In the realm of motorcycle performance and aesthetics, lower fairings play a crucial role, particularly for Indian Motorcycle riders. These components not only enhance the aerodynamic profile of models like the Indian Challenger and Chieftain but also provide vital wind protection for riders. As we explore the design elements, material choices, and market dynamics of these lower fairings, business owners can gain insights into how to better serve their customers’ needs in terms of comfort, style, and functionality. Each chapter delves into specific aspects: the aerodynamic benefits, the construction materials and aesthetic options available, and a comparative analysis between aftermarket and OEM versions. This comprehensive approach will help motorcycle business owners understand the value these components bring to both riders and their businesses.

Streamlining Speed: Aerodynamics, Wind Management, and the Quiet Power of Lower Fairings on Modern Touring Motorcycles

Across the sweeping lines of a modern touring motorcycle, lower fairings do more than frame the bike’s silhouette. They are quiet workhorses in the aerodynamics equation, shaping how air behaves around the machine at speed and how the rider experiences that air. When wind fills the gaps in the front of a motorcycle, it creates drag, turbulence, and buffeting that can translate into fatigue, reduced stability, and a taxing ride on long stretches of highway. Lower fairings, designed with both form and function in mind, redirect air toward smoother passages around the engine and undercarriage. The goal is to minimize drag while preserving the bike’s essential cooling and intake characteristics. The result is a more efficient flow field where air glides past the front of the bike rather than slamming into it. This subtle but powerful reorganization of air not only improves top speed potential and fuel economy but also enhances rider confidence, especially when a long day’s ride stretches from dawn to dusk along open, windswept corridors or through rolling landscapes where gusts continually rearrange the air’s path.

Aerodynamics is not merely about reducing a number on a wind tunnel chart; it is about a practical, rideable harmony between machine and atmosphere. The lower fairing is a central instrument in that harmony. Its contours are shaped to guide air over the radiator, around the cylinder head, and along the machine’s underside with minimal separation. When air remains attached to the surface rather than peeling away in a chaotic pattern, the resulting laminar-like flow reduces pressure differentials that would otherwise birth instability, especially at elevated speeds. In real riding conditions, this translates into steadier steering input requirements and a calmer feel in the cockpit. The rider notices less wind drift, particularly at higher speeds or when off axis gusts push from the side. The bike becomes more predictable, and the rider can focus more on steering and line choice than on fighting the wind. The psychological benefit of smoother air—less fatigue, more confidence, and a greater sense of control—often translates into longer, more comfortable touring sessions.

From a technical standpoint, the lower fairing acts as a bridge between the bike’s front and its belly, working with the chassis and suspension to stabilize the machine’s vertical and pitch movements. The fairing’s lower edge interacts with the boundary layer of air that hugs the ground. A well designed edge can help reattach air that would otherwise swirl into the engine bay or around the rider’s legs, smoothing the flow as it travels toward the rear. In this sense, the fairing is less about a dramatic design statement and more about a calculated, aerodynamically informed choice. The fairing’s surface is typically composed of durable materials that resist the occasional stone strike and the sun’s ultraviolet assault. These materials—often fiberglass or high impact polymers—are chosen not just for their lightness and strength but for their ability to hold a precise shape under a wide range of temperatures and riding conditions. The color options, including classic black, allow riders to match a factory finish or customize the look without compromising the aerodynamics by introducing visual clutter or high contrast edges that could disrupt airflow perception.

Ventilation is a particularly important consideration in the design of vented lower fairings. Many contemporary lower fairings feature vent grills and screens that are not merely decorative but functional. The mesh or vent screens are placed to capture and direct a portion of the air toward cooling channels, not to starve the engine of air at speed but to optimize its journey so that heat is carried away efficiently. This balance—ventilation without overexposure—illustrates a broader principle in aerodynamic design: you want airflow to do useful work, which means keeping the engine and the rider cool while ensuring that the flow remains smooth around critical junctures. When implemented well, vented designs help dissipate heat by creating a controlled path for warm air to escape, reducing hot spots under the bike and improving overall thermal management during long stretches of riding, particularly on hot days or during climbs where the engine works harder. The upshot is a cooler engine and a more comfortable rider, both of which contribute to sustained performance and a more confident riding tempo on long tours.

The aesthetic impact of lower fairings should not be overlooked. A well integrated fairing blends with the bike’s lines to emphasize its aerodynamic intent. The look communicates efficiency even when the bike is idling in a showroom, and that impression often translates to perceived performance for riders. The sleek, sculpted contours can make a touring machine appear more purposeful, while the black finishes and subtle venting details maintain a restrained, sporty presence. This congruence of form and function helps riders feel that their machine is optimized not merely for appearance but for real world riding efficiency. In practice, the material choice, the method of assembly, and the paint or finish all contribute to the final effect. The result is a visual language of airflow, a promise that the bike is designed to cut through air cleanly and calmly rather than to slam into it with every mile.

Beyond the aesthetics, the practical implications involve maintenance and durability. Lower fairings are not disposable aesthetics; they are built to withstand road debris, stone impacts, and the occasional scrape while maintaining their shape. Regular care—gentle washing to remove road grime, inspection of mounting points, and periodic checks of vent screens—keeps the airflow channels clear and the contour fidelity intact. The maintenance rhythm is simple: wipe, inspect, and re secure any fasteners that may have loosened during a tour. When a fairing is kept in good condition, its aerodynamic role remains effective across thousands of miles and through a spectrum of weather conditions. In addition, the ability to match color or finish helps preserve the bike’s cohesive look, ensuring that the aerodynamic features do not clash with the overall styling but rather reinforce it. For riders who value a clean, uninterrupted line from front to rear, the lower fairing delivers both functional benefit and a sense of visual continuity that reinforces the machine’s design philosophy.

From the standpoint of performance and energy efficiency, the cumulative effect of lower fairings on modern touring motorcycles can be meaningful over the lifespan of a ride or a season. Reducing drag translates to better fuel economy at steady speeds and improved acceleration margins when passing or merging. The smoother the air around the bike, the less energy the engine needs to devote to overcoming air resistance. Even modest gains in efficiency add up over long journeys where every mile counts. More importantly, the rider feels a steadier balance and a reduction in the fatigue that can accompany high speed riding or crosswind exposure. The rider’s posture and steering input remain freer to adapt to road conditions because the air pressure on the torso and limbs is less intrusive. In practical terms, this means fewer micro adjustments mid ride and a more relaxed, confident posture after hours of riding. These benefits are especially appreciated when the scenery becomes a blur and the road stretches out with a patient, unbroken rhythm.

To connect these aerodynamic principles to real world choices, consider the ways a lower fairing can be integrated with a bike’s other bodywork and with the rider’s needs. Some designs focus on maximum wind protection for the chest and hands, while others emphasize a balance between airflow and cooling or on the ease of maintenance and customization. The choice often comes down to riding style, typical weather, and the rider’s tolerance for wind pressure during long distance journeys. The lower fairing’s role is thus not a standalone performance upgrade but a piece of a larger system. It interacts with windscreen height, helmet shield design, seat position, and even tire selection to determine the total aerodynamic and ergonomic package a rider experiences on the road. When all these elements align, the result is a motorcycle that feels lighter at speed, more planted in gusts, and capable of sustaining comfortable, steady performance through many days of riding.

For riders curious about broader fairing options beyond a single brand, the landscape of aftermarket and OEM alternatives offers a spectrum of designs that share the same aerodynamic goals. A useful way to explore options is to consider how venting, contouring, and material choice affect a bike’s airflow path. If you’re curious about a specific model family’s fairings, you can explore targeted options such as those developed for other touring or sport-touring machines. An example of a relevant category that demonstrates the breadth of fairing design can be found in sections dedicated to Yamaha fairings, where you can see how vented lower panels can be configured to optimize intake routing, radiator cooling, and wind protection across different models. For example, you can explore Fairings for Yamaha YZF models to gain perspective on how various shapes and vents influence airflow and rider comfort. This cross-brand comparison helps emphasize that the aerodynamic principles at work in lower fairings are universal, even as the specifics of fitment and style vary.

Looking ahead, the evolution of lower fairings will likely continue to refine the balance between wind protection and aero efficiency. Advances in materials science may introduce lighter, stiffer composites that hold their shape better under heat and impact, while an ongoing dialogue between aerodynamics and rider ergonomics will shape how contours are sculpted to reduce fatigue without sacrificing protection. The integration with active aero systems could further tailor airflow to changing conditions, offering more adaptive comfort without overwhelming the rider with complexity. Yet even as technologies advance, the core purpose remains clear: to tame air, to shield the rider from wind pressure, and to let the motorcycle’s power and handling express their full potential with less effort from the rider. The lower fairing, in this light, is not a mere accessory but a functional piece of a larger system that enables riders to cover more miles with less effort and greater confidence.

To close this thread, the aerodynamics of lower fairings are a testament to the practical science that underpins riding comfort and performance. They are designed not only to sculpt the bike’s profile but to shape the rider’s experience, turning wind into an ally rather than a foe. In a touring context, where miles accumulate and wind can be relentless, the value of calm air around the machine cannot be overstated. The best lower fairings deliver a quiet, steady hand on the controls, a cooler engine, and a smoother ride that keeps fatigue at bay. They enable a rider to maintain steady tempo across long days, negotiating highway speeds with less effort, and facing gusts with steadier balance. In sum, the lower fairing blends engineering pragmatism with aesthetic restraint to create a vehicle that feels engineered for the long haul an ally on the road who quietly makes speed, stability, and endurance seem almost effortless.

External resource: https://www.indianmotorcycle.com/en-us/technology/aerodynamics

Armor in the Air: Material Realities and Visual Language of Indian Lower Fairings

The lower fairings on a modern touring motorcycle do more than frame the engine and hide its bulk. They are the practical interface between wind, heat, and rider comfort, and they shape the silhouette that communicates the bike’s character to the world. In the Indian market, as in many premium segments, the balance between performance and aesthetics hinges on two intertwined choices: material composition and the finish that coats it. The material determines how the piece behaves when the bike dives into air at highway speeds, how it resists the weather and road debris, and how forgiving it is when treated to the occasional curb or gravel patch. The finish determines how that same piece contributes to the machine’s visual story, from stealthy satin blacks to gleaming chrome accents or factory-matched tones that disappear into a seamless, integrated look. Together, these factors drive a subtle but real difference in ride quality, durability, and owner satisfaction over the life of the bike.

From a structural standpoint, ABS plastic has long been the default for lower fairings. Its appeal rests in a triad of strengths: adequate impact resistance, light weight, and ease of manufacturing. ABS can absorb minor hits without cracking, which matters when a fairing brushes a garage pillar or a stray rock on a washboard road. It also keeps weight down, a critical factor for any two-wheeled chassis where even a few pounds in the fairing section can affect handling at speed and mounting dynamics during aggressive riding. Weather exposure—sun, rain, temperature swings—poses less risk to ABS than some other polymers, provided the formulation includes UV stabilizers and proper surface finishes. This resilience helps maintain fitment and alignment over time, which in turn preserves the aerodynamics that fairings are designed to deliver.

Yet the road to optimal performance isn’t limited to a single material. For riders seeking enhanced stiffness and the ability to tailor properties to specific use cases, composites such as glass fiber-reinforced resins offer appealing advantages. These materials bring superior strength-to-weight ratios and improved heat resistance, which can contribute to better high-speed stability. The reinforcement layers can be molded into intricate shapes, allowing designers to craft aero-efficient contours that optimize airflow around the lower half of the bike. This is particularly valuable when venting strategies are employed. A well-designed vent system in a lower fairing can help manage pressure buildup under the motorcycle, reducing turbulence that might otherwise disrupt stability at turbocharged or high-performance cruising speeds. The downside, however, is brittleness. Some composites crack under sharp impacts rather than bending, which complicates repairability after a tumble or a heavy drop. In the real world, the choice often comes down to how a rider uses the bike and how the owner weighs repairability against the potential performance gains of a stiffer, lighter fairing.

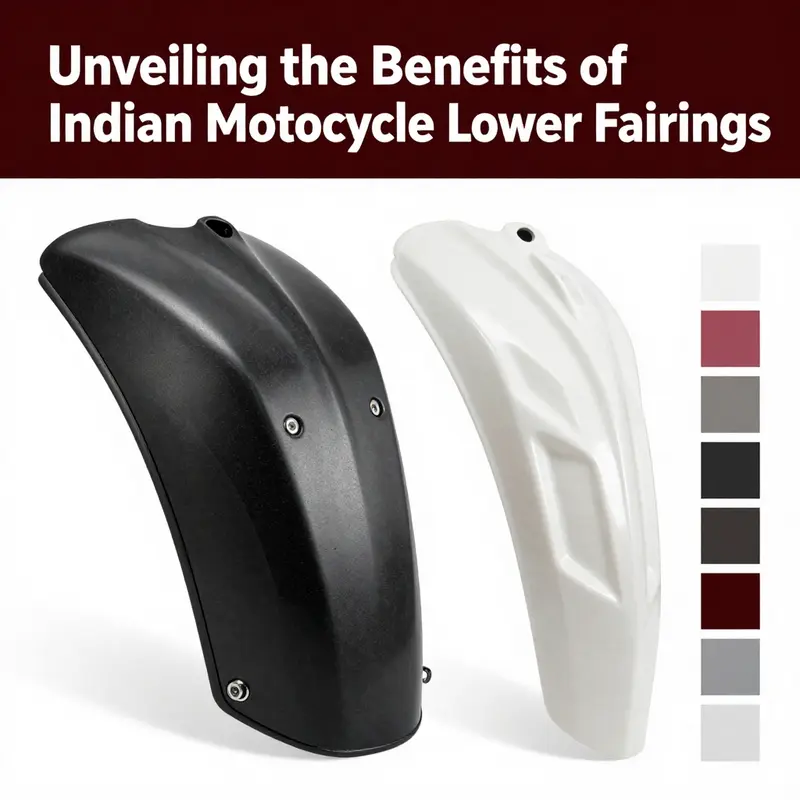

The decision between these materials also intersects with manufacturing realities and cost considerations. ABS-based fairings are generally easier and cheaper to produce at scale, allowing manufacturers to offer a broader range of colors and finishes that align with factory aesthetics. This means an owner can choose a look that either blends into the background of the motorcycle’s palette or stands out with a bold, contrasting accent. A satin black finish can emphasize clean lines and reduce the visual footprint of the bike, while chrome accents on the fairing edges or vent grilles can evoke a classic, reflective contrast with the motorcycle’s paint. The option to wavelength-match factory colors ensures a cohesive appearance, especially when paired with other body panels that share the same hue. This capacity for seamless color integration is a strong reason ABS remains a baseline choice in many aftermarkets and OEM programs.

Vent design is another layer of the aesthetic and functional equation. Many lower fairings incorporate vented patterns that serve dual purposes: they channel air to nearby components for cooling and reduce pressure build-up under the bike that can affect handling at speed. A mesh grille or vent screen can be more than a visual feature; it can be a performance feature when executed with attention to airflow dynamics. The presence of vented designs often signals a focus on rider comfort and drivetrain reliability, as cooler ambient air can help moderate temperatures around the engine and transmission while contributing to a more stable ride. From a styling perspective, vented fairings can contribute a sportier, more technical look, especially when paired with matte or satin finishes that highlight the geometry of the air channels and the lines that guide air along the bike’s profile. In practice, riders frequently appreciate how venting reduces wind pressure against the rider’s legs and torso, especially at highway speeds or in long-distance touring where fatigue is a critical concern.

The aesthetic spectrum for lower fairings is broad and, in practice, highly personal. A satin black finish is a popular choice because of its understated elegance and compatibility with a wide range of color schemes. It can give the bike a more aggressive, no-nonsense stance while keeping maintenance simple, since satin surfaces hide micro-scratches better than gloss paints. In contrast, polished chrome accents can lend a touch of vintage refinement or a classic cruiser ethos, catching the light in a way that defines the fairing’s perimeter and giving the bike an eye-catching profile without altering the core form. Factory-matched colors—choices that mirror the factory’s own palette—offer the cleanest integration with surrounding panels. They help the lower fairing disappear visually into the bike’s overall design, producing a cohesive, integrated machine rather than a patchwork of separate parts. The choice among these finishes is rarely only about looks. It communicates the rider’s intent—whether they want a discreet, streamlined look to emphasize performance or a more expressive finish that makes a bold statement on the road.

Beyond color and finish, the structural narrative of lower fairings intersects with how they interact with other bodywork elements. The fit and finish of a fairing panel contribute to the machine’s overall aero profile. When a fairing is well designed and properly installed, it guides airflow smoothly around the engine bay and underbody. This reduces drag and can help manage lift and side wind effects at speed. The interplay between panel curvature, edge treatment, and the radii at interfaces with adjacent components determines how air accelerates and settles around the bike. In this sense, the lower fairing is both shield and sculptor: it protects critical components and shapes the air as it passes by, contributing to stability and rider confidence even at the upper end of cruising speeds. The design challenge is to balance rugged durability with the sculptural language that communicates the bike’s personality. ABS’s flexibility supports a variety of profiles, while composites offer the sculptor’s precision for more aggressive aero forms.

From a practical perspective, many riders encounter a marketplace where OEM replacements and aftermarket options coexist. The availability of lower fairings in multiple colors or textures means a rider can pursue a subtle upgrade or a more dramatic transformation. The decision may hinge on how much of the fairing’s surface the rider intends to alter, how closely a color matches the rest of the bike, and how the chosen finish will age with exposure to sun and road grime. There is also consideration of maintenance. ABS-based finishes, particularly those with UV stabilizers and protective clear coats, can be relatively straightforward to clean and polish. The risk of color fading is present, but a well-applied, durable finish can maintain its look for many seasons. Composites, with their potential for high gloss and a crisp, high-contrast edge line, demand careful finishing practices to maintain their performance aesthetics over time. In either case, a consistent finishing approach across all fairing panels helps maintain the bike’s cohesive appearance and aerodynamic integrity.

Fitment considerations should not be overlooked. The fairing’s geometry must align with mounting points, fasteners, and adjacent panels to prevent vibration, rubbing, or misalignment under load. Proper fitment ensures that vent screens and mesh grills remain effective, that edges align with nearby contours, and that color and texture transitions appear intentional rather than improvised. For riders contemplating upgrades, consulting official parts catalogs or trusted accessory providers can clarify compatibility with their machine’s year and trim. While the materials set the stage, the installation quality determines whether the theoretical benefits translate into practical, ride-ready performance. This is why many riders value the guidance of experienced technicians and reputable suppliers who understand how the lower fairing integrates with the bike’s overall aerodynamics, electrical routing, and cooling strategy.

The broader aftermarket ecosystem reflects a clear desire for customization without sacrificing the mechanical integrity that performance-oriented riders expect. Even when opting for a generic ABS-based panel, riders can select vented or non-vented designs, choose a finish that highlights or tones down the fairing’s presence, and consider how the panel will age in sun and weather. The range of options supports diverse riding styles—from long-distance touring where quiet operation and wind protection matter most to sportier cruising where venting, edge definition, and surface luster contribute to the machine’s character. In this context, the lower fairing becomes a canvas for personal expression that remains faithful to the bike’s core design language.

For readers seeking further exploration of how different brands approach fairings and to compare generic market options, a broader catalog exists that illustrates how various manufacturers address similar design challenges. This broader look can provide perspective on geometry, venting strategies, and finishing choices, helping riders understand why certain features appear universally while others remain brand-specific choices. As a reference point, you can explore the BMW fairings collection to see a parallel approach to form and function across different engineering philosophies. BMW fairings collection.

As a practical observation drawn from field experience and the curated literature cited in this chapter, the material backbone of Indian lower fairings is designed to endure with grace. ABS-based solutions deliver dependable performance with a wide aesthetic reach, while composites offer a potential upgrade path for riders who demand higher stiffness and more aggressive aero behavior. The finishes—ranging from satin black to chrome accents or factory-matched coats—provide a visual vocabulary that lets riders express their intent. Whether the aim is understated efficiency or a bold, sport-focused statement, the lower fairing plays a central role in shaping both the ride and the look. It protects, it directs, and it completes the silhouette that follows the rider’s gaze as they ride toward the next horizon. For those who want tangible detail about how finish level can influence the perception of speed and air pressure around the bike, the practical realities of material choice and surface treatment offer a useful map to what is possible on a modern touring machine.

External resource reference: For a real-world listing that exemplifies how lower fairings are marketed and described in a commercial context, see the Amazon listing referenced in the detailed materials for this chapter. External resource: https://www.amazon.com/dp/B07VZJQXWY

Factory Precision or Custom Potential: A Deep Dive into Indian Motorcycle Lower Fairings

Lower fairings do more for a motorcycle than simply dress its belly. On Indian motorcycles, these lower panels serve as a confluence point where form meets function. They sculpt the airflow around the machine, guiding it to reduce turbulence and pressure buildup under the chassis, while also directing wind in a way that can soften rider fatigue on longer rides. For models that sit near the edge of speed and comfort, like touring-focused or performance-oriented variants, the lower fairings become a practical extension of the bike’s overall design philosophy. Aerodynamics matters not just for speed, but for stability, heat management, and even throttle response at higher cruising velocities. In the weathered dance between air and metal, the lower fairings act as a shield for the rider and a keeper of the machine’s character, preserving the silhouette the manufacturer envisioned and the experience the rider seeks. This nuanced role helps explain why the choice between OEM components and aftermarket options deserves careful consideration, even for riders who are more focused on riding than tinkering.

The decision between OEM and aftermarket lower fairings rests on a balance of fit, quality, cost, and aesthetics, all within the context of how the bike is used. OEM components are built to a factory script: they must align with every other piece of the bike’s architecture, with tolerances calibrated to preserve not just fit and finish, but the subtle lines and gaps that give a motorcycle its visual coherence. When a rider looks for that seamless, factory look, OEM lower fairings deliver. The paint match, texture, and curvature are tuned to the original factory finish, and the installation is designed to be straightforward without the need for custom modifications. Beyond appearance, the durability of OEM parts is anchored in the same quality controls that govern the rest of the model line. In a world of variables—ambient temperature, moisture, UV exposure, and road debris—a part that leaves the factory floor is a known quantity, tested and certified to perform within the bike’s own ecosystem. The upshot is a risk profile that tends toward reliability and predictability, which is particularly valuable for riders who depend on consistent performance and a straightforward maintenance path.

That predictability comes with a price. OEM lower fairings typically sit at a higher upfront cost, reflecting the investment in precise fit, color matching, and the assurance of seamless compatibility with the bike’s other bodywork and systems. The trade-off, however, is not merely financial. The installation experience—tight tolerances, exact screw locations, and a finish that bypasses color corrections—often means faster, easier assembly and fewer surprises during the refit. For those who value resale value and an unbroken factory aesthetic, the OEM route is the most straightforward path to preserve the bike’s original narrative. The aesthetic consistency is not just about color or texture; it extends to how the fairing integrates with the tank, the side panels, and the engine bay’s lines. The result is a look that feels as if the bike had never changed hands, a continuity that many riders prize when they visualize the machine as a single, coherent instrument.

On the other side of the ledger lies the aftermarket approach, which can expand both the look and the performance envelope of the motorcycle. Aftermarket lower fairings embrace variety—different lines, materials, finishes, and vent configurations—turning a stock silhouette into a canvas for personalization. The appeal is twofold. First, design variety allows riders to express a personal taste that aligns with their riding persona, whether that persona emphasizes aggression, elegance, or a rugged, sport-inspired vibe. Second, the performance-oriented features that some aftermarket options bring to the table can yield tangible gains. Venting architectures, mesh screens, and optimized channeling can influence airflow and cooling, contributing to a calmer engine bay and more refined under-bike pressure management. In some setups, vented designs do more than reduce drag or raise efficiency; they actively participate in cooling, helping to maintain optimal operating temperatures under demanding conditions. The potential upside is a bike that not only looks the way the rider wants, but also breathes and behaves more efficiently in real-world riding.

Yet the aftermarket path is not without its caveats. With the wider design and material palette comes a degree of variability that can complicate fitment and consistency. The range of plastics, resins, or composites used in aftermarket components can differ from OEM standards in rigidity, weather resistance, and long-term stability. The result can be minor misalignments, gaps that collect dust or moisture, or color shifts that show up under different lighting. Even when a design promises enhanced venting or airflow, the actual performance depends on how well the piece integrates with the bike’s telescoping structure, cable routing, and radiator or oil cooler inlets. In practice, a rider must weigh the allure of visual customization and potential airflow benefits against the possibility of a fitment compromise, more involved installation, or the need for additional refinements to preserve the bike’s overall balance.

The narrative of OEM versus aftermarket is richer when anchored to real-world contexts. In the spectrum of Indian motorcycles, the lower fairing is not simply a panel; it is part of the system that influences how the machine behaves during acceleration, at speed on highway stretches, or in the heat of city congestion. Consider the cases where the design team intentionally vented certain models to prevent pressure from accumulating underneath, which, in turn, reduces flutter, enhances stability, and improves rider comfort by cutting wind blast. A vented design can materially change the way the bike feels when you push through a long, sustained ride. The same concept applies to the way a rider perceives the bike’s weight distribution at speed—the lower fairing’s geometry can subtly shape how the machine settles into a straight line and how it responds when steering inputs are applied at higher speeds. OEM designs have the advantage of precise alignment with the bike’s frame and body lines, ensuring that those subtle dynamics are preserved. Aftermarket alternatives can achieve similar goals but require more careful consideration of fit and integration with the rest of the bodywork and mechanical systems.

To ground this discussion in concrete considerations, it helps to think through a few practical dimensions. First, fitment. OEM lower fairings are engineered for a given model year, with exact mounting points and compatible hardware that minimize the risk of warping or misalignment. A well-fitted OEM panel preserves the bike’s aerodynamic envelope, ensuring that the fairing’s edges sit flush against the fairing mounts and that the line transitions from tank to side panels remain crisp. In contrast, aftermarket options come in a broader range of construction methods—some using robust ABS, others fiberglass or composite blends. The result can be a wider tolerance band. In some cases, better-fit aftermarket panels require additional trim or heat-shielding steps, while others snap into place with a similar level of ease to OEM parts. The rider who prioritizes ease of installation and a factory-like finish may find OEM more appealing, whereas someone seeking a unique look or a targeted performance tweak may be willing to invest the extra time required for a precise fit.

Second, material quality and finish. OEM parts are selected to endure the rigors of daily riding and seasonal exposure. They tend to resist warping, fading, and micro-cracking more predictably than some aftermarket composites, especially those sourced from smaller suppliers or non-traditional manufacturing partners. The trade-off is a narrower selection of textures or finishes, which may constrain a rider’s ability to perfectly match color or gloss levels with the rest of the bike. Aftermarket lower fairings, by contrast, can deliver bold, distinctive looks and a broader spectrum of finishes. Some riders value this freedom as a route to a truly one-off machine that stands out in the crowd. Others may encounter finishes that age unevenly or require careful color matching under varying light conditions. A practical approach is to assess whether the desired aesthetic is compatible with the bike’s existing color family and whether the finish can be maintained within the rider’s preferred maintenance routine.

Third, maintenance and durability. OEM panels are generally designed to withstand routine scrapes and the occasional encounter with road debris, and their finisher coatings are chosen to hold up to UV exposure and cleaning solvents used by the dealer network. Aftermarket parts may vary in impact resistance and surface coatings. Some riders report that certain aftermarket fairings can be more brittle in colder weather or more flexible in high-heat environments, depending on the material. Others find that the vented channels and mesh grids, while offering better cooling or improved airflow, require more frequent inspection to ensure the vents remain clear and unobstructed. In practice, the most durable choice is often a balance: a robust stock panel for those who expect a lot of mileage with minimal fuss, or a credible aftermarket solution for riders who are after a distinct look and a targeted performance gain—provided they are prepared to invest the time to verify fit and maintain the system.

The conversation around value is nuanced. For some riders, value means preserving the bike’s resale and perpetuating the factory feel; for others, it means maximizing personal expression and leveraging design tweaks that yield performance advantages. This nuance matters because it reframes the decision from a simple price comparison to a broader assessment of how a chosen lower fairing aligns with a rider’s goals. The seller’s side of the equation—whether a dealer or an independent shop—can also shape the experience. OEM components often come with factory-backed warranties and a clear service path through authorized networks, which can simplify future repairs or replacements. By contrast, aftermarket options may carry their own warranties, but the coverage can vary by supplier and the scope of installation work required. Riders considering long-term ownership or frequent modifications may weigh the reliability and service ecosystem differently than those who plan to keep their bike stock for several seasons.

The practical impact on ride quality is a thread that weaves through this analysis. A lower fairing that fits well and integrates cleanly with the rest of the bodywork can reduce wind pressure against the engine bay and undercarriage, which in turn can affect stability and even heat management. Even small changes in airflow around the chassis can influence how the bike responds to gusts or crosswinds, how it handles at high speeds, and how much wind blast the rider experiences. If venting is a feature, it is essential to consider how the vent paths align with the engine’s cooling needs and how the mesh or grills interact with stray debris. A well-engineered vent system contributes to a smoother, more controlled airflow, which can translate into a more confident ride, particularly on long highway stretches or aggressive canyon runs. The difference may be subtle in ordinary riding, but on the edge it can be meaningful.

Nearing the end of the decision tree, many riders discover that the choice between OEM and aftermarket is not a single moment but a process of alignment. It starts with acknowledging what you want from your machine: a factory-perfect appearance, predictable service and warranty coverage, or a bold personal statement and a potential performance edge. It continues with a practical evaluation of your bike’s current setup and how a new lower fairing would interact with it—frame, radiator inlets, belly pan integrity, and even the stance created by the side panels. Installation considerations matter as well. An OEM piece is expected to go in with minimum fuss, while an aftermarket unit may require a few precision tweaks—perhaps trimming edges or reconfiguring mounting points—to achieve a consistent fit. If you’re a rider who values slip-free, straightforward maintenance, the OEM path often offers more comfort. If your goal is to shape the bike’s character and optimize airflow in a personalized way, an aftermarket option can be a compelling avenue, provided you approach the upgrade with a clear plan for fitment verification and ongoing care.

In the end, the chapter of a motorcycle’s life—especially one as expressive as an Indian model with its renowned blend of performance and presence—will always be written by the rider’s choices around the fairings. The lower panel is not just a shield; it is a statement about how the bike is used, how it is perceived, and how its operator wants to interact with the machine at speed. The difference between factory precision and customized potential is, in many ways, a reflection of riding philosophy: whether you chase the serenity of a seamless, factory-kept workflow or the thrill of a tailored, performance-conscious silhouette. Both paths can deliver a rewarding riding experience; the key lies in clarity about priorities and in a careful, informed approach to sourcing, fitting, and maintaining the panel that defines the bike’s lower visage.

For riders who want to explore the breadth of options and get a sense of how different brands handle fairings, the broader market offers a spectrum of finishes and venting concepts that can inform a decision about Indian motorcycles as well. If you’re curious about the breadth of aftermarket lines and how they compare in terms of design language and build quality, a look at various fairing categories across brands can be instructive. The underlying lesson remains constant: the lower fairing is a critical component that shapes aerodynamics, heat management, and style, and the choice between OEM and aftermarket should be guided by how these factors align with your riding goals, maintenance preferences, and long-term ownership plans. A thoughtful approach to this choice ensures that the bike’s lower body remains a confident and cohesive element of the overall machine, rather than a compromise between aesthetics and function.

Internal link: For a broader sense of how aftermarket lines vary in fit and finish, explore the Honda fairings category. This can provide a helpful benchmark for material choices, finish quality, and installation approaches that riders may encounter when evaluating Indian lower fairings. Honda fairings category.

External resource for further reference: For official fitment details and authentic OEM guidance, refer to the manufacturer’s product listing and installation specifications, which offer model-specific information and mounting references. https://www.indianmotorcycle.com/en-us/vehicle-parts/accessories/outer-lower-fairing-left-blksmok.html

Final thoughts

In conclusion, Indian motorcycle lower fairings represent a blend of style and functionality that significantly contribute to rider experience. Understanding the aerodynamic advantages they offer, alongside the diverse material and aesthetic choices available, enables business owners to better cater to their customers’ preferences. The comparative analysis between OEM and aftermarket options reveals market opportunities for retailers looking to provide well-informed choices to their clientele. By integrating this knowledge into sales strategies, businesses can enhance customer satisfaction and drive sales in the competitive motorcycle accessory market.