mold design, cycle time, and secondary processes like painting or coating. For example, higher-viscosity compounds require optimized gate design and stronger injection pressures, while UV-stable blends permit simplified topcoat systems that extend long-term finish durability. Selecting the right resin family is therefore an early, decisive engineering choice that links material behavior to tooling cost and the intended service environment of the motorcycle.

Tooling technology has kept pace with material advances. Multi-cavity molds and hot-runner systems have become standard for high-volume fairing lines, improving throughput and reducing scrap. Multi-cavity molds allow several identical parts to be formed in each cycle, which lowers per-piece tooling amortization and benefits aftermarket and OEM runs alike. Hot-runner systems eliminate large amounts of runner waste and produce more consistent melt delivery, improving appearance and dimensional stability. Mold cooling design is another area of intensive development: conformal cooling and optimized channel layouts reduce cycle times and minimize warpage, ensuring that the complex contours of modern fairings meet fitment requirements without time-consuming rework.

Digital tools now shape fairing development from concept to production. Integration of CAD and CAM lets engineers simulate structural loads, analyze airflow, and refine parting lines before a single cavity is machined. Computational fluid dynamics (CFD) models merge with structural simulation to resolve trade-offs between aerodynamic performance and crash behavior. These digital iterations reduce the number of physical prototypes needed and expose potential assembly or interference problems early. Meanwhile, CAM-driven machining of molds, often controlled by five-axis systems, translates the digital geometry into steel with micron-level precision. This digital thread—from 3D concept to final cavity—bridges creativity and manufacturability, enabling designers to explore aggressive shapes without sacrificing manufacturability.

Rapid prototyping accelerates validation. Additive manufacturing is widely used to produce test patterns and functional prototypes that verify fit, ergonomics, and initial aerodynamics. While 3D-printed parts are not a substitute for injection molded components in mass production, they are invaluable for functional mock-ups and early-stage wind tunnel testing. Prototyping supports a more iterative design process, where feedback loops with riders and technicians refine aesthetics and attachment strategies. For customized or limited-run fairings, tooling-free or low-tooling approaches combined with rapid prototyping shorten time-to-market and support rider personalization trends.

Surface finishing technologies have matured to meet high expectations for paint quality and longevity. Automated painting lines and UV-stable coating chemistries create durable finishes that resist abrasion and sun exposure. Professional technicians frequently develop proprietary paint mixes to ensure color consistency across batches, rather than relying on generic color codes that can shift under different substrates. Pre-treatment, such as plasma or corona treatment, improves adhesion for topcoats on low-energy surfaces. These finishing advances matter not just for appearance but for long-term protection against chemicals, road debris, and extended outdoor exposure.

Manufacturing efficiency and supply-chain integration also define modern fairing production. Clusters of specialized factories equipped with high-speed injection presses, robotic handling, automated inspection, and in-house painting create vertically integrated production hubs. This integration reduces handoffs, shortens lead times, and lowers logistic friction for global buyers. When legal terms like delivered duty paid are offered, buyers face fewer administrative hurdles when importing assembled fairing kits. The proximity of mold shops, plastic compound suppliers, and surface finishing providers in these hubs enables rapid iteration and responsive scaling. For international brands and aftermarket distributors, this integrated model translates to predictable quality and more agile replenishment.

Quality control has shifted from manual checks to automated, data-driven inspection. Automated vision systems and coordinate measurement machines validate part dimensions, hole locations, and surface defects with speed and repeatability. Traceability systems that record raw material batches, process parameters, and inspection results help manufacturers isolate root causes quickly when issues arise. Because fairings influence rider safety and vehicle assembly, maintaining strict quality protocols is essential for both OEM suppliers and aftermarket producers. Documentation and process control help ensure a replacement cowl or full fairing kit will fit and perform comparably to the original equipment.

Customization, though, is one of the most visible outcomes of these technologies. Modern injection molding and finishing approaches support short runs and model-specific kits that fit an increasing number of motorcycles. Suppliers can deliver painted kits tailored to particular models with high consistency, often matching complex graphics and layered clear coats that mimic factory finishes. This capability feeds enthusiast demand for personal expression and track-ready conversions, while still protecting function and fit. For buyers seeking model-specific solutions, channels exist that categorize kits by motorcycle family and model year, simplifying the search for compatible components.

Finally, innovation in fairings is as much about systems thinking as it is about single technologies. Changes in material chemistry affect mold life and finishing; tooling advances influence cycle time and unit cost; digital design reduces late-stage surprises. The most successful manufacturers harmonize these elements, aligning design choices with production capabilities and quality systems to deliver parts that balance aesthetics, durability, and manufacturability. That integrated approach is what enables fairings to remain ever more refined, lighter, and aerodynamically efficient while staying affordable for riders across markets.

For those exploring model-specific fairing options, a practical starting point is the selection and fitment resources available for specific motorcycle families, such as fairings for Ninja. For a broader industry perspective and market trends related to these technologies, see this market overview: https://www.marketsandmarkets.com/Market-Reports/motorcycle-fairing-market-165729847.html

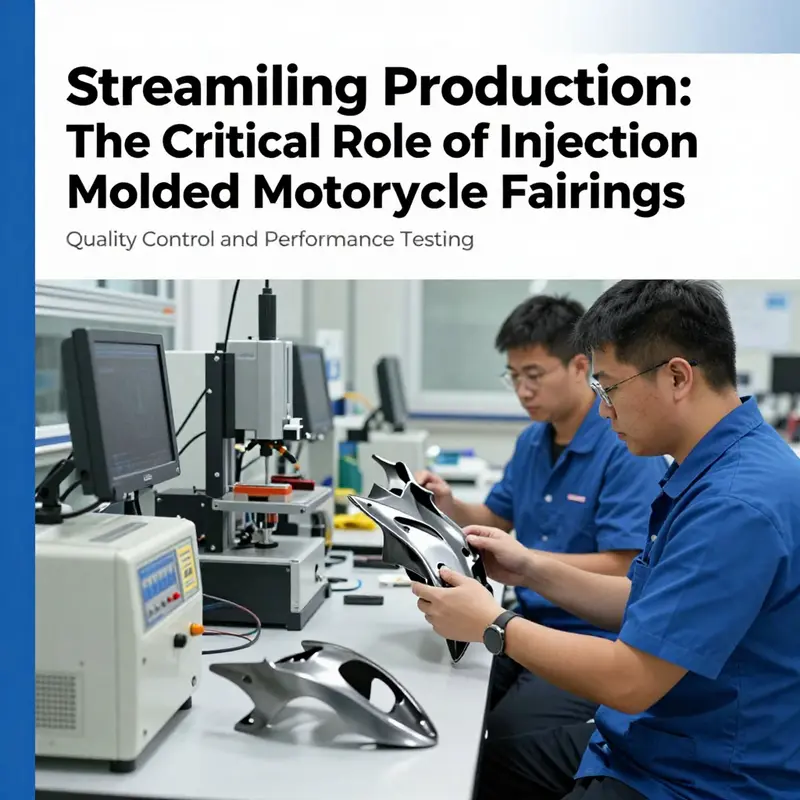

Blueprints in the Wind: Quality Control and Real-World Testing of Injection-Molded Motorcycle Fairings

In the high-velocity world of motorcycle design, the fairing is more than a graphic skin. It is the aerodynamic surface that shapes flow, a protective shield against debris, and a canvas where a brand’s identity is projected at speed. The success of injection molded fairings rests on a quiet chain of precision that begins long before the first shot of plastic enters a mold and ends only when a rider experiences the panel’s performance under sun, salt, wind, and rain. The chapter of quality control and performance testing unfolds across a tightly integrated manufacturing ecosystem, where the physics of air and the chemistry of polymers meet in a factory floor that runs like clockwork.

In regions where this industry has matured, thousands of injection molding machines hum in unison. The local advantage lies not just in capacity but in the completeness of the supply chain: the ability to source high-grade thermoplastics, to machine and validate molds, to apply durable coatings, and to finish parts with automated painting lines—all within a network that can move components from raw resin to painted kit with remarkable speed. In such ecosystems, lead times are compressed through vertical integration, and logistics are streamlined with bonded warehouses and near-port distribution. When a buyer orders a full fairing kit, the path from molten polymer to a finished, ready-to-fit component is designed to minimize variance at every step. The result is a predictable product that keeps both the assembly line and the shipment calendar in rhythm.

Quality control begins with materials. The choice of resin is not a matter of color alone; it is a matter of performance under the stress of fast, repetitive loads, varying temperatures, and harsh weather. Modern practice favors engineering-grade thermoplastics that offer impact resistance and dimensional stability, with UV resistance built into coatings and finishes that resist fading and cracking over years of exposure. Professional QC teams scrutinize raw materials for batch consistency, moisture content, and color stability. When the resin arrives, it is tested for melt flow, viscosity, and purity, because even tiny deviations can ripple through the molding cycle and show up as misalignments or surface imperfections on a completed fairing.

Mold machining then enters the stage. The die—steel tooling that defines every contour and interface—must be machined to extreme tolerances. Skilled technicians dial in dimensions, radii, and draft angles so that the finished part slides into its mate with minimal gap and no interference. Once the mold is ready, inspection becomes a continuous discipline. Modern factories deploy automated systems that use 3D scanning and coordinated metrology to confirm that every cavity, gate, and cooling channel adheres to design within microns. This pursuit of dimensional fidelity is not a one-off check; it is a system of feedback that feeds into process control. If a deviation is detected, cycle adjustments are made, the mold is re-calibrated, and production resumes with minimal waste. Surface finish is not neglected. The exterior texture, gloss, and color depth must be reproducible across thousands of parts, so automated painting lines and UV-resistant coatings are calibrated to preserve the appearance while defending against weathering. In practice, this means integrators who can balance instrumented measurement with the artistry of a factory painting line, ensuring that the final aesthetic remains faithful to the original design.

The testing regime mirrors the multifaceted purpose of the fairing itself. Dimensional checks are complemented by rigorous functional tests. Each part is examined for straightness and fit, with fixtures that simulate real mounting tolerances. Surface integrity is evaluated for micro-scratches or waviness that could undermine aerodynamics or rider comfort. Durability tests probe the plastic under load, checking for crack initiation when bolts and mounting points endure repeated vibration. For environmental resilience, coatings receive accelerated aging: UV exposure, humidity cycles, and chemical resistance tests that mirror road conditions, cleaning agents, and seasonal humidity. These steps ensure that a glossy finish does not degrade into dullness after a winter of rides.

Performance testing adds another layer of scrutiny. Aerodynamic performance may be inferred through specialized bench tests that mimic high-speed airflow and flutter tendencies, while more sophisticated programs use wind tunnel data or computational fluid dynamics during prototyping. The aim is to ensure that a fairing’s shape, thickness, and surface finish do not generate unexpected drag, buffeting, or noise at speed. Thermal cycling also reveals how the polymer behaves under extreme temperature swings, which can be common in regions with intense sun and cold nights. Impact resistance tests put the panels through simulated road debris strikes, examining how the material and the coating stand up to sharp objects and vibrations that would occur on real roads. The insights from these tests guide adjustments in wall thickness, ribbing, and mounting points before a full-scale run is approved.

Beyond the chemistry and physics, the longevity of a fairing rests on process discipline. Sourcing considerations emphasize vertically integrated hubs that can shorten lead times and stabilize quality through end-to-end visibility. Bonded warehouses near major ports simplify duties and logistics, enabling Delivered Duty Paid arrangements that reduce supply-chain risk for designers and manufacturers who rely on consistent, predictable deliveries. In practice, this makes it feasible to offer customized, fully painted fairing kits aligned with specific mounting patterns and color systems devised by professional technicians, rather than relying on generic color codes that may drift over time. The combination of precise tooling, repeatable painting, and controlled assembly creates a chain of custody from resin to rider, allowing brands to deliver consistent quality at scale.

Embedded in this narrative is a broader imperative: to capture data at every transformation stage and to use it to sustain improvement. Digital records tied to material lots, mold serials, coating runs, and inspection outcomes enable traceability that supports corrective actions and after-sales reliability. When a batch exhibits a deviation—whether in dimensional accuracy, surface texture, or coating adhesion—the root cause can be traced through the entire sequence, from material storage through final inspection. Engineers can then adjust process parameters, refine quality gates, or recalibrate equipment. The objective is not mere conformity, but consistent, durable performance under the wide array of operating conditions riders will encounter.

For buyers and partners, the practical upshot is a combination of confidence and flexibility. Confidence arises from the assurance that every fairing unit has passed a comprehensive circuit of tests and verifications, while flexibility comes from the possibility of OEM/ODM collaborations that honor a designer’s intent without sacrificing reproducibility. The most robust suppliers offer not only the base components but also engineering guidance on mold design standards, paint systems, and testing protocols, helping new entrants and established brands alike optimize their processes. This collaboration, tempered by rigorous quality controls, is what turns an artful silhouette into a reliable aerodynamic tool that can endure the daily rhythms of riding life.

As this chapter moves toward the broader landscape of sourcing and manufacturing ecosystems, it points to a simple truth: the performance of a fairing is inseparable from the discipline that governs its creation. The fairing is proof that high-volume production and high-precision engineering are not mutually exclusive. It is the product of a system that treats every millimeter as a critical variable, every bolt as a mounting guarantee, and every coat of paint as a shield against time. In that sense, the dialogue between quality control and performance testing is not a checklist but a continuous negotiation between design ambitions and real-world endurance. The resulting products, born in a region where tooling, polymers, coatings, and logistics converge, embody the blend of science and craft that keeps riders safe, stylish, and confident as they navigate both the road and the promise of advanced manufacturing.

Looking ahead, the next discussions will explore how polymer science, mold design standards, and digital metrology converge to push further improvements in automatic quality gates and durable coatings, keeping pace with evolving aerodynamic goals and environmental regulations.

External resource: https://www.injectionmoldingmachineguide.com/comprehensive-guide-to-motorcycle-molding-machine/

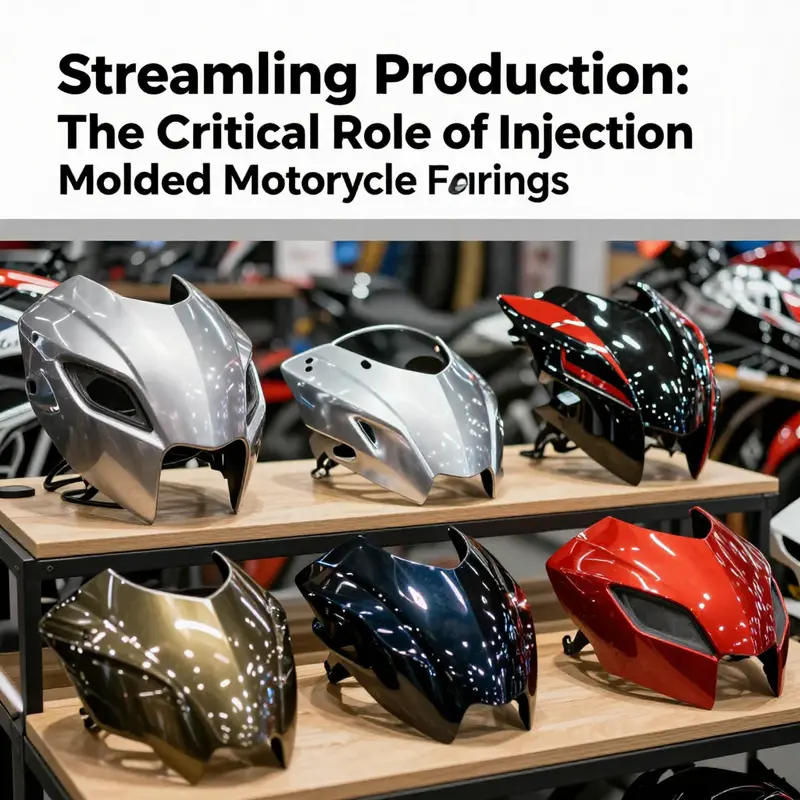

Injection-Molded Motorcycle Fairings: Customization, Craft, and Market Momentum

Injection-molded motorcycle fairings sit at a pivotal intersection of performance, aesthetics, and mass customization. They are engineered panels that influence aerodynamics, weight distribution, and rider perception. The journey from molten thermoplastic resin to finished, field-ready bodywork hinges on precision in materials, tooling, and process control. In modern practice, ABS remains the backbone of this ecosystem because its balance of impact resistance, surface finish, and processability is well aligned with the demands of high-volume, quality-driven production. Yet the story goes beyond the raw material. It encompasses a tightly woven manufacturing ecosystem—one that blends design freedom with scalable manufacturing, rapid prototyping, and sophisticated finishing techniques that collectively push forward what riders expect from factory and aftermarket fairings alike.\n\nThe propulsion behind this evolution is a combination of materials science, tooling strategy, and an integrated supply chain that thrives in regions renowned for advanced plastics manufacturing. Guangdong Province in China, especially the cities that drive the injection-molding industry, exemplifies the modern fairing supply chain. Here, thousands of dedicated factories operate with high-precision molding machines, UV-resistant coating lines, and automated painting facilities. The result is a capability to produce complex geometries at scale with consistent tolerances and repeatable surface aesthetics. These hubs also demonstrate a logistics ingenuity that matters to buyers: streamlined options for Delivered Duty Paid shipping, proximity to major ports for global distribution, and a port-to-door workflow that reduces friction in cross-border transactions. When a manufacturer can couple 3D-mimicked curvature with automated painting and a reliable coating system, the lead time advantages compound, allowing lead times to compress meaningfully—an efficiency gain that translates into competitive pricing and faster time-to-market for new model lines.\n\nIn the broader market, the demand for customized appearances drives much of the current growth. Riders increasingly seek authentic personalization—the kind that lets a fairing kit mirror a rider’s individual taste while preserving performance. The modular approach to fairings has become a practical solution. Rather than a single, monolithic piece, kits are designed with modular components, pre-drilled mounting points, and precise fitment data that reduce installation complexity. This modularity accelerates the process for enthusiasts who want to swap styles or update a look without a full professional rework, cutting installation time dramatically, in some cases by as much as half compared with traditional aftermarket arrangements. Where fit and finish used to be a gamble for DIY adopters, modern designs address those concerns with model-specific fitment features that preserve alignment and minimize common paint-issue pitfalls that arise from misaligned panels.\n\nCustomization is not purely about looks; it is increasingly linked to performance, durability, and longevity of the finish in the real world. ABS remains the go-to polymer because it tolerates high-speed airflow, resists UV degradation, and holds paint well under cycling temperatures and varying humidity. Yet the market is not static. Hybrid concepts that blend ABS with lightweight alloys or composite reinforcements are making inroads where higher stiffness or marginal weight reductions yield measurable performance benefits on sport and touring platforms. These hybrids can offer a fairing assembly that is up to twenty percent lighter than traditional, all-metal alternatives while maintaining the structural integrity needed for aggressive riding and occasional impact—an appealing proposition for riders seeking a balance of agility and protection.\n\nSafety and compliance form a foundational layer of modern fairing development. As the riding environment becomes more scrutinized and regulated, fairings must meet rigorous standards that cover impact scenarios, crash integrity, and road-legal certifications. This emphasis on standards pushes suppliers to invest in robust mold design practices, stricter tolerance control, and validated coating systems that resist yellowing and cracking under sun exposure and road salt. The payoff is a more reliable consumer experience: panels that stay aligned, retain their color, and withstand the environmental hazards of long highway stints and weather exposure. In this sense, the value of high-precision injection molding becomes not just about form but about dependable performance that riders can trust when they push the limits of speed and endurance.\n\nThe market dynamics surrounding distribution and access also shape how customization translates into real-world adoption. Global platforms have expanded the reach of well-engineered fairing kits, enabling riders and workshop networks to source model-specific, paint-ready assemblies with relative ease. This global reach is meaningful for consumers who value consistency and depth of options, as well as for repair shops that need dependable, repeatable parts to minimize downtime. The possibility of model-specific kits—crafted to align with the exact geometry and mounting standards of a given motorcycle—reduces the trial-and-error typically associated with aftermarket parts. Material choices and finish techniques in these kits emphasize durability against debris and weather, while aerodynamic design details continue to help riders achieve smoother airflow and reduced drag. In practice, aerodynamic improvements translate into practical benefits such as better stability at speed and, in some cases, marginal gains in fuel efficiency through reduced parasitic drag.\n\nAmong the most telling indicators of market health is the breadth of model coverage these kits pursue. Suppliers often offer OEM/ODM services that cater to a wide spectrum of models and trims, providing fully painted kits that align with various factory color schemes and finishes. The ability to deliver curated colors built from proprietary paint blends—rather than relying on generic color codes—contributes to the premium feel that many riders seek. Such capability supports a perception of reliability and quality that is crucial for brand confidence in the aftermarket space. While glossy, vivid finishes capture attention, there is also growing demand for finishes with improved resistance to fading and micro-scratches, essential for maintaining showroom-like aesthetics after exposure to road grit and UV light.\n\nFor readers seeking concrete touchpoints in the market, the online ecosystem reflects these trends through model-specific cataloging and cross-border logistics options. The global supply chain recognizes the value of a turnkey experience: ready-to-install fairing kits with pre-fitted hardware, straightforward instructions, and dependable paint finishes. This approach aligns with the broader movement toward streamlined procurement for workshops and dealers who must balance cost, lead time, and quality. It also highlights a critical capability gap that the Guangdong-based manufacturing cluster has been filling for years: end-to-end solutions that combine design, molding, coating, and packaging in a supply chain that can accommodate variable demand and short-notice orders.\n\nWithin this evolving landscape, a prominent reference point for the industry’s online exploration is the comprehensive cataloging of model-specific kits that appears across international marketplaces. These listings offer a spectrum of features—from aerodynamic refinements aimed at drag reduction to protective elements that shield paintwork from debris and weather. Embedded in these offerings is the implicit promise that a rider can pursue a customized look without sacrificing reliability or compatibility with the underlying frame and mounting system. The convergence of customization with practical engineering is what ultimately sustains the momentum of injection-molded fairings as a core component of modern motorcycle design. As manufacturers continue to refine the balance between finish quality, fitment precision, and environmental resilience, riders will increasingly expect not only striking visuals but also the assurance that these panels perform consistently under the stresses of spirited riding, long tours, and seasonal exposure.\n\nFor readers curious about concrete pathways into the market, one relevant avenue through which many buyers explore options is a widely used model-category portal that aggregates kit options by brand and model. This resource demonstrates how suppliers translate engineering accuracy into accessible consumer choices, with design goals oriented toward both speed and customization. A practical takeaway for enthusiasts and professionals alike is that the current generation of injection-molded fairings enables a more meaningful alignment between personal style and riding performance. The same engineering discipline that produces precise fitment and robust surface finishes also underpins the potential for rapid, model-specific color customization and durable coatings that stay vibrant where sunlight and road spray would typically erode surface quality. In this sense, customization becomes a solved problem, not a compromise, and market momentum follows accordingly as riders seek to express identity while preserving the ride quality they expect from modern motorcycles.\n\nUltimately, the trajectory of injection-molded fairings rests on maintaining this delicate balance: enabling highly capable, aerodynamically informed shapes; delivering consistent, durable finishes; and supporting a supply chain that can translate design intent into ready-to-install components with minimal friction. The Guangdong ecosystem, with its integrated manufacturing and logistics capabilities, anchors this trajectory by offering the scale and coordination required to meet rising demand for customization without sacrificing reliability. For readers who want to explore further practical examples of how these principles manifest in real-world products, the following resource provides a representative snapshot of kit-level specifications, materials, and customer feedback. External reference: https://www.alibaba.com/product-detail/KAWASAKI-652NINJA-ER6F-2012-2016-Motorcycle_1600724348425.html?spm=a2700.184913.0.0.5f1a3d4cJwXWbS. For a closer look at model-specific fairings within a curated category, see the Kawasaki fairings page: https://ultimatemotorx.net/product-category/kawasaki-fairings/

Final thoughts

Understanding injection molded motorcycle fairings transcends the technical aspects of design and production. These components are crucial not only for their functional capabilities in enhancing motorcycle performance but also for their role in international trade and consumer satisfaction. As technological advancements shape the future of manufacturing and customization options expand, business owners must remain vigilant to harness these opportunities, ensuring they stay competitive in a rapidly evolving marketplace. Embracing innovation in injection molding can lead to significant advantages, revolutionizing how motorcycle fairings are produced and marketed.