The motorcycle industry continues to evolve, with innovations that cater to both aesthetics and functionality. One such advancement is the detachable motorcycle fairing, which provides motorcycle enthusiasts and business owners with the opportunity to enhance both the appearance and performance of their rides. This feature is particularly valued by riders looking for versatility without compromising on comfort. In the following chapters, we will explore the aesthetics and functionality of detachable motorcycle fairings, delve into the critical aspects of installation and compatibility, and examine current market trends to provide a comprehensive overview of this exciting component.

Detachable Fairings: The Seamless Confluence of Aerodynamics, Aesthetics, and Adaptability

A detachable fairing is not merely a piece of bodywork; it is a design philosophy that treats the motorcycle as a living, evolving tool rather than a fixed sculpture. In riding culture, where the open road tests human stamina as much as mechanical limits, the ability to reconfigure the bike for the moment becomes a form of expressive technology. The detachable fairing embodies a quiet pragmatism: riders can tune wind protection, weight distribution, and aerodynamic efficiency without surrendering identity or style. This fusion of form and function is what makes detachable fairings compelling, even transformative, for those who use motorcycles as both transportation and conversation with the road.

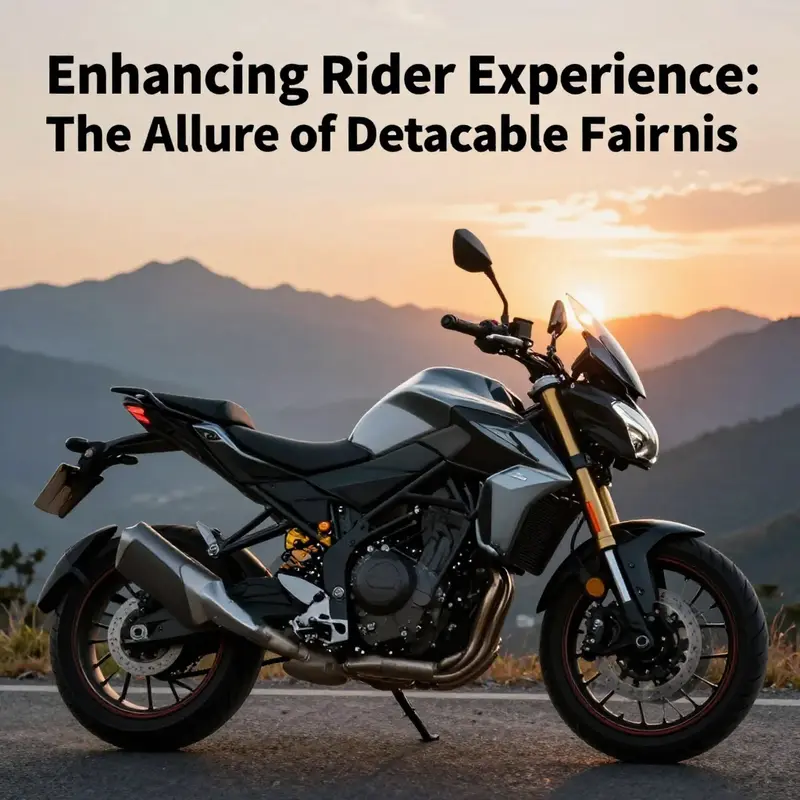

The heart of the concept lies in balance. On long stretches of highway, the road becomes a wind instrument, and the rider is the player who must modulate the air column. A well-designed detachable fairing channels air with precision, reducing the energy that would otherwise couple with the rider’s body, shoulders, and wrists. The wind is guided past the cockpit, over the shoulders, and away from the chest, inviting a calmer, more controlled posture. This reduction in buffeting translates into tangible benefits: less fatigue after hours in the saddle, steadier hand control, and greater confidence when speeds climb or headwinds intensify. In city riding, where stop-and-go and micro-murling gusts define the rhythm, the same fairing can be removed to reveal a cleaner silhouette and a lighter, more playful chassis feel. The rider’s relationship with the machine changes in an instant, and that relational shift is where the technology becomes more than a mechanism; it becomes a partner in the rider’s ongoing story.

Aesthetics and performance are not opposing forces in this design paradigm; they are two faces of a single system. The visual language of detachable fairings tends toward clean, modern lines that emphasize the bike’s underlying architecture. The outer panels skim the air with slim curves, while the inner structure remains robust enough to serve as a protective envelope for vital components. The result is a sleek profile at speed and a sculptural presence when parked, a quiet confidence that speaks to the rider’s attention to detail. Custom finishes—ranging from smooth, untextured gloss to tactile textures that catch the light differently—offer personalization without compromising aerodynamic integrity. The ability to swap finishes, colors, or subtle accents allows a rider to express mood, season, or personal taste without the need to alter geometry or core components. In this way, the detachable fairing doubles as a canvas for identity, while remaining loyal to the bike’s structural proportions.

The technology behind detachable fairings is, at its core, about modularity. A common concept is the two-piece approach: an inner shell that anchors to the chassis and a detachable outer shell that serves as the visible skin. This arrangement benefits maintenance, customization, and acoustic control. When the outer shell needs repair or a new appearance, it can be swapped without disturbing the inner shell’s alignment with the bike’s frame. The inner shell, meanwhile, keeps essential systems—electrical wiring, sensors, radiator pathways, and mounting points—protected and accessible for service. The modular strategy reduces downtime and waste, allowing riders to refresh the look or adjust the wind management characteristics without a full component replacement. It is an approach that mirrors other modern industrial design practices, where systems are designed to be disassembled, upgraded, and reassembled in future configurations with minimal disruption. The philosophy here is durability through adaptability, a recognition that a motorcycle is not a single snapshot but a continuum of riding conditions and personal preferences.

Among the most practical benefits of detachable fairings is wind protection that can be tuned to the rider’s needs. Long-distance cruising benefits from wind deflection that reduces fatigue and shields the rider from direct wind pressure on the chest, shoulders, and head. At higher speeds, stabilizing the air flow around the torso helps maintain a smoother posture and reduces the dynamic load on the neck and lower back. But the same fairing can be removed to reduce wind pressure and air resistance in situations where the rider seeks a more direct, naked-bike feel or a lighter, quicker handling response in urban environments. The ability to switch configurations on the fly means the rider can adapt to weather, season, and road type without compromising comfort or safety. This adaptability also translates into practical advantages for protection of mechanical components. The fairing acts as a shield against road debris, water spray, and dirt, keeping critical parts cleaner and reducing the likelihood of contamination that could affect performance or reliability. When the weather shifts, the ride quality responds accordingly, reinforcing the idea that the fairing is not just a cosmetic feature but a functional envelope for both rider and machine.

Designers approach detachable fairings with a careful eye toward compatibility. The goal is to maintain the bike’s original character and geometry while integrating a flexible docking system that can accommodate a range of configurations. Compatibility is not a one-size-fits-all proposition; it is a model-specific design conversation that respects the frame’s geometry, mounting points, and airflow requirements. Alignment accuracy is critical. The docking points must engage with precision to ensure consistent reattachment and predictable aerodynamics each time the fairing is fitted. Because riders may change configurations in the field, the system often relies on tactile cues—clicks, detents, and well-defined alignment marks—that guide the user to a secure, repeatable fit. This reliability supports rider confidence, making the transformation feel as natural as removing and installing any non-essential accessory. The result is a seamless blend of engineering discipline and rider empowerment, a hallmark of a mature approach to bodywork that transcends mere aesthetics.

The modular design also opens opportunities for personalization that go beyond color and texture. Hidden audio modules, integrated storage, or discreet instrument housings can be incorporated without altering the fairing’s external silhouette. In practice, this means riders can add features that enhance comfort and enjoyment while preserving the clean lines that attracted them to the system in the first place. The ability to conceal technology within the fairing’s structure aligns with a broader design principle: keep the surface language simple and let the hardware live in the interstices, ready to be deployed when needed. This approach preserves elegance and reduces visual clutter, especially important on bikes whose identity rests on a crisp, cohesive look. Personalization becomes less about projecting a brand message and more about shaping an experiential space around the ride—one that respects the rider’s preference for speed, comfort, and ambience.

Material science plays a significant role in how detachability is achieved without compromising strength or safety. Modern fairings leverage composites and thermoplastic materials that balance stiffness, impact resistance, and weight. The choice of material influences how cleanly the outer shell can detach and reassemble, how well it resists weather exposure, and how it behaves under stress during riding. A well-chosen material provides a smooth surface for aero performance while offering resilience against road-rash in a tip-over scenario or debris impact. The inner shell, designed to bear the brunt of mountings and connections, benefits from engineered laminates or reinforced plastics that resist fatigue over time. The synergy between materials and geometry is what makes detachable fairings durable enough for daily use and adaptable enough to accommodate evolving rider needs. In sum, material science is the quiet engine behind the practical magic of rapid transformation, safety, and longevity.

The conversation about detachable fairings inevitably touches on maintenance and lifecycle considerations. A primary virtue is accessibility. When routine checks, cleaning, or minor repairs are necessary, the modular arrangement makes access simpler without disassembling the entire unit. Fasteners, seals, and latch mechanisms are designed to be robust yet serviceable, so wear can be monitored and addressed promptly. Weather sealing remains a critical concern; designers emphasize seals and gaskets that prevent water intrusion while allowing relatively easy disassembly when needed. This balance—ease of service without sacrificing weather protection—ensures the system remains reliable over time, even as exterior finishes and internal layouts are updated to reflect new styling directions. The lifecycle narrative for detachable fairings extends beyond a single riding season. The modular approach invites a gentle, ongoing evolution: a rider may change finishes, add discreet features, or revise the way air is managed as riding habits shift. Rather than discarding a complete assembly, the rider can curate a sequence of configurations that reflect growing expertise, changing needs, and a deeper appreciation for the interplay between wind, weight, and mood.

There is also a cultural dimension to detachable fairings that deserves attention. The rider who chooses this path often seeks continuity between performance and tradition. A fairing that can be removed to reveal a classic silhouette speaks to a desire to honor the machine’s lineage while embracing modern engineering. It is a sonic reminder that bikes are not solely about speed or showroom polish; they are instruments for personal expression, capable of morphing to reflect the rider’s current priorities. This duality—the push toward aerodynamic efficiency and the pull toward timeless aesthetics—defines a narrative in which detachable fairings are more than attachments. They are statements about how a rider wants to live with a machine over time. The chapter’s throughline is simple: a detachable fairing is a practical answer to a rider’s evolving relationship with wind, road, and self. It offers a disciplined path to balance, where form and function reinforce each other rather than compete for scarce attention.

To appreciate the breadth of this approach, one can imagine how a rider might navigate through a season with an evolving sense of purpose. In spring, a rider may opt for the full aerodynamics package to maximize stability during longer commutes, saving energy and keeping weather at bay. As summer heat intensifies and traffic patterns shift, a lighter configuration becomes appealing, enabling more direct interaction with the road and a heightened sense of control. In autumn and winter, the weather protection of the fairing can be tuned to deflect chill winds and shield exposed components from damp conditions. Across these transitions, the docking hardware remains the steady interface by which the rider engages with the machine’s adaptive front end. The system’s beauty lies in its predictability and resilience: once aligned, it behaves as a trusted partner that respects the rider’s choices while preserving the bike’s core personality.

The broader significance of detachable fairings, then, is not simply about changing appearances or chasing the latest trend. It is about acknowledging that riding is a dynamic experience, one that invites repeated reconfiguration as conditions, ambitions, and daily rhythms change. The detachable fairing becomes almost a platform for experimentation—where riders can explore different wind environments, soundscapes inside the cockpit, and even slight changes in perceived geometry without committing to a permanent redesign. It invites a more mindful approach to customization, one that values interchangeability, careful fitment, and a thoughtful selection of finishes. And because this approach respects the bike’s architecture, it preserves the integrity of the rider’s investment: the vehicle remains coherent, safe, and reliable across a spectrum of configurations. In this light, the detachable fairing is not a peripheral add-on but a central element of modern riding practice—an instrument of adaptation that makes the bike feel less like a static machine and more like a responsive companion.

For readers seeking practical pathways to engage with this concept, it helps to consider the ecosystem around detachable fairings as a holistic system rather than a collection of independent parts. The docking interface is as important as the shell it holds; the fasteners, seals, and alignment features work in concert to deliver repeatable performance. Maintenance planning should account for periodic inspection of mounting points, seal integrity, and the condition of the outer shell’s finish. The choice of finish—whether to emphasize gloss, satin, or textured surfaces—should align with the rider’s broader aesthetic goals, ensuring that the fairing harmonizes with the bike’s other visual elements. The opportunity to customize extends beyond color and texture; it includes interior options for storage, sound, or instrument integration that respect both safety considerations and the rider’s desire for a coherent, unified look. In practice, the rider’s journey with a detachable fairing is an ongoing collaboration between person, machine, and road, a dynamic triad that thrives on thoughtful adjustments rather than dramatic, one-off transformations.

One practical note about sourcing and fitment is that, in a real-world context, compatibility often hinges on precise mounting geometry and the intended interaction with the bike’s electrical and braking systems. While the idea of a universal solution is appealing, the reality is more nuanced: certain configurations are tuned to particular chassis families, and the alignment of the docking points must be exact to maintain structural integrity and aerodynamic performance. This nuance does not diminish the appeal; it simply grounds it in a reality that professional designers and skilled riders share. The promise of detachable fairings remains strong: a single, well-conceived platform can accommodate a range of rider needs over time, preserving both performance and personality. The rider’s ability to swap between configurations without sacrificing safety, comfort, or style is a direct outcome of thoughtful engineering, meticulous testing, and a clear sense of rider-centered design. The result is a product category that does not demand compromise but instead invites continual refinement.

As this conversation advances, it is useful to situate detachable fairings within the broader arc of motorcycle design history. They represent a natural extension of a long-standing tradition: to adapt form to function without erasing identity. The modern detachable system embodies the same impulse that has driven motorcycle evolution for decades—to push the machine toward being more than the sum of its parts, to make technology feel inevitable in the hands of the rider, and to keep the road in harmonious conversation with the rider’s intentions. In this light, detachable fairings are less a trend and more a durable instrument of versatility, capable of translating a rider’s day into a sequence of comfortable, controlled, and visually cohesive experiences. They remind us that riding is a choreography of air, metal, and will—a choreography that becomes richer when the surface that shapes it can be shaped again and again, in small steps or bold shifts, as the road unfolds.

For those curious to explore related avenues of choice and design, the broader ecosystem of fairings offers a spectrum of options, from fully enclosed shells to minimalist panels that emphasize naked-bike lines while still offering targeted wind protection. The key is to balance the rider’s aspirations with the bike’s inherent geometry and the practical realities of maintenance and use. The detaching and reattaching process, when well-executed, becomes almost routine, as natural as flipping a switch or adjusting a clicker on a windscreen. It is a ceremony of customization that honors the rider’s agency while preserving the machine’s identity. The outcome is not simply a different look or a marginal gain in comfort; it is a renewed sense of control, a subtle re-tuning of how the bike meets air, motion, and weather. The detachable fairing, therefore, stands as a thoughtful, integrated solution—part technology, part craft, part personal ritual—that elevates riding from a passive experience to an active partnership with the road.

To deepen understanding and broaden practical knowledge, readers can explore curated resources that discuss OEM-leaning, model-specific considerations, and general principles of aerodynamics in motorcycle design. For a deeper dive into category-wide considerations and compatible options, you can explore the Honda fairings category, which offers a spectrum of fairing components and related accessories that illustrate how modular front-end design can be approached across different platforms. This link provides a lens into how standardized interfaces and thoughtful fitment enable riders to achieve both aesthetic cohesion and functional adaptability: Honda fairings.

As the road travels under the wheels, the detachable fairing remains a quiet partner in the rider’s evolving practice. It is a device of restraint and release, offering restraint where wind and weather demand it and release where the rider seeks simplicity or a different visual language. It is, at heart, a practical artifact that respects both the rider and the bike’s shared journey, letting wind, light, and color converge into a riding experience that is as personal as it is mechanical. In this sense, detachable fairings do more than shield or shade; they invite a continuous conversation between human intention and machine capability, a conversation that unfolds with each mile and each new configuration. And in the hands of a rider who values adaptability as a core principle, the fairing becomes not a fixed shell but a living interface—one that keeps pace with changing roads, shifting seasons, and the enduring desire to ride with both purpose and style.

External reference for further reading: Rock N’ Roll Highway – Detachable Fairings. https://www.rocknrollhighway.com/detachable-fairings

Aligned for Adventure: Installation Precision and Compatibility in Detachable Motorcycle Fairings

Detachable motorcycle fairings offer a practical诉and often transformative way to tailor a bike’s silhouette, wind management, and overall character to a rider’s journey. The promise is straightforward: a streamlined, aerodynamically efficient profile for highway miles, and a cleaner, classic look when the road narrows to city streets or when the wind and sun dictate a different mood. But that promise rests on a foundation of careful installation, exacting fit, and a thoughtful approach to compatibility. A detachable fairing is not simply a cosmetic accessory; it is a system of parts that must cooperate with the bike’s headlight housing, steering geometry, and internal routing of cables and lines. The success of such a system hinges on meticulous alignment, precise mounting, and a clear understanding of how every component interacts with the bike’s native architecture. When these elements align, the rider experiences not only improved aerodynamics but a sense of confidence that the machine behaves as a single, well-tuned instrument rather than a fused afterthought.

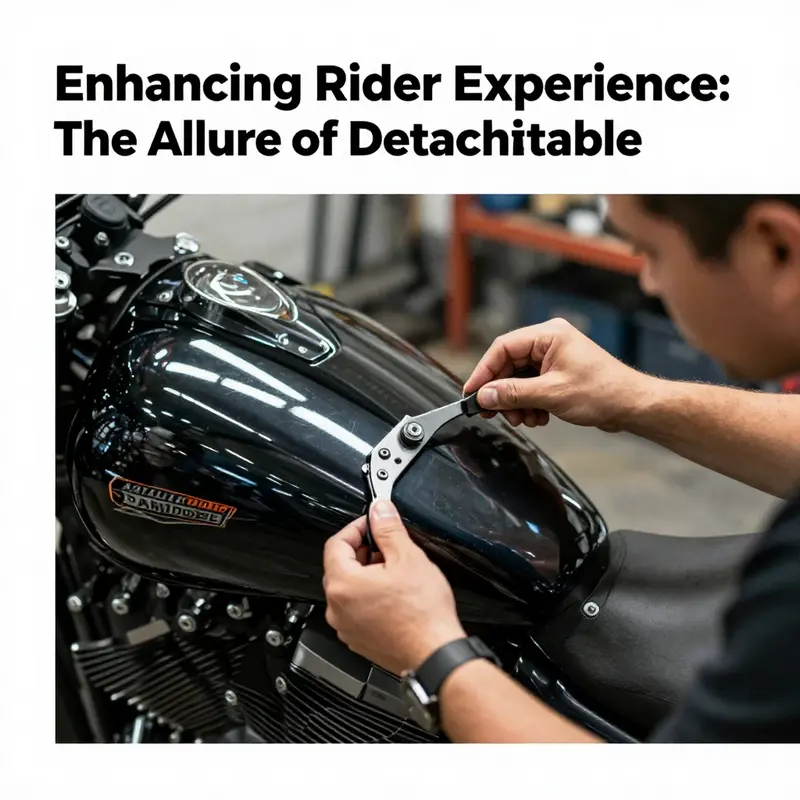

The process begins long before any wrench touches metal. It starts with fitment verification. Motorcycle builders and serious enthusiasts recognize that a fairing’s effectiveness is inseparable from how it sits in relation to the headlight, the fairing’s own window of motion, and the rider’s posture. Even a discrepancy as small as a few eighths of an inch can propagate a cascade of effects. A slight tilt or misalignment of the fairing can create a marginal increase in drag, produce buffeting at certain speeds, or alter the wind line that travels past the rider’s chest and helmet. These are not merely comfort complaints. They can translate into fatigue over hours on the road and, in worst cases, interference with steering inputs or control feel when shock and fork travel compress through rough pavement. The aim is to thread the line between rigidity and adjustability so the fairing remains secure without binding or vibration while allowing a tiny bit of in-motion adaptability to respond to rider repositioning, helmet size, or a change in seating position.

In practical terms, installation is a study in precision. A conventional detachable system relies on a dedicated docking hardware kit—often a four-point or similarly distributed interface—that anchors the fairing to engineered points on the frame or fender area. The docking system is designed to bear the load of wind pressure and vibration while maintaining consistent alignment across the fairing’s perimeter, windshield, and surrounding components. The first checkpoint is the bike’s mounting surface: is it clean, flat, and free of debris that could create microgaps once the fairing is clamped in place? The counterpoint to cleanliness is the necessity of protection. The mounting points must be free of corrosion or any foreign material that could deform under torque or heat cycling. A clean start reduces the risk of misalignment and ensures consistent torque on the fasteners.

Next comes precise alignment with critical geometries. The headlight housing is not just a beacon for night riding; it is a fixed reference point from which the fairing must derive its central line. The fairing’s centerline should mirror the bike’s longitudinal axis so that wind deflection is symmetrical and predictable. This alignment is not a matter of aesthetics alone. In the worst case, misalignment could skew the beam pattern, reduce the effectiveness of wind deflection, or introduce stray air currents that find their way around the edges, causing turbulence that reverberates up toward the rider’s helmet. To achieve proper alignment, technicians and experienced riders check multiple references: the gap between the fairing edge and the headlight bezel, the symmetry of the left and right fairing flanks at eye level, and the vertical alignment of the windshield relative to the rider’s line of sight. A discrepancy as small as 3/8 inch—an amount that might seem negligible on a tape measure—can become noticeable at highway speeds. Onerous as it may seem, the remedy is straightforward: re-check the docking points, re-seat the fairing, and re-torque the fasteners to manufacturer-specified values, ensuring that the system sits evenly without any binding before the wind is introduced.

Handlebar clearance is another essential dimension. The rider’s reach and the handlebars’ sweep interact with the fairing’s side panels and upper shrouds. If the fairing presses against cables, brake lines, or the tops of the fork legs, vibrations and chafing can occur, which not only damages the components but degrades the ride experience. When clearance is marginal, a rider might notice a slight rubbing as the front wheel turns or as the suspension cycles through its travel. The fix is not simply to bend a panel; it is to adjust the docking hardware or reposition the fairing within its allowed tolerances so that every line and hose maintains its intended route. Again, this is why choosing a docking system that is designed for compatibility with the specific bike model matters as much as selecting the right fairing style. The goal is a clean, breathable space around every connection, where movement is smooth, but the overall assembly remains rock-solid at speed.

Beyond the headlight and handlebar considerations lie the subtler pathways—roughly the routes that carry the bike’s electrical harness and, where applicable, hydraulic or pneumatic lines. The fairing’s installation must respect these routes, avoiding any tight bends or points where a line could kink or wear over time. A line that curves tightly around a corner or lingers near a sharp edge is a signal that the mounting system or fairing geometry needs adjustment. These routing concerns are not cosmetic; they are protective measures against long-term failure. The system should maintain ample slack where needed for flex and articulation, plus adequate protection against heat from the engine and exhaust, which can soften plastics or degrade seals over extended periods. The narrative here is not about adding complexity for its own sake; it is about ensuring reliability in the long arc of ownership, where wind, rain, heat, and vibration all leave their marks.

The interplay between aftermarket options and factory-fitment realities is a recurring theme in any discussion of detachable fairings. A well-designed docking system anticipates a degree of cross-compatibility, but a universal standard is rarely present. The reality is that compatibility is often model-specific and year-specific—an offset in mounting points, a slightly different curvature of a fairing panel, or a distinct angle of windshield geometry can make all the difference between secure fit and frustrating wiggle. The prudent rider or installer treats fitment details as sacred. Reading the official fitment charts and installation manuals for the exact bike and year is not a formality; it is the foundation of a durable, reliable assembly. For some combinations, the manufacturer will offer a complete package that bundles docking hardware and fairing panels in a curated system. In others, the buyer will assemble components from multiple sources, which raises the importance of verifying the exact dimensions, mounting hole locations, and any warnings about interference with stock equipment such as a thunderstorm of lines, control cables, or sensors embedded in the fairing area.

It is also essential to understand the limits of compatibility when considering aftermarket parts. The literature and practical guides consistently emphasize that aftermarket components may not guarantee seamless integration with a detachable fairing system. Even with careful alignment, a mismatch in dimensions or a nonstandard clip point can create an inconsistent fit. The caution here is practical: always review installation instructions, confirm that the parts you plan to use are certified as compatible by the mounting system’s designer, and avoid improvisation that could compromise safety or performance. The result of careful verification is a system that behaves predictably under load. A well-fitted fairing does not merely sit on the bike; it works with the bike’s aerodynamics and its chassis geometry, smoothing the wind stream in a manner that reduces fatigue and improves stability at highway speeds.

From a rider’s perspective, the sensation of a properly installed detachable fairing is one of confidence. When the fairing is correctly docked, the wind settles into a predictable pattern, and the rider can tune wind pressure and deflection by adjusting the windshield angle. These adjustments are not cosmetic levers; they are functional tools that adapt to the rider’s height, seating position, and riding style. For long-distance journeys, this adaptability translates into a more comfortable ride, reduced helmet buffeting, and less stress on the upper body. In everyday riding, the same system can deliver a cleaner appearance, lower wind noise, and a silhouette that suits the rider’s mood without compromising safety. The dual nature of detachable fairings—form and function—depends on precise installation, rigorous fitment checks, and disciplined adherence to compatibility guidelines.

To ground these considerations in the broader landscape of the riding ecosystem, it helps to think of docking hardware as a modular interface rather than a single part. The four-point or similarly distributed docking system is designed to bear the aerodynamic and mechanical forces the bike experiences while allowing controlled disassembly. This concept mirrors the idea of modular vehicle customization in other domains: a stable, repeatable interface, defined tolerances, and clear installation sequences reduce the risk of misalignment after a reconfiguration. In practice, the installation workflow often begins with securing the docking hardware to its mounting points, followed by attaching the fairing’s primary panels, then performing a staged alignment pass that checks both front and rear contact points. Finally, the system is torqued to specified values, and a field test is conducted to ensure there is no inadvertent contact with moving parts or braking components. The rider’s own workflow—whether they prefer to detach the fairing for a quick city ride or keep it mounted for a long road trip—should be reflected in the maintenance cycle: inspect docking connections, verify alignment after a few thousand miles, and re-torque as recommended by the system’s guidelines. This discipline is not overly technical; it is practical and repeatable, designed to preserve the bike’s integrity and the rider’s sense of control over the machine’s character.

Another layer of consideration concerns the broader ecosystem surrounding detachable fairings. The compatibility discussion expands beyond the fairing itself to how it interacts with luggage systems, passenger accommodations, and even electronics like audio or navigation mounts. Some factory accessory packages are designed to integrate neatly with the docking hardware, providing a cohesive look and predictable installation steps. Others may present a blend of components from different suppliers that require careful cross-referencing of mounting points and hardware sizes. The aim remains consistent: a coherent system where every part is designed to work together. This holistic approach is especially important when a touring mindset is part of the rider’s goals—where protection from wind and weather, storage connectivity, and rider comfort converge. When a system is assembled with attention to how each piece contributes to the whole, the result is a silhouette that is as reliable as it is refined.

For riders who like to explore options and broaden their knowledge, engaging with the broader category of fairings can be a useful exercise. For example, the online catalog of motorcycle fairing options for different brands and models offers a spectrum of styles, mounting schemes, and wind management strategies. The intent is not to copy a particular design but to understand the vocabulary of fitment and the range of possibilities. A rider might begin by surveying the general alignment principles, then drill down into the specifics for their own bike as catalogued by the manufacturer or installer community. As part of this exploration, readers may wish to review a broader portfolio of fairing designs in related product categories, which can be found in category pages such as the Honda fairings page. This kind of cross-reference is not merely academic; it helps to crystallize the practical realities of different docking geometries and their implications for fitment, clearance, and long-term reliability. See more about Honda fairings here: Honda fairings.

Sound engineering practice also invites a conservative approach to test riding after installation. The initial test ride is not about carving the twisty sections at breakneck speed; it is about confirming that all connections remain secure under real-world loading, that there is no unwanted vibration, and that wind deflection behaves as predicted. The rider should listen for any droning noises, check for looseness in mounting points after a few miles, and observe whether the fairing remains aligned as the bike encounters road irregularities. If a notice arises—such as a shift in the fairing’s angle, a change in airflow, or a new rattle—the adjustment should be local and conservative, focusing on rechecking the docking hardware’s torque values, re-seating the fairing, and confirming that every path for cables or lines remains unbound. This iterative approach helps preserve the fairing’s performance across seasons, weather, and miles.

The dialogue about installation and compatibility is incomplete without acknowledging the vendor ecosystem. Some manufacturers offer complete, model-specific docking hardware with weight-rated fasteners and installation guides. In these environments, the fitment process is built around a curated set of components that are tested to function in harmony with the bike’s original geometry and with each other. In less standardized contexts—where riders assemble components from multiple sources—the onus is on the rider to perform due diligence: confirm that hole patterns match, verify that the panel curvature aligns with the frame’s lines, and check that the combined weight distribution does not introduce unintended load to the fork or steering head. It is a process that rewards patience and methodical verification. The ultimate objective remains the same: a detachable fairing that can be mounted, removed, and re-installed with repeatable confidence, without compromising the bike’s structural integrity, electrical routing, or ride quality.

In closing, the installation and compatibility journey for detachable motorcycle fairings is a microcosm of broader automotive and motorcycle customization practices. It invites a careful balance between engineering discipline and riding spontaneity. A well-executed installation is not merely a technical achievement; it is a commitment to the rider’s evolving needs—swiftly changing weather, shifting road demands, and the desire for a look that reflects the moment. The discipline of alignment, the rigor of fitment verification, and the respect for the bike’s internal pathways all converge to produce a system that feels like an integral part of the machine. The result is not just improved aerodynamics or a better-looking silhouette; it is a more confident, adaptable, and enjoyable riding experience. As riders continue to explore the boundaries of what detachable fairings can do, they will rely on the same principles that ground this discussion: precise alignment with critical references, careful management of docking points and routing, and a clear-eyed respect for compatibility. When these elements come together, the rider experiences a true fusion of form and function, where the bike’s character is enriched rather than constrained by the removable defense against wind. The journey from concept to road-ready configuration becomes a well-lit path that respects the bike’s native design while embracing the freedom that detachable fairings can offer.

External resource: https://www.harley-davidson.com/us/en/accessories/motorcycle-accessories/road-glide-limited-package.html

Switchable Skins and Market Currents: Trends, Mechanics, and The Growing Reach of Detachable Motorcycle Fairings

Detachable motorcycle fairings have moved beyond a niche convenience into a durable expression of a rider’s appetite for adaptability. They are more than just a quick cosmetic swap; they are a system that reconciles two seemingly opposing impulses in motorcycling: the desire for aerodynamic efficiency on open roads and the pull toward a clean, uncluttered cruiser silhouette when the mood or the setting shifts. The result is a product category that reflects a broader shift in motorcycling toward modularity and personalization, where the same machine can be tuned for distance, weather, or style in minutes rather than days. In this sense, detachable fairings are a microcosm of how riders think about their motorcycles today: not as a fixed artifact but as a flexible platform that can morph to suit the ride, the weather, and the rider’s mood.

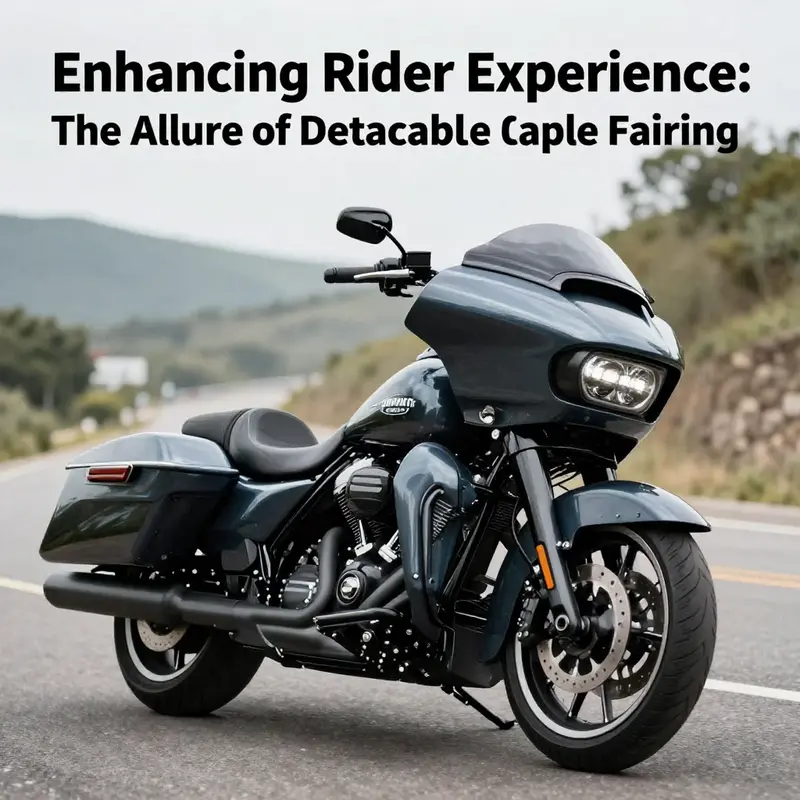

The market trajectory for detachable fairings follows closely the broader aspirations of modern riders to tailor performance and aesthetics without sacrificing convenience. When a rider embarks on a long highway journey, the fairing’s role expands from purely decorative to actively protective. The deflection of wind and the shielding of shoulders, arms, and upper chest become not just comforts but practical safeguards that influence fatigue levels and ride quality over hours, not minutes. The same rider, upon arriving at a city or returning to a boulevard, can reconfigure the bike to emphasize a leaner silhouette, reduced frontal area, and a more traditional, minimalistic presence. This dual utility—enhanced wind management on the highway plus a cleaner profile at the street—helps explain why detachable fairings have gained an audience beyond the sportbike or touring veteran crowd and have found a receptive market among riders who prize both performance and style.

In markets with a robust touring culture, including the long-standing cruiser-touring continuum, detachable fairings have become a focal point of customization options. The concept resonates particularly with riders who rack up miles and still value a bike’s personal aesthetic. A multi-point docking approach, with reliable quick-release capabilities, enables a fairing to be attached or removed in a short window, allowing riders to switch configurations in a single afternoon or even between stops on a single day. This practical flexibility aligns with a broader aftermarket trend that prioritizes user-friendly installation and secure, repeatable mounting. The result is an ecosystem in which windshields, fairing shells, and mounting hardware are designed to work together in an integrated manner, reducing the friction between concept and execution.

From a design perspective, detachable fairings sit at an intersection of function and form. On one hand, the system must deliver wind protection and engine shielding at highway speeds, maintaining stable deflection patterns and reducing buffeting. On the other, it must preserve or enhance the bike’s identity when the fairing is detached. This dual objective drives the geometry of the fairing itself, the curvature of the panels, and the relationship between the fairing and the cockpit. The windshield size, for instance, often centers around an 11-inch profile in common configurations, chosen for a balance between forward visibility and wind deflection. Compatibility with standard headlight setups, such as 7-inch units, is another practical consideration that expands the range of bikes that can benefit from a detachable system without requiring extensive electrical or cosmetic rework. These are not merely accessory choices; they are engineering decisions that affect handling, vibration characteristics, and the perceived value of the system for the rider who relies on it daily.

The market’s geographic breadth contributes to a wider set of expectations. In large, multi-region markets, aftermarket ecosystems flourish because riders expect consistent quality, reliable fit, and the ability to source mirror mounts, plug kits, and docking hardware through familiar channels. Accessibility has improved in tandem with digital ordering and robust in-store pickup options, allowing a rider in a regional town to assemble a complete detachable setup as readily as a rider in a metropolitan center. The modularity trend—where fairings, windshields, mirrors, and mounting racks are offered as compatible components—has lowered the barrier to entry for new riders and created a more inclusive marketplace for customization. It is this accessibility that underpins the segment’s resilience amid broader market fluctuations and supply chain voices that have tested the industry in recent years.

To understand the scale of interest, consider the broader motorcycle market’s size and trajectory. Global motorcycle market value hovered around a sizable figure in 2023 and is projected to grow toward a substantial milestone by the end of the decade. The post-pandemic rebound has been strong, with consumers continuing to invest in upgrades that extend a bike’s utility and personalize its character. The emphasis on aftermarket packages—windshields, fairings, mounting hardware, and even integrated mirrors—reflects a consumer appetite for tangible, modular upgrades that deliver immediate, observable improvements in comfort and daily usability. In particular, the aftermarket segment for fairings and related accessories has shown durable, double-digit momentum in several markets, reinforcing the idea that this is not a fleeting trend but a maintained preference among riders who value both performance and personal expression. The market’s expansion is not solely about selling more pieces; it is about strengthening the relationship between rider and machine by offering configurations that respond to changing needs without requiring a complete overhaul of the bike’s core structure.

Viewed through the lens of a rider’s practical needs, detachable fairings deliver benefits that extend beyond aerodynamics. They enable a more comfortable sit at cruising speeds, especially when the rider is tall or the road conditions demand a more controlled airflow. The shielding effect can translate into reduced fatigue on long trips, enabling longer rides with less physical stress. This is not purely a matter of comfort; it can influence how long riders stay on the saddle before they need a break—a subtle but meaningful factor in ride planning and overall satisfaction. In a culture that prizes both performance and longevity, the detachable fairing becomes a useful tool for managing rider stamina over extended journeys. Moreover, the aesthetic flexibility allows a rider to present the bike’s skin in a way that aligns with evolving tastes, neighborhood norms, or the mood of the season, creating a living canvas rather than a fixed sculpture.

From the perspective of the dealer and the aftermarket supply chain, the growth of detachable fairings has helped diversify the product mix and expand the range of compatible accessories. The pathway from a docking hardware kit to a fully functional, detatchable system is increasingly standardized across brands, reducing the complexity of a installation and enabling faster turnaround times for customers who want to switch configurations on a regular basis. The modular nature of these kits, the way panels and supports click into place with defined alignment points, and the ability to swap in windshields of varying heights or tint levels all contribute to a user experience that feels coherent and dependable. This consistency is vital for sustaining consumer confidence, particularly as new entrants enter the market with their own interpretations of what a detachable system should offer. In a landscape defined by rapid product evolution, reliability and ease of use become significant determinants of long-term adoption.

In the broader ecosystem of aftermarket options, the story of detachable fairings intersects with related categories such as fairing-mounted mirrors and integrated lighting solutions. These components extend the functional value of the system beyond wind protection. Mirrors mounted on the fairing, for example, provide improved visibility and a cleaner line for the overall silhouette, while integrated lighting can enhance conspicuity and rider comfort in low-light conditions. The interdependence of these elements underscores a design philosophy that favors cohesive systems rather than isolated parts. When a rider can source a windshield, fairing shell, mirrors, and mounting hardware from a compatible family of products, the perceived value rises—because the installation becomes simpler, the risk of misfit is reduced, and the final appearance is more harmonious.

In terms of price and value, consumers encounter a spectrum. Basic plug kits and simple mounting hardware can be accessible to a broader audience, offering a quick path to initial experimentation with detachable configurations. At the same time, premium, edge-cut or precisely engineered fairing shells and mounting solutions can command a higher price, reflecting advances in materials, finishes, and aero-tuning capabilities. The price ladder mirrors the performance and aesthetic payoff, giving riders a clear incentive to invest in a turnkey system or to build a customized setup piece by piece. This pricing reality supports a healthy, two-sided market: affordability and experimentation on one end, and durability and refinement on the other. The result is an ecosystem that invites both new riders and longtime enthusiasts to explore how different configurations can reshape the riding experience without requiring a full rebuild of the motorcycle.

The marketing narrative around detachable fairings also benefits from the way the product category speaks to a rider’s evolving identity. People who begin with a windscreen or a small fairing often discover that the modular system offers a gateway to greater personalization. They may start with a stealthier, classic aesthetic and later pivot toward a more modern, aerodynamic look as mileage and confidence grow. This progression strengthens the role of the fairing as a dynamic accessory rather than a one-time purchase. It creates opportunities for retailers to guide customers through a curated journey—from the simplest, most modular configurations to a fully integrated touring setup. In effect, detachable fairings become a tool for storytelling as much as for mechanical function, allowing riders to narrate their riding life through the changing skins of their machines.

For those exploring the wider landscape of options and brands, the concept of modular fairing systems also invites cross-brand comparisons and a broader education about fitment, compatibility, and installation practices. The idea of a docking framework, which ensures that a panel can be removed and reattached without tools or with minimal effort, is a recurring theme across manufacturers. This consistency supports confidence among riders who may upgrade their bikes incrementally, adding or swapping components in stages rather than committing to a single, permanent modification. The net effect is a marketplace that rewards informed decisions and patient experimentation, where riders can balance wind protection, aesthetics, and the ease of reconfiguration as their riding calendar and preferences shift.

In sum, the market for detachable motorcycle fairings is not a flash in the pan. It represents a strategic alignment of rider needs with engineering practicality. It embodies the push toward modularity in an industry that values both performance and self-expression. As the aftermarket ecosystem continues to mature, riders can expect more cohesive product lines, more intuitive docking systems, and more flexible options that make it easier to switch between configurations without compromising safety, reliability, or style. The trend signals a future in which the bike’s outer skin is not a fixed shell but a living interface—one that can be tuned to the road, the weather, and the rider’s evolving sense of identity. For enthusiasts, that is precisely the kind of evolution that makes motorcycling more than transportation; it makes it a personal medium for exploration and storytelling.

To see how this design philosophy translates across brands and markets, consider how certain manufacturers present the broader fairing family as a modular, upgradeable system rather than a single, monolithic add-on. The modular approach appeals to riders who crave a smoother transition between configurations, ensuring that the performance benefits of a dedicated touring setup do not come at the expense of the bike’s character when the fairing is removed. The result is a flexible platform that supports a spectrum of riding styles, from long-distance cruises to casual Sunday spins. In that sense, detachable fairings are less about a one-size-fits-all solution and more about enabling a practice: riding with intention, and adjusting that intention as circumstances demand.

For readers who want to explore further into how these systems are positioned within the broader market and what it implies for the future of motorcycle customization, a relevant entry point is the range of accessible accessory categories available through manufacturer-approved channels. The breadth of options—from fairing shells and windshields to mounting hardware and mirrors—illustrates how the industry is moving toward turnkey, integrated solutions that simplify setup and maintenance. The aspirational yet practical nature of these products resonates with a broad audience and helps explain why detachable fairings have sustained interest across decades of riding culture. The market response to this demand is not only a reflection of rider preferences but also a signal of how manufacturers and retailers are aligning product development with real-world usage, durability expectations, and the evolving standards of aftermarket commerce.

If you’re curious about how detachable fairings look within the broader spectrum of fairing design and fitment options, you can explore additional categories such as the BMW fairings, which illustrate how fitment standards and modular principles translate across different brand architectures. This cross-brand perspective helps illuminate common design challenges and the ways in which the market solutions converge on rider-friendly, install-and-go experiences. BMW fairings category provides one such entry point into that wider ecosystem, offering a concrete example of how modular fairings are organized and marketed in an accessible, brand-spanning way.

Looking ahead, the industry’s trajectory for detachable fairings hinges on several converging factors: continued demand for customization, improvements in instrumented wind management, and a growing emphasis on installation ease and reliability. Innovations in materials—where lightweight composites meet durable coatings—will expand performance envelopes without imposing excess weight. Faster, tool-free docking systems will reduce the interlude between configuration changes, encouraging riders to experiment with different looks and wind-management settings during a single ride. At the same time, the aftermarket will likely see an expansion of integrated accessories—mirrors, lighting, and even sensor housings—that maintain symmetry and safety when the fairing is in place or stowed. This makes the detachable fairing not only a practical tool but a platform for ongoing experimentation and personalization, a living component of the motorcycle that can evolve with the rider’s needs just as their riding liabilities and preferences do over time.

The numbers help frame the story. The broader motorcycle market, valued at hundreds of billions globally in recent years, is anticipated to grow steadily through the next few years, suggesting sustained demand for aftermarket enhancements that complement core OEM offerings. Aftermarket trends consistently show that riders are investing not just in products but in the systems that anchor those products—mounting hardware, brackets, alignment fixtures, and robust windshields—that make upgrades durable and repeatable. In this climate, detachable fairings occupy a sweet spot: they offer tangible benefits in comfort and efficiency, they deliver a clear sense of personal customization, and they fit into a cost structure that can be scaled from entry-level kits to higher-end, more refined configurations. This combination makes detachable fairings a compelling case study in how a relatively specialized accessory can anchor a broader narrative of modularity, rider comfort, and market resilience.

The interplay between rider demand, engineering practicality, and market accessibility is what makes this segment noteworthy. It is a case study in how a well-executed modular concept can align with the realities of consumer purchasing behavior, the realities of distribution networks, and the realities of a diverse riding culture that values both performance and self-expression. As the aftermarket ecosystem continues to mature, we should expect to see not only more options but also smarter, more synchronized product families in which every component—from the smallest plug kit to the largest fairing panel—contributes to a coherent, reliable, and aesthetically satisfying riding experience. In short, detachable fairings are a definitive example of how supply chains, design pragmatism, and rider aspiration converge to create products that live up to the promise of customization without complexity.

External insight helps contextualize this momentum within the broader industry. For a detailed, data-driven view of how aftermarket accessories are expanding and what that means for consumer behavior, consult the latest aftermarket trends report issued by the industry council. It offers a rigorous decomposition of sales patterns, regional differences, and the evolving mix of products driving growth in the aftermarket landscape. This context is valuable for readers who want to connect the micro-level experience of installing a detachable fairing with macro-level market dynamics and long-term industry outlooks.

Final thoughts

Detachable motorcycle fairings represent a significant advancement in the realm of motorcycle accessories, catering to riders’ desires for both form and function. As business owners explore options to enhance their offerings, understanding the benefits, installation practices, and market dynamics of these components becomes essential. By providing customizable solutions to riders seeking to balance comfort and aesthetics, businesses can better meet the demands of the evolving motorcycle market and foster customer loyalty.